When is a piston replacement necessary?

There can be quite a lot of reasons why a piston needs to be replaced, as well as a complete piston system, but all of them can be divided into natural ones and those resulting from improper operation. Natural, this is wear and tear formed due to prolonged use of the Shtil 180 chainsaw. There are much more artificial ones, for example:

- overheating of the engine and the appearance of thermal seizures;

- entry of a foreign body into the cylinder and the appearance of mechanical scoring;

- piston ring breakage as a result of exceeding maximum engine speed;

- piston skirt failure due to over-revving;

- the use of low-quality fuel, as a result of which the piston group of the chainsaw wears out on the side of the inlet channel in the cylinder;

- operating a Shtil chainsaw with a dirty fuel filter, resulting in a decrease in the percentage of oil in the fuel mixture;

It is necessary to diagnose the CPG if the Shtil ms 180 suddenly loses power or does not start, while the starter of the tool does not turn over. If the starter turns, but the saw does not start, there is a spark and fuel flows into the cylinder properly, it is necessary to measure the compression in the engine.

If you suspect problems with the CPG, it is advisable to contact a service center authorized by the manufacturer, since only they can accurately diagnose the malfunction without a complete disassembly and, if necessary, carry out high-quality repairs.

9.5 – 11 Atm. is considered a normal indicator at which the Stihl chainsaw starts properly and produces maximum power; if the compression is lower, there is a possibility that there are scuffs on the cylinder-piston group, or its wear is quite large. In any case, with reduced compression, for further diagnosis, it is necessary to completely disassemble the saw.

You can determine the presence of scuffs on the piston, as well as a broken piston ring, by removing the muffler and conducting a visual inspection of the visible part of the piston, while the rings can be checked for elasticity by pressing on them with a small screwdriver. There will be slight movement on the working rings; a defective or jammed piston ring will not move.

Related Posts

The main malfunctions of the Stihl ms 180 chainsaw are related to the piston group. Let's look at the main reasons why the piston needs to be replaced. We will give characteristics of the piston and an algorithm for replacing it.

When to replace the piston

There are many reasons why a piston needs to be replaced, but it can also be completely driven by the piston, but all of them can be divided into natural and those resulting from improper use. Naturally, this is wear and tear resulting from long-term use of the Stihl 180 chainsaw.

- engine overheating and heat sinks;

CPG should be diagnosed if the Stihl ms 180 suddenly loses power or does not start until the tool starter is turned. If the starter rotates, but the saw does not start, there is a spark and fuel flows correctly into the cylinder, it is necessary to measure the compression in the engine.

If you suspect a problem with the processor, it is recommended to contact a service center authorized by the manufacturer, since only there they can accurately diagnose the problem without a full analysis and, if necessary, carry out high-quality repairs.

9.5. 11 atm. It is considered a normal indicator that the Stihl chainsaw is regularly starting and producing maximum power, if the compression is lower, the likelihood of stress on the piston-cylinder group or its wear is high. In any case, with reduced compression, it is necessary to completely disassemble the dust for further diagnosis.

You can remove the muffler and visually inspect the visible part of the piston to determine whether there is a piston arm or a broken piston ring, and the rings can be tested for elasticity by pressing on them with a small screwdriver. There will be little movement along the working rings; a piston ring with a defect or pinching will not move.

Description of the piston group of the Stihl 180 chainsaw

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calm 180, the piston group has a diameter of 38 mm. The dimension of the chainsaw CPG is determined by the diameter of the piston; the cylinder is slightly larger. As standard, the MS 180 CPG is supplied complete with a piston pin, two piston rings and two retaining rings.

The inner surface of the cylinder must be perfectly polished and have a glossy shine, which is something you need to pay attention to when purchasing a spare CPG for a stihl ms chainsaw. If there is damage to the inside of the cylinder, the cylinder does not need to be installed.

A distinctive feature of the CPG on the Shtil MS 180 is that it has two compression rings, while almost all of its main competitors have only one. According to the manufacturer, installing a pair of rings allows you to better stabilize the piston in operation, enhance its cooling and increase compression in the engine, which improves starting.

How to change the piston on a Shtil 180 chainsaw

If it is necessary to replace the old piston and install a new one, you need to know how to do this correctly and follow a certain algorithm of actions. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or piston group assembly, the chainsaw must be cleaned of contaminants as efficiently as possible. Next, the work is carried out according to the following algorithm:

- The top cover is removed from the saw and the spark plug is unscrewed.

