The popularity of artistic forging is difficult to overestimate. The solidity, beauty of forged metal, and the rhythm of flat and three-dimensional patterns involuntarily attract the eye.

An example of metal products with elements of artistic forging.

There are different technologies for manufacturing forged products - hot and cold forging.

A type of cold forging is metal pressing. Hot forging, as well as pressing, requires the presence of a production area and quite complex equipment, while for cold forging an outhouse or garage where you can bend metal and assemble finished products is quite sufficient.

Forged bridge according to sketchWhy are sketches of forged products made?

Forging is a very beautiful way of making metal products. However, making forged jewelry according to a clear drawing is almost impossible, since the process of performing the work itself does not make it possible to ensure sufficient accuracy. Therefore, during production, sketches of forged products (hereinafter forged sketches ) are used.

Reasons for making sketches:

- The client must clearly understand what he is ordering and what the finished work will look like. Therefore, the sketch is made in the form of a clear drawing in pencil, taking into account all the wishes and dimensions specified by the client.

- Calculation of the required amount of material and deadline for completing the work. Based on the sketch, the master will determine the required amount of material and deadlines, and therefore the cost of the order.

It is for these reasons that a sketch is always drawn before starting work.

Cold forging devices

Having simple equipment and devices, you can not only make forged products to decorate your home or country house, but also open a small production of forged products. Cold forging involves the use of a round or square metal rod, as well as a metal strip. To assemble the products you will need a welding machine.

To make gratings, fences, railings, and furniture with forged elements, you need some equipment that you can either purchase in special stores or make yourself. The drawings for this equipment are simple and quite understandable for a master of any level. Minimum required equipment for cold forging:

Tools for cold forging: hammer, bent, snail, twister, wave, volumetric and others.

- Snail. This device allows you to make curls in the form of spirals. In order to obtain curls with different bending radii, you need to have several units of such equipment, made using different stencils. A pre-bent piece of strip is welded onto a sheet of metal, according to which, like a template, curls are made by bending. You can make a drawing of such a snail yourself.

- Bent - equipment for bending a rod at a fixed angle or along any radius. The equipment is a system of rollers mounted on a metal plate and has a design that allows you to change the distances between the rollers.

- The “Flashlight” device is used for the production of volumetric spiral elements with the same name. This equipment can also be used to produce the “basket” element.

- Twister. This device is used to twist a square rod or strip in the longitudinal direction. The result is beautiful twisted rods. The equipment has a simple design, and, having a simple drawing, it is easy to make it yourself.

- Volume, sometimes called “globe”. Using this device, parts are made that are curved in 3D format, making it possible to obtain three-dimensional forged ornaments.

- The “wave” device is similar in design to a pipe bender. Using two rollers, one of which is mounted on a movable lever, it is possible to produce parts curved to any radius. This equipment is used in the production of wave-like patterns with elements of large radii.

Features of forged sketches

Unlike a drawing of any other thing, forged sketches are a ready-made option and will not be altered in the future. Therefore, they have several features:

- Compliance not only with proportions, but also with the scale of the product, taking into account all sizes.

- Carrying out a sketch after specifying the dimensions of the product.

- Artistic design. Since forged sketches are drawings of products, they are performed at a professional level, with all decorative elements applied and in compliance with the rules of artistic drawing.

- Volumetric images. If possible and necessary, the sketch of a forged product is made in volume for greater clarity.

Taking into account all these features, the master carries out the drawing with great care.

How to make a drawing of the finished product

Drawings of forged patterns can be found in catalogs of finished products and in other similar literature. If you wish, you can independently draw a pattern for a lattice, fence, or railing. The basic principle of composing forged patterns is the rhythmic repetition of a certain ornamental motif. Simple elements can create a very beautiful pattern.

To make the product interesting, you need to find a harmonious combination of elements of varying complexity - from simple straight rods and rings to intricate lanterns. A simple combination of identical curls, located at different angles, and straight rods to which the curls are attached, makes it possible to create many different patterns.

https://moyakovka.ru/youtu.be/eO3dqHbirkc

To give forged patterns a finished look, the “collar” element is often used, with the help of which parts of the patterns are fastened together. However, this element serves only a decorative role, covering the welds and creating the impression of connectedness of the pattern elements.

Sketches currently

Why draw a sketch? If so, can I take a photo? If you order a mass-produced product, then in principle a photograph will be sufficient. But, in the case of making an individual order, forged sketches are required. They can be:

- Independent image. In this case, the product is not part of another structure, but is an independent unit. For example, forged flowers, which have become increasingly popular lately.

