Description and purpose of the saw

The creation of German engineers - the Stihl 180 chainsaw, was developed specifically for performing light tasks in garden plots, alas, practice shows that its use is also well suited for solving more complex tasks.

For example, the saw can easily cut ten cubic meters of wood into logs, and at the same time it will consume much less fuel than is needed for the more massive models of Shtil chainsaws. Stihl 180 chainsaws are equipped with tires of different sizes. In the configuration, the standard is equipped with a 14-inch long tire, but if desired, a 16-inch tire can be installed. This increases the speed of work, alas, it can affect how long the tool will not require engine repair, due to the increased load there.

The chainsaw engine is two-stroke, single-cylinder and uses a mixture of gasoline and oil to perform work. The consistency proportion is 1:50, i.e. for making 5 liters. The finished consistency will require only 100 ml of oil.

The body of the Shtil 180 chainsaw is made of impact-resistant plastic and does not even have iron parts, which allowed the manufacturer to significantly reduce weight compared to similar saws from other brands.

Preliminary step

Repair of any equipment must begin with the preliminary work step, and the Stil 180 saw is no exception. At the preliminary step, well before the Shtil 180 chainsaw is disassembled, you need to remove the side cover, chain and tire from the chainsaw. Next, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil stains and the rest.

When cleaning the saw, special attention should be paid to the place where the chainsaw drive sprocket is located, since this is the dirtiest area.

In places where there is a huge accumulation of oil, there is an option to wash with clean gasoline.

Basic malfunctions and ways to eliminate them

The tool must be used in accordance with the instructions supplied with it. The start button should be turned on only after the chain tension and the presence of the fuel mixture and oil have been checked. Having secured the chainsaw securely in your hands, you can begin to work.

Read also: Borax flux how to use

If the tool refuses to work, then first of all it is necessary to identify the cause of the malfunction. And the most common equipment for repairing a chainsaw is suitable: various screwdrivers, socket and wrenches, hexagons.

Chain oil leaking

Every tool owner will face this problem sooner or later. The cause of this malfunction is a violation of the tightness at the junction of the oil pump and the hose from the oil tank.

To fix this problem you will have to almost completely disassemble the chainsaw .

- If the hose is damaged, it is best to replace it with a new one. You can try filling it with sealant, after degreasing and washing it.

- Oil may leak due to a clogged or broken saw oil filter. It should be checked and cleaned or replaced.

If the chainsaw does not start

If you believe the experts, then in case of such a problem, the first thing you need to do is simply open and close the cap on the gas tank. After this, you need to ventilate the combustion chamber , and also remove and dry the spark plugs. These actions are often enough to get the tool started and working. If the malfunction remains, then the cause should be sought elsewhere.

- The fuel supply is affected by the breather. Therefore, if it becomes clogged, a vacuum forms in the fuel tank and the saw does not start. Repairing the breather is very simple - it should be cleaned with a needle.

- The Shtil 180 chainsaw may not work due to a broken cylinder. If there are chips or unevenness on the cylinder, then this is the reason.

- If the tool does not start, holds power for a short time, or stalls immediately after switching on, then the cause of the breakdown may be in the muffler. It may be clogged with any deposits that occur during operation during the exhaust process.

- The saw may not start well due to a faulty starter. To look at it, you should remove the cover from the carburetor and twist the special screen located behind the chainsaw drum. If the contact wire has come off the starter, it must be attached using a blowtorch. If the problem lies in an oil leak, then simply wipe the starter with a cloth.

The chainsaw engine runs intermittently

The cause of such a malfunction may be a breakdown of the cylinder-piston group , which can be easily repaired with your own hands.

To remove the cylinder from the tank, you need to unscrew the four bolts on its head. Then carefully check the piston, which should not have any burrs, scratches, or chips. If any are present, the piston will need to be replaced.

The optimal pressure in the combustion chamber is ensured by the piston and piston rings, which must fit fairly tightly on the piston body. If the piston inserted into the cylinder has free movement when rocking, this indicates its wear.

This defect can be eliminated by boring the cylinder and installing repair parts. However, the easiest way is to simply replace the entire set of CPGs.

Specifications

Chainsaw Shtil 180 has the following technical properties:

- engine displacement 31.8 cm 3;

- engine power 2.7 l. With;

- the weight of the saw without gasoline, oil and saw bar is only 3.9 kg;

- Picco Micro 3 (PM3) chain, 3/8" P pitch;

- oil tank volume 145 ml. Fuel tank 250 ml;

- The sound pressure parameter is 97 dB(A).