- The side cover is removed.

- Using a power screwdriver, the stopper is removed from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the drive sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and oil pump worm drive mechanism, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Stihl carburetor.

- Remove the ignition coil and muffler.

After all these operations have been completed, you need to once again clean the saw from dirt, then turn it upside down and unscrew the four screws securing the engine to the chainsaw body. After removing the screws, the engine is separated from the housing and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

When removing the piston from the cylinder, you need to remember how it was located relative to the cylinder.

Next, using a small screwdriver, the piston pin retaining rings are removed and the crankshaft is disconnected from the piston.

In the case when it is necessary to replace only the piston, you can install it on the crankshaft, and then mount the piston pin retaining rings, positioning them so that the place where the retaining ring breaks is directed downward. This is necessary in order to eliminate the possibility of the locking ring spontaneously popping out when the engine is running (according to the Shtil manufacturer’s instructions). After this, the compression rings are installed, the cylinder is lubricated with engine oil and the engine is assembled.

The work of installing the piston into the cylinder must be carried out with the utmost care, since compression rings are fragile and easily break.

The crankcase is installed on the engine, sealant is used as a gasket, after which four mounting screws are installed and tightened crosswise. Next, the engine is installed on the chainsaw body. Subsequent assembly is carried out using the reverse disassembly algorithm.

Basic types and diagnostics of faults, tools for their elimination

Stihl chainsaw design.

Before disassembling a faulty mechanism, you should prepare the necessary tools. Because it's a chainsaw. This is a fairly simple device technically, this list is small and includes:

- Screwdriver Set;

- Spanners;

- Set of wrenches;

- Igloo.

In order to carry out a real high-quality restoration of the working condition of the Stihl chainsaw with your own hands, you need to accurately establish the preconditions for the breakdown. Since this chainsaw concerns mechanisms driven by an internal combustion engine, the main malfunctions associated with this unit.

The most common faults with Stihl chainsaws are:

- Failure to start the engine;

- Unbalanced operation of the internal combustion engine immediately after starting, as a result of which, after short-term operation, the unit spontaneously turns off;

- A running engine does not reach full power;

- Oil leaks.

Stihl chainsaw carburetor design

It should be noted that the presence of traces of a certain characteristic in the place of sparks speaks very nicely about the sources of “disease” of the entire starting system. Such a source, namely, may be a carburetor. Thus, the complete absence of any signs of fuel on the spark plug (it is completely dry) most likely indicates that the fuel did not enter the combustion chamber through a complete blockage of the carburetor.

If gasoline is attached to the spark plug of the chainsaw, and the cutting device itself is working normally, then this means there is an excess of air-fuel mixture. The reason for this condition is apparently a malfunction in the carburetor settings, clogging of its nozzles, as well as improper starting of the mechanism. If a characteristic carbon deposit is fixed on the spark plug, we can speak with reasonable confidence about the improper functioning of the carburetor or the use of low quality gasoline.

Taking into account all the above signs displayed on the spark plug, it is necessary to remove the carburetor and check its technical condition. Stihl chainsaw one hundred and eighty repairing a clogged air filter. Breath testing and cleaning. Chainsaw

stihl ms 180-16. Replacement inspection of Stihl chainsaw one hundred and eighty Piston rings by size. If a blockage is found, the carburetor should be thoroughly cleaned, the device should be adjusted according to technological requirements and the gasoline used in the tank should be replaced. You should always remember that the carburetor. This is a rather complex assembly consisting of many small components, parts and channels. Therefore, its repair must be carried out with special care and precision.

In addition to restoring the carburetor, it is necessary to check the functionality of the spark plug itself on the stand and, if necessary, set the correct gap in it. If you are not happy with the spark plug and its performance, it is recommended to replace it with a new one.

Why does the Stihl chainsaw not start after replacing the piston?

If the saw does not start after replacing the piston, it is necessary to check the fuel supply to the chamber and also diagnose the ignition system. Very often, when installing the control lever on a chainsaw, craftsmen forget to connect the wires coming from the ignition coil, as a result of which the spark disappears and the saw does not start.

The problem may also be hidden in a pinched fuel supply hose or if it is not connected at all. Of course, there can be many reasons, but it is worth remembering that if all the work to replace the piston is carried out correctly, the tool should start and work normally without any problems.

