Among the existing chainsaws, the portable model Stihl 180 is highly reliable. If you follow the rules specified in the operating instructions, the likelihood of breakdowns will be minimized. If problems arise, some malfunctions of the Shtil 180 chainsaw can be repaired yourself.

To ensure correct setup and regulation of the device, it is necessary to entrust the work to specialists. They have all the necessary knowledge and tools to repair such devices. However, most owners are afraid of the cost of such services, so they try to figure out the situation on their own.

Preparatory stage

Repair of any equipment must begin with the preparatory work stage, and the Stil 180 saw is no exception. At the preparatory stage, before disassembling the Shtil 180 chainsaw, it is necessary to remove the side cover, chain and tire from the chainsaw. Next, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil stains and other things.

When cleaning the saw, special attention should be paid to the place where the chainsaw drive sprocket is located, since this is the most contaminated area.

In places where there is a large accumulation of oil, you can wash it with clean gasoline.

Principle of operation

Before identifying a malfunction and repairing the Shtil 180 chainsaw, you should study the principle of its operation and what structural elements it consists of. A chainsaw must contain its main element - a two-stroke engine. It is he who is responsible for the reliability and performance of the device. The engine is involved in starting the chain drive and maintaining its movement under the influence of the centrifugal clutch. In addition to the electric motor, the chainsaw includes:

- starter;

- flywheel, also known as a cooling unit;

- ignition unit;

- clutch and brake mechanism;

- carburetor with STIHL compensator;

- air filter;

- fuel and oil tank;

- muffler;

- anti-vibration system.

Fuel from the tank enters the carburetor , where it is mixed with air coming from the cleaning unit. From the carburetor, a mixture of air and fuel enters the engine. The saw carburetor has one adjustment screw that controls the idle speed. All device settings are made at the factory and ensure optimal supply of the fuel-air mixture.

The mixture is ignited in the engine cylinder, and the engine is started using the starter. Under the action of the piston, the shaft that is part of the crank mechanism begins to move. There is a sprocket on the shaft onto which the chain links are placed.

The chainsaw uses a single-cylinder motor.

A clutch is used as a protection mechanism, which allows the electric motor to switch to idle mode in the event of a chain jam. At the initial revolutions, special linings located in the radial direction are pressed by springs to the middle of the shaft, thereby preventing it from rotating. At high speeds, centrifugal force increases, which leads to compression of the springs. The linings are pressed away from the center of the shaft, the sprocket rotates and the chain starts. The electrical circuit of the device is involved in the ignition system. Due to the use of a flywheel with magnets, an electromotive force (EMF) is generated during rotation, which leads to the appearance of current in the electronics unit. The block sends a signal to the spark plug, causing a spark to appear at its terminals. This spark ignites the mixture coming from the carburetor. After a successful start has occurred, the chainsaw begins to repeat all work processes in the cycle.

The device chain is made up of teeth and connecting elements. To protect the user from kickback, the device is equipped with a brake system. Oil supply occurs automatically under the action of a pump.

Removing the handle

Direct disassembly of the Shtil 180 begins with removing the handle, which is attached to the chainsaw body using three rubber shock absorbers. To remove it, you need to remove the plastic plugs from the internal cavity of the shock absorbers, then using a powerful screwdriver, first press out the upper shock absorber, then the one closer to the rear handle.

At the rear of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod; in order to disconnect the rod from the gas trigger, you need to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, you need to unscrew the chainsaw body from the inside of the handle and, bending it to the side, remove the body from the last rubber band.

Identifying problems in starting the unit

A problem may arise in which the STIHL 180 does not start. It is usually associated with a breakdown of the starter. In fact, the unit does not start after the cord is pulled.

Reasons for failure to start the starter may be:

- Spring failure.

- Cracked or broken pulley.

- Rope break for starting.

Before you find out the causes of the breakdown and begin repairing the chainsaw starter, the body of the chainsaw is removed. To do this, unscrew the screws that hold the cover with the starter.