These characteristics are official, because are listed on the manufacturer’s website and are publicly available.

The demand for Stihl mc 180 chainsaws among hobbyists is due to ease of use and reliability. The base model weighs only 3.9 kg. Saber, blade length 35 cm allows you to saw logs or drop trees with a cross-section of up to 30 cm. Two-stroke engine power 2 liters. s., which allows you to perform all household work related to cross-cutting boards and even firewood from any type of tree. The fuel tank capacity is only 0.25 liters, but this allows you to work without stopping for 45-55 minutes.

For refueling, you should use a mixture consisting of the recommended or transmission oil with unleaded gasoline AI-92 and AI-95. The ratio is 25 ml of additive per liter of gasoline.

The Shtil 180 chainsaw chain is an endless closed belt of 50 links. Other parameters:

- chain pitch - 3/8 inch;

- groove width - 1.3 cm;

- Material of manufacture: high-carbon steel, chrome-plated steel, pobedite brazing.

The working mechanism, the saw set, includes a bar, a sprocket and an automatic lubrication system.

The chain tension system is located on the side, which is convenient. A chain brake is provided.

Depending on the length of the tire and the modernization of the Shtil MS 180 chainsaw, there are several modifications. Saws with a saber length of 35 cm belong to models whose markings include 14, their length in inches is 14. The same configuration in terms of the engine and its parameters, but with a bar length of 40 cm, is called MS 180 16.

Description of the device and technical parameters

Shtil 180 has a standard configuration. However, like all modern chainsaws. Its components:

- Front and rear handle with anti-vibration system.

- Saw bar with chain.

- Two-stroke single-cylinder engine.

- Fuel and ignition systems.

- Housing made of high quality plastic.

Chainsaw Shtil 180, technical characteristics:

- A gasoline engine that runs on a mixture of fuel and oil in a ratio of 1:50. It has a power of 2 liters. With.

- The weight of the saw is approximately 4 kg.

- The saw is equipped with an easy start system.

- The capacity of the fuel and oil tanks is 250 and 140 ml, respectively.

- The saw bar is 14 inches (35 cm) long.

- Automatic chain lubrication.

Removing the handle

Specific disassembly of the Shtil 180 begins with removing the handle, which is attached to the chainsaw body using 3 rubber shock absorbers. To remove, you need to remove the plastic plugs from the internal cavity of the shock absorbers, then using a strong screwdriver, first squeeze out the upper shock absorber, then the one closest to the rear handle.

At the back of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod. If you set a goal to disconnect the rod from the throttle trigger, you need to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, you need to unscrew the chainsaw body from the inside of the handle and, bending it to the side, remove the body from the last rubber band.

Currently reading: File for shtihl 180 diameter

Device

The stihl ms 180 chainsaw has a fairly ordinary design, created for maintenance by users without specific experience. The saw's carburetor is designed in such a way that it is impossible to adjust it at most engine speeds. The only available adjustment screw is responsible for stable idle operation.

The stihl ms 180 chainsaw consists of the following structural elements:

- engine;

- starter;

- flywheel, also known as cooling fan;

- ignition module;

- clutch;

- saw chain brake mechanism;

- carburetor;

- air filter with replaceable filter element;

- oil and fuel tanks;

- muffler;

- side cover with chain tension adjustment mechanism;

- control handle and saw handle.

Read:

Let's look at the structure of a chainsaw and how the main elements work in more detail.

To start the engine, you must pull the starter cord.

The starter transmits force through the flywheel to the crankshaft and drives the piston. At this moment, under the influence of an air pulse from the engine crankcase, transmitted through special channels to the carburetor, the fuel pump begins supplying gasoline and oil to the carburetor, where a fuel-air mixture is formed and supplied under the piston.

At the same time, when the piston is at TDC (top dead center), an electrical discharge is supplied from the ignition coil to the spark plug, which ignites the fuel mixture under the piston in the cylinder and forces the piston to move down, thereby making a power stroke.

After a successful start-up, the saw cyclically repeats all work processes and works stably.

Pump structure, lubrication system and principle of operation

The oil pump drive consists of two parts: a plastic gear with a worm gear and a wire lever that transmits force from the drum sprocket to the worm gear.

