Grinder - what is it, application, choice, safety precautions

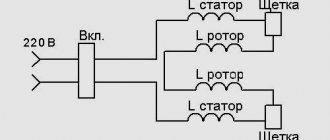

An angle grinder, or angle grinder, or grinder is a hand-held power tool for cutting, grinding and other processing procedures of metal, stone and plastic. The device has a small cylindrical body, on one side of which there are devices for installing attachments on the spindle, on the other - a handle for holding the device during operation. Inside there is an electric drive powered by a 220 V household network.

Angler grinders differ in size, power and corresponding scope of application into 3 main types:

- Large-sized. Dimensions 500 by 150 mm, power up to 3000 watts. Used for production. Able to work continuously for a long time. They have a high resource.

- Average. Case dimensions – 350 by 130 mm, power up to 1.5 thousand watts. Used in professional work. The device can be used for several hours daily.

- Small ones. The dimensions do not exceed 270 by 110 mm, and the power is 1.2 kW. Intended for everyday use. Allowed to work for a limited period of time with pauses.

Most often, small models of grinders with a power of up to 1.2 kW are used for domestic purposes. Source expertnov.ru

Sometimes those who are just starting to use a grinder reduce the basic rule of operation to deciding which direction the nut is unscrewed to change the attachment. In fact, this is only the technical side of servicing the device - to use it successfully, you must first of all choose the right model for its purpose, convenience and power.

For example, the most comfortable operation will be facilitated by the correct selection of a device according to a number of parameters such as:

- The number of handles, their location, the presence of anti-vibration pads.

- Motor power. The characteristic must correspond to the work, as well as the types of nozzles used. So, the smaller the disk, the higher the speed of its rotation. However, the use of a wheel that does not comply with the manufacturer’s recommendations can lead to equipment failure and violations of safety regulations.

- High quality. Both the device itself and the replacement attachments must be of proper quality. Since the work involves rotating mechanical parts, the destruction of which can lead to catastrophic consequences.

Only high quality angle grinders and equipment allow you to quickly and safely cut workpieces Source 1metallocherepica.ru

One of the main conditions for effective work with an angle grinder is compliance with safety requirements. First of all, these include:

- Correct selection and preparation of a safe work site.

Before starting work with an angle grinder, it is necessary to prepare the place in accordance with the following series of requirements:

- Select a flat, free space of sufficient area.

- For maximum reliability and safety of using the grinder, the workpieces being processed are fixedly fixed to the bolted connection with the required side, and, as necessary, they are unscrewed and reinstalled in accordance with the work plan.

- If necessary, remove nearby objects that could be damaged by sparks, smoke and other factors in the operation of the device.

- All fire hazardous elements – solvents, fuel, rags, etc. – are removed from the work area.

- When working on a construction site with building materials, primary fire extinguishing means are prepared - sand, a fire extinguisher, and water supplies.

The angle grinder can be used in dry weather outside and indoors with normal air humidity.

You can operate the grinder in conditions of normal air humidity Source mosoblzhilservice.rf

- Use of personal protective equipment.

Using an angle grinder at home is associated with a risk of injury. Therefore, in order to protect themselves, the user must use the following protective equipment during operation:

- Wear goggles or a face mask to prevent sparks or fragments of material and disc from entering.

- To muffle the sound, use earplugs or construction headphones.

- Protect your hands with gloves or mittens made of thick fabric. At the same time, their material should not be old, worn out, with dangling threads, and the products themselves should be accurate in size.

- To prevent dust from entering the respiratory system, use a respirator.

- Wear boots made of thick leather with metal inserts on the toes to protect your feet from sparks and falling objects.

In addition, the entire body must be securely covered with protective clothing made of thick fabric. In this case, the form should not have freely dangling parts that could wrap around the rotating elements of the device.

When working with an angle grinder, the operator must have reliable protection Source mosoblzhilservice.rf

See also: Catalog of companies that specialize in completing unfinished houses

- Use only serviceable tools.