In this case, screwdrivers or a special tool are used. A visual inspection of the starter reveals the reasons why the tool does not start.

Damage to the pulley by cracks and tears affects the performance of the tool. Detection of mechanical failure or defects in the place where the soft release spring is attached.

The attachment point, as well as the tip of this spring inserted into it, is vulnerable. If faults or damage to individual starter parts are detected, they are replaced with new ones.

Disassembly and maintenance of the STIHL 180 chainsaw piston system - video

The unit can be repaired efficiently if the parts fully match the brand of the chainsaw. The same scheme for replacing spare parts also applies to electric saws when doing DIY repairs.

STIHL chainsaws are most often used for sawing wood and construction work. Due to its versatility, the saw is used very often. The main advantage of Shtil MS 180 is its low vibration level. Like any piece of equipment, a chainsaw can break down and require maintenance and repair, so it's important to understand what problems you may encounter and how to fix them.

Removing the starter

At the next stage, the top housing cover is removed and the 4 starter mounting screws are unscrewed, after which it is necessary to remove the covers of the oil tank and fuel barrel. The starter is removed quite simply and there should be no problems.

After removing the starter, the opened internal cavity of the chainsaw must be cleaned, since there is usually a large amount of compressed small sawdust on the body under the starter.

Other popular malfunctions of Stihl chainsaws

In addition to the malfunctions discussed above, Stihl chainsaws sometimes encounter the following:

- the ignition system fails;

- pours a candle;

- The carburetor becomes upset, as a result of which fuel consumption increases or the chain saw simply stalls even under light load.

The engine may malfunction if low-quality fuel is used or if the fuel supply system is depressurized.

One of the articles on our website describes in detail how to adjust the carburetor on a Stihl MS 180 chainsaw.

One of the frequent breakdowns of Stihl chainsaws and how to fix this problem is described in the following video:

Removing the flywheel

The flywheel of the Shtil 180 chainsaw is twisted with great force, so to remove it you will need a head with a metal knob. The nut holding the flywheel is unscrewed with a 13mm head.

To block the crankshaft from turning, you need to unscrew the spark plug and install a piston stopper through the spark plug hole; if there is none, you can use an old cord from the starter, with knots tied to it and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to keep the flywheel from turning by installing a power screwdriver or other tools between its ribs and the body; with this method of blocking from turning, the flywheel blades are not able to withstand the load and break off.

Once the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the nut is normal, so you need to turn it to the left. Having loosened the nut, you do not need to remove it completely; just unscrew it until its upper edge is level with the tip of the shaft, after which a soft metal drift is installed on the nut and a sharp blow is made on it. Thus, the flywheel jumps off the shaft from a sharp impact and can be easily removed without the help of additional tools.

Failure of the fuel supply system (FSS)

During operation, some are faced with the fact that the fuel mixture stops flowing into the cylinder. This problem can happen for several reasons:

- Dirty filter. In this case, you need to remove the hose and check the flow of the fuel mixture. The filter will need to be cleaned or replaced. As a preventative measure, this part should be changed every trimester.

- Clogged breather. You can verify this theory by disconnecting the hose. If you find a blockage, you should clean it with a thin needle.

- Small amount of fuel. Make sure that the fuel mixture is regularly present in the tank and is supplied correctly to the engine. Supply interruptions are possible due to a clogged filter. To avoid such problems, it is necessary to clean the filters from time to time.

It is very important to choose good quality fuel for your chainsaw. In addition, you need to ensure that the amount in the tank corresponds to the norm.

The STIHL saw itself is a fairly simple piece of equipment. However, despite this, many have difficulties with its repair, because there can be many reasons for the breakdown. Therefore, before starting repairs, you should make a diagnosis and identify the cause.

Finally, I got around to writing the ending about the repair of the STIHL 180 saw. Everything basic has already been written in Repair of the STIHL 180 chainsaw photo report (Part 1) Now I’m adding a few points on assembly

The main thing is not to rush, double-check that you are assembling everything correctly. Watch YouTube on this topic. It's better to see once... Since the repair, the saw has been working normally. If you have any questions write...