The lever is rigidly mounted to the gear and they are supplied as one piece. The tip of the wire lever has a characteristic bend, which is designed for better adhesion to the drive sprocket drum. The drum has a special slot for installing the drive.

The Shtil 180 oil pump is made entirely of metal and has a non-separable design. On the pump body there is a receiving hole for oil and a groove-channel through which oil from the oil wire enters directly into the pump. The mechanism is installed in the body of the Stihl 180 chainsaw.

At the moment the engine speed increases, the sprocket drum begins to rotate the worm gear by the wire lever, and it in turn causes the oil pump plunger to rotate, as a result of which oil begins to be pumped through the oil channels to the chainsaw bar.

The oil line of the chainsaw, at the end of which there is an oil receiver, is also directly involved in the operation of the system. The oil receiver is also a filter. On the second side of the oil hose, there is a rubber extension, with which the hose is installed into the body of the Stihl 180 chainsaw immediately behind the oil pump.

Don't buy until you watch the video! Review of Stihl MS-180 chainsaw calm.

We unpack, assemble, check, and start up the Stihl MS-180 chainsaw. We discuss recommendations for use.

To avoid fire, start-up must be carried out at a safe distance from the place where the chainsaw is refueled.

Let's consider how the force from the engine is transmitted to the drive sprocket and causes it to rotate the saw chain. For this purpose, the stihl ms 180 chainsaw has a centrifugal clutch, which is installed inside the drive sprocket and is rigidly fixed to the engine crankshaft.

As the engine speed increases, the clutch opens and, resting against the sprocket body, transfers force from the engine crankshaft to it, forcing it to rotate the chain mechanism.

The next element of the Shtil 180 chainsaw is the saw chain brake. The brake device is quite simple and consists of a control lever and a metal plate that wraps around the drive sprocket and is installed in the saw body. In the working position, the chain brake plate securely holds the drum sprocket.

When the saw chain brake is set to the working position, it is forbidden to increase the engine speed, as this will lead to disturbances in the clutch mechanism.

Malfunctions of the pump and the system as a whole

As you know, nothing lasts forever in this world and everything has to be repaired over time. The oil system of the Shtil ms 180 is no exception, and has its own specific malfunctions. Let's take a closer look at them.

Signs of a malfunctioning lubrication system are as follows:

- the chainsaw chain is absolutely dry and does not shine;

- oil does not leave the oil tank;

- the chain stretches quickly and this happens constantly;

- the saw bar moves to the side when sawing;

- The tire also heats up in the area of the drive sprocket and the paint melts.

All these signs directly or indirectly indicate problems in the chainsaw chain lubrication system.

The first thing to do after you suspect that chain lubricating oil is not being supplied is to check its supply. There are two ways to do this. The first is described in detail in the instructions for the tool and consists in the fact that you need to start the chainsaw, increase the gas as much as possible and point it towards any obstacle.

If the lubrication system is working properly, the oil will fly off from the tip of the tire and a strip of oily drops will appear on the surface towards which the tire is pointed. If there are still violations in the system, the surface will remain clean.

The second way is to remove the tire from the chainsaw and start it. When the engine speed increases, oil will flow from the oil channel at the tire shank installation site; if this does not happen, it is necessary to look for the cause of the malfunction.

Diagnostics

Diagnostics should begin with inspecting and checking the oil receiver (filter) of the Stihl 180 saw. As a rule, if the filter is very dirty, the oil supply may stop.

Next, you need to remove the drum sprocket and check the condition of the drive gear. The thread on it must be clearly defined, not licked or have any other defects; also, when the gear is removed, it is necessary to check the wire lever. It must press the gear tightly and not turn, otherwise the gear stands still and does not transmit force to the pump, as a result of which the oil supply stops.

If all of the above methods to detect and eliminate faults do not produce results, it is necessary to use extreme measures, i.e. dismantle the pump.

How to remove the pump

The oil pump is installed on the right side of the bottom of the housing, in the same place an oil line coming from the chainsaw tank is connected to it. To remove the pump, you will first need to release the saw from the handle; to do this, unscrew the rear handle of the unit and disconnect the throttle control rod. At the next stage, you need to remove the handle shock absorber plugs and, using a powerful slotted screwdriver, squeeze them out of their seats on the handle.

After the handle is removed, the chainsaw body is turned upside down. The hose leading from the oil tank to the pump will be immediately visible. It must be removed from its seat.

