The seeds of many vegetable crops are tiny in size: this complicates the sowing procedure, and thinning is subsequently necessary for normal plant growth. Cultivation of crops becomes complex and painstaking, and as a result of high seed consumption, production costs increase. To save resources and make the work of workers easier, a manual precision seeding seeder is used, which will be discussed below.

Carrot seeder - an overview of ready-made and home-made devices

Not a single garden can do without healthy carrots. If a person has a garden, then he tries to grow his own products in it.

This is correct, because only by planting crops with our own hands can we be sure of their quality and usefulness. The work of a summer resident cannot be called simple; during the season you need to do a lot of different things, without which you cannot get a harvest. To make your work easier, you can use different devices - a carrot seeder is a good example of this. You can buy it in a store, or make it yourself, there are many options and let’s get to know them. This is interesting! Nowadays, there are more than 60 varieties of orange root vegetables; its homeland is the original Afghanistan. Europeans learned about carrots around the 10th century.

Store options for seeders

Syringe

A fairly simple and accessible device for everyone. As you can see in the photo, the syringe has a transparent cylinder where carrot seeds are placed, and a rod that pushes them through a special hole in the base. This device is sold in gardening stores and hardware stores. Convenient, simple. The price, depending on the region, is about 100-150 rubles.

The second option, which has long won respect among summer residents, is a seeder for sowing carrots, which is shown in the photo below. The principle is the same as that of a syringe - the seeds are placed in a barrel, and then pressed into rows in the garden using a rod and a spring. Very budget-friendly - up to 100 rubles and a simple option. But these two planters are suitable for small areas that can be planted by hand without much difficulty. But if you need to sow a large area in the garden, then you will have to purchase more serious units, more on them later.

Roller seeder

Convenient, technically simple device. Our country produces videos as well as foreign analogues. The price of the Russian unit is 200-250 rubles. You can buy such a device in garden stores and online stores. The principle of operation is elementary - the round body opens, the seeds are poured in, the lid closes. After that, the handle-handle is inserted and sowing is done in the rows that were made in advance.

The big advantage of such a roller is that you don’t need to bend over, as is the case with the first two devices, because you can even make a handle with your own hands and to suit the required height. The roller makes it possible to easily sow a large garden, but if you have an impressive area, then the units described below are suitable for you. But it is worth noting that we will be talking about seeders for small-family crops, which are suitable specifically for manual work in the garden, and not about complex machines with many attachments for fields like walk-behind tractors.

On a note! Another advantage of this roller seeder is that it is suitable for sowing not only carrots, but also other vegetables, herbs and even peas.

Precision seeder

Such devices are perfect for carrots, beets, peas and other crops. Yes, they already cost an order of magnitude more, but they also make the work much easier. Again, such units can have a complex design, a simple one, differ in size, functionality, or be from our manufacturers or foreign ones. This affects the cost. See below for examples of commonly used seeders and their photos.

Precision seeding units:

- SOR-1/1. Seeder from , single-row. It can have a different design - either sowing using a brush mechanism, or using a sleeve mechanism. Quite an inexpensive option - up to 3 thousand rubles. The grain basket holds quite a lot of seeds. It can sow different crops, for which the bushings that come with the kit are changed;

- 1001-B. This seeder is already from, which is located in America. The option is compact, light - up to 4 kg, can plant different crops and medicinal herbs, sowing depth is adjusted. The set includes six discs that can be changed and make it possible to plant 28 crops, including vegetables and herbs. The price of the unit is more expensive - up to 7-8 thousand;

- Seeder SMK-1. Again from, a good unit that you can simply attach to the cutting and then control it. Price – up to 1000 rubles. The mechanism has brushes and a shaft, sowing is carried out in one row. If your area is large, then you can purchase another modification - the SMK-5 seeder is five-row, sows crops to a width of 6 cm, SMK-2 is a two-row. The width can be adjusted from 6 to 24 cm. Pour the seeds into the container and sow, everything is quite simple, but at the same time effective;

- AL-KO US 45. A very good option for a precision seeder for both carrots and other crops and for spreading fertilizers. It costs no more than 2 thousand rubles, you can order it on the Internet. A German unit, convenient in that it has a 22-liter tank, where you can pour a lot of seeds and fertilizers, as well as a handle that is easy to hold with two hands.

