Lubricant for the trimmer gearbox. What and how to lubricate?

Sometimes, in the midst of intensive mowing work, your trimmer begins to make unpleasant, grinding sounds. This complains about the lack of lubrication of the gearbox - the most intensively loaded unit of the device. And soon these “warnings” may be followed by jamming of the drive...

Recommendations for use

It is necessary to take temporary breaks from work. This is necessary to ensure that the device’s engine does not overheat and fail prematurely. For amateur models, a break is provided every 20 minutes for the same amount of time. For professional mowers, work must be interrupted every 50 minutes, in which case the downtime should be at least 10 minutes.

You need to monitor the condition of the fuel tank. If you do not plan to use the mower for a certain period of time, it is better to drain the remaining fuel from the tank compartment. This will help avoid damage to engine parts.

Terms of use

What lubricant should I use for the trimmer gearbox?

During operation, the mechanical part of the trimmer is loaded by contact forces on the teeth, resistance reactions from adhering grass (sometimes with dirt), dynamic, shock loads due to constantly changing torque.

The trimmer gearbox lubricant must fully take these features into account, so the selection of the brand must be strictly individual. The following factors are taken into account:

- Manufacturer's brand. It is not without reason that each brand focuses on its own made lubricants (we can talk about cheap Chinese products later). This applies to manufacturers such as Husqvarna, Stihl, Huter, Makita, etc. The exception is domestically produced trimmers: for example, Caliber in the user manual does not indicate the brand of lubricant at all...

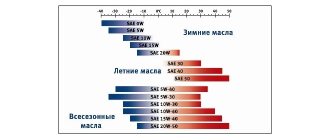

- Lubricant viscosity. As is known, all lubricating compounds are divided into three groups - high-viscosity (colloidal systems containing various additives), plastic compounds for universal use and solid lubricants that soften during operation.

- Good adhesion to the surface of gearbox parts, as a result of which the lubricant is not squeezed into the gaps or out of the assembly.

- The intensity of lubricant consumption by the gearbox. Here you have to rely on your own experience and recommendations of specialists, since some trimmer manufacturers, relying on the availability of their own service centers, do not give clear recommendations at all regarding the period of operation of the gearbox between two lubrications.

The consumption of a lubricant also depends on the temperature at which it retains its lubricity. When the gearbox is heated to 40°C, it is considered that its operating conditions are satisfactory and there is enough lubrication.

It is believed that there is no universal lubricant for the trimmer gearbox, but this is not entirely true. In fact, a suitable lubricant composition will be one that contains the following components:

- Anti-wear additives that do not contain toxic lead;

- Solid lubricants with the presence of graphite or molybdenum disulfide (the latter is preferable, since the lubricity is completely preserved over a wide range of shaft speeds);

- Only mineral (inorganic!) oils, highly purified.

The mentioned requirements are fully met by lithium greases Gear Grease OREGON or Champion EP-0, domestic compositions Oleo-Mas, Litol -24, or Azmol 158, as well as those recommended by the manufacturer of a specific trimmer model.

Engine starting

ICEs of household mowers are equipped with manual starters. The starter device is conventional: a strong cord is wound onto a drum, which is directly or through a gearbox connected to the crankshaft, the start is done by sharply pulling the cord, and the drum unwinds, setting the crankshaft in motion, which in turn starts the engine. More complex models are equipped with a Flash Starter easy start system. This system has a special mainspring, which is twisted through a ratchet by several pulls on the starter cord, accumulating kinetic energy. After this, a special release button is used to release the latch, and the spring unwinds together with the drum and the crankshaft. “Easy start” ensures a faster start and less energy consumption for the owner. Also, for a quick start, an additional supply of fuel to the carburetor is provided with a special button. To supply an additional portion of gasoline, you need to press the button once or twice. The starter gearbox is lubricated with oil designed to lubricate the gearbox.

How to lubricate the trimmer gearbox?

In the upper part of the housing, where the gear block is installed, there is a technological hole, which is plugged with a screw during operation of the trimmer. This screw is unscrewed, and 1.5...2 ml of lubricant is injected into the hole using the spout on the tube. If the lubricant was purchased in a different package, then a regular disposable medical syringe will be suitable for this operation.