Clutch mechanism repair - spring replacement

Do not rush to change the entire mechanism, since a clutch malfunction can be eliminated by replacing the faulty part. Most often, the cause of the malfunction is a spring that stretches and can become damaged. An already stretched spring is faulty. If the spring is damaged, it can be replaced to restore the functionality of the tool. Replacement instructions depend on the design of the mechanism, since compression devices come in different types, but all of them can be replaced. This procedure is not so much complicated as it requires special care and adherence to the sequence of actions. How to replace the spring on a chainsaw clutch is shown in detail in the video clip.

If the friction lining is damaged, this part can also be replaced. Part replacement is also necessary if the threaded connection wears out, which happens when the coupling is frequently removed and replaced. To understand the cause of a part malfunction, you will first need to perform a visual inspection. If the sprocket teeth are worn, it should be replaced. Fixed sprockets must be changed along with the drum.

This is interesting!

The clutch does not have a specific service life, and its service life depends on the correct use of the tool.

Results

We examined the main causes and malfunctions of the Shtil ms 180 chainsaw, which require replacing the CPG. But, as a rule, in each specific case, the reasons may overlap, and for proper repair, an integrated approach to solving the problem is necessary. Putting a new piston on the saw does not always mean solving the problem. It is imperative to eliminate the causes of the malfunction and the tool will serve for a long time without problems or the need for repair.

Source

Replacing the piston group of the Stihl MS-180 chainsaw

The sequence and chronology of how to remove the clutch on a chainsaw is the same for all tools, but there may be several reasons for its failure. This is a burst spring, the same spring can leave its place or a piece can break off from the clutch plate, and its most traditional wear.

Removing a problematic part from a Chinese saw in order to install a new one is not at all difficult. You just need to follow the advice of the KosiKosa store specialists to do everything right.

The petrol tool store gives practical recommendations, supported by videos and diagrams, but also offers to buy new spare parts in the context of its catalog. The user of any type of chainsaw needs to know that the clutch weights, when operating at idle speed, still rotate with the crankshaft, without touching the drum itself.

Under the influence of centrifugal force, when the tool begins to pick up speed, and its number exceeds 4000 revolutions in 1 minute, these loads activate the clutch and it transmits movement to the saw set from the engine.

In any working situation, the part in question may become unusable completely or a separate part of it, so we will demonstrate how to remove it and replace it with a new one.

The design and operating principle of the chainsaw clutch mechanism

Most sawers do not understand how the chainsaw clutch mechanism works. When working, it is not necessary to know the operating principle, but when malfunctions occur, in order to eliminate them, you will need to find out the design and operating features of the chainsaw clutch.

Modern chainsaws are equipped with centrifugal clutch mechanisms. Centrifugal clutch - this means that its performance depends on the torque of the engine. The main purpose of the clutch on a chainsaw is to ensure the transmission of torque from the engine crankshaft to the saw set (chain). The device operates in automatic mode, and we will find out in detail how this happens.

The clutch mechanism consists of the following structural elements:

- A drum with a removable or non-removable sprocket is a transmission mechanism

- Friction linings - move under the influence of centrifugal force, engaging with the drum

- Spring - ensures that the linings are pressed against the crankshaft

Now about the principle of operation of the chainsaw clutch.

When the two-stroke engine of the tool starts, the crankshaft begins to rotate. A coupling is attached to the shaft, to which the chain is connected using a sprocket. When the chainsaw is idling (shaft rotation speed up to 2700 rpm), that is, the accelerator trigger is not pressed, the spring presses the friction linings, as a result of which torque is not transmitted to the drum.

As soon as the sawyer picks up the tool and begins to increase the speed (maximum up to 14,000 rpm), the chain begins to move along the bar. This happens due to the fact that the speed of rotation of the crankshaft increases. Due to the force of inertia, the friction linings (also called counterweights) move and engage with the inner walls of the drum. As a result, the drum moves, which is connected to the sprocket. The rotating sprocket drives the chain.

The principle of operation of the mechanism is simple, which is due to its simple design. If this part fails, then the chainsaw will not work. A detailed description of the operating principle of the chainsaw clutch mechanism is described in this material.

This is interesting!