Of course, there are very, very many seeders, each company has its own, but the principle of operation is largely similar, the efficiency is the same, only the cost can differ many times. If you have a large or small garden next to a private house or in a country house, then these seeders are perfect, they won’t take up much space and won’t require special skills. Well, we’re moving on to the second part, and these will be life hacks on how to make simple devices for sowing small-seeded crops with your own hands and at no cost.

On a note! Nowadays, there is a special adhesive tape on sale, on which the seeds are already applied at the required distance. It just needs to be buried in rows, sprinkled with soil and watered, as with regular sowing.

Types of seeders and their design

Types of equipment differ in size, design and sowing methods. If large seeders are suitable for large farms, then in the garden a attachment for a walk-behind tractor is sufficient.

Trailed/mounted

According to the method of attachment to the equipment, trailed and mounted seeders are divided. The former require less productive machines to operate. For example, a tractor with a power of 45–60 hp. With. or seeding devices Kinze 3000, MT-8, YP-1630F, which have a power of 80 hp. With. They are aggregated with an eight-row YP-825 130 liter seeder. With.

Attachments are used to work with productive machines of at least the second class and tractors with high power (250–320 hp and 200–220 hp).

Mechanical/pneumatic

Corn sowing occurs in a dotted manner. In this case, seeders have a pneumatic or mechanical mechanism.

Mechanical seeders are gradually becoming obsolete and disappearing into oblivion; in many countries they have already been discontinued. To change the types of seeds, you have to completely dismantle the working panel and adjust the row spacing in a new way. There is simply not enough time for such a procedure.

Pneumatic corn seeders have a more advanced design, which includes:

- lump remover;

- furrow filler;

- compaction wheel;

- wedge tip;

- skid opener.

Her labor productivity is much higher with minimal time investment. Fertilizers are added along with the seeds. Among the significant disadvantages are:

- high price of the seeder;

- insufficiently effective work on problematic grounds;

- impossibility of use in fields where there are a lot of roots in the ground.

Manual/for walk-behind tractor/for special equipment

Manual devices are one of the most popular for sowing corn in small areas. Used in medium and small farms. They are characterized by high productivity: 0.5 hectares are sown in one day, provided that the land is prepared. They operate using a seed disc or plate at the bottom of the seed tank.

Seeders for walk-behind tractors allow seeding to be done in even steps in each row. To use them, holes are made in advance at a selected distance. Use devices only on loose and soft soils. Do not use on clay and heavy soil. The simple design is too heavy and bulky.

Seeders for special equipment are multifunctional. With their help, several types of corn are sown at once, simultaneously covering the maximum number of rows, the seeds are distributed over the marked holes, they are fertilized and covered with soil. This equipment has large dimensions and weight; it is used only on tractors and other machines with a power of 45 to 320 hp. With.

DIY carrot seeders

Plastic bottle

This is the most common garden device for sowing small seeds. Take a 1.5 liter bottle, unscrew the cap, make a hole. This can be done using a screwdriver. We insert a juice tube here and secure it at the base with thread or tape. Mix the seeds with sand so that they do not fall thickly and at the same time there is drainage. We sow in rows and water.

Paste and bottle

This is the second version of a manual seeder for carrots, which you can do with your own hands and, again, from a bottle. We also make a hole in the lid, but without a tube. Cook a sticky mass from a liter of water and a spoon of flour. Pour the seeds here and mix them thoroughly. Pour into a bottle and plant. The nutrient mass will distribute the seeds so that minimal picking is needed.

Homemade manual seeder: nuances of accurate and simple sowing

Every summer resident and gardener knows how important it is to plant vegetables correctly. This process is labor-intensive, quite expensive in both time and money. After all, it is necessary not only to evenly distribute the planting seeds in the furrows, but also to further thin out the seedlings manually, forming crops. A special seeder will help to significantly simplify the work, which, even in manual mode, will be a real help in planting. The article will discuss the nuances of the operation of planting structures, the principle of manual assembly of the simplest mechanisms, the features of operation and the creation of manual machines for more accurate seeding.

Functions and types of seeders

A modern seeder performs several tasks simultaneously:

- Make a furrow in the ground using a harrow;

- The seeds are then placed inside the furrow;

- Two metal devices close the previously open groove.

Some seeders are equipped with a compaction roller, which helps the grains stick to the ground, facilitating germination.