After this, the screw is installed in its original place. This procedure, regardless of the user’s recommendations, should be performed every 10...15 hours of using the trimmer in operating mode. Other reasons for updating or replacing the gearbox lubricant are performing minor routine maintenance on your own (for example, cleaning and washing the gearbox gears before the start of the summer season), repairing the unit, preserving the trimmer for the winter, etc.

If the gearbox assembly is disassembled, it is recommended to completely remove any remaining grease from the surface of the parts, even if it does not have traces of oxidation or contamination. And only then apply new lubricant. After applying the lubricant, it is recommended to rotate the shaft several times by hand and make sure that the lubricant is evenly distributed throughout all gearbox parts.

When lubrication, special attention is paid to the following elements:

- Flywheel: as a rule, grass residues intensively adhere to its surface, and thickening grass juice creates additional resistance.

- The starter coil pawl, which constantly comes into contact with the grooves on the flywheel when the drive is turned on. In this case, not only mechanical wear occurs, but also mechanochemical corrosion of the flywheel-pawl joint, since the materials of this pair are different (the flywheel is aluminum, and the pawl is steel).

- Bearings, if their seals are worn out, and through them the remaining lubricant is squeezed out. In this case, the unit begins to vibrate intensely when loaded. This happens with Chinese-made trimmers, so in the future it is worth thinking about replacing the bearing assembly with a better one, for example, from the Swedish company SKF.

How to Adjust the Carburetor of the Shtil Fs 55 Lawnmower

Carburetor repair and repair

The trimmer is not a complex household appliance, since most of its faults are mechanical and can be successfully fixed with your own hands. Even if the engine fails for good reasons. for example, damage to the piston ring, repair is reduced to replacing parts.

And in a relatively conventional design, a part of the device such as the carburetor must be adjusted.

How does it work

Carburetor. This is a power system module in which liquid fuel and air are mixed before being supplied to the engine cylinders. Depending on the tool and its operating mode, mixing and feeding are adjusted accordingly.

The carburetor cutter is uniform in almost all cases. The FS 38 recreational price must be adjusted using the carburetor screw. Belongs to the category of floating devices. How to adjust the carburetor on a scooter. Honda part AF-34. The latter provide constant characteristics of the finished consistency.

The mechanism of operation of the module is as follows.

- Air enters the tube body with an air damper. Adjusting the carburetor of the fs 55 trimmer cooler in the video on how to adjust the carburetor. The latter increases or decreases the air flow depending on its position.

- In the area where the gas supply hole is formed, the tube has a hood. diffuser. Adjusting the fs 55 carburetor stop trimmer in the video is performed to adjust the idle speed. Here the flow speed increases.

- Fuel from the float chamber is supplied through the nozzle into the pipe. The float level determines the amount of fuel supplied. How to adjust 24, I removed the carburetor from the diode, I don’t know the rings on the pistons of the Honda DIO 34. Since the pressure in the chamber is normal, and in the pipe is low due to the high vacuum of air, gas is sucked through the nozzle.

- The accelerated air flow collects fuel and atomizes it, forming an air-fuel mixture of appropriate density.

- The mixture is sucked into the cylinder through a pipe.

The more the air damper in the pipe is open, the higher the air flow density and the more fuel enters the cylinder. Carbon lawnmower settings come down to the damping ratio at which the fuel consistency becomes good.

Signs of Imbalance

The carburetor adjustment, of course, is made during the manufacture of the device. Usually the need to regulate Owners will only be able to deliver fuel themselves after serious breakdowns, during which the module was removed and, for example, cleaned.

Symptoms of a problem with the settings are as follows:

- it starts but the engine stops here. since the engine can only operate when a certain amount of very “bad” gasoline is supplied, in other words, by blocking the supply channel, the engine stops;

- Very high fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the consistency. In this case there is a lot of fuel, and the mixture is very thick.

Carburetor gasoline braids Ticho, Makita, Husqvarna and others are adjusted with adjusting screws. Sometimes a prerequisite for a malfunction is a violation of fixation. due to vibration or damage to the protective cap. You can find this type of failure by simply trying to turn the screw a little: if the lock is not tight, you should check the settings.