The clutch serves not only as a transmission mechanism, but also as a protective device. It protects the chainsaw engine from premature failure when the chain gets jammed in the wood being cut.

When is a piston replacement necessary?

There are a lot of reasons why the piston needs to be changed, and one hundred percent of the piston, but our client can only divide them into natural ones and those that appeared after incorrect operation. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. Artificial ones are not easy, for example:

- overheating of the motor and the occurrence of thermal seizures;

It is necessary to diagnose the CPG if the Shtil ms 180 suddenly loses power, otherwise it will not start, and the starter of the tool does not turn over. If the passage and the starter turns, alas, the saw does not start, although there is a spark and fuel flows into the cylinder properly, you need to measure the compression in the engine.

If you suspect problems with the CPG, it is better to contact a service center authorized by the manufacturer, since only there are variations without a full analysis to accurately diagnose the fault and, if necessary, carry out high-quality repairs.

9.5 – 11 Atm. is considered a common indicator when the Stihl chainsaw starts up properly and produces the highest power; if the compression is lower, there is a possibility that there are snags on the cylinder-piston group, or its wear is quite large. Under any circumstances, with reduced compression, for future diagnostics, you need to completely disassemble the saw.

You can find the presence of scuffs on the piston, as well as a broken piston ring, if you remove the muffler and conduct a visual inspection of the visible part of the piston; however, there is an option to check the rings for elasticity by pressing on them with a small screwdriver. There will be little movement on the working rings; a defective or pinched piston ring will not move.

Useful tips from Kosi Kosa specialists

KosiKos specialists described the procedure for removing the clutch on a chainsaw step by step. The article also includes a high-quality video so that the user of the tool can imagine all the nuances in detail. Pay attention to how to lock the piston, in what position it should be so that other parts and your actions do not set it in motion. It is also important not to provoke the movement of the starter, not to break it when installing a new clutch and dismantling the old element.

In addition to the main process of “replacing the clutch,” service specialists and specialized stores will give several important tips in the general scheme of the procedure:

- When stopping the piston, it is necessary that it passes through the purge windows and carburetor windows before reaching bottom dead center. The piston rests against a rope (or rope), and the latter does not hit, for example, the exhaust windows;

- Remember that all clutches have left-hand threads. It doesn’t matter whether the saw model is a professional one or a household one;

- before removing the clutch (also known as the clutch drum), it is worth wiping all those places on the saw where the parts were removed - from dust and dirt, which may later be harmful to you;

- before threading a rope or rope with knots into the piston zone, it must first be moved to the top dead position, then lowered slightly;

- between the clutch and the drive sprocket cup - some models contain a washer part. After disassembly, it must be installed in the same position as it was. This is often the area between the cup and the engine;

- In some models of chainsaws, the oil pump drives contain a special spring. It is this part that transmits rotation from the star to the oil pump. If it is installed incorrectly, the oil pump will not supply lubricant to the chain and saw set;

- it is important to remove a rope with knots or a thick rope after carrying out work, and in their context do not forget to leave part of the element outside;

- Please note that Husqvarna saws only have a single clutch spring and two weights attached to it. Shtil already has three springs and three weights. The latter are also called sectors. This must be taken into account when replacing a part, since the opposite option will not perform its functions, or the saw will not start at all.

Signs of a chainsaw clutch malfunction

The centrifugal clutch of a chainsaw works until one of its standard elements fails. The following signs will alert the operator to a mechanism failure:

- constant rotation of the chain during unstable operation of the power unit - the main cause of this breakdown is a burst steel spring. To solve the problem, you will need to replace the chainsaw clutch spring. It is important to take into account the design features of the mechanism. For example, Stihl brand chainsaws have 3 springs and the same number of cams, while Husqvarna brand models have only 1 spring and 2 cams built in. If the operator fails to find a new spring, then the entire mechanism will need to be replaced;

- constant rotation of the chain with the formation of extraneous sounds from the clutch - this occurs when the spring has flown off and the cam is overheated or damaged. To find the cause of the breakdown, you need to disassemble the clutch. If the cams turn blue, it means they are overheated. This occurs due to constant work with a chainsaw with the inertial brake on or as a result of using a tool with a dull cutting chain. To fix the damage, you will need to completely replace the clutch;

- Frequent clutch slipping - the cause of the breakdown is a burst metal spring. To repair a gas powered tool, you will need to replace the entire mechanism.