Removing the clutch and oil pump drive

Before disassembling the clutch, it is necessary to remove the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With a high head of 19, you need to unscrew the clutch. The thread on it is left-handed, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are put on the shaft without any fastening.

Repair tools STIHL 180

To carry out a relatively high-quality repair of the STIHL ms 180 chainsaw yourself, you will need to have:

- air compressor (for cleaning the chainsaw and blowing out the main components and assemblies);

- a vacuum gauge is necessary to check the tightness of the crankcase and carburetor, as well as to identify defective seals;

- piston stopper to limit the stroke of the crankshaft;

- electronic tachometer in order to correctly adjust the chainsaw carburetor;

- T-key STIHL Torx 27 or equivalent;

- puller for crankshaft bearings.

Only if you have these tools, do-it-yourself repair of a STIHL 180 chainsaw can be done with sufficient quality.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have a socket 8 and an extension, with which it is convenient to unscrew the nuts securing the carburetor and air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and choke rod from the engine control lever and remove the lever, only after this the air filter and carburetor are removed.

The Shtil 180 muffler is secured with two nuts, which you need to unscrew to pull it towards you, it can be easily removed.

The coil is secured with two screws; to remove it you just need to unscrew them.

Do-it-yourself replacement of STIHL 180 oil seals

Replacing the piston group on a STIHL MS180 chainsaw

In this video we will show you how to replace the piston group on a STIHL MS180 chainsaw and the crankshaft seals.

A distinctive feature of the CPG on the STIHL MC 180 is that it has two compression rings, although virtually all of its main rivals have only one. As the manufacturer convinces, installing a pair of rings allows you to better stabilize the piston during operation, enhance its cooling and increase compression in the engine, which improves starting.

Replacing a STIHL 180 Piston Chainsaw Video

How to change the piston on a STIHL 180 chainsaw

The main malfunctions of the STIHL ms 180 chainsaw are related to the piston group. Let's look at the main reasons why the piston needs to be changed. Let's give a description of the piston

and the method of its replacement.

IMPORTANT. An experienced electrician leaked to the network the secret of how to pay half for electricity, a legal way. Read more

Removing and disassembling the engine

The engine is held in place by 4 screws installed on the bottom of the Shtil 180 chainsaw. To remove it, you need to unscrew them, and then carefully remove the engine from the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a thin screwdriver, then press out the piston pin from the opposite side, after which the piston is removed to the side.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common.

The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

Sequence of steps when performing repairs:

- To begin repairing the carburetor, they begin by cleaning it from dirt and dust particles and small wood. A brush is used for this. When the surface is completely free of debris, the repairman removes the cover, and then the filter.

- The air collector is released after unscrewing the air filter mounts. The user now has access to the accelerator and rods. The accelerator lever is removed as soon as the throttle is lowered by pressing down with your finger.

- The carburetor moves away from its seat after the choke lever is removed and closed. Then the wire is removed and pulled towards itself to stop the engine. The plastic lever, which is the place where the wire is attached, is photographed.

- It is raised from the left. As a result, the carburetor is freed, which makes it possible to pull it out and clean it. For these purposes, it is convenient to use a compressor. In its absence, the parts are washed in clean gasoline.

The saw carburetor assembly process is carried out in reverse order. If, after this process, smoke appears from the muffler and the saw engine does not start well, then you need to make sure that there is a spring located under the lever needle.

The spring cuts off the fuel supply. In its absence, a spontaneous “overflow” of fuel into the spark plug occurs. It is important to ensure that the spring is installed in its place and to ensure that the spark plug is working.

If a candle is filled with gasoline, it should be dried. To do this, the part is unscrewed and the excess fuel that gets inside is drained through the existing hole. The candle takes more than half an hour to dry. Then it is installed in place, and the chainsaw is brought into working condition.

Insufficient contact between the high-voltage wire and the end of the spark plug can also be one of the reasons for tool failure. Repair of STIHL chainsaw parts can be done by replacing problematic parts.