To better understand the process of removing the pump, you can watch the video below. In the video, the service center master shows in detail how to remove the oil pump from a chainsaw, and also describes the main malfunctions of the supply system.

After the pump is removed, it must be cleaned and purged. As a rule, the main failure of the oil pump is its blockage. Having eliminated it, you can install the pump in place.

Replacing the pump is only required if it is not possible to remove the blockage.

The reason for oil leaks on the bottom of the chainsaw

The Shtil 180 chainsaw has a characteristic malfunction, which consists in insufficient sealing of the installation site of the oil hose in the chainsaw body and the appearance of a leak at this point. To eliminate it, just remove the handle of the Stihl MS 180 saw, disconnect the hose itself, wash and degrease the seat in the body and the hose shank, then apply sealant and install the hose in place. This simple operation will reliably eliminate the malfunction and the oil will stop leaking.

Removing the flywheel

The flywheel of the Shtil 180 chainsaw is twisted with enormous force; to remove it you will need a head with an iron knob. The nut holding the flywheel is unscrewed with a 13mm head.

To block the crankshaft from turning, you need to unscrew the spark plug and install a piston stopper through the spark plug hole; if there is none, use an old cord from the starter, with knots tied to it and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to stop the flywheel from turning by using a power screwdriver or other tools between its ribs and the body; with this method of blocking from turning, the flywheel blades are not able to withstand the load and break off.

How to easily and simply remove a flywheel from a chainsaw without having a special puller

The flywheel is mounted on the crankshaft quite firmly and many do not know how it can be removed without a special puller. But there is a way and I will tell you about it. On any chainsaw, in order to get to the flywheel, you need to remove the starter. I will show the example of the Shtil ms 180 chainsaw.

After removing the starter, unscrew the spark plug and install a safe piston stopper. You can read more about it here.

Next, using a 13mm socket, loosen the flywheel mounting nut. There is no need to twist it at all, just loosen it a few turns.

Now we need two hammers, or a metal blank, ideally made of soft metal. I use a small hammer without a handle, which in my opinion is more convenient. We set the hammer as shown in the photo.

Next, using a second hammer, we apply a sharp blow. As a rule, one blow is enough and the flywheel flies off the crankshaft. If you don't succeed the first time, you can repeat it. You don't have to worry about the thread, because... the shock is transmitted through the nut, which is screwed on almost all turns.

And here is actually the reason why I needed to remove the flywheel. The key on it was cut off; apparently the nut was not tightened completely or had loosened during operation.

In the following publications I will tell you in more detail about why the key was cut off and how a chainsaw with a similar malfunction behaves, so

subscribe to the channel so as not to miss it and don’t forget to rate the publication and share it with friends.

Source

Disassembling chainsaw Shtil 180 part 1

Here in the video we will show you how to change the piston group on a Stihl MS180 chainsaw and crankshaft seals.

If the piston in the cylinder is blocked, of course unscrew the flywheel nut. The thread in the nut is straight, so you need to turn it to the left. Having loosened the nut, you will not remove it completely, just turn it out until its upper edge is level with the tip of the shaft, after which a drift made of soft metal is installed on the nut and a sharp blow is made on it. Thus, the flywheel jumps off the shaft from a sharp impact and can simply be removed without the help of additional tools.

Currently reading: No oil comes out of the chainsaw tank

Removing and replacing the clutch on a chainsaw. Review, instructions

Chainsaws, for various reasons, need repairs from time to time. Of course, you can contact a service workshop or an experienced mechanic. However, many problems can be fixed at home with only a minimal set of skills and tools.

Answering the question of how to remove the clutch from a chainsaw, we note that this is not a difficult operation if you strictly adhere to the disassembly technology.

Owners of the tool may encounter certain difficulties if the chainsaw has been in use for a long time and the clutch parts have become stuck to each other.

However, even in this case, you can disassemble it yourself.

Clutch faults

| Malfunction | Possible reason | Remedy |

| The chain spins without stopping, with any carburetor adjustments. The engine is running erratically. | The spring in the drum burst. | Remove the spring and replace it with a new one, or install a new unit. |

| The chain rotates almost constantly, making strange sounds. | Cam chip. The spring came off. | Replacing the entire assembly |

| During operation, the chain slips. | Clutch wear | Replacing the unit |

Reasons why clutches need to be disassembled:

- Faulty or burst spring;

- As a result of loads on the chainsaw and wear of parts, the spring left its place;

- Chips on the clutch plate;

- Wear of parts.