To successfully operate an angle grinder, each user must have an idea of which direction to unscrew the disc and how to change it in general. However, in addition to this basic requirement, before starting work, the device must be checked for serviceability according to the following points:

- The power cord and plug must have a complete sheath and be free of kinks and other defects.

- The guard is tightly secured and positioned in a direction that prevents sparks from hitting clothing or the face.

- The gear handle must be solid, without cracks and tightly screwed in.

- The working disk must be installed level, without the slightest distortion.

In addition, any user should know how to use the grinder correctly and which direction of rotation of the disk in relation to the material being processed to choose.

In which direction does the Earth rotate?

The Earth revolves around an imaginary mowing line that passes through the North and South Poles of the planet. This line is called the axis of rotation, and our planet rotates around it once every 24 hours. Rotation occurs towards the east and counterclockwise. In our planetary system, almost all the planets (except Venus) rotate around an axis in the same direction as the Sun.

The Earth rotates once every 24 hours relative to the Sun and once every 23 hours 56 minutes and 4 seconds relative to the stars.

Tidal interactions

Over millions of years, the rotation was significantly slowed down by tidal acceleration due to gravitational interactions with the Moon.

This gradual rotational deceleration is empirically documented with estimates of day lengths derived from observations of tidal rhythms and stromatolites. A compilation of these measurements showed that the length of the day has been steadily increasing from about 21 hours 600 million years ago to the current 24-hour value.

Equatorial speed

Our planet's equatorial speed is 1,040.4 mph. Some sources state that the equatorial speed is slightly less, or 1,669.8 km/h. The speed is calculated by dividing the equatorial circumference by 24 hours.

The tangential rotation speed at any point on the Earth can be approximated by multiplying the equator speed by the cosine of the latitude.

Periods

The period of rotation relative to the Sun (solar noon to noon) is a true solar day or an apparent solar day. This depends on the orbital motion of our planet and thus depends on the change in eccentricity and inclination of its orbit. Both factors vary over thousands of years, so the annual changes in true solar day also vary.

The period of rotation relative to the fixed stars, called the sidereal day, is 86,164.098,903,691 seconds of mean solar time.

The period of rotation relative to the moving average spring equinox, called the sidereal day, is 86,164.090,530,832,88 seconds. Thus, the sidereal day is shorter than the sidereal day by about 8.4 milliseconds.

Both sidereal day and sidereal day are shorter than the average solar day by about 3 minutes 56 seconds.

Operating rules

Due to its specificity, the grinder belongs to the category of the most dangerous household power tools. Since its design does not imply all-round protection, like, for example, a circular saw, but rotates at a speed of more than 10 thousand rpm. the disk can rupture for various reasons and fly apart in any direction.

There are many reasons for the rotating disc of an angle grinder to rupture. Source ytimg.com

In this case, the flight path of the fragments can be anything. Moreover, the tool itself can break out of the operator’s hands during operation and also go in an unpredictable direction. However, it is still possible to operate the device quite safely, but provided that a number of requirements relating to the following several aspects are strictly observed:

- Preparing for work.

- Position of the device during operation.

- Backfire.

- Preventing disc rupture.

Let's look at each of them in more detail.

Preparation

It is necessary to prepare for the upcoming work in advance. You need to have a basic understanding of how to service the angle grinder, in particular, in which direction, if necessary, to unscrew the nut securing the circle. In addition, you must complete the following series of preparations:

- Make sure that the device and its attachment are in full working order. It should work smoothly, without interruptions, and the disk should not be damaged.

- Use protection for the face and eyes - in the form of a reinforced protective mask or goggles.

- Overalls should be tight, but not restrict movement; however, they should not be too wide to create the possibility of the fabric being caught by rotating parts.

One of the main safety requirements for working with an angle grinder is properly selected workwear Source montazh-saidinga.ru

- Use mittens or gloves made of thick leather to protect against abrasions, cuts and flying sparks.

Important! When working with an angle grinder, the operator must have normal reaction speed and coordination in space. Therefore, in case of fatigue, taking specific medications or ill health, it is better to postpone the event to a more favorable time.

boatman March 15, 2012

But in vain you are doing this! At our work, we often receive notices of accidents in the industry (nuclear energy), which we familiarize ourselves with under signature. Grinders, including those with fatal consequences, are far from the last source of danger.

