When is a piston replacement necessary?

There can be quite a lot of reasons why a piston needs to be replaced, as well as a complete piston system, but all of them can be divided into natural ones and those resulting from improper operation. Natural, this is wear and tear formed due to prolonged use of the Shtil 180 chainsaw. There are much more artificial ones, for example:

- overheating of the engine and the appearance of thermal seizures;

- entry of a foreign body into the cylinder and the appearance of mechanical scoring;

- piston ring breakage as a result of exceeding maximum engine speed;

- piston skirt failure due to over-revving;

- the use of low-quality fuel, as a result of which the piston group of the chainsaw wears out on the side of the inlet channel in the cylinder;

- operating a Shtil chainsaw with a dirty fuel filter, resulting in a decrease in the percentage of oil in the fuel mixture;

It is necessary to diagnose the CPG if the Shtil ms 180 suddenly loses power or does not start, while the starter of the tool does not turn over. If the starter turns, but the saw does not start, there is a spark and fuel flows into the cylinder properly, it is necessary to measure the compression in the engine.

If you suspect problems with the CPG, it is advisable to contact a service center authorized by the manufacturer, since only they can accurately diagnose the malfunction without a complete disassembly and, if necessary, carry out high-quality repairs.

9.5 – 11 Atm. is considered a normal indicator at which the Stihl chainsaw starts properly and produces maximum power; if the compression is lower, there is a possibility that there are scuffs on the cylinder-piston group, or its wear is quite large. In any case, with reduced compression, for further diagnosis, it is necessary to completely disassemble the saw.

You can determine the presence of scuffs on the piston, as well as a broken piston ring, by removing the muffler and conducting a visual inspection of the visible part of the piston, while the rings can be checked for elasticity by pressing on them with a small screwdriver. There will be slight movement on the working rings; a defective or jammed piston ring will not move.

What repairs are required?

Having determined the presence and degree of engine wear, we begin to eliminate the causes.

If engine oil consumption is high, the compression is measured; if it is low, the valves are changed. If bubbles are found when checking the condition of the coolant, change the cylinder head gaskets immediately. Carbon deposits on spark plugs require replacement of piston rings and valve stem seals. Blue smoke and drops of oil from the exhaust pipe indicate the need to replace the piston rings.

The engine needs repair if extraneous noises, knocks are heard, and increased fuel and oil consumption is observed. Overheating, a drop in engine power, and interruptions in operation are reasons to work on the engine. Especially when there are several of the above reasons at the same time.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calm 180, the piston group has a diameter of 38 mm. The dimension of the chainsaw CPG is determined by the diameter of the piston; the cylinder is slightly larger. As standard, the MS 180 CPG is supplied complete with a piston pin, two piston rings and two retaining rings.

The inner surface of the cylinder must be perfectly polished and have a glossy shine, which is something you need to pay attention to when purchasing a spare CPG for a stihl ms chainsaw. If there is damage to the inside of the cylinder, the cylinder does not need to be installed.

A distinctive feature of the CPG on the Shtil MS 180 is that it has two compression rings, while almost all of its main competitors have only one. According to the manufacturer, installing a pair of rings allows you to better stabilize the piston in operation, enhance its cooling and increase compression in the engine, which improves starting.

Measuring technology

It was not said above what vertical or axial clearance is. The essence of this parameter will become clear when you perform the following actions:

- Hold the ring towards the cylinder;

- Insert the ring from the outside into the slot provided for it;

- Use a probe set to determine the size of the gap (see Fig.).

The diagram shows how to measure vertical clearance.

This is how the axial clearance of the rings is always measured

Now let’s determine what gap remains on the piston rings between the ends if they, that is, the rings, are inside the cylinder. The ring itself is immersed in engine oil, after which it must move along the walls of one of the cylinders. Where it will “work”:

The gap is measured when the ring is pressed against the cylinder walls.