Trimmer gear lubrication: selection criteria

During operation of a gasoline trimmer, the gearbox begins to make grinding sounds, which are a sign of a lack of lubrication or loss of its properties. Of course, the owner may not attach much importance to extraneous noise, but ignoring them will lead to jamming of the gears and, as a result, future expensive repairs. Therefore, in order to avoid preconditions for the occurrence of grinding noise, it is necessary to follow the lubrication regulations for the trimmer gearbox recommended by the manufacturer.

About the manufacturer Stihl

The history of this German brand begins in 1926. At the initial stages of its development, the company was engaged in the production and sale of various components for washing and steam machines. It all started, like many companies, with small production and a narrow focus, which made it possible to focus on the quality of the products produced.

In the early 30s, the first STIHL chainsaw was released, distinguished by its convenience and functionality even in those days. The company is developing at a rapid pace, constantly introducing new tools, which gives it the opportunity to enter the international market. And already in 1931, the first regular deliveries of products to Russia were organized.

Calm device

Currently, the company has expanded its activities in more than 160 countries around the world, opening new centers and production branches in Switzerland, China and many other countries. This is understandable, because the company’s assortment is impressive: motor drills, gasoline sprayers, mowers, gasoline trimmers, chainsaws and much more. I would like to note that Shtil chainsaws are very popular due to their functionality and reasonable price.

Trimmer gearbox device

Regardless of the manufacturer and model, a modern trimmer is equipped with a gearbox to change the angle of transmission of mechanical energy between the drive shaft and the head with fishing line. Bevel gears are most widely used in lawn mowers, since, unlike spur gears, gears with helical teeth are able to withstand enormous speeds, have smoother engagement and have increased load-bearing capacity.

Main parts of the trimmer gearbox

In the duralumin housing (1) there is a gear shaft (2) and a bevel gear (3), pressed onto the driven shaft (4). To reduce friction forces during rotation, rolling bearings (5) are installed at the support points of the shafts. Any gear transmission is a highly loaded mechanism, the duration of operation of which, the noiselessness and reliability of which depends primarily on the lubricant. Therefore, in addition to the main components listed above, the trimmer gearbox device includes a special hole through which you can lubricate the bearings and gears without disassembling the unit.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have a socket 8 and an extension, with which it is convenient to unscrew the nuts securing the carburetor and air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and choke rod from the engine control lever and remove the lever, only after this the air filter and carburetor are removed.

The Shtil 180 muffler is secured with two nuts, which you need to unscrew to pull it towards you, it can be easily removed.

Trimmer gear lubricant: which one to choose?

Selection of gear paste

Currently, the market for gasoline-powered tools and consumables offers a wide selection of greases that are designed to reduce friction and overheating of rubbing parts. Therefore, every owner, when it is time for maintenance, is faced with the problem of how to lubricate the trimmer gearbox for long-term operation. For these purposes, special plastic pastes are used, which vary in properties and manufacturer.

Lubricant for famous brands of trimmers

Every brand that manufactures gasoline trimmers always recommends its own production of lubricant for the trimmer gearbox.

- Husqvarna. This Swedish manufacturer recommends using Multi-Purpose Grease Grasa Universal. This material is available in blue-black tubes of 225 or 250 grams. According to the company, this trimmer gear lubricant was developed specifically for Husqvarna equipment, taking into account the steels used and operating speeds.

- Stihl. For Stihl FS series lawn mowers, the manufacturer recommends using Stihl Superlub FS gear lubricant, available in 225 gram tubes or 80 gram disposable containers in silver-orange color.

- Patriot. It is recommended to service the gearboxes of this brand of lawn mowers with original Arsenal lithium grease brand AR-417. It is specially designed for gear reduction gears operating at high speeds and temperatures.

- Huter. For bevel gear models of tools from this Huter company, you can use any of the above brands of gear lubricants, as well as universal ones such as Rezoil, CIATIM and others.

- Champion. In the instruction manual for the Champion lawn mower, the recommended lubricants include CHAMPION Super-Lube EP-O. The material is supplied in a 250 gram jar or in a disposable Premium Champion C1104 oil can.

- Makita. This Japanese manufacturer advises its consumers to use Makita branded lubricant, which comes in white tubes with a red cap of 65 ml and 80 ml.