Clutch replacement

When replacing the clutch, we do not recommend using metal or plastic objects as a stopper. The former can scratch the cylinder, the latter can litter it.

Centrifugal clutch chainsaw

Disassembling the clutch:

- We turn on the chain stop brake, remove the protective cover and dismantle the saw set;

- We remove dirt, sawdust, dried grease, if any;

- Remove the air filter and spark plug;

- Using a spark plug wrench, unscrew the spark plug;

- Rotating the crankshaft, bring the piston to the top point, then withdraw it by 6-9 mm;

- Use a rope, 7-8 mm in diameter, to stop the piston in the upper position;

- Use a special wrench to unscrew the nut on the clutch.

Most of the moving parts of a chainsaw have right-hand rotation. Therefore, the clutch nut has a left-hand thread. Remove the cover by turning the key clockwise. It is forbidden to carry out this operation with a hammer and chisel - you will knock off the edges!

- Remove the cover and drive sprocket. We diagnose faults and evaluate wear of parts. We assess the condition of the needle bearing;

- If necessary, we replace parts with new ones (most often the drive sprocket needs this);

Installation of the chainsaw clutch system is carried out in the reverse order, but you should pay attention to some features

Nuances when installing the clutch system:

On some chainsaw models there may be a washer between the drive sprocket and the clutch.

Pay attention to which side it faces the engine;. Some oil pump drives are equipped with a special spring (whisker), which is responsible for transmitting rotational motion from the drive sprocket to the oil pump

It is important to adjust the spring so that its free end (whisker) fits into the corresponding groove on the sprocket body. Otherwise, the saw set will not be lubricated; Some oil pump drives are equipped with a special spring (whisker), which is responsible for transmitting rotational motion from the drive sprocket to the oil pump

It is important to adjust the spring so that its free end (whisker) fits into the corresponding groove on the sprocket body. Otherwise, the saw set will not be lubricated;

Some oil pump drives are equipped with a special spring (whisker), which is responsible for transmitting rotational motion from the drive sprocket to the oil pump

It is important to adjust the spring so that its free end (whisker) fits into the corresponding groove on the sprocket body. Otherwise, the saw set will not be lubricated;

Important: after dismantling and assembling the clutch, be sure to check the operation of the automatic oil supply system

Important: after dismantling and assembling the clutch, be sure to check the operation of the automatic oil supply system

review

Clutch Removal Overview

Stihl chainsaw clutch repair review

Review of replacing a burnt chainsaw clutch

SHTIL MS 180: assembly

Group: Assembly and review of parts for the Stihl MS 180 chainsaw.

Assembling the stihl ms 180 saw backwards is quite easy, the main thing is to follow the following method:

- Install the piston on the connecting rod, the arrow on the piston should point in the direction of the Stihl 180 chainsaw, and to the left of the piston should be the side of the crankshaft, which is designed for installing the flywheel;

- Carefully insert the piston back into the cylinder; a place for mounting the coil should be made on the side where the flywheel is installed on the crankshaft;

- Install the bearings, oil seals, retaining ring on the shaft and lower it to our client; it remains assembled in the seat in the cylinder;

- Next, degrease the crankcase installation site and the crankcase itself, then coat it with sealant and install 4 fastening screws in the area;

To assemble the Shtil 180 saw when you get tired of the engine being assembled, you must follow the reverse disassembly sequence. It is important to pay close attention to the process and remember to install the rods on the carburetor and connect the ignition wire.

Below, watch the disassembly of the Shtil 180 in the video, it is made for inexperienced users; the process is carefully shown on a personal computer.

Disassembling the Shtil 180 chainsaw and assembling it, if you have some experience, is quite easy, the main thing is to clean the saw well before starting work and not even rush. To ensure that small parts do not get lost, it is necessary to use containers on which spare parts should be laid out during the process.

Chainsaw carburetor malfunctions and repairs

What should you do if the tool stops starting, starts stalling, loses power, and doesn’t hold idle speed? Quite often, the cause of such breakdowns lies in the carburetor, which could become clogged with dust, dirt or sawdust. You can cope with this problem with your own hands.

All carburetors are cleaned the same way, the main thing is not to be afraid and not to lose anything. For repairs you will need to prepare:

- any brush;

- Phillips screwdriver;

- head for 8;

- some gasoline.