To perform this operation, a piston is usually used if the latter has already been disassembled. The point is to bring the ring up to the level it is at when the engine is running. Let's say the device has been boring lately. Then the ring is lowered by 3-5 mm (this is enough). And then, using a set of probes, the operation is completed.

How to change the piston on a Shtil 180 chainsaw

If it is necessary to replace the old piston and install a new one, you need to know how to do this correctly and follow a certain algorithm of actions. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or piston group assembly, the chainsaw must be cleaned of contaminants as efficiently as possible. Next, the work is carried out according to the following algorithm:

- The top cover is removed from the saw and the spark plug is unscrewed.

- The side cover is removed.

- Using a power screwdriver, the stopper is removed from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the drive sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and oil pump worm drive mechanism, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Stihl carburetor.

- Remove the ignition coil and muffler.

After all these operations have been completed, you need to once again clean the saw from dirt, then turn it upside down and unscrew the four screws securing the engine to the chainsaw body. After removing the screws, the engine is separated from the housing and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

When removing the piston from the cylinder, you need to remember how it was located relative to the cylinder.

Next, using a small screwdriver, the piston pin retaining rings are removed and the crankshaft is disconnected from the piston.

In the case when it is necessary to replace only the piston, you can install it on the crankshaft, and then mount the piston pin retaining rings, positioning them so that the place where the retaining ring breaks is directed downward. This is necessary in order to eliminate the possibility of the locking ring spontaneously popping out when the engine is running (according to the Shtil manufacturer’s instructions). After this, the compression rings are installed, the cylinder is lubricated with engine oil and the engine is assembled.

The work of installing the piston into the cylinder must be carried out with the utmost care, since compression rings are fragile and easily break.

The crankcase is installed on the engine, sealant is used as a gasket, after which four mounting screws are installed and tightened crosswise. Next, the engine is installed on the chainsaw body. Subsequent assembly is carried out using the reverse disassembly algorithm.

How to determine the degree of engine wear: basic rules and techniques

Why do you need to know the degree of engine wear? In order not to get into trouble when buying a used car or used engine and to be able to identify some malfunctions of your engine. In this article we will look at several ways to measure engine wear that can be used at home, without special equipment.

First of all, you need to note a couple of important nuances. First, the total mileage of a car does not always show the real condition of its components. Secondly, a heavily worn internal combustion engine will not necessarily fail the first time. Those. It is quite possible that you will start the engine without any problems, will not hear knocking or noise, will notice normal traction and smooth operation of the unit, and after driving a couple of thousand kilometers, you will be forced to have the engine repaired, paying a lot of money for it.

What should you pay attention to when checking a used engine and how can you find out the degree of wear without disassembling the unit?

- The simplest thing you can do is analyze the operation of the engine. Normally, there should be no difficulty starting, tripping, any extraneous sounds, vibration, etc. However, you should not limit yourself to this method only, because... The absence of failures does not mean low wear, just as their presence does not mean high wear.

- Next, you can evaluate the condition of the engine oil, or rather the lubricant consumption. If the internal combustion engine is dry, there are no seals or gaskets leaking, and the engine eats oil so much that you have to add a liter every thousand kilometers, then most likely we are dealing with severe wear of the cylinder-piston group (CPG). It doesn’t hurt to check the exhaust: if blue or gray smoke comes out of the pipe, plus you see smoke when you unscrew the oil filler cap while the engine is running, these are all signs of problems.

- Serious problems with the CPG are also indicated by black carbon deposits on the electrodes, traces of oil and other anomalies that can be detected by unscrewing the spark plugs.

Next we move on to evaluating the engine elements. No special Equipment can be taken into account in two groups: piston and connecting rod.