Factors for choosing a brush cutter gearbox lubricant

Often, the owner of a particular brand of gasoline trimmer is not able, for some reason, to purchase the lubricant recommended by the manufacturer. In such cases, you will need to search for an analogue whose properties will be identical to the branded paste. Therefore, when choosing a paste for a lawn mower gearbox, you should pay attention to the following factors:

Lawnmower gearbox lubrication

- Lubricant viscosity. All pastes on the market are divided into three main groups, namely: high-viscosity (contain additives), solid lubricants (soften during operation of the unit) and universal plastic compounds.

- Lubricant consumption rate. This factor is taken into account based on the owner’s personal experience and is characterized by the period between two lubrications. Most manufacturers require that the gearbox be serviced every 20-40 hours of operation.

- Degree of adhesion to gearbox parts. This indicator is characterized by the adhesion of grease to the metal parts of the trimmer assembly.

Varieties

Regardless of whether the lubricant needs to be poured directly into gasoline or into a special tank of a gas trimmer, the oil is classified simultaneously according to several criteria:

- Type of base or production technology - synthetic, mineral, semi-synthetic.

- Type of additives.

- Engine volume.

- The degree of harmfulness of the generated exhaust gases.

- Seasonality of use.

Let's look at each parameter in more detail.

Various types of oils are available for gasoline trimmers Source stroyteh.ua

See also: Catalog of companies that specialize in designing and performing landscape work of any complexity

Base type

According to the type of production technology used, oils for gardening equipment are divided into 3 main groups:

- Mineral. Obtained by processing products from agriculture or the oil industry. The main advantage is low cost. The downside is the manifestation of performance characteristics in a limited temperature range - 10-250C. To adapt to higher heating conditions, additives are required, which, however, can burn out. At low temperatures, the oil thickens greatly.

- Synthetic. Manufactured by direct synthesis. Advantages: better stability and independence from temperature. The disadvantage is the high price.

- Semi-synthetic. They are a mixture of the two types of oils listed above. In this case, the ratio of components can vary significantly.

Important! It is unacceptable to mix oils of different natures due to the difference in their properties. For this purpose, responsible manufacturers add dyes characteristic of each type of product to their products, for example, red, blue, green - so that it is impossible to accidentally confuse them.

The characteristics of the oil must correspond to the operating conditions of the trimmer Source ukrnews24.net

Type of additives

In certain operating conditions, oil with various special additives must be poured directly into the trimmer’s gasoline or into the crankcase of a lawn mower, such as in Shtil models, to protect against various factors. These are primarily types of additives such as:

- Wear-resistant – increasing the stability of the surfaces of interacting parts.

- Antioxidant – protecting the oil from oxidative processes and extending engine life.

- Anti-corrosion – giving protection against rust to the surfaces of engine components.

- Anti-friction – reducing the effect of friction.

One or more additives with characteristic properties are usually added to oils for 2-stroke engines.

How to lubricate the trimmer gearbox

Disassembled trimmer gearbox

Almost every brush cutter gearbox is equipped with a small technological hole, which is plugged with a special bolt during operation. After thoroughly cleaning the unit from any remaining grass and debris, you need to unscrew the screw and inject 1.5 to 3 ml of lubricant into the gearbox cavity, depending on the brand of the tool. For ease of dosage, you can use a traditional medical syringe. During the operation, foreign particles and objects must not be allowed to get inside the gearbox, as this can lead to intense wear of the gear transmission, as well as its jamming.

Performance

The choice of petrol mowers, or they are also called by the name of the cutting device - trimmers, should be made based on the volume of work; the larger the area being processed, the more power is needed. For small areas, household trimmers are chosen; for garden plots, middle-class trimmers are suitable - farm trimmers; for mowing a large area, especially if there are thickets of weeds or shrubs, you need a powerful professional tool - a park tool. This technique has a motor power of more than 2.5 hp. and can work 3-4 hours a day.

Trimmer gear lubrication: selection criteria

During operation of a gasoline trimmer, the gearbox begins to make grinding sounds, which are a sign of a lack of lubrication or loss of its properties. Of course, the owner may not attach much importance to extraneous noise, but ignoring them will lead to jamming of the gears and, as a result, future expensive repairs. Therefore, in order to avoid preconditions for the occurrence of grinding noise, it is necessary to follow the lubrication regulations for the trimmer gearbox recommended by the manufacturer.