I agree - if you saw off your head with it, or climb into the bathtub with it turned on, or even stick your fingers into a socket instead. Take a close look at the rotation of the circle, and then try to describe, from the point of view of the laws of physics, the possibility of imparting such energy to HALF OF THE CIRCLE! Do not confuse a grain of sand from this circle moving at a speed of 60-70 m/s, and even then on a new circle. The message has been edited by the boat driver: March 15, 2012 - 19:55

Video description

Video on how to choose the correct direction of rotation of the grinder disk:

- Excessively long operation. Any disk has a limited period of use. The closer it is ground to the base, the higher the risk of it breaking.

- Improper use. When a cutting wheel is used for sanding, its thickness and strength quickly decrease, making it more likely to break.

- Presence of a defect. A crack, break or chip may be present on the wheel even when it leaves the factory, and may arise during operation.

Note! From a safety point of view, the angle grinder should rotate to the side clockwise - if you look at the open side of the disk. The reason for this is simple: if the disk jams, it is almost impossible to hold the device, and in this direction it will simply go away from the user, and not towards him, as in the opposite direction of rotation, that is, counterclockwise.

What are the dangers of an angle grinder?

An angle grinder is a dangerous tool. This is caused by the following reasons:

- high rotation speed of the working nozzle - it exceeds 10,000 rpm;

- openness (unprotected by the casing) of most of the disk;

- the ability to break the abrasive disk into fragments of different sizes, which fly to the sides at considerable speed;

- frequent inability to properly organize the workplace;

- the formation of small particles when cutting metal (or other material) or grinding.

When the disk jams, which occurs even due to its slight misalignment, it is almost impossible to hold the grinder in your hands, especially a powerful tool. This is caused by the high speed of rotation of the attachment. Therefore, beginners are recommended to work with low-power models equipped with discs with a diameter of 115-125 mm. The latter must be free from the slightest defects that could lead to their sudden destruction and tearing of the angle grinder out of your hands with uncertain consequences.

Video description

Video advice on how to properly hold an angle grinder while working:

The problem can be solved with the following tricks:

- Overalls made of thick fabric reliably protect the operator from spark flow. Since the temperature of the sparks is low and does not cause much harm.

- A mask or goggles reliably protect your eyes and face from accidental sparks.

- The guard can direct the sparks so that they only fly downwards.

In the practice of working with a grinder, there are situations when the tool needs to be positioned so that the rotation of the circle is reversed to the safe position. In such a situation, the operator needs to use more reliable means of protection. However, the device should be used in this position in exceptional cases.

Xenos WIGHT Mar 15, 2012

That's right. I once asked an older comrade how to do it correctly, the answer was - when you worked at a factory with Italians, the first time you received a reprimand, the second time you received half your salary, the third time - you were fired.

There was one little crest at our construction site who kept saying that only idiots direct sparks at themselves. Only when I took the grinder after him, I still didn’t know this, and therefore I almost hit my face with this grinder in the very first second of work. I thought then that if something were to fly into my face, it would be better if it were sparks than the Bulgarian woman herself. Even if I missed a spark (for example, I didn’t put on my glasses), I would only have to go to the emergency room (Bulgarian women provide fifty percent of the work for local ophthalmologists), and You may not survive a meeting with a working Bulgarian woman.

Video description

Video on how to properly unscrew the fastening nut on an angle grinder:

However, sometimes after work the nut becomes so tight that it cannot be unscrewed even with a special wrench. The reason for this is the use of a wheel that is too large or equipment that is not designed to work according to factory parameters. In addition, the threads may become welded, oxidized, or rusted.

There are the following ways to solve this problem:

- Heat the nut with a torch, which will cause the metal to expand and weaken the contact.

- Use a special insert into the holes of the nut. Creating a lever will allow for greater effort to unscrew.

- Saturate the thread with oil, turpentine or WD-40, and then, after some time, unscrew the nut with a wrench.