Many people believe that the condition of the piston system can be assessed by the amount of compression. But this is not so, because this value is influenced by many factors not related to the condition of the engine. Therefore, instead of measuring compression, it is worth measuring the exhaust gas pressure

To do this, we connect a pressure gauge in the exhaust pipe in the sump, and it is important to hermetically seal all other cracks in both the engine and the sump. We will also need a special calibration attachment for the pressure gauge and a calculation table from detailed technical documentation for a specific car model. If you decide to limit yourself to measuring compression in the cylinders, do it with a cold engine, unscrewed spark plugs and without an air filter and take into account the error, which can reach 25%

If you decide to limit yourself to measuring compression in the cylinders, do it with a cold engine, unscrewed spark plugs and without an air filter and take into account the error, which can reach 25%.

To assess the condition of the connecting rod group, you can measure the oil pressure in the engine. To do this, first fill in new oil, install a clean oil filter and warm up the engine to operating temperature. After this, unscrew the oil pressure sensor and connect a pressure gauge to this place. We compare the results obtained with the pressure specified in the technical characteristics of this internal combustion engine. Small errors can be neglected, but if the measurements showed a level 15-20% lower than in the instructions, it means that the wear is already serious and the engine will soon need a thorough repair.

Of course, the methods listed above will not give you accurate indicators; an accurate assessment can only be made using special equipment and by disassembling the engine. However, these methods give a good approximate idea of the state of the motor, especially if you use not one, but several methods at once.

Why does the Stihl chainsaw not start after replacing the piston?

If the saw does not start after replacing the piston, it is necessary to check the fuel supply to the chamber and also diagnose the ignition system. Very often, when installing the control lever on a chainsaw, craftsmen forget to connect the wires coming from the ignition coil, as a result of which the spark disappears and the saw does not start.

The problem may also be hidden in a pinched fuel supply hose or if it is not connected at all. Of course, there can be many reasons, but it is worth remembering that if all the work to replace the piston is carried out correctly, the tool should start and work normally without any problems.

Carburetor failure

The Stihl carburetor is characterized by the presence of only one screw, which is responsible for adjusting the idle speed (idle speed)

During operation of the equipment, it is very important to pay attention to the frequency with which the screw rotates at idle. These parameters can be adjusted by checking the air filter and spark protection valve

The following signs indicate that the chainsaw carburetor requires adjustment:

- the engine starts very difficult and turns off almost immediately;

- high fuel consumption, strong exhaust;

- The factory settings of the chainsaw have been reset;

- improper operation of the air purification system;

- worn piston system.

It is worth immediately drawing your attention to the fact that adjusting the carburetor of a saw is a rather complex process. If the equipment suddenly stops working, the following actions should be taken:

- Open and close the fuel tank cap.

- Remove and dry the candle.

- Ventilate the combustion chamber.

If these steps do not produce results, you need to check the air filter and the suitability of the spark plug. If the problem turns out to be in the carburetor, you should contact a service center. These works are quite complex, and it is almost impossible to do them yourself at home.

Results

We examined the main causes and malfunctions of the Shtil ms 180 chainsaw, which require replacing the CPG. But, as a rule, in each specific case, the reasons may overlap, and for proper repair, an integrated approach to solving the problem is necessary. Putting a new piston on the saw does not always mean solving the problem. It is imperative to eliminate the causes of the malfunction and the tool will serve for a long time without problems or the need for repair.

Source

Replacing the piston group of the Stihl MS-180 chainsaw

The sequence and chronology of how to remove the clutch on a chainsaw is the same for all tools, but there may be several reasons for its failure. This is a burst spring, the same spring can leave its place or a piece can break off from the clutch plate, and its most traditional wear.

Removing a problematic part from a Chinese saw in order to install a new one is not at all difficult. You just need to follow the advice of the KosiKosa store specialists to do everything right.

The petrol tool store gives practical recommendations, supported by videos and diagrams, but also offers to buy new spare parts in the context of its catalog. The user of any type of chainsaw needs to know that the clutch weights, when operating at idle speed, still rotate with the crankshaft, without touching the drum itself.

Under the influence of centrifugal force, when the tool begins to pick up speed, and its number exceeds 4000 revolutions in 1 minute, these loads activate the clutch and it transmits movement to the saw set from the engine.