There are mainly two types of seeders on the market today:

- Universal row seeders that are used for sowing wheat, barley, alfalfa and thousands of other types of seeds;

- A precision seed drill, which is much more complex than the previous one and is usually used to distribute one seed at a time at exactly equal intervals along parallel rows

These machines can be simple, capable of seeding only, or combined with fertilizer spreaders, capable of simultaneously distributing fertilizer locally, or with tillage implements (usually rotary harrows).

Seeders can also be divided according to the functioning of the distribution bodies into mechanical or pneumatic. Based on the type of coupling to the tractor, they can be divided into semi-mounted and trailed.

Tool requirements

A completely working structure is made from available materials: various recyclable materials, tin cans, plastic bottles.

It is advisable to use more complex structures made of metal sheets only for industrial-scale cultivation of vegetable crops. A good example of the simplest design for planting is a carrot seeder.

Certain aspects apply to self-made mechanisms for planting vegetables.:

- The placement of seed into the soil must be in a certain quantity (per 1 linear meter) and to the required depth.

- Seeds should be distributed evenly, without gaps and without damage.

- The mechanism ensures straightness of planting rows and row spacing.

- After each laying, the grooves should be filled with loose soil.

Sowing small seeds is best done using mini-seeders. Such devices are suitable for growing carrots, onion sets, salad greens, that is, those crops that have rather small planting material.

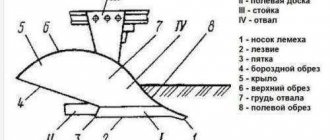

Seeder structure

The seeders consist of:

- Support frame (with or without wheels);

- Bunker intended for seed material;

- Devices for hilling seeds.

Typically, the seeder is equipped with a control structure that allows you to change the dosage or distance in the seed row, as well as the seeding depth, instruments to monitor any anomalies or malfunctions of the seeder, and rule-furrow or row markers that make it easier to control the machine by indicating the track on the ground that needs to be followed. move during subsequent stages of work in the field to maintain uniform spacing between rows.

Upon request, growers can supply a mechanical or electronic device called a hectare counter to measure planted hectares.

Features of application

The basic principle of operation of the simplest sowing mechanism is to limit the spilling of seeds out.

An open box with a double good bottom is used for this procedure. A movable plate is inserted into the formed space. Grains or seeds are poured into the bottom of the box (upper) with holes slightly larger than the size of the planting material; in the lower tier of the mechanism there are larger holes, they coincide with the top. When pushing in the middle intermediate plate, the holes in the bottoms do not communicate, which means the grains do not spill out. If the valve is moved, the sower will start working again. To avoid thickening of the crops, you should not pour a large number of seeds into the structure at once, rolling them over the mechanism.

Many vegetable growers equip the movable (middle) plate with a spring, which facilitates the operational process.

Using the landing mechanism is very simple. A furrow is marked in the garden bed. They place a homemade seeder on it and move the device forward. The tank begins to rotate - grain or seeds are poured out evenly. Then, using an improvised hoe, the plantings are covered with loose soil.

The seeds are fixed in the seeder using a transparent plastic tank. The entire structure can be easily converted for any vegetable crop; for example, in a radish seeder, the holes in the tank need to be made smaller than in a mechanism for planting corn. It is very easy to make improvised parts using simple materials. For economical and high-quality planting of different vegetable crops, it is necessary to make about 3-4 tanks with holes of different sizes for the seeder.

Adjustment

In manual seed drills, before sowing the following settings are performed:

- Seeding rates;

- Seed placement depths;

- Row spacing.

Lawn seeder

These settings are very important for quality sowing.

Seeding rate

The accuracy of the seeding rate on different types of seeding devices is regulated in its own way:

- In bush sowing devices, the seeding rate is regulated by selecting a bushing with the corresponding holes and the pitch between them;

Important! In order to make a bushing with non-standard holes and pitch, you can buy a blank and, having marked it according to the given parameters, make recesses (holes for seeds) of the required diameter.

- In brush sowing devices, the seed sowing rate is adjusted using a calibration disk with holes. The seeding rate is regulated by installing a corresponding hole on the calibration disk opposite the outlet window of the sowing apparatus.

Planting depth

The depth of seed placement is adjusted in seeders with a chain drive of the sowing apparatus. The adjustment process occurs as follows:

- The seeder is installed on a flat area;

- Place a board under the rear press wheel with a thickness equal to the planned sowing depth;

- Using the adjusting bolts, the coulter is lowered until it touches the floor. In this case, it is not the tip of the opener that should touch the floor, but its entire lower plane.

