Punch and die

The punch and matrix are technological form-building equipment of industrial machines, which changes the parameters of metal, concrete and other materials: dimensions, surface configuration.

Order punches and dies! Send the drawings to the Workshop. High quality, favorable price!

Punch-die sets are the main working units in the production and processing of metal products. With the help of punches, marking, stamping, pressing, perforating, cutting out metal blanks, casting parts, and bending sheet metal are carried out. These kits are also used in the production of building materials (slag blocks, aerated concrete floor slabs with shaped cavities, etc.). And also bricks, facing and paving tiles.

The matrix is a base (box) into which the workpiece is placed. The matrix sets the parameters of the future part, acts as a response unit of the punch, the profiles coincide.

A punch is a tool that acts as a closing element of the system. It forms the shape of the product from above and works as a press, marking machine, or stamp.

Punch and die materials

During production, the tooling undergoes the following impacts:

- High blood pressure;

- High temperature background (during hot processes);

- Cold temperatures (in emergency cases of forced cooling);

- Sudden changes in temperature environment;

- Contact with liquid medium.

Taking into account the listed factors, the matrix and punch for the stamp must be made of material with the following qualities:

- increased strength;

- resistance to wear;

- resistance to corrosion.

In addition, when heated, the material should not change its dimensions significantly - this can lead to damage to the manufactured parts. It is also taken into account that some materials change their properties at elevated temperatures. Thus, alloy steel becomes brittle when exposed to heat, so punches made from it are not used for hot processes.

Production Features

The process of producing press dies is a labor-intensive and technologically demanding task, which requires special criteria. As a result, in order to improve the quality characteristics of the structure, they are made detachable. Various metals are used to produce matrices. Small batches are produced from low-carbon steel that is hardened. In mass flow, carbon or tool alloy steel is used. Afterwards the parts are hardened.

The matrices for the press are different:

- Wear resistance;

- Anti-corrosion characteristics;

- High strength index.

In most cases, high-quality steel and aluminum alloys are used to produce these products, after which they are hardened and ground. The hardness of the working surface reaches 60 HRC.

Recommended metals for punches and dies

For cold processes:

- steel of increased strength, hardenability (degree of hardening - up to hardness 55-65 HRC);

- tool steel, grade 6ХВ2С. The hardness of the punch must have the specified values over its entire height, the hardness of the matrix - at a distance of 5 mm along the working line, at a depth of half the height.

For hot processes:

- high-strength wear-resistant steels, resistant to deformation temperatures. The material of the punch is stronger than the material of the manufactured product, the base is not only made of metals, but also of rubber, polyurethane (hardness 98 Shore units). Sometimes easily destructible materials (clay, gypsum) can be used for the base: for example, if you need to cast parts with through openings.

Finishing and testing of the mold

At the third stage, the mold is refined to produce a product of the required quality and with a given production cycle time. Obtaining a mold of a given quality is the main goal of all the processes described above, and if the mold does not show the desired results under operating conditions, it is necessary to look for errors in the first two stages. The duration of finishing the mold directly depends on the quality of manufacturing of the mold - the more thoroughly the work is done, the less time it will take to finish it. The mold is tested under conditions close to the actual operating conditions of the mold. The most important part of this process is the equipment on which the molds are tested - injection molding machines - ideally, the equipment installed for testing the mold should correspond to the equipment on which the production of plastic products will be carried out. Not every enterprise specializing in the manufacture of molds and technological equipment is capable of designing and manufacturing a mold for a complex plastic product that meets the high requirements of the modern consumer. At the same time, the costs are quite significant - highly qualified personnel, time, expensive materials and specialized equipment are required for the production of molds. All this ultimately affects the price. The cost of a new high-quality steel tool ranges from 50 to 500 thousand euros. Author: Academy of Industrial Market Conjuncture PlastExpert recommends: Article on how to choose a manufacturer of molds for plastic injection

Types and types of punches and dies

Types of punches differ in design, which is dictated by technological purpose:

- punched, perforated;

- cutting;

- piercing;

- molding;

- bending

Each type of tool is designed to perform operations; the catalog contains photos of punches of all types.

Punching punch: performs punching, cutting holes in sheet material, separates part of the material, forming an internal closed loop. Can be used for perforating sheet material. Often equipped with a release mechanism to release the cut-out part.