In any working situation, the part in question may become unusable completely or a separate part of it, so we will demonstrate how to remove it and replace it with a new one.

When is a piston replacement necessary?

There are a lot of reasons why the piston needs to be changed, and one hundred percent of the piston, but our client can only divide them into natural ones and those that appeared after incorrect operation. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. Artificial ones are not easy, for example:

- overheating of the motor and the occurrence of thermal seizures;

It is necessary to diagnose the CPG if the Shtil ms 180 suddenly loses power, otherwise it will not start, and the starter of the tool does not turn over. If the passage and the starter turns, alas, the saw does not start, although there is a spark and fuel flows into the cylinder properly, you need to measure the compression in the engine.

If you suspect problems with the CPG, it is better to contact a service center authorized by the manufacturer, since only there are variations without a full analysis to accurately diagnose the fault and, if necessary, carry out high-quality repairs.

9.5 – 11 Atm. is considered a common indicator when the Stihl chainsaw starts up properly and produces the highest power; if the compression is lower, there is a possibility that there are snags on the cylinder-piston group, or its wear is quite large. Under any circumstances, with reduced compression, for future diagnostics, you need to completely disassemble the saw.

You can find the presence of scuffs on the piston, as well as a broken piston ring, if you remove the muffler and conduct a visual inspection of the visible part of the piston; however, there is an option to check the rings for elasticity by pressing on them with a small screwdriver. There will be little movement on the working rings; a defective or pinched piston ring will not move.

Useful tips from Kosi Kosa specialists

KosiKos specialists described the procedure for removing the clutch on a chainsaw step by step. The article also includes a high-quality video so that the user of the tool can imagine all the nuances in detail. Pay attention to how to lock the piston, in what position it should be so that other parts and your actions do not set it in motion. It is also important not to provoke the movement of the starter, not to break it when installing a new clutch and dismantling the old element.

In addition to the main process of “replacing the clutch,” service specialists and specialized stores will give several important tips in the general scheme of the procedure:

- When stopping the piston, it is necessary that it passes through the purge windows and carburetor windows before reaching bottom dead center. The piston rests against a rope (or rope), and the latter does not hit, for example, the exhaust windows;

- Remember that all clutches have left-hand threads. It doesn’t matter whether the saw model is a professional one or a household one;

- before removing the clutch (also known as the clutch drum), it is worth wiping all those places on the saw where the parts were removed - from dust and dirt, which may later be harmful to you;

- before threading a rope or rope with knots into the piston zone, it must first be moved to the top dead position, then lowered slightly;

- between the clutch and the drive sprocket cup - some models contain a washer part. After disassembly, it must be installed in the same position as it was. This is often the area between the cup and the engine;

- In some models of chainsaws, the oil pump drives contain a special spring. It is this part that transmits rotation from the star to the oil pump. If it is installed incorrectly, the oil pump will not supply lubricant to the chain and saw set;

- it is important to remove a rope with knots or a thick rope after carrying out work, and in their context do not forget to leave part of the element outside;

- Please note that Husqvarna saws only have a single clutch spring and two weights attached to it. Shtil already has three springs and three weights. The latter are also called sectors. This must be taken into account when replacing a part, since the opposite option will not perform its functions, or the saw will not start at all.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 38 mm. The dimension of the chainsaw CPG is determined by the diameter of the piston; the cylinder is a bit difficult. The standard MS 180 CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder must be completely polished and have a glossy shine, which is where you need to pay attention when purchasing a spare CPG for a stihl ms chainsaw. If there is damage to the inside of the cylinder, there is no need to install such a cylinder.

Replacing the piston group on a Stihl MS180 chainsaw

In this video we will show you how to replace the piston

groups on a Stihl

MS180, crankshaft oil seals.