Row spacing

The row spacing is adjusted by changing the distance between the sowing units or extending the marker. The latter option is more convenient and allows you to create large row spacing when sowing, for example, a crop such as corn.

DIY making

By using a mechanism for planting small seeds, sowing can be accelerated 10 times. As an example of a simple hand-held device, consider a carrot seeder.

To make it you will need the following materials::

- Plastic or metal shaft. You can use a part from a thick-walled pipe.

- A wheel made from a tin can (a small bicycle wheel will do).

- A bunker made from a plastic bottle, container, or shampoo container.

- Retaining rings designed for the wheel.

- Foam rubber.

- Transport bracket (1 piece).

- Wooden handle.

- Screw “M 4” (from 4 to 8 pcs.).

- Restrictive rings/clamps (from 2 to 4 pcs.).

- Nut “M 4” (from 4 to 8 pcs.).

For high-quality assembly you will need tools: a screwdriver, drills with different diameters, scissors, a drill, a knife.

The process of manufacturing a simple manual seeder takes place in several stages:

- The shaft is being prepared. In the middle of the plastic pipe, recesses of different diameters are drilled (for large and small seeds). The pipe is not drilled through.

- Wheels are made from tin cans. To ensure better grip, rubber rings are placed on the wheels in several rows. In the middle, using scissors, a hole is cut equal to the diameter of the shaft.

- A hopper is cut out of a plastic container. The lower part is cut off, holes are made on the opposite walls for the sowing shaft. The bottle is placed upside down.

- The hopper is placed on the shaft. Foam rubber is laid and glued to the bottle walls so that during further rotation the excess seeds are removed. That is, when the foam brush is turned, the shaft should produce small cells, each of which will contain one or two seeds.

- The transport bracket is attached to the shaft with wheels and secured with screws.

- The hopper is carefully attached through a metal plate to the bracket. When the shaft rotates, it should not move.

- A wooden handle is installed.

The simple design will significantly reduce labor costs . This is how you make a manual seeder with your own hands. The main disadvantage of this mechanism is the limited sowing (only in 1 row) and the sowing of only one vegetable crop due to the different size of the seeds. The problem can be solved by using several replacement cans with different holes.

Much more complicated is a self-made sowing device, with which you can work with seeds of different crops. The main working mechanism in the universal design is the sowing shaft, which is an aluminum tube with a diameter of 30 mm. Holes are drilled in three rows of different sizes. Each line is made for one crop.

Popular brands

Let's look at the main characteristics of well-known models of corn seeders.

Gaspardo

The Italian unit is distinguished by its original placement of seeds in the soil . The equipment has a double grain switch with adjustment to sow processed seeds and irregularly shaped or sized seeds. The seeding depth is adjusted mechanically using a special handle. The seeds are pressed into the soil in a stainless steel circle. This solution ensures uniform growth of cereals.

Interesting! The model has a seeder module setting for various types of crops and land. The gearbox of the gearbox allows for simple and quick installation.

MT-8 has a fertilizer sowing system with dosing capabilities from 50 to 700 kg/ha.

The price of the model is 450–1400 thousand rubles. According to reviews, this is one of the most popular brands among its peers. The only one with special seeding sensors, it practically does not break. Parts are sold at low prices.

Amazone

The German manufacturer has two models of machines for sowing corn: ED and EDX. The second is intended for growing in large areas, where time is very important. The operating speed of the equipment is 15 km/h.

ED models are available with 4, 6, 8 or 12 rows. Seeds are placed in the soil according to the principle of air suction. The vacuum pulls the grains into the holes and places them in the ground. The seeders are equipped with a central seeding drive. The gear train has 36 steps - depending on the discs used, intervals from 2 to 53.8 cm are obtained.

The price of the device is 2.5–10 million rubles. According to farmers' reviews, the brand is considered one of the most reliable. There are practically no negative aspects mentioned, apart from the high price.

"A red star"

Ukrainian produces a model for sowing corn SUPN-8, which places fertilizers in a special furrow, sprinkles them and produces high-precision sowing of corn seeds, creating optimal conditions for them to grow. Seeder productivity is 3.36–3.9 ha/h at a flow rate of 2 to 16 kg/ha.

Cost - 295–599 thousand rubles. The positive aspects include a fairly low price and cheap spare parts. Among the disadvantages are frequent breakdowns.