- Tighten the circle that has not been used for a long time even more tightly, and then unscrew it in the usual way.

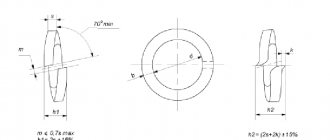

Recommendation! To ensure that the nut is not over-tightened during operation, and can then be easily unscrewed, a cardboard spacer must be installed between it and the circle.

Xenos WIGHT Mar 15, 2012

That's right. I once asked an older comrade how to do it correctly, the answer was - when you worked at a factory with Italians, the first time you received a reprimand, the second time you received half your salary, the third time - you were fired.

There was one little crest at our construction site who kept saying that only idiots direct sparks at themselves. Only when I took the grinder after him, I still didn’t know this, and therefore I almost hit my face with this grinder in the very first second of work. I thought then that if something were to fly into my face, it would be better if it were sparks than the Bulgarian woman herself. Even if I missed a spark (for example, I didn’t put on my glasses), I would only have to go to the emergency room (Bulgarian women provide fifty percent of the work for local ophthalmologists), and You may not survive a meeting with a working Bulgarian woman.

Briefly about the main thing

A grinder is a power tool for processing metal, stone and plastic. Based on size, power and scope of application, angle grinders are divided into large, medium and small. When choosing, the features of the handles, the power of the electric drive and the overall quality of the tool are taken into account. Effective operation of the device is associated with compliance with safety rules - selection and preparation of the location, use of protective equipment and full serviceability of the device.

Safe operation of the angle grinder is possible with proper consideration of a number of aspects:

- Preparation.

- Device position.

- Backfire.

- Disk rupture.

The direction of rotation of the working disk that is safe for the operator is clockwise. In this case, you need to unscrew the nut on the grinder in the same direction in which the working disk rotates - in the standard case, clockwise.

Ratings 0

Alexandr29 Mar 15, 2012

I have been interested in the question for a long time - what is the right way? I myself usually put the rotation on myself, but many times I have come across another option. Moreover, supporters of both options foamed at the mouth to prove that only they were right, and the rest were wrong.

Eternal dispute From my experience, it’s easier for me to work when the sparks come from me, but I allow myself this only occasionally, when it doesn’t work out any other way. Because psychologically it is much more comfortable to realize that if something happens, this infernal machine will run away from me and not run over me.

IMHO, the “photo” is from Photoshop. I've had discs torn more than once, but the disc always shattered into small fragments. You only get half when you step on the lying disc with your foot.

Installing a cutting disc for metal

Before sawing with a grinder, it is important to install the cutting disc correctly. One side is the outer side; most often a sticker or other design is applied to it. The other side is internal.

A pressure washer is placed on the outside, which is secured with a nut. In such a situation, it is easier to unscrew the nut when replacing the disk. Installation with the front side allows you to quickly find out technical information about the wheel, this is necessary when processing parts made of different materials.

If there is a metal ring on the disk, this side is the outer side and the washer is attached to it

How to cut correctly with a grinder, towards yourself or away from you?

Grinder cutting concrete, tiles, stone

. Cutting concrete, tiles or stone must be done with special wheels designed to work with these materials. When cutting these materials, a lot of dust is generated, which is harmful to health. For wall chasers, a more closed protective casing with a pipe for connecting a vacuum cleaner is made to remove dust.

If it is impossible to organize dust extraction, you need to use a respirator with a P2 class filter. You can suppress dust using a jet of water directed at the cut, or use room ventilation.

Particular care must be taken when making wall cuts to accommodate various piping, electronic cables and fittings. When a disc hits there, sometimes a reverse impact occurs. Damage to electronic wires around can cause short circuits; accidental cutting of a gas pipeline leads to an explosion. Before working in unfamiliar places, you need to study them for the presence of communications.

Backlash

. The main danger when working with an angle grinder is the reverse blow. sharp and unexpected kickback of the tool and therefore jamming of the rotating circle in the workpiece. With all this, the circle is often destroyed.