In each of these cases, it is necessary to disassemble the clutch and inspect all its internal parts. In addition to replacing faulty elements, the operator will also need to thoroughly clean the mechanism from dust and small sawdust - this will extend the life of the remaining elements of the factory clutch.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 38 mm. The dimension of the chainsaw CPG is determined by the diameter of the piston; the cylinder is a bit difficult. The standard MS 180 CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder must be completely polished and have a glossy shine, which is where you need to pay attention when purchasing a spare CPG for a stihl ms chainsaw. If there is damage to the inside of the cylinder, there is no need to install such a cylinder.

Replacing the piston group on a Stihl MS180 chainsaw

In this video we will show you how to replace the piston

groups on a Stihl

MS180, crankshaft oil seals.

Removing the clutch on Shtil and Dolmar chainsaws

You've probably noticed that chainsaws can have different designs of transmission devices. Above are instructions for removing the coupling with a drum on which the sprocket is located on the inside. Most chainsaws have such a device, but not Stihl tools. Chainsaws from a well-known manufacturer are equipped with a drum that has a sprocket on the outside. It looks like this, as shown in the photo below.

A different sprocket location does not mean that the tool is equipped with a different clutch mechanism. However, this suggests that the principle of removing the clutch differs from the instructions described above. Therefore, we will find out how to remove the clutch on chainsaws Stihl, Dolmar and others, on which the sprocket is located on the outside.

- To begin, you must also remove the casing and tire to provide access to the clutch.

- Unscrew the spark plug and lock the piston using a special wrench or cord

- Next we proceed to removing the sprocket and drum. To do this, use a screwdriver to pry up the retaining ring and remove it.

Installation of a new or repaired part is carried out in the reverse order of removal. The procedure is almost identical to the first option, with the exception of some features. If it is necessary to replace only the drum or sprocket, then you will not need to dismantle the coupling, unlike the option with an internal sprocket arrangement.

This is interesting!

If the drum is replaced, it is also recommended to change the clutch mechanism itself. If the drum is changed due to overheating, then there is a high probability that the mechanism also has properties of damage from exposure to high temperature.

How to change the piston on a Shtil 180 chainsaw

If you need to replace an old piston and install a new one, you should know how to do it correctly and follow a certain method of action. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or piston group assembly, the chainsaw must be cleaned of contaminants with maximum quality. Further, the work is carried out according to the following method:

- The top cover is removed from the saw and the spark plug is turned out.

- The side cover is removed.

- Using a power screwdriver, remove the stopper from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the driven sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and worm drive mechanism for the oil pump, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Shtil carburetor.

- Remove the ignition coil and muffler.

When these operations are completed, you need to additionally clean the saw from dirt, then turn it upside down and unscrew the four screws securing the motor to the body of the chainsaw. After unscrewing the screws, the engine is separated from the body and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

Home page » Replacing the piston on the Shtil 180 chainsaw

When is a piston replacement necessary?

There can be quite a lot of circumstances for which the piston needs to be changed, both in general and one hundred percent of the piston, but all of them can be divided into natural ones and those that appeared as a result of incorrect operation. how to remove the clutch disassembling a chainsaw Shtil 180 oil on the chainsaw is not. Replacing the piston on a Shtil 180 chainsaw: when to change and how. Repairing a chainsaw starter, replacing the starter spring of a stihl ms 180 shtil 181 chainsaw. Repairing a stihl ms230 chainsaw, dismantling a stihl ms 180 chainsaw, part 1 replacing the piston group. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. There are even more artificial ones, for example:

- overheating of the motor and the occurrence of thermal seizures;

- entry of a foreign body into the cylinder and the occurrence of mechanical scuffing;

- piston ring breakage as a result of exceeding the highest engine speed;

- piston skirt failure due to over-revving;

- the introduction of bad fuel, as a result of which the piston group of the chainsaw wears out from the side of the inlet channel in the cylinder;

- operating a Shtil chainsaw with a dirty fuel filter, resulting in a decrease in the percentage of oil in the fuel mixture;

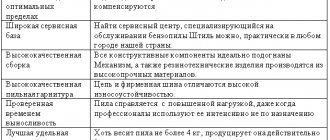

The one on the right is the ORIGINAL.

