Couplings are devices that connect the shafts of mechanisms and equipment. Their main task is to directly connect and transmit torque, to implement kinematic and power connections between parts of equipment; couplings also have several additional properties and tasks.

Most types of complex industrial equipment are assembled from separate parts, and several types of couplings are used.

Couplings are classified according to various characteristics.

First of all, there are two large groups:

- Blind (rigid non-disengaging couplings) - with them 2 shafts work as one

- Compensating - to correct misalignments.

According to the principle of operation:

- Permanent (non-detachable, deaf);

- Controlled (triggered);

- Self-controlled (triggered under certain conditions)

Depending on the load perception:

- rigid (they connect the shaft tightly and do not compensate for accidental impacts and interference),

- elastic (compensate for misalignment of axes and vibrations)

By type of energy used:

- mechanical

- electrical (electromagnetic)

- pneumatic

This is the main classification of couplings according to specific parameters.

Standards

Due to the importance of the unit for any system, the characteristics and application are regulated by GOSTs:

- GOST R 50371-92: Mechanical couplings for general machine-building applications. Terms and Definitions.

- GOST 15622-96: Friction safety clutches. Parameters, design and dimensions.

- GOST R 50893-96: Ball safety couplings. Basic parameters and dimensions. Technical requirements.

The documents include basic information on the parts under consideration with a description of groups and types, the principle of operation of each specific element.

Cast iron sewer pipes

Cast iron sewerage uses two methods of coupling connections:

- With rubber seal. The principle is the same as for plastic sewerage; the large mass of the pipe and coupling, however, makes the connection much more labor-intensive.

- Couplings for connecting pipes for embossing. They have been in use for over a century; These are two bells directed in opposite directions.

Installation of a cast iron coupling with caulked joints

Here, connecting the pipe to the coupling requires some skills, so let’s look at it in a little more detail.

- To seal the joint, you need access to the pipe and coupling along its entire circumference. If the sewer system is installed right next to the wall, you will have to hollow out a section of the wall.

- Kabalka, an oil-impregnated organic fiber, is used as a sealant. You can also emboss the joints with a graphite gland, the result will be no worse.

- The pipe must be inserted into the coupling until it stops. Otherwise, the seal will simply fall inward.

- The bobbin is minted in several turns; each of them is compacted along the entire circumference of the pipe;

- If you don’t have a special tool, you can get by with a thin steel tube with a flattened end or a wide screwdriver;

- After compaction, the joint is covered with cement mortar.

Sewerage assembly will not be quick here

Read also: How to properly do men's manicure

Areas of application

Couplings are used to connect shafts. In this case, the following are eliminated:

- misalignment of shafts and the presence of distance between them;

- the presence of an angle between the axes of rotation;

- sharp blows and shocks in the operation of production machines.

The purpose of the coupling is to protect equipment. Using the device in a gearbox allows you to protect the unit from overload - if the mechanism jams, the cheaper coupling is destroyed. To transmit torque between shafts of different diameters, compensating types of devices are used.

An important function of the device is quick dismantling. If a part of the mechanical assembly needs to be serviced, the coupling can be easily removed. The serviced machine parts are quickly connected and are completely ready for use.

How to connect mechanism shafts?

To transmit axial rotation, shafts are used, on which various gears and sprockets can be mounted. The connection is carried out using various methods, for example, couplings are used to connect shafts. Their features include the following points:

- It is possible to dismantle.

- The collection and production of the final product is greatly simplified.

- Many types of products allow you to compensate for various types of displacements that may occur during operation of the device.

- The device can withstand significant load.

Today, parts are connected to each other using welding technology extremely rarely. This is due to the fact that vibration and other impacts can cause cracks and other defects.

Incorrect fixation may result in device failure. The product is selected depending on the operating conditions. For example, shafts can move in a variety of directions.

Classification of couplings

There is a classification of couplings by design:

- managed;

- uncontrollable.

Interesting: How is surface roughness indicated in the drawing - classes and GOST

And also by purpose:

- deaf (hard);

- compensating;

- elastic;

- coupling;

- automatic;

- magnetic and electromagnetic principles of operation.

Each type is used based on the specific operation of the unit.

Varieties by design

Design features distinguish the following types of couplings:

- Spring. Another name is a coupling with a serpentine spring. The device compensates well for sudden dynamic loads. It is a safety element, that is, it can collapse if there is excessive load on one of the shafts.

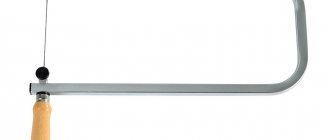

- Bush coupling. A rigid or blind bushing that connects the two ends of shafts. Minimally compensates for misalignment, has high strength and a low transmitted torque.

- Flange coupling. The connecting element is made of two parts in the form of flanges, mounted on the shaft shanks. It is assembled with bolts; to protect against overloads, bolts made of soft steel can be installed, which are cut off when overloaded on the drive. Transmits high torque.

- Elastic coupling with star. The design solution is a type of cam-disk mechanism. The working planes of the cams are divided by an elastic star.

- Elastic sleeve-finger coupling. The design of this coupling is made in the form of two coupling halves and static pins in one of them. There are rubber bushings on the fingers, which are the contact area of the fingers with the second coupling half.