First of all, using a brush, dirt and dust are cleaned. Then remove the lid and filter. The two air filter nuts are unscrewed and the air collector housing is removed. Now you can see the carburetor and the choke and accelerator rods. By lowering the throttle down with your finger, you will need to remove the accelerator lever.

To move the carburetor from its seat, you must first remove the choke lever and close it completely. Now you need to remove and pull the engine stop wire towards you. It is also necessary to remove the plastic lever on which the wire is attached. On the right it is inserted into the hole, and on the left it can be lifted.

The carburetor is freed and can be pulled out and cleaned. This is best done with a compressor, but if you don’t have one, then the parts can be washed in clean gasoline .

Don’t forget about the fuel filter, which also needs to be removed and the fuel hose blown out. Everything is put together in reverse order.

If, after assembling the carburetor, the saw does not start well and smoke comes out of the muffler, then most likely the spring located under the needle lever has been lost. Due to the absence of this spring, the needle does not shut off the fuel supply, so the spark plug is “flooded” with gasoline. Of course, to fix this problem, you should find the spring and put it in place.

When repairing a carburetor, you should remember that it is a rather complex unit, which consists of various small rings and parts. Therefore, it is necessary to clean and repair it with special care and caution.

If the chainsaw does not start or stalls, then in addition to the carburetor itself, you should check the functionality of the spark plug . If it is faulty, it should be unscrewed and dried. Also, excess fuel must be drained from the spark plug through a special hole.

It must be remembered that drying must be done for at least thirty minutes, after which the candle is put in place and the tool is started.

The cause of the malfunction may be poor contact between the end of the spark plug and the high-voltage wire. If you don’t like the work of the candle at all, then it is better to replace it with a new one.

Parts of the Shtil 180 chainsaw, such as anti-vibration elements, chain, tire, and drive sprocket, wear out faster than others. Therefore, to quickly replace them, it is recommended to keep spare parts in the workshop.

Eliminating the causes of chainsaw malfunctions with your own hands will in any case cost less than repairing the tool in a service workshop. In order not to rack your brains over why the tool stopped working, you can watch video instructions for troubleshooting various breakdowns of the Shtil 180 chainsaw. However, in case of serious damage, it is better not to do the repairs yourself and entrust the work to a specialist.

The Stihl MS 180 chainsaw is one of the most popular models on the market. This saw stands out for its durability, reliability, and ease of use. Thanks to a solid reserve of torque, the Stihl 180 chainsaw can be used not only in private households, but also in forest felling. At the same time, the tool shows modest fuel consumption and high cutting accuracy of any type of wood.

Read also: Triac engine speed controller

Peculiarities

The working mechanism of the saw is the chain. The production of saw chains is carried out using a special technology:

- The cutting element is made of high-carbon steel, and chrome plating or a pobedite layer is applied to the cutter. The more complex the manufacturing technology, the higher the cost of the chain.

- The hinge holes are ground to reduce friction and extend service life.

- Only rivets that are hardened using a special technology are used.

- Marks are applied to the teeth, by which you can determine wear and perform uniform sharpening.

- After connecting the links into a chain, the product is stretched to ensure dimensional stability during operation.

A sophisticated automatic chain lubrication system increases service life. New saws must be selected according to the characteristics specified in the operating instructions for the Shtil 180 chainsaw.

You need to know that chains with pobedite surfacing are 3-5 times more expensive than regular chains, but it is impossible to sharpen them with your own hands when repairing a Shtil 180 chainsaw. Employees of the Ministry of Emergency Situations use this tool more often.

People often ask whether it is possible to make longitudinal cuts with a Shtil 180 saw. The power of the saw allows you to cut wood only across the grain.

For the most part, reviews of Shtil saws are good. There are complaints about the insufficient power of the tool. It is necessary to choose an assistant for the task. The lightweight and affordable Shtil 180 chainsaw is designed for occasional use. There are special products for felling and cutting wood. At home, this option is not justified. The tool is much heavier and cannot be used to saw through small boards.

The price of the Stihl MS 180 chainsaw differs significantly. The most inexpensive basic model of the usual configuration. The cost of the device depends on the country of manufacture. A German or American product is more expensive than a Chinese one for well-known reasons.

The modern stihl ms 180 chainsaw has several design features that must be mentioned.