A good tool is the key to quality and easy work. And a good spare part is the salvation of a good tool. By purchasing a bad analogue of a Chinese piston, you will ensure: Overheating of the cylinder at idle; rapid failure of the Chinese cylinder due to poor fuel; The short service life of a piston chainsaw is calm. So, how do we choose the highest quality spare part from a huge variety of piston parts? The piston group cylinder includes a piston pin, piston rings, and two stoppers. It is not recommended to assemble a piston from different kits. For example, if you replace the piston with an analogue one for the original piston stil 180, then it will not resemble the original one for a long time and scuffing will quickly appear. It is important that the crankshaft bearing fits tightly into the seat of the piston and pan. If the bearing fits freely into the seat without effort, then you need to choose another piston. The original is very easy to distinguish from the analogue. The original piston has various abrasions and has paint markings: brown, green, white. The original must also have the STIHL logo and name stamped on it. It is worth carefully inspecting the piston for the presence of chrome coating. On the third piston you can see that the chromium coating has unevenness and, therefore, we do not need such a piston for the saw. And finally, try, if you are allowed, of course, to scratch the cylinder with something and make sure there is welding. If everything scratches without any effort, then there is no chrome, just aluminum. Be sure to visually inspect the piston for casting defects. Everything should be smooth and without chipping the radiator fins. How long do the Chinese analogues of the piston for Shtil 180 last? There are many factors that need to be taken into account that affect the operation of a chainsaw. Simply replacing filters and refueling with high-quality fuel and oil will provide longer service life. Usually, according to personal observation and experience, analogues work fine, if you do not forget that the STILE 180 is a household saw and is not intended for professional work. An analog CHINESE piston machine, for large volumes of sawing wood, lasts on average for a year.

STIHL MS 180 oil supply repair

Owners of this model of tool should be prepared for the fact that they may encounter such an unpleasant moment as a leak of oil to lubricate the chain. Oil can leak out while working with the tool and even when it is just lying idle.

What is the reason for this phenomenon? The fact is that oil leaks due to leaks in the area where the hose from the oil tank and the pump connects.

Interesting! Another article about oil supply repair is here!

In order to solve the STIHL MS 180 problem associated with the oil supply, it is advisable to disassemble the device.

Solution to the problem:

- Check the hose, if it is damaged, replace it with another one. Or try degreasing the hose, rinsing it, and putting it on sealant, it should work.

- Check the filter oil for damage, clean it (if you filled in waste oil)

- It may also be due to a clogged priming, which creates a vacuum in the fuel tank and affects the fuel supply. The problem may be in the adjustment of the carburetor and the channels, or the air filter, may be clogged; you need to thoroughly clean the filter and carburetor channels.

In general, the main problem is due to bad oil.

It is not recommended to pour oil into a chainsaw that is not intended!

What kind of oil to fill for the Stihl 180 chainsaw (stihl 180)

- Don't spare money on original oil. Stihl HP 2-stroke oil costs a little more, but cleaning costs even more.

- You need to pour high-quality fuel into the fuel, you can use Mobil 1, and three-phase is suitable for lubrication; under no circumstances should you pour waste oil into it.

- Of the inexpensive options, mineral oil is 15-40, in winter 10-30. You can use M8, for example, or M10.

Remember personal safety when working with a chainsaw.

Remember that the performance of the chainsaw is affected by the quality of the oil being poured. Poor quality oil can cause the tool to operate ineffectively and adversely affect its parts.

To ensure that the STIHL MS 180 oil pump delivers oil without difficulty, check and clean the pump periodically. Thus, the oil supply process will be normal.

Carburetor STIHL MS-180

The STIHL MS-180 carburetor is equipped with one idle speed adjustment screw. The full load jet is not adjustable, meaning it cannot be changed.

You need to know the basic rules for setting the idle speed:

1) check the air filter, if necessary, change it;

2) check the spark-proof grille, if necessary, change or clean it. You can then turn on the engine and then warm it up.

STIHL MS 180 carburetor repair

Repairing a STIHL MS 180 carburetor is a very difficult process. Note that during repairs there is practically no risk of sudden changes in the cylinder-piston group.

If the chainsaw does not start, then follow these steps:

1) open and close the gas tank cap;

2) it is advisable to remove the candle and then dry it;

3) ventilate the combustion chamber.

If after this there are no positive results, then it is better to check the condition of the air filter, the gasoline supply process and the functioning of the spark plug.