- Coupling with toroidal shell. The main purpose of the device is components and assemblies with a high level of vibration and shock during operation. Perfectly compensates for radial displacement of shaft axes up to 5 mm.

The mechanical coupling has a long service life in the absence of peak loads on the equipment. It does not require maintenance. Before starting work, an audit inspection of the main couplings of the main production drives is carried out.

According to damping abilities

Damping mechanisms make it easier to overcome the resonant moment of a mechanical drive. Most often these are devices with elastic elements in the design. For example:

- flange type - elastic bushings;

- cam – star or gear made of dense plastic;

- spring type - a design in the form of a coil of a spring with a reinforced cross-section.

Interesting: Types of metal cutting equipment

According to compensating abilities

Compensating links include elastic and rigid varieties. The purpose of the application is to eliminate shaft misalignment, and the elastic ones additionally smooth out sudden loads during startup. The most common examples are:

- cam;

- serrated.

Varieties by material

When used on pipeline lines, couplings act as repair and installation elements. Differ by material:

- For steel pipes, models without thread and with thread are used. Threaded connections are dismountable and can be repaired. Threads will be required on the two pipes being connected. Additional sealing is done using winding, sealant, and lock nut. Elements without threads require the installation of a one-piece plan by welding.

- For copper pipes, crimp threaded couplings and solder couplings are used. Soldered joints withstand high pressure and do not change their characteristics when the metal expands due to heat. The work uses a special flux, solder, and burner. Crimp couplings install faster, but due to the softness of copper as a non-ferrous metal, they can weaken over time.

- For cast iron pipes, crimp couplings with gaskets are widely used. The devices consist of two elements held together by bolts. Installation on the repaired area does not require welding, soldering or special skills. The selection is made for a specific pipeline diameter; a slight misalignment of the two ends of the pipe is possible.

- For plastic and polymer pipes, couplings made of similar materials are used. Installation depends on the specific model and involves soldering, crimping, and tightening like couplings for cast iron. For sewer pipes made of plastic, the couplings are fitted with a seal without additional fastening.

Definition and purpose of sewer outlet

Plastic single-socket elbow

A manifold elbow is a pipe element bent at a certain angle. The second name for the fitting is corner, elbow. The main function of the product is to change the direction of the sewer flow towards the central riser or septic tank from the entrance from the wall of the house and in its other areas. As a rule, the outlet has the same cross-section as the sewer pipe.

Read also: What is copper ore for?

Plugs and tees are used as additional fittings when installing sewer systems. The first helps to limit the movement of water flow. The second allows you to branch the collector if the system is being laid for two or three buildings at the same time, or if storm and fecal wastewater from two different systems will flow into a common receiver.

Types of coupling connections

Any mechanical coupling connection is considered to be permanent and detachable. There is a classification by type.

Hard

Rigid links can be used if the axes being connected are exactly aligned, as well as with a slight deviation from the axis. In practice, an example of such a link is either a sleeve or flange device. The sleeve type can connect shafts up to 100 mm and transmit small torque. The flange type transmits higher torque and is used in powerful drives.

Interesting: What is a gearbox and where is it used?

Elastic

Elastic devices dampen excess vibrations and dynamic overloads that arise during the operation of a mechanical unit. Excess energy is absorbed by the elastic element. In flange type devices, it is used as polymer bushings on studs. Cam devices have a star-shaped damper.

Coupling

It is rational to use clutch couplings in systems where it is necessary to periodically disconnect the driven and drive shafts. The first part of the coupling is attached to one shaft, and the second element slides along the axis of the other shaft. The connection occurs when two elements of the device engage. They are divided into the following types:

- gear - clutch with teeth or cams;

- frictional - the principle of operation is based on the force of friction;

- hydrodynamic - the driving force is transmitted by hydraulic fluid from the driving to the driven impeller;

- magnetic and electromagnetic - based on permanent or electromagnets. Will be discussed below.

Compensating

This type helps to eliminate the difference in shaft diameters, the displacement of their axes in the same plane or at an angle. They can be of elastic or rigid type.

Self-governing

Self-acting couplings disconnect and connect shafts when a certain torque is reached. Their use makes it possible to maintain normal operating conditions of components and assemblies in compliance with industrial safety standards. Are divided into:

- overtaking – direction of rotation;

- centrifugal – dependence on drive speed;

- safety - to control the amount of torque.

Varieties

Connecting couplings are intermediate links between two sections of the main line that need to be connected. First of all, pipelines for various purposes and cables need such a connection. They can be connected in series, adjacent to the side, branched, and change the direction of laying at different angles. Installation of the system often occurs with elements of different diameters or cross-sections. In such cases, transition structures are used, the end edges of which have suitable dimensions.

Connections involve joining options, both temporary and permanent, without the possibility of disconnection. Where it is not possible or necessary to weld, a detachable coupling connection is used. It can be of a threaded type, when internal or external threading is used. Bolted connections are also used. They also use clamps, ties, and crimp structures.

Sealing of bolted connections of connectors with possible leaks of liquid, steam or gas is carried out with gaskets, and tow or other sealants are used for threads. According to the design of the couplings, there are straight (barrels, bends), angular, tees and branches, transitional.