"Lidselmash"

The Belarusian manufacturer produces the SPCh-6 model with precision seed sowing and use for row crops. Like SUPN-8, it allows you to place fertilizers in the furrows. The maximum number of rows is 6 (with a storage volume of 20–30 liters, a flow rate of 3-7 pieces/m and a furrow width of 45–70 cm).

Price - from 260 thousand rubles. Among the advantages, farmers note the relatively low price and the availability of a transport device. The disadvantages are the inability to use fertilizers during sowing, the device’s “dislike” for wet weather and the ability to work only on perfectly prepared soil.

John Deere

The American company produces model 7000, which operates on a mechanical principle. The seeder weighs 3.85 tons. The unit has an 8-row structure with a storage volume of 56 liters. Price - from 1.5 million rubles.

There are practically no negative reviews of John Deere seeders on the Internet. Most owners of this model have no complaints about it, but point out the high price and the fact that in rainy weather the device becomes clogged with stuck damp earth.

Precision seeding mechanism

An important task of using seeding structures is to ensure uniform planting . To plant seeds in the ground at a strictly defined distance, manual precision seeding drills are used; these mechanisms are easy to make with your own hands, just like the simplest devices described above.

Design

The device consists of one or more containers with seeds, a frame on wheels, and a control handle.

To independently manufacture such a unit, you will need a turning tool or a drill to drill metal sheets, the thickness of which is approximately 1 or 2 mm, and the diameter is about 5-8 mm. When planning a connection between a seeder and a walk-behind tractor, it is better to use rigid bolts that are more vibration-resistant instead of rivets . The front wheels are designed to form furrows in the beds, where the seeds fall from the hopper. Using the rear wheels, the resulting holes are filled with loose soil.

PRINCIPLE OF OPERATION OF THE GRAIN SEEDER

While the seeder is moving with the coulters lowered, the seeds and fertilizers contained in the boxes and bins flow by gravity into the receiving compartment of the sowing devices, from where they are grabbed by the rotating coils of grain and fertilizer mechanisms, directing them into the necks of the seed tubes.

From the seed tubes, the grain is delivered to the inter-disk space of the coulters and, through the structures guiding its movement, is placed on the bottom of the recess formed by the disks.

Following the placement of seeds and fertilizers, their incorporation into soil is carried out by the shelf mechanisms of the seeder.

Range of modern seeders

If making a planting unit yourself causes difficulties, it is recommended to immediately purchase ready-made structures.

The assortment on the market is quite large. The American model of precision seeding “1001 - B” is equipped with 6 replaceable discs. With such a seeder you can plant 28 types of vegetable crops. Using the adjusting screw, you can change the planting depth. Newtechagro seeders are single-row types. Designed for sowing beets, carrots, onions, and cabbage . But such designs are expensive.

But there are also cheaper analogues - precision seeders "SOR - 1/1". They are also single-row, can be equipped with a bush or brush sowing unit, the row marker is 0.5 m. This is quite enough for an average garden.

Using a manual seeder can significantly reduce labor costs, increases the speed of the planting process, simplifies the technology, significantly improves the quality of crops, and hence excellent harvests in the future.

Wheeled manual and self-propelled

1-Self-propelled seeder 2-Wheel manual seeder

In this case, it is better to immediately start with the disadvantages - the quality of operation of these devices depends on the topography of the site; they work well only on a flat, pre-prepared surface. In addition, the cost of wheeled vehicles is significantly higher than that of their manual counterparts.

Expert opinion

Kulikov Vladimir Sergeevich

However, if you plan to sow a large area, you cannot do without such equipment, because The bin volume of wheeled seeders can reach up to 40 liters, and the processing width can be up to 3 meters.

Expensive models have the following advantages:

- Possibility of precise adjustment of the dispenser for any seed size.

- Sowing seeds at a certain depth, which ensures their germination and saves seed material.

- The presence of a device for leveling the soil after sowing, the seeds are not only distributed in the soil, but also buried in it.

Gardena L

An inexpensive manual wheeled seeder with a hopper capacity of 12.5 liters and a working width of 45 centimeters. In one load it will sow a lawn of 400 square meters. meters. Can be used to apply any bulk materials: fertilizers, lime, sand, salt. The adjustment lever is conveniently located and does not complicate control.

Price – 3,000 rubles.

Wolf-Garten WE

Another model from Germany, the high cost of which is compensated by the corresponding quality and accuracy. It is equipped with a hopper with a volume of 20 liters and has a passage width of 43 centimeters. In addition to sowing seeds, it can be used for dosed dispersion of any bulk materials and chemicals. Unused raw materials can be stored directly in the bunker, and specially designed wheels prevent damage to the soil and grass.