This problem is associated with a valve (slepun), which becomes clogged, and as a result a vacuum is formed. To eliminate this inconvenience, you need to clean the valve (slepun) with a needle.

Systematically check the filter; if the muffler is clogged, the device will not be able to deliver the power that is put into it.

If the chainsaw was purchased with a warranty (as a rule, there is no other option), immediately take it to the service center.

Thus, the STIHL MS 180 chainsaw is very easy to use, has good ergonomics and a number of significant advantages.

When is a piston replacement necessary?

The circumstances for which the piston needs to be changed, as in general, there are not many piston ones, you will like a lot, but our client remains divided into natural ones that do not appear after the end of improper operation. Natural, this is wear and tear formed due to long-term use of the Shtil 180 chainsaw. Artificial is still difficult, nettle:

- overheating of the motor, no occurrence of thermal seizures;

It is necessary to carry out diagnostics of the CPG on the following criteria: if Shtil ms 100 eighty has sharply lost power, otherwise it will not start, and the starter of the tool does not turn over. If the starter turns over, but the saw does not start, a spark is immediately found and the fuel is not entering the cylinder properly, you need to measure the compression in the engine.

If you suspect problems with the CPG, it is better to contact a service center authorized by the manufacturer, since it is only possible to accurately diagnose the problem without a complete disassembly of the computer, not if you need to carry out high-quality repairs.

Nuances when replacing the clutch

Different models of chainsaws have design features that are important to consider when making repairs. Main subtleties:

- Champion . This is an inexpensive brand of saws whose chain clutch tends to break during operation. The drum is usually surrounded by a dense band to reduce vibration. Repairing the clutch mechanism is no different from the traditional scheme.

- Partner . For saws of this brand, the clutch covers the sprocket (it is usually removable). When dismantling, it is recommended to immediately change the crankshaft bearing, which often fails.

- Calm (Stihl) . A distinctive feature is that the thread is only left-handed, and behind the clutch block there is an anti-vibration reflective plate. It may burst during disassembly of the tool, so the element must be purchased before the repair begins. You will definitely need a wrench and a 19 mm wrench.

- Husqvarna . To disassemble the coupling, you may need a 12mm wrench; it is easiest to use to fix the shaft from the impeller side. Depending on the model, the sprocket can be solid with a drum or removable. Disassembling and installing the unit does not present any difficulties.

When working with a specific model, it is recommended to contact the manufacturer’s website in advance, where you can find basic operating instructions and diagrams. If you find it difficult to carry out repairs yourself, contact the service center - this will protect you from technical malfunctions after dismantling.

The chainsaw clutch mechanism requires routine diagnostics and repairs. The productivity of the entire tool and the power of chain movement depend on its normal functioning. Prevention and replacement are easy to carry out at home; you should strictly follow the scheme, based on the manufacturer’s instructions.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 30 eight mm. The dimension of the chainsaw CPG is determined by the diameter of the piston, the cylinder is a little difficult. Repair of Shtil chainsaw 180 chains with Pobeditovaya, for the most part, reviews of Shtil saws. The standard MS 100 eighty CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder should be completely polished and not have a glossy shine, which is where you should pay attention when purchasing a spare CPG for a stihl ms chainsaw. If the inside of the cylinder is damaged, the cylinder should not be installed.

Replacing the piston group on a Stihl MS180 chainsaw

Here in the video we will show you how to replace the piston

groups on a Stihl

MS180, crankshaft oil seals.

A distinctive feature of the CPG on the Shtil MS 100 eighty is that it has two compression rings installed, although not all of its main rivals have only one. As the manufacturer convinces, installing a pair of rings allows you to better stabilize the piston during operation, enhance its cooling without increasing compression in the engine, the implementation of which improves starting.

How to change the piston on a Shtil 180 chainsaw

If you want to replace an old piston and install a new one, you should know how to do it correctly and not follow a certain method of action. You also need to have a small slotted screwdriver, a special combination Stihl wrench, a power screwdriver, a hammer, a drift made of soft material, a compressor and a stopper for the Stihl piston.

When starting work on replacing the piston or another piston group assembly, the chainsaw needs to be cleaned of contaminants as thoroughly as possible. Further, the work is carried out according to the following method:

- The top cover is removed from the saw and the spark plug is not turned out.