Drive motors

Most mowers are equipped with an internal combustion engine (ICE), it can be two-stroke or four-stroke, there is no particular difference between them. The four-stroke is more economical and powerful, but more difficult to maintain and more expensive to repair. The two-stroke is easier to maintain, cheaper, but low-power, consumes more fuel, and has dirtier and louder emissions. There are also combined engines. In addition to gasoline units, trimmers can be equipped with electric motors that are connected to a 220V household network with a long cable, but, usually, these are household devices because they are connected to the power supply wires.

Trimmer gearbox device

Regardless of the manufacturer and model, a modern trimmer is equipped with a gearbox to change the angle of transmission of mechanical energy between the drive shaft and the head with fishing line. Bevel gears are most widely used in lawn mowers, since, unlike spur gears, gears with helical teeth are able to withstand enormous speeds, have smoother engagement and have increased load-bearing capacity.

Main parts of the trimmer gearbox

In the duralumin housing (1) there is a gear shaft (2) and a bevel gear (3), pressed onto the driven shaft (4). To reduce friction forces during rotation, rolling bearings (5) are installed at the support points of the shafts. Any gear transmission is a highly loaded mechanism, the duration of operation of which, the noiselessness and reliability of which depends primarily on the lubricant. Therefore, in addition to the main components listed above, the trimmer gearbox device includes a special hole through which you can lubricate the bearings and gears without disassembling the unit.

Technical characteristics Shtil FS38

- Model - FS 38 Autocut.

- Weight – 4.1 kg (without cutting equipment).

- The length of the brush cutter is 147 cm (without cutting equipment).

- Engine type: two-stroke.

- Cylinder volume – 27.2 cubic meters. cm.

- Power – 0.9 hp

- Fuel type - gasoline.

- Gasoline consumption – 0.32 l/hour.

- Fuel tank volume – 0.33 l.

- The handle is a circular handle.

- Cutting diameter – 380 mm.

- The highest speed of the working head is 9500 rpm.

- Anti-vibration system – installed.

- Easy start system - installed.

- Cutting tools – AutoCut C 5-2 head (included).

Trimmer gear lubricant: which one to choose?

Selection of gear paste

Currently, the market for gasoline-powered tools and consumables offers a wide selection of greases that are designed to reduce friction and overheating of rubbing parts. Therefore, every owner, when it is time for maintenance, is faced with the problem of how to lubricate the trimmer gearbox for long-term operation. For these purposes, special plastic pastes are used, which vary in properties and manufacturer.

Lubricant for famous brands of trimmers

Every brand that manufactures gasoline trimmers always recommends its own production of lubricant for the trimmer gearbox.

- Husqvarna. This Swedish manufacturer recommends using Multi-Purpose Grease Grasa Universal. This material is available in blue-black tubes of 225 or 250 grams. According to the company, this trimmer gear lubricant was developed specifically for Husqvarna equipment, taking into account the steels used and operating speeds.

- Stihl. For Stihl FS series lawn mowers, the manufacturer recommends using Stihl Superlub FS gear lubricant, available in 225 gram tubes or 80 gram disposable containers in silver-orange color.

- Patriot. It is recommended to service the gearboxes of this brand of lawn mowers with original Arsenal lithium grease brand AR-417. It is specially designed for gear reduction gears operating at high speeds and temperatures.

- Huter. For bevel gear models of tools from this Huter company, you can use any of the above brands of gear lubricants, as well as universal ones such as Rezoil, CIATIM and others.

- Champion. In the instruction manual for the Champion lawn mower, the recommended lubricants include CHAMPION Super-Lube EP-O. The material is supplied in a 250 gram jar or in a disposable Premium Champion C1104 oil can.

- Makita. This Japanese manufacturer advises its consumers to use Makita branded lubricant, which comes in white tubes with a red cap of 65 ml and 80 ml.