According to the laws of physics, the reactive movement of the tool occurs in the direction opposite to the rotation of the disk. Kickback is usually the result of operator error. To prevent it or avoid serious consequences when, if it nevertheless occurs, certain precautions will help:

- You need to hold the tool firmly with both hands. For this purpose, standard handles are made and used.

- The body must be in a stable position. This will help withstand the force of the reverse strike.

- It is necessary to be away from the correct selection of the studio of the place where

the instrument will move during a reverse strike. If the cutting wheel is driven “pull”, if there is a revolving impact, the power tool can bounce directly on the operator. - When working corners and sharp edges, extreme care must be taken and preparation for possible tool kickback is required. Quite often, a reverse blow occurs at the end of the cut, when the last bridge connecting the individual parts of the workpiece is cut. In this case, in order to avoid a reverse blow, it is recommended, without finishing the cut, to remove the circle and carefully cut the jumper and in addition.

- If jammed, you must turn off the tool and remove it from the cut.

Angle grinder device and its capabilities

The angle grinder (angle grinder) is characterized by its simplicity of design. It is based on a motor that rotates the shaft using a gearbox. Cutting discs or grinding attachments are attached to the shaft.

All Bulgarians are divided into categories.

According to technical characteristics:

Depending on the design, they are available with or without handles.

To power professional machines, 380 V must be supplied. For semi-professional and household machines, a 220 V outlet is sufficient.

Important! The grinder is indispensable for construction, auto repair shops and other types of work. It has found wide application in industry and everyday life.

The nuances of cutting some materials

When cutting concrete, follow these recommendations:

- before work, check for the presence of pipes, fittings, and electrical wiring embedded in concrete (with a metal detector or devices for searching for wiring);

- to reduce dust, the work surface is moistened with water (for example, from a spray bottle or a brush);

- periodically cool the cutting element with air or water.

In the absence of a tile cutter, a grinder can also be used to cut tiles. Experts even cut circles into the tiles. Stone and tiles are cut in two ways:

- wet (wet the work area with water);

- dry (without moisture).

With the first option, cooling improves, but dirt remains, and with the second, a lot of dust is released. The wet method is used for large volumes of upcoming work, and the dry method is used for one-time cutting.

Any material should be cut smoothly so that the disc is immersed in it with little pressure, almost only under the influence of the angle grinder’s own weight. This is necessary to prevent distortions of the disk and reduce the likelihood of it jamming. If the process slows down, then it is necessary to replace the nozzle with a new one.

The grinder should be used in accordance with the operating instructions and safety regulations. The working part must rotate in the direction of movement of the tool. Before starting the process, be sure to turn on the device at idle speed. At the same time, there should be no vibration, heating of the angle grinder, as well as extraneous sounds from it. The circles must be used without damage. The most dangerous factor is the kickback. To prevent this, it is necessary to avoid jamming of the wheels by cutting materials to break.

Alexandr29 Mar 15, 2012

I have been interested in the question for a long time - what is the right way? I myself usually put the rotation on myself, but many times I have come across another option. Moreover, supporters of both options foamed at the mouth to prove that only they were right, and the rest were wrong.

Eternal dispute From my experience, it’s easier for me to work when the sparks come from me, but I allow myself this only occasionally, when it doesn’t work out any other way. Because psychologically it is much more comfortable to realize that if something happens, this infernal machine will run away from me and not run over me.

IMHO, the “photo” is from Photoshop. I've had discs torn more than once, but the disc always shattered into small fragments. You only get half when you step on the lying disc with your foot.

boatman March 15, 2012

But in vain you are doing this! At our work, we often receive notices of accidents in the industry (nuclear energy), which we familiarize ourselves with under signature. Grinders, including those with fatal consequences, are far from the last source of danger.

I agree - if you saw off your head with it, or climb into the bathtub with it turned on, or even stick your fingers into a socket instead. Take a close look at the rotation of the circle, and then try to describe, from the point of view of the laws of physics, the possibility of imparting such energy to HALF OF THE CIRCLE! Do not confuse a grain of sand from this circle moving at a speed of 60-70 m/s, and even then on a new circle. The message has been edited by the boat driver: March 15, 2012 - 19:55