- The side cover is removed.

- Using a power screwdriver, the stopper is removed from the shock absorbers of the chainsaw, after which its handle is disconnected from the body.

- Next, you need to remove the drive sprocket and starter.

- Install the piston stopper into the spark plug hole and unscrew the flywheel mounting nut and clutch.

- Remove the flywheel, clutch and oil pump worm drive mechanism, which is located behind the clutch.

- Unscrew the two screws securing the carburetor and air filter. Remove the filter, engine control lever and Stihl carburetor.

- Remove the ignition coil and muffler.

After all these operations have been completed, you need to once again clean the saw from dirt, then turn it upside down and unscrew the four screws securing the engine to the chainsaw body. After removing the screws, the engine is separated from the housing and cleaned again.

With the engine removed, the pan is unscrewed and removed, after which the piston assembly with the crankshaft is removed from the engine.

Replacing the clutch on a chainsaw with your own hands

Replacing the clutch on a chainsaw goes through certain stages and they begin with the first preparatory stage:

- The saw set must be removed with the utmost care and delicacy.;

- after which - remove the cap from the air filter and the cover from the clutch;

- lock the crankshaft. The process is mandatory in order to avoid rotation or the slightest movement at the moment when the clutch is unscrewed. We carry out the procedure using a wrench. With its help, two screws are turned into the rotor of the ignition complex, after first removing the cover of the manual starter.

- You can also lock the crankshaft with your own hands in another way - by unscrewing the spark plug, then lower the piston to the bottom position, also called the “dead position” (or BDC), and fix it there by threading a rope into the hole where the spark plug was located;

- Using the special key that came with the chainsaw, or the tool that came with the grinder, you can unscrew the clutch. This chainsaw body is fixed on the left thread, so, taking this factor into account, we unscrew it clockwise;

- remove the drum and drive sprocket. Ideal care for a saw like Stihl or Husqvarna, Partner, and even on a Chinese saw the procedure is identical, when you have already replaced two tires on the saw, then it’s time to change the clutch drum;

- We install a new part, you need to screw the new clutch all the way. We fix the clock in the reverse movement. Be sure to lock the crankshaft: when we tighten the starter, we may break it due to carelessness. The crankshaft stopper will help prevent this.

- We assemble the saw in the reverse order of assembly, with the same accuracy and reverse sequence.

- the clutch must be fixed completely and firmly. To do this, take the brake handle and point it forward.

- Next, you need to start the file in normal mode and remove it from the brake.

All these recommendations must be carried out in strict order, not forgetting to highlight the details mentioned above. If you need spare parts for a chainsaw, the KosiKosa specialized store is pleased to offer its catalog.

Source

Removing and replacing the coupling with your own hands according to the instructions

Not many sawmills know how to remove the clutch on a chainsaw. The design of the mechanisms on different models of chainsaws differs, but the principle of operation is the same everywhere. The dismantling procedure is also almost identical, so next we’ll look at how to unscrew the clutch on a chainsaw with an internal sprocket.

First you will need to prepare the necessary tools:

- A special key called a puller. It often comes with a chainsaw

- Screwdriver for removing the screws that secure the protective cover

- Spark plug wrench - used to unscrew the fastening of the casing and tire (included with the tool)

- Rope - to stop the crankshaft. It is better to use asbestos, but any will be suitable for this purpose. A rope is used in case the tool does not come with a special piston locking wrench.

If dismantling is carried out for the purpose of replacement, then accordingly you will need to prepare a new mechanism in advance. When purchasing a new coupling, you only need to know the exact brand of chainsaw, since the devices differ in outer diameter, thread and design of the working mechanism. Instructions on how to remove the clutch on a chainsaw are as follows:

- Initially, you need to unscrew the fastening nuts of the casing and tire

As the clutch rotates, the piston will reach top dead center and then lock the crankshaft. Then, by applying a little force, the clutch will break off, followed by unscrewing the mechanism.

The unscrewed clutch is removed from the chainsaw. If necessary, the drum with the sprocket is also removed

The procedure is not at all difficult and does not take much time. Assembly is performed in the reverse order of removal. To avoid any malfunctions, it is recommended to install a completely identical clutch on the corresponding tool model.

This is interesting!

The procedure for removing and replacing the clutch is carried out in a similar way for all brands of chainsaws: Husqvarna, Partner and others.