Cutting punch (cotter pin): separates the workpiece from the outer closed contour of the part. The punch of the cutting die, depending on the configuration, can cut out metal at angles from 1 degree, in 1-2 stages. The punch and die are most often used to work with material up to 1.5 mm thick.

Piercing punch for a press: creates holes (through/blind) in the workpiece by displacing metal. It can be solid/hollow, creating holes of small or large (500-800 mm) diameters, respectively.

Forming punch: creates a three-dimensional relief product of a closed contour from a metal sheet, often in one step.

Bending punch: bends metal along a given line, pressing into the workpiece to the required depth, thereby forming a bend.

The punch part can have different shapes: simple geometric (cylinder, hexagon, square, rectangle), or shaped (complex), which is used to create parts with a complex contour.

According to the type of its design, the matrix can be

- Solid matrix: for working with parts of a simple external contour.

- Complex matrix: for processing complexly contoured products.

- Prefabricated matrix: manufactured on high-precision machine equipment using a minimum of manual work. To start working, you just need to quickly and easily press its elements into the holder.

- Composite matrix: consists of several identical modules. It is used in molds with several cavities. Split bases are used if the future product has complex geometry. Most often, simple modules are used.

Depending on the characteristics of the product being manufactured, the punch and matrix can be used as complementary parts of a set, or separately. Thus, the base can be used without a punch if it is necessary to produce a part with a flat sole. In the production of building materials, in some cases its use is also not required: for example, when molding standard bricks, when surface quality is not important. If sheet material is stamped, the work can be carried out without a base module - only a flat base is placed under the workpiece.

Design and technological preparation of production

The first stage of mold production includes the preparation of product sketches (sketch graphics), construction of a 3D model, and photorealistic visualization. Designing a mold includes design development of the model and division of the assembly model into individual structural elements. Preparation of each specific element, design of the part’s parting line as well as gates, signs, inserts and mold area. The gating system is of particular importance. Warping, streaks, slitins and other defects can be avoided or minimized as much as possible using computer simulation of the form filling process. It is also possible to control the distribution of melt temperature, flow rates and other parameters. At the initial stage of mold production, all existing ideas and drawings are transferred to a computer, on which molds are designed using certain programs. When designing molds, CAD/CAM systems, automated, end-to-end design are used. The Mold-Works mold design system for SolidWorks is designed to automate the designer's work and perform automated mold layout tasks. Checking the mold for “spillability” is carried out on a computer using Mold - flow analysis. The leading suppliers of computer software in the field of design and manufacture of molds and dies are the companies Unigraphics, ProEngineer, Cimatron. The first stage is extremely important for determining the required amount of work at the second stage of mold manufacturing, since the necessary set of standard and special products necessary for the manufacture of the mold is determined. Mold manufacturing The second stage of mold production includes design (ordering standard parts, processing blanks, manufacturing special mold elements), prototyping, and direct assembly of the mold.

Features of dies and punches

In order for the manufactured products to have the proper high quality, the geometric dimensions of the tooling modules must be extremely accurate, match each other, their surface is absolutely smooth, the cut line is even, precise, and the press must be precisely centered. To ensure these indicators, the tool undergoes double grinding (roughing, finishing), polishing, and sharpening. Modules of shaped type are produced by technological imprinting, and complex contour ones are made on milling and planing machine units. Then the equipment is hardened at high (about 780°) temperatures.

In cases where the configuration of the punch is more complex than the matrix, it is first manufactured, and then a base is created based on its impression. Special control is carried out to ensure that the gap between the nodes is maintained. Clearance is maintained through independent processing or mutual adjustment.

If the quality of the set is decent, it will last a long time, will give an accurate cut line, and the parts made on it will not require additional processing.

The punch and matrix in the die are advantageous for their versatility, versatility, and practicality. During operation, such equipment can be easily mounted/dismantled without additional effort, the coatings applied to it are uniformly deposited over the entire surface, and the planetary rotation function is available.

Servicing the equipment is not difficult: it is necessary to systematically clean the surface of metal, concrete and other residues (using scrapers, brushes), rinse with water jet pressure and then dry.

Worn sets are not restored, but are promptly replaced with new ones, since their surface wears out and their dimensions lose the required value and accuracy. A tool made from a material selected for a specific task functions without loss of quality for up to several years (4-6 maximum). Therefore, purchasing equipment with a large margin of safety and service life is more rational than frequent replacement of less durable sets.