Price – 7,500 rubles.

Bellon SSM50

A universal model designed for domestic and commercial use. The possibility of multi-purpose year-round use is provided: for sowing seeds, applying fertilizers, preparations and reagents. Tank volume 50 liters, processing width 60 centimeters.

Price – 70,000 rubles.

To sow lawn grass, I used a two-wheeled Gardena L seeder. The result pleased me and made my neighbors jealous - now there is no end to those who want to borrow this wonderful equipment.

Pyotr Savelyev July 15, 2018

About the design of a seeder for manual precision sowing of seeds

A manual precision seed drill, just like a garlic seeder, in its design features looks like a rather unpretentious invention . It consists of one or more containers where the seed will be located, a control handle and a frame located on wheels.

The wheels, which are located in front of the device, form holes or furrows, after which the seed from the hopper falls there, and the rear wheels fill the resulting hole with loose soil.

As we can see, the principle of operation is quite simple. In fact, you simply direct the unit over the area where you plan to grow various vegetable crops, and behind you there will already be holes with seeds.

At the same time, with the help of a manual seeder and a lawn seeder, you can plant not only seeds of lawn grass and vegetables, but also fill sand or fine gravel on icy and snowy paths in winter, so that you can safely walk on them without fear of falling.

In general, the process of working with a manual precision seeder can be divided into three stages:

- Assembly process. First you need to install the control handle from the transport position to the working position, and then put the rear wheel on the axle (if the unit used consists of two wheels). If necessary, we adjust the marker.

- Carrying out regulatory actions. Depending on what kind of crop the seed will be used, the installation of a specific disc in the bunker will depend. It is difficult to confuse them because they are all properly labeled.

- The depth of the share must also be adjusted according to the specific seed.

- Carrying out sowing work. After we put the unit into action, torque is transmitted from its front wheel to the disk through a belt or chain drive. This disk captures the seed from the container, and the ploughshare forms the desired depth of the hole.

- The marker is responsible for ensuring that the row of seeds planted is level , so he forms a line on the ground for the next row.

For convenience, as well as for uniform distribution of seeds in the soil, it is recommended to sow the first row along predetermined contours. You can drive two pegs along the edges, connecting them with rope or thread. Thus, following parallel to this border, you will get a very even and visually beautiful row.

Principle of operation

Seeder

A mechanical precision seed drill of the simplest type works as follows:

- A sowing bushing with holes for a specific crop is installed on the drive shaft

- Seeds are poured into the hopper;

- Using a marker (for seeders of the second type described above), the row spacing is set

- The seeder is installed at the beginning of the first row of the sown area;

- The seeder is set in motion with a smooth and jerkless movement;

- The process of sowing seeds, hidden from the human eye, occurs as follows: each seed fits tightly into a hole in the bushing, then when it rotates, it falls into a groove made by a harrow and is filled up.

- If there is a press wheel at the back of the seeder, installed exactly in the center of the row being sown, the soil above the seeds is thoroughly compacted. This improves the contact of the seed material with the soil, accelerates its germination, absorption of nutrients and moisture by the sprout and its root system

- When working with such a unit, the sower must periodically check the amount of seeds in the hopper, filling it with new ones if necessary.

- After sowing is completed, the remaining seeds are poured out of the hopper, the sowing hub, coulter, harrow, and support wheels are removed and cleaned. The drive chain and sprockets are periodically lubricated with special lubricant.

Important! When operating the seeder, it is necessary to check the coulter, which can become clogged with grass or wet soil. If such an operation is not performed, gaps may appear - unseeded places that can only be discovered when seedlings appear.

When operating the seeder, it is necessary to check the coulter

Models, technical specifications and prices - which one is better to buy

Manual precision seeders are designed to speed up the sowing process. Therefore, few people question the feasibility of purchasing them. However, to make the right choice, you need to pay attention to several main points:

- The cost of the unit, which can vary greatly among different manufacturers.

- The total number of containers for seed material. Again, the more data bins, the higher the cost of the device.

- The depth of the holes being formed will depend on the crop whose seeds are planted.

- The weight of the device also plays a role, especially when working over large areas

- The presence in the unit of additional devices that make the sowing process more convenient (marker, plow for filling seed, etc.).

Why do you need to use mechanization?