Oil supply system repair

Often in this model of gasoline saw the oil system breaks down . This breakdown can be identified by the presence of smudges or a dry chain.

Before entering “do-it-yourself chainsaw repair video Shtil 180” into a search engine in search of the appropriate instructions, you should first inspect the oil mixture supply hose. You should also check the fitting connection of this element.

When repairing the oil supply system, you must also thoroughly clean the filter. Often the presence of contaminants in it causes the mixture to not pass well enough.

If you encounter an oil leak or it begins to lubricate , then most likely there is a leak in your chainsaw. First of all, the problem may be with the oil filters and the hose itself. Often, malfunctions of this kind appear due to mechanical damage to parts.

If upon inspection it turns out that the integrity of the hose has been compromised, then it must be replaced. In case of minor damage, the problem can be solved by using an ordinary sealant. This method will save on repairs.

Removing the clutch and oil pump drive

Before disassembling the clutch, you need to remove the driven sprocket. For this purpose, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With the tallest head at 19, you need to unscrew the clutch. It has a left-hand thread, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are mounted on the shaft without any fastening.

Currently reading: What is better than a Stihl or Husqvarna chainsaw: comparison, which one to choose

Communities › Do It Yourself › Blog › Repairing a STIHL 180 chainsaw photo report (Part 2)

Finally, I got around to writing the ending about the repair of the STIHL 180 saw. Everything basic has already been written in Repair of the STIHL 180 chainsaw photo report (Part 1) Now I’m finishing up a few points on assembly

The main thing is not to rush, double-check that you are assembling everything correctly. Watch YouTube on this topic. It’s better to see once... Since the repair, the saw has been working normally. If you have any questions, write...

How to remove the clutch

Before unscrewing the clutch, you need to remove the drive sprocket. Remove the corkscrew washer and remove the sprocket and needle bearing. Unscrew the clutch. Remove the reflector plate and pump.

The chain is not lubricated

When repairing a chainsaw, you may notice that no oil is getting onto the chain. If the chain is not lubricated, it means there is a problem with the lubrication system. There are such malfunctions:

- The chain is dry, light in color.

- The chain stretches too quickly.

- The tire is too hot and the paint on it has melted.

- The oil in the tank does not decrease.

- With a sharp chain, the saw began to cut worse.

Such signs indicate that a violation of the lubrication process has occurred. To check the oil supply to the lubrication unit, you need to remove the tire and turn on the chainsaw. Then increase the speed and observe the end point of the oil line. If oil flows, it means that its volume is not enough for proper lubrication. If there is no supply, you need to clean the filter. The oil supply should also be adjusted. If there are no malfunctions, further diagnostics and DIY repairs are required. If it turns out that the substance is not supplied, then the oil system is repaired.

Let's look at the main faults and methods for eliminating them:

- Broken oil hose. This can be seen upon inspection. In this case, the hose must be replaced.

- If there is no thread on the oil pump shaft, it should be replaced.

- If there are any defects in the thread, it must be replaced.

- If the main shaft corkscrew is missing, you can install a nail of the same diameter in its place.

- The filter may be clogged. This happens often with the STIHL MS 180 saw. You can wash it with gasoline. If this does not resolve the problem, the filter should be replaced.

The STIHL 180 chainsaw often has depressurization of the oil line. This occurs where the oil line coming from the tank is inserted into the body of the tool. A breakdown can be detected by oil leaks at the bottom of the saw.

To fix the problem, you need to remove the saw handle and pull out the hose. After this you need to clean the hose. Then apply sealant to it and place it in the tool body.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have an 8 socket and an extension, which can be used to comfortably unscrew the carburetor and air filter mounting nuts. While dismantling the carburetor, you need to disconnect the ignition wire and the choke rod from the engine control lever and remove the lever, only after which the air filter and carburetor are removed.

The Shtil 180 muffler is secured with 2 nuts, after unscrewing them you need to pull it towards yourself, it will simply be removed.

The coil is secured with two screws; to remove it you just need to unscrew them.

Removing and disassembling the motor

The engine is held in place by 4 screws installed on the bottom of the Shtil 180 chainsaw. To remove it, you need to unscrew them, then carefully pull the engine out of the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed; then there is the option of removing the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools; if the bearings were pressed onto the shaft with force, then a special puller will be useful for dismantling.

To remove the piston from the connecting rod, you will need to pull the lock ring out of the seat using a thin screwdriver, then press out the piston pin from the back side, after which the piston is removed to the side.