Mold processing

The main part of the processing of mold elements is carried out on CNC milling machines and electrical discharge machines. The processing technology involves three stages of mechanical processing and three stages of heat treatment: Annealing - roughing - normalization - semi-finishing - hardening - final processing - chrome plating. • Annealing is necessary for any workpiece to remove residual stresses; • During roughing, the main amount of material is removed, allowances for working surfaces are 0.5-2 mm. • Normalization (annealing) is necessary to relieve the main stresses in the workpiece, this reduces the risk of large leads during hardening. • Semi-finishing is carried out with an allowance of 0.3-0.1 mm. During this processing, the maximum possible selection of unheated material is made and the surface is prepared for final finishing. • Hardening is a very important moment in the entire technology. If no serious mistakes are made in the technology, then hardening does not go beyond the limits of reasonable risk. This processing stage is especially important, since it is at this point that all the fine processing is carried out. To achieve the required processing accuracy, special expensive tools, mandrels and fixtures are often required; all work is carried out with imported high-quality tools. • Polishing, fitting and assembly. This is the job of a tool maker. For each specific mold, the content of this work may be different; this is where all errors are detected and corrected. Sometimes assembling and testing a mold causes unexpected problems, which increases production time. • Chrome plating is necessary to obtain high surface hardness of mold parts subject to increased wear. A matrix with a hardness of 44-46 HRc has a guaranteed service life of 600-700 thousand cycles. The service life of a chrome plated mold is significantly longer. The described stages of making a mold in general terms reveal the technology and allow the customer to compare the price of the work and its content.

The principle of operation of the matrix

A workpiece is placed in the matrix, or in the space between it and the punch, or the initial mixture is poured. The punch directly, either transmitting force through the press washer, presses on the material, pressing it against the matrix, or pushing it through it. If the material is granular, additional vibration can be applied to increase density.

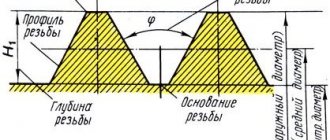

The role of the gap between the matrix and the punch

The size of the gap between the punch and the matrix determines the cleanliness and evenness of the cut, and depends on:

- type of operation performed;

- type, thickness of the source material.

The recommended clearance is 4-16% of the thickness of the material being processed. Stamping with a punch with a clearance of 30% is acceptable if its edges are sharp enough. However, the manufactured parts will only be of satisfactory quality. During operation, shear surfaces are formed at the cutting edges of the punch and die. They must coincide with each other and form a common cleavage surface. This only happens if the gap between the tooling elements is optimal.

Reasons for the extreme importance of lumen size:

- An underestimated gap provokes delaminations and tears on the cut surface. This occurs due to the mismatch of shear cracks that form a bridge, which subsequently transforms into a burr.

- An exaggerated gap is accompanied by bending of the material and leads to rounding of the edges of the part if the workpiece is thick. Rupture of a thin workpiece, stretching and jaggedness of its edges.

An incorrectly selected gap leads to negative consequences:

- poor quality of the edges of the processed part, holes;

- material deformation;

- slow leaf removal;

- increased abrasion of the tool surface, leading to a reduction in service life;

- the cost of additional effort;

- strengthening of the resulting burrs by deformation;

- abnormal increase in temperature.

A correctly selected gap ensures:

- cleanliness, smoothness of the edges of the part, holes;

- no deformation of the material;

- easy sheet removal;

- tool service life (2-3 years).

The correct gap can be determined by the following criteria.

- Too little clearance results in a break in the die cut at a small angle to a small smooth area.

- A large gap forms a rough fracture on the die cut at a large angle to a small smooth area.

- The optimal gap ensures the same angle of the upper and lower breaks, uniformity among themselves.

The use of punches and dies in production and material processing extremely speeds up the production of similar parts and reduces the cost of piece production. The kits are manufactured not only for industrial enterprises, but also for domestic use.

Cooling system elements

The casting cycle consists of more than 50% of the casting cooling belt. To create a mold cooling system that is reliable in operation, easy to manufacture and maintainable during operation, a variety of standard parts are offered: quick-release connections, overflows, fortanation tubes, turbulators, heat pipes, heat sinks, O-rings, plugs and plugs. It is recommended to connect the mold cooling system to the hoses of the refrigerant source (thermostat, cooler, shop return line) using quick-release connections consisting of a nipple and a coupling. Elements of the cooling system, as a rule, are present in the catalogs of manufacturers of standard parts for molds. At the same time, there are companies specializing in the production of cooling system elements.