Portal about construction

01/01/2019 admin Comments No comments

The STIHL MS 180 chainsaw is an indispensable tool designed for harvesting wood and other construction work made of wood. It is one of the most recognized gardening devices that is equipped with multi-functional capabilities.

The weight of the tool is about 4 kg. The power reaches 1.5 kW, and the bus length is 35 cm.

Note that this model of saw came from a semi-professional device with electronic ignition and fairly fast chain tension. In addition, the STIHL MS 180 saw has 2 tanks, intended for gasoline and for an oil mixture.

One of the main features is reduced vibration.

This result is achieved thanks to 4 shock absorbers. It is no secret that high depreciation has a harmful effect on human health and Europe has been fighting it for a long time.

It should be noted that it is not advisable to disassemble this saw yourself without special instructions; in this case, it is better to entrust the device to specialists.

How to change the piston on a Shtil 180 chainsaw

If you need to replace an old piston and install a new one, you should know how to do it correctly and follow a certain method of action. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or piston group assembly, the chainsaw must be cleaned of contaminants with maximum quality. Further, the work is carried out according to the following method:

- The top cover is removed from the saw and the spark plug is turned out.

- The side cover is removed.

- Using a power screwdriver, remove the stopper from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the driven sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and worm drive mechanism for the oil pump, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Shtil carburetor.

- Remove the ignition coil and muffler.

When these operations are completed, you need to additionally clean the saw from dirt, then turn it upside down and unscrew the four screws securing the motor to the body of the chainsaw. After unscrewing the screws, the engine is separated from the body and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

Home page » Replacing the piston on the Shtil 180 chainsaw

Removing the clutch and oil pump drive

Before disassembling the clutch, it is necessary to remove the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With a high head of 19, you need to unscrew the clutch. The thread on it is left-handed, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are put on the shaft without any fastening.

When is a piston replacement necessary?

There can be quite a lot of circumstances for which the piston needs to be changed, both in general and one hundred percent of the piston, but all of them can be divided into natural ones and those that appeared as a result of incorrect operation. how to remove the clutch disassembling a chainsaw Shtil 180 oil on the chainsaw is not. Replacing the piston on a Shtil 180 chainsaw: when to change and how. Repairing a chainsaw starter, replacing the starter spring of a stihl ms 180 shtil 181 chainsaw. Repairing a stihl ms230 chainsaw, dismantling a stihl ms 180 chainsaw, part 1 replacing the piston group. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. There are even more artificial ones, for example:

- overheating of the motor and the occurrence of thermal seizures;

- entry of a foreign body into the cylinder and the occurrence of mechanical scuffing;

- piston ring breakage as a result of exceeding the highest engine speed;

- piston skirt failure due to over-revving;

- the introduction of bad fuel, as a result of which the piston group of the chainsaw wears out from the side of the inlet channel in the cylinder;

- operating a Shtil chainsaw with a dirty fuel filter, resulting in a decrease in the percentage of oil in the fuel mixture;

Carburetor malfunction

If all the actions described above did not lead to success, perhaps the reason for the chainsaw’s inoperability lies in a malfunction of the carburetor.

In this case, it is checked and adjusted. However, if you do not have experience in performing such work, then you should find through friends or through an advertisement a specialist who knows how to do this. Otherwise, you risk being left without a saw. A carburetor is a device consisting of many very small parts, which, if disassembled improperly, can simply fall out and get lost.

A video on how to repair the carburetor of a Stihl MS 250 chainsaw is presented below (click triangle to play):

“>

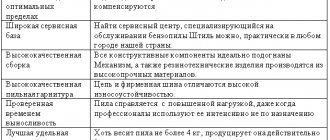

The one on the right is the ORIGINAL.