For example, if a spark plug fails, it is replaced with a reliable one. Chains, sprockets, and tires are subject to rapid wear. They solve anti-vibration problems in the chainsaw device, so they replaced urgently. It is recommended to keep such spare parts in stock.

Buy gas-powered tools in our online store with advice from specialists

By offering each client the necessary product online, or by consulting by phone, we perform an important task, allowing each person to purchase electric and gas-powered tools of specific technical characteristics. Choosing the right tool is a serious aspect, since the correctness of the decision affects many circumstances, including:

- Volume of material processing per day;

- Speed and performance;

- Technical parameters of processed materials;

- Payback of gasoline tools, which is influenced by the cost of products and the level of service life completed before the use of spare parts.

When buying tools in the city of Poltava, or ordering the necessary sets of spare parts for chainsaws in Zaporozhye or another city in Ukraine, you can always rely on the staff of the KosiKosa store. Experienced and trained specialists will help you select spare parts for a lawn mower or saw from the required manufacturer in original quality. Also, unlike other suppliers who offer similar products and deceive people with low-quality goods, our Kosi-Kosa online store supplies spare parts and tools to cities such as Odessa or Kiev, Vinnitsa and others, only at a high level of quality. In addition, a properly conducted consultation allows you to quickly put all products into operation, for example, if necessary, replace trimmer heads using a minimum number of tools.

5 reasons why clients choose us

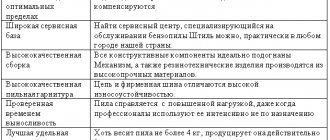

Based on the above, the superiority of the Kharkov company “KosiKosa” over many others has significant arguments that allow customers to choose spare parts for gasoline tools and the necessary components here. Among these there are five main reasons:

- Our spare parts are high-quality products manufactured in official factories.

- All gas and electric tools have a warranty for the period of use.

- A convenient online catalog that allows you to easily find products by name, determine their type from a photo, and order online.

- The lowest prices possible, allowing you to choose blades for brush cutters or gas tanks for saws, as well as other products at an equally favorable price.

- We deliver throughout Ukraine in a convenient way for everyone, regardless of whether you need to deliver ordered tools to Kyiv or send wholesale components for them to Dnepropetrovsk.

It is the quality and large selection of products, affordable prices and fast delivery throughout the country that have become our calling card, making us one of the best in the eyes of hundreds of satisfied customers.

Sources used:

- https://benzopilok.ru/brend/stihl/ms-180-razborka-sborka.html

- https://pochini.guru/svoimi-rukami/remont-benzopilyi-shtil-180

- https://www.kosikosa.com/index.php

FakeHeader

Comments 40

Yesterday, for some reason, the crankshaft bearings jammed during startup. I sorted out the dirt there and washed and lubricated everything. everything started spinning. assembled in reverse order. The saw does not start, there is a spark, there is gas. there is a current one BUT. assembled using transparent silicone sealant. I assembled it and after an hour I started trying to start it. is silent. and also poured zero under the candle. Maybe it won't start because the sealing is bad? The new saw was used 5 times in total.

dirt in the bearing means dirt in the gasoline! I don’t even know, try a different sealant. But that’s probably not the reason!

in the first part in the photo you can see a bottle with 80% oil that they are scorched because of this and are scuffed

How did you determine that it was scorched?

Container color print quality. Well, a great video right away.

Well, you are an “expert”! 1) The label is not really visible in the photo, but you saw the quality of the print and identified a fake, or rather, YOU SAW IMMEDIATELY) 2) The color of the bottle can distort the camera in any way, depending on the white balance settings and the sensitivity of the camera itself. 3) The oil was not bought on the market, but from an OFFICIAL STIHL DEALER along with the saw!

They even repair chainsaws here))). And they say it’s a car site. I also have a calm, 290 ms, and I took apart the current oil hose and changed it

Nice chainsaw. It has been working for me since 2008 and there are no problems. I cut about 12 cubic meters a year to heat my house.

This is what it looks like, more or less, it’s just a mini bikini