The amount of harvest obtained per unit area of land depends on the timeliness of agricultural work. To ensure healthy plant growth, all operations must be carried out at optimal times. The quality of seed work is of great importance. Nowadays, manual labor is still used. This is a very labor-intensive process that requires a lot of time and the involvement of additional workers, which affects the profitability of the enterprise.

Manual work also makes accurate sowing difficult. Further care of plants becomes more complicated. The way out of this situation is to use small-scale mechanization machines, the category of which includes a manual vegetable precision seeder. It guarantees high-quality and timely planting of small-seeded vegetable crops. This is a very useful model, the peculiarity of which is the economical consumption of seed material.

The precision seed drill is used for sowing work and field experiments on farms and private farms.

How to make a homemade seeder with your own hands

made quite simply with your own hands but before starting work you need to make sure that you have everything you need. In particular, you will need a seed container, which should be made of plastic.

Here you can get acquainted with the work of the Viking cultivator.

Kamaz running on methane means high productivity and great savings.

The boat cart has become very popular among Russian fishermen.

This is explained by the fact that plastic products are transparent, which allows you to control the amount of seed. In addition, we will need the following components:

- a bolt that acts as an axis. The container with seeds will rotate on it during operation of the device;

- We will also need a plastic pipe, the length of which should be identical to the depth of the plastic bin container. In addition to the plastic one, we will also need a steel pipe, its length should be the same;

- to secure the hopper we will need washers, as well as aluminum wire.

Let's move on to the assembly process. We will describe it in the format of step-by-step instructions so that an approximate algorithm of sequential actions can be seen:

- of the plastic jar that serves as the future bunker needs to be determined. A through hole must be drilled at the marked point. We remove the cover, after which we make another through-type hole in the side, but this one is rectangular in shape;

- The hopper will be filled with seed through this hole.

- We place a plastic pipe in the center of the plastic jar, which will protect against material spilling out of the hopper. Then you need to install a steel pipe into this pipe and screw a bolt inside it. Then we tighten the bolt with a nut, which will allow our structure to rotate freely;

- On the side of the plastic container we mark points for future holes. The distance between them should be approximately 30 mm. We heat the nail, and then make holes in the marked places (the diameter of the nail must be chosen so that the seeds pass into the holes made by it);

- Then you can move on to making the handle. You can take a regular shovel handle, then attach it to the seeder. It is fastened with a regular bolt and nut, so you need to first drill a through hole at the end of the handle into which the bolt is placed;

- In order for the sowing process to be more automated, it is necessary to provide a device that would fill the holes with seeds. An ordinary sheet of iron will do, but it needs to be bent a little so that it rakes the earth better;

- We attach our workpiece to the handle so that it is higher than the container with the seed.

In principle, our homemade device is ready, i.e. you can begin full-fledged sowing work. Naturally, this device diagram is quite simplified, but it copes with its main responsibility.

The main point of all homemade products is to save money, so there is no point in complicating the design with additional devices.

By the way, before starting sowing work, it is necessary to carry out preliminary preparation of the surface where the work will be carried out. It involves removing excess debris from the area, as well as loosening particularly hard areas of soil.

It won’t hurt to water the soil with enough water. If you have not included a device in your homemade seeder that scoops up the holes with seeds, then you need to prepare several buckets of soil to fill our seeds.

Design

The design of the precision seeder is very simple:

- It consists of a solid body mounted on a wheeled platform.

- For ease of control, the mechanism is supplemented with holders.

- The hopper is equipped with a lid that prevents seeds from spilling out or being blown away by the wind. It is made in a certain shape, so there are no dead zones in the corners of the hopper where seeds accumulate.

- The dosing shaft can be with one or two rows. The special design provides better grip, movement of seeds under the brush and clearer discharge. The shaft, which acts as a dispenser, rotates freely, ensuring sowing of seeds for any vegetable crops.

- The width of the row is set with special markers.

- The trapezoidal coulter, located at the base of the seeder, cuts a furrow and facilitates the shedding of soil into it after seed placement. Additionally, fertilizers can be applied. Thanks to the special shape of the coulter, lumps of soil do not get into it, and this in turn prevents jamming.

- The whiskers ensure free release of seeds along the step of the dosing shaft.

- A special seal helps reduce the germination time of seeds.

If necessary, seeders are connected into multi-row blocks for mechanized sowing using small wheeled tractors.

This is done using connecting strips. This method of joining is also advisable if it is necessary to organize work together.