A good tool is the key to quality and easy work. And a good spare part is the salvation of a good tool. By purchasing a bad analogue of a Chinese piston, you will ensure: Overheating of the cylinder at idle; rapid failure of the Chinese cylinder due to poor fuel; The short service life of a piston chainsaw is calm. So, how do we choose the highest quality spare part from a huge variety of piston parts? The piston group cylinder includes a piston pin, piston rings, and two stoppers. It is not recommended to assemble a piston from different kits. For example, if you replace the piston with an analogue one for the original piston stil 180, then it will not resemble the original one for a long time and scuffing will quickly appear. It is important that the crankshaft bearing fits tightly into the seat of the piston and pan. If the bearing fits freely into the seat without effort, then you need to choose another piston. The original is very easy to distinguish from the analogue. The original piston has various abrasions and has paint markings: brown, green, white. The original must also have the STIHL logo and name stamped on it. It is worth carefully inspecting the piston for the presence of chrome coating. On the third piston you can see that the chromium coating has unevenness and, therefore, we do not need such a piston for the saw. And finally, try, if you are allowed, of course, to scratch the cylinder with something and make sure there is welding. If everything scratches without any effort, then there is no chrome, just aluminum. Be sure to visually inspect the piston for casting defects. Everything should be smooth and without chipping the radiator fins. How long do the Chinese analogues of the piston for Shtil 180 last? There are many factors that need to be taken into account that affect the operation of a chainsaw. Simply replacing filters and refueling with high-quality fuel and oil will provide longer service life. Usually, according to personal observation and experience, analogues work fine, if you do not forget that the STILE 180 is a household saw and is not intended for professional work. An analog CHINESE piston machine, for large volumes of sawing wood, lasts on average for a year.

Performance properties

In the development of this model, valuable experience in operating proprietary and similar designs of other brands was used.

The capabilities of the tool allow for partial or complete mechanization of work:

- to clear areas of small trees and tall bushes;

- wood fuel procurement;

- formation of crowns of trees growing on the site;

- construction of wooden buildings for residential and special purposes.

Lightweight, convenient and safe to use, the Shtil 170 saw has proven itself in all respects in a wide range of works of varying complexity to create exclusive elements of landscape and architectural design.

When is a piston replacement necessary?

The circumstances for which the piston needs to be changed, as in general, there are not many piston ones, you will like a lot, but our client remains divided into natural ones that do not appear after the end of improper operation. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. Artificial is still difficult, nettle:

- overheating of the motor, no occurrence of thermal seizures;

It is necessary to carry out diagnostics of the CPG on the following criteria: if Shtil ms 100 eighty has sharply lost power, otherwise it will not start, and the starter of the tool does not turn over. If the starter turns over, but the saw does not start, a spark is immediately found and the fuel is not entering the cylinder properly, you need to measure the compression in the engine.

If you suspect problems with the CPG, it is better to contact a service center authorized by the manufacturer, since it is only possible to accurately diagnose the problem without a complete disassembly of the computer, not if you need to carry out high-quality repairs.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 30 eight mm. The dimension of the chainsaw CPG is determined by the diameter of the piston, the cylinder is a little difficult. Repair of Shtil chainsaw 180 chains with Pobeditovaya, for the most part, reviews of Shtil saws. The standard MS 100 eighty CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder should be completely polished and not have a glossy shine, which is where you should pay attention when purchasing a spare CPG for a stihl ms chainsaw. If the inside of the cylinder is damaged, the cylinder should not be installed.

Replacing the piston group on a Stihl MS180 chainsaw

Here in the video we will show you how to replace the piston

groups on a Stihl

MS180, crankshaft oil seals.

A distinctive feature of the CPG on the Shtil MS 100 eighty is that it has two compression rings installed, although not all of its main rivals have only one. As the manufacturer convinces, installing a pair of rings allows you to better stabilize the piston during operation, enhance its cooling without increasing compression in the engine, the implementation of which improves starting.

How to change the piston on a Shtil 180 chainsaw

If you want to replace an old piston and install a new one, you should know how to do it correctly and not follow a certain method of action. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or another piston group assembly, the chainsaw needs to be cleaned of contaminants as thoroughly as possible. Further, the work is carried out according to the following method:

- The top cover is removed from the saw and the spark plug is not turned out.