Modifications of the Shtil 180 chainsaw

Along with the main modification of the saw, the Stihl company produces an improved version of the Stihl MS 180 chainsaw. The prefix C-BE is used to designate the tuning model.

The Stihl MS 180 C-BE chainsaw has the following improvements:

- STIHL ElastoStart – soft start mechanism. It is implemented by installing a special spring in the chainsaw starter, which compensates for engine resistance when starting, making starting smooth and easy.

- The quick chain tension system is designed to adjust the chain tension without using any additional tools, which is very convenient, since there is no need to constantly carry a universal wrench with you.

- Side chain tensioner, some models not equipped with a quick chain tensioner have a slight improvement on the standard tensioner. Simply put, in such tools, the tension screw of the mechanism is located on the side cover, which makes tensioning the chain much more convenient than in the standard version.

Equipment

As standard with a saw, there must be a 35 centimeter (14 inch) bar and a chain suitable for this bar length (50 links). The manufacturer cares about the safety of customers and already offers customers a protective cover for the tool tire as standard.

Also included in the kit is a universal screwdriver key for unscrewing the spark plug, unscrewing the side cover and tensioning the chain, and an adjusting screwdriver for adjusting the idle speed.

Any saw must be supplied with an instruction manual, which describes in detail how to use the Shtil 180 chainsaw, as well as how to carry out diagnostics and maintenance.

Ignition system

If the equipment does not want to start at all, the malfunction may lie in the ignition system or the starting mechanism. If everything is in order with the starting device, then you need to inspect the condition of the spark plug, which should first be unscrewed.

- Electrodes whose surface may be coated with plaque deserve special attention. If you find a red-brown coating, this indicates that the entire starting system is faulty.

- If the ignition functions stably and properly, but the chainsaw does not work properly, then the malfunction may be related to excess air-fuel mixture. In this case, it is necessary to clean the jets and adjust the carburetor.

- If you find carbon deposits on a spark plug, you should consider using higher quality gasoline. Another reason is incorrect carburetor operation.

To get rid of the problem, you need to:

- dismantle the carburetor and check it;

- clean it and set it up;

- change fuel;

- check the carburetor and put it back.

It is necessary to remember that the carburetor is a unit with a rather complex configuration. Therefore, if you need to disassemble or repair it, it is better to use the services of experienced specialists.

Do not forget that for a gasoline saw you must use only the fuel specified in the equipment operating manual. Using low quality fuel can lead to a variety of problems.

If you have lost the packaging box of the equipment and you need to get a manual for its use, then you can use the Internet for this. Just enter “Chainsaw Stihl 180 operating instructions” into any search engine and download the necessary document to your PC.

Using this information, you can repair the Shtil 180 chainsaw yourself.

The Shtil 180 chainsaw has proven itself well in the construction market. This portable device has a power of 1400 W and a motor capacity of 31 cc. cm. The length of the saw chain is 350 mm; at idle it makes more than 2 thousand revolutions. Its popularity among consumers is also explained by the reasonable cost of the tool. However, when using a chainsaw, malfunctions occur from time to time. Tool repairs in service are not cheap, so those who understand at least a little about technical issues fix breakdowns with their own hands.

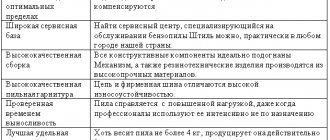

Comparison of saws with competitors: advantages and disadvantages

The main competitors of Shtil 180 are saws from the Swedish concern Husqvarna. The quality of Shtil and Husqvarna products is considered the same, but depending on personal preferences, many users tend to praise the model they use.

Based on the design features, we can highlight one purely technical point that slightly elevates the Shtil 180 above its competitors. In calm MS 180, two compression rings are installed on the engine piston, this gives:

- stable location of the piston in the cylinder;

- increased compression;

- enhanced cooling (as you know, rings transfer thermal energy from the piston to the cylinder and, accordingly, the larger the contact area, the more energy will be spent on the cylinder and the piston will be better cooled).

All these points make the Stihl 180 chainsaw a little more reliable than its competitors, but this is the personal opinion of the author of the article, based on experience in the repair and operation of Stihl and Husqvarna chainsaws, and is not of an official nature.

A video review of the tool, with comments from the author, in which the new chainsaw is assembled and prepared for use, can be viewed below.