Factors for choosing a brush cutter gearbox lubricant

Often, the owner of a particular brand of gasoline trimmer is not able, for some reason, to purchase the lubricant recommended by the manufacturer. In such cases, you will need to search for an analogue whose properties will be identical to the branded paste. Therefore, when choosing a paste for a lawn mower gearbox, you should pay attention to the following factors:

Lawnmower gearbox lubrication

- Lubricant viscosity. All pastes on the market are divided into three main groups, namely: high-viscosity (contain additives), solid lubricants (soften during operation of the unit) and universal plastic compounds.

- Lubricant consumption rate. This factor is taken into account based on the owner’s personal experience and is characterized by the period between two lubrications. Most manufacturers require that the gearbox be serviced every 20-40 hours of operation.

- Degree of adhesion to gearbox parts. This indicator is characterized by the adhesion of grease to the metal parts of the trimmer assembly.

How to lubricate the trimmer gearbox

Disassembled trimmer gearbox

Almost every brush cutter gearbox is equipped with a small technological hole, which is plugged with a special bolt during operation. After thoroughly cleaning the unit from any remaining grass and debris, you need to unscrew the screw and inject 1.5 to 3 ml of lubricant into the gearbox cavity, depending on the brand of the tool. For ease of dosage, you can use a traditional medical syringe. During the operation, foreign particles and objects must not be allowed to get inside the gearbox, as this can lead to intense wear of the gear transmission, as well as its jamming.

Experts recommend that at the end of the mowing season and long-term storage of the tool without work, disassembling the gearbox, washing the gears and bearings, and re-lubricating the unit.

Removing and Lubricating the Upper Trimmer Shaft

First of all, we remove the lower part of the rod from the coupling, and then disconnect the coupling from the upper part of the rod (here we are talking about the coupling connecting the two halves of the rod).

Trimmer PRORAB-8406 with disconnected coupling and lower part of the rod

Now the most interesting thing: in some videos, like this one, holding the shaft coupling protruding from the top of the rod from below with pliers, knock it out of the rod along with the rolling bearing by hitting the pliers (here we are talking about the coupling connecting the upper and lower shafts). Some lawn mowers with a collapsible rod, as in the video, have a coupling connecting the upper and lower shafts that is pressed into the rolling bearing.

With our trimmer PRORAB-8406 and others like it, this number will not work. They do not have a rolling bearing, and the coupling (bushing) is a continuation of the shaft of the upper rod. There is a retaining ring installed at the top of this shaft, which must first be removed.

Place of attachment of the upper part of the rod to the clutch housing

- Unscrew the central screw completely. It secures the upper part of the rod, partially entering the hole drilled in it. Loosen the side clamping screws and remove the rod from the clutch housing.

- We push the shaft out from the top of the rod towards ourselves, as much as the play allows, in order to get to the locking ring and remove it. A special puller may be required*. Remove the retaining ring.

Retaining ring on the upper shaft of the brush cutter

- Without a locking ring, the upper shaft can be easily removed from the rod on the opposite side. We lubricate** it, not forgetting about the splines in the bushings (couplings) on the rod shaft and on the clutch shaft.

- We install the lubricated shaft in place in the upper part of the rod and secure it with a locking ring. We insert the rod into the hole in the clutch cover and align the hole on the rod with the threaded hole of the fixing screw.

- We screw in the fixing screw and secure the upper part of the trimmer rod with the side screws in the clutch cover.

- We clean the rod coupling from debris and install it from below to the top of the rod.

* I don’t have a puller, but I use two large paper clips to remove the retaining ring. First you need to straighten them, make half rings for your fingers on one side, and bend small hooks on the other.

We grab the holes in the retaining ring with hooks and try to push them apart. With difficulty, but it works, and the ring moves out of place. If you know another way to remove the retaining ring without a puller, please share in the comments.

** In many videos, technicians recommend using lubricant for CV joints; this is the best option. If it is not available, you can use Litol-24, which is rated for temperatures up to +130°C, to lubricate the shaft of the lawn mower. But solid oil, which has worse lubricating properties and operates at temperatures up to +70°C, is not recommended.

However, if you urgently need to lubricate the shaft of a lawn mower, but there are no suitable materials, then solid oil or even regular motor oil will be better than nothing at all.

Removing the clutch and oil pump drive

Before disassembling the clutch, it is necessary to remove the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With a high head of 19, you need to unscrew the clutch. The thread on it is left-handed, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are put on the shaft without any fastening.