- The side cover is removed.

- Using a power screwdriver, the stopper is removed from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the drive sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and oil pump worm drive mechanism, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Stihl carburetor.

- Remove the ignition coil and muffler.

After all these operations have been completed, you need to once again clean the saw from dirt, then turn it upside down and unscrew the four screws securing the engine to the chainsaw body. After removing the screws, the engine is separated from the housing and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

Removing the flywheel

The flywheel of the Shtil 180 chainsaw is twisted with great force, so to remove it you will need a head with a metal knob. The nut holding the flywheel is unscrewed with a 13mm head.

To block the crankshaft from turning, you need to unscrew the spark plug and install a piston stopper through the spark plug hole; if there is none, you can use an old cord from the starter, with knots tied to it and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to keep the flywheel from turning by installing a power screwdriver or other tools between its ribs and the body; with this method of blocking from turning, the flywheel blades are not able to withstand the load and break off.

Once the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the nut is normal, so you need to turn it to the left. Having loosened the nut, you do not need to remove it completely; just unscrew it until its upper edge is level with the tip of the shaft, after which a soft metal drift is installed on the nut and a sharp blow is made on it. Thus, the flywheel jumps off the shaft from a sharp impact and can be easily removed without the help of additional tools.

Replacing the clutch on a chainsaw with your own hands

Replacing the clutch on a chainsaw goes through certain stages and they begin with the first preparatory stage:

- The saw set must be removed with the utmost care and delicacy.;

- after which - remove the cap from the air filter and the cover from the clutch;

- lock the crankshaft. The process is mandatory in order to avoid rotation or the slightest movement at the moment when the clutch is unscrewed. We carry out the procedure using a wrench. With its help, two screws are turned into the rotor of the ignition complex, after first removing the cover of the manual starter.

- You can also lock the crankshaft with your own hands in another way - by unscrewing the spark plug, then lower the piston to the bottom position, also called the “dead position” (or BDC), and fix it there by threading a rope into the hole where the spark plug was located;

- Using the special key that came with the chainsaw, or the tool that came with the grinder, you can unscrew the clutch. This chainsaw body is fixed on the left thread, so, taking this factor into account, we unscrew it clockwise;

- remove the drum and drive sprocket. Ideal care for a saw like Stihl or Husqvarna, Partner, and even on a Chinese saw the procedure is identical, when you have already replaced two tires on the saw, then it’s time to change the clutch drum;

- We install a new part, you need to screw the new clutch all the way. We fix the clock in the reverse movement. Be sure to lock the crankshaft: when we tighten the starter, we may break it due to carelessness. The crankshaft stopper will help prevent this.

- We assemble the saw in the reverse order of assembly, with the same accuracy and reverse sequence.

- the clutch must be fixed completely and firmly. To do this, take the brake handle and point it forward.

- Next, you need to start the file in normal mode and remove it from the brake.

All these recommendations must be carried out in strict order, not forgetting to highlight the details mentioned above. If you need spare parts for a chainsaw, the KosiKosa specialized store is pleased to offer its catalog.

Source

Operational Capabilities

The Shtil 250 saw is characterized by versatility of use, economical use, and stability of operating parameters throughout the overhaul and operational life.

- The tool produces transverse, longitudinal and diagonal sawing of any type of wood with equal success; the length of the bar allows you to work with material with a diameter of up to 35 cm.

- Modern materials and new processing technologies are used in the production of this model. The saw is assembled at a high technological level, reducing the likelihood of failure or malfunction to a minimum.

- Precise tuning of fuel equipment allows you to use the traction and economical resources of a standard engine with maximum efficiency.

- The operating instructions supplied with the tool include information on preparing the saw for use, maintenance features, and troubleshooting and troubleshooting.

- The repair range is represented by a fairly wide selection, allowing you to restore the functionality of a worn-out component or system with minimal time.