- Addition to other drawings. In the case of the manufacture of decorations for other products, or the manufacture of various sections of fences, gates, etc., sketches of forged products may be part of other drawings, or the general appearance of the object. Thus, the appearance and full dimensions of the future product are determined.

Making elements and parts using hand forging is practically an art, akin to painting. That is why forged sketches have not lost popularity at the present time. And many workshops hire individuals with artistic talent to work on such projects.

Types of cold forging

In the manufacture of metal products, 7 types of cold forging can be distinguished. These are a kind of stages of creating elements that need to be performed when working with blanks.

All work must be carried out in accordance with the requirements and rules, otherwise you should not hope to receive a beautiful forged product.

The most important stage is forging metal blanks. This is the largest, most responsible, complex and serious process, so you need to treat it very carefully. Cold forging can be of several types:

- Upsetting - it is performed under high pressure. This is necessary in order to increase the workpiece on the sides by reducing its height.

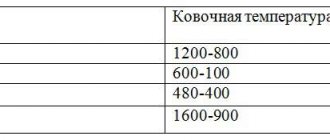

- Broaching - this stage is performed by heating a metal part and then hammering it. This is necessary in order to reduce the cross-sectional area by increasing the length of the metal rod.

- Firmware - this stage involves making holes inside the workpiece. When doing this work, you can get holes of different diameters and lengths. It can be open or closed.

Upsetting and broaching makes the structure of the metal workpiece more fragile, so further work must be carried out very carefully to prevent breakage of one or another part of the structure.

- Stamping - at this stage, plastic deformation of the metal occurs, which leads to a change in the shape or size of the workpiece. Stamping can be volumetric or sheet. In the first option, work is performed under pressure. In this case, the part is heated and pressed to the desired size. This method is more suitable for production scale, when you need to make a large batch of identical elements. Sheet stamping differs from the first option in that the parts are made from sheet iron. This method is suitable for the manufacture of small or medium-sized parts, and they will be of high quality and durability.

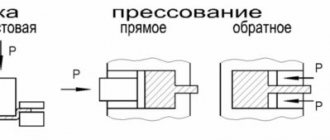

- Pressing - at this stage, the density of the metal workpiece increases and its shape changes due to high pressure. Pressing can be direct or reverse. With the direct method, metal blanks are extruded through various holes, which leads to the production of various rods, pipes and profiles. In reverse pressing, metal products are placed in a special mold, while pressure is applied in the opposite direction.

- Drawing is the process of drawing metal, only already pressed, through a special matrix. With this processing method, various shaped profiles, wires or thin pipes can be obtained.

- Rolling is the final stage of processing, which involves the law of friction. When special rollers rub against a metal surface, the workpiece becomes deformed. Rolling can be of several types, depending on the method of rotation of the rollers:

- longitudinal - in which the rollers rotate in different directions. This leads to a gradual compression and elongation of the metal part. In this way, sheet and strip iron is produced;

- transverse - in which the movement of the rollers occurs in one direction. This leads to deformation of the workpiece in the transverse direction. This method is used to produce cylindrical gears with knurled teeth;

- screw - in which the arrangement of the rollers is made at an angle to each other. In this case, the workpiece passes simultaneously through two rollers with translational and rotational motion, which makes it possible to obtain a small gap into which the metal falls. In this way, pipe blanks, “sleeves,” are obtained.

The procedure for making a sketch of forged products

In order to correctly complete a sketch, the artist must have some skills:

- Be able to draw at an intermediate or advanced level. Da Vinci's talent is not required to complete the sketch, but it is necessary to draw clearly and beautifully.

- Have a clear knowledge of geometry. Forging includes additional decorations that must be correctly distributed over the area. And for this, you need to be able to calculate this area, including complex figures.

Sketch stages:

- Determining the size of a product or decoration.

- Product design definitions. In full cooperation with the customer, the appearance of the product is developed and all types and quantities of decorative ornaments are specified.

- Drawing the general outline of the product, taking into account the scale and exact dimensions.

- Distribution of all decorative decorations in their places.

conclusions

Making sketches of forged products is a labor-intensive and complex process that requires the artist to have certain skills and strictly adhere to the rules of both drafting and artistic drawing. Proper preparation of the sketch is a guarantee that all the customer’s wishes and product dimensions will be met. Making forged elements is too labor-intensive a process to redo it all over again. Therefore, if you are offered to do a job without a sketch “by eye,” do not agree, waste your time and money. Strict adherence to all elements and dimensions of the sketch is a guarantee of high-quality manufacturing of the part.