Potatoes have always been considered one of the main vegetables in the kitchen. It is used for preparing first and second courses, desserts, etc. Growing this vegetable requires a lot of labor, because to get a good harvest you need to hill up the potato bushes several times a season.

Thanks to hilling, oxygen access to the roots improves, channels in the ground are destroyed, as a result of which less moisture evaporates, and the number of tubers increases.

Hilling up bushes is carried out in summer cottages mechanically using a hoe. However, this is a long and difficult process.

To help farmers and gardeners specializing in growing potatoes, a special tool called a hiller has been created.

Do-it-yourself manual plow. Housings

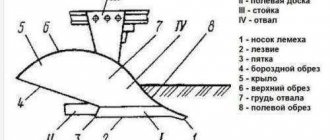

According to the number of bodies, plows are single-body, double-body and multi-body. The body consists of several parts:

- rack;

- working surface - ploughshare and blade;

- field board.

Body with share and blade

The ploughshare and blade are the working surface - this part is responsible for the quality and type of plowing. The soil layer is cut with a ploughshare, along which it rises to the dump. Here the soil crumbles and turns over. The degree of formation rotation depends on the shape of the dump. A field board is attached to the bottom of the body. Its task is to prevent the plow from moving towards the already plowed area.

If you are going to make your own plow, you need to choose a design based on the type of soil you are going to cultivate. Plow bodies are:

- Dump. For plowing with full or partial rotation of the formation. Such plows promote soil formation (grown plants are cut and placed at the bottom of the furrow, where they rot), and enrich the soil with oxygen (due to loosening).

- cultural - used for long-cultivated lands, crumbles the soil well, wraps to a medium degree;

- semi-screw moldboard bodies are used for cultivating virgin soil, plowing heavily turfed soil, it wraps the soil well, crumbles it moderately (models with an elongated feather wrap the layer completely);

- screw - good for cultivating virgin soil - the layer is completely wrapped;

Types of plowshare plow bodies

- Dumpless. Used in arid climates to conserve moisture and in regions at risk of wind erosion.

- Cutout. Suitable for soils with a small arable horizon. The lower part is only loosened, without rising outward, the upper part is removed and thrown onto the previous furrow, in which lies the podzolic layer loosened during the previous pass.

- With subsoiler. They are mainly used on marginal lands. The subsoil loosens the podzolic layer, which helps to increase the thickness of the fertile layer.

- With retractable chisel. Use on clay, loam, soil with a lot of stones. A chisel mounted on a stand in front of the plowshare prevents damage to the cutting edge. As grinding progresses, the chisel is pushed forward - for this there are special holes on it.

- Disk. It is used to treat waterlogged soils; it is also good when there are a large number of roots.

Tractor disc plow

Principle of operation

Gardeners know that hilling potatoes should be carried out several times a season. If the soil on the site is well-cultivated and loose, this contributes to a better process of oxygen exchange. The air entering the soil has a positive effect on the development and growth of plants. Timely loosening increases yield by 30–60%. Thanks to the design of the working body of the hiller, furrows with the required depth are obtained. The loosened soil falls off on both sides of the resulting ditch. Tubers are placed in it, and then the grooves are filled with earth. As the potatoes grow, you need to add a thick layer on top. This contributes to the formation of a large number of tubers. This addition is again ensured by loosening with the formation of a groove along the planted seedlings. This is achieved by the fact that the working parts of the hiller, when moving between the rows, cut off the top layer of soil.

In addition to potatoes, other crops that are planted in rows and require hilling, for example, tomatoes, eggplants, and peppers, can be processed with a hiller. Tool designs differ in grip width, manual or mechanized operating principle. The first option is quite primitive, requiring two operators, one of whom takes the front handle, and the other presses on the rear link. As a result of the efforts, the device goes deep into the ground, cuts the soil, and when moving inside the formation, leaves a noticeable trail of earth. The automated version is attached to a tractor or walk-behind tractor and is controlled by one operator.

Manual and automated hillers can be divided into the following types:

disc is a simple tool suitable for one person;

garden plow is a universal plow that requires the presence of two operators.

It is clear that disc options are easier to use; they are also often automated by coupling with motor vehicles. The ridges of the earth after the disc hillers are higher. There is also a negative point in these devices - the price. Compared to a plow hiller, it is four times higher. Externally, the tool looks like a frame with wheels on which disks are suspended. The distance between them can be changed in accordance with the width of the rows. The discs are set at a certain angle, which is not recommended to be adjusted relative to the vertical. Without a constant equal distance between the circles, the tool will pull sideways.

The simplest type of hand plow has a predetermined working width, wings (ploughs) shifted relative to each other, which are motionless. This is convenient if the row spacing has already been determined and the tool fits them. Another advantage of hillers with a fixed working width is the ability to use them with light cultivators weighing up to 30 kg. The advantage lies in its compactness, and the negative side lies in the limited work in wet areas. Here the tool will stick in the soil.

A hiller with variable working width is the most common option. The adjustment mechanism is simple, but it allows you to move or extend the wings, adjusting them to the desired width to the row spacing. The tool can also be automated, but only with heavy walk-behind tractors. The wings of such a hiller push the earth in both directions at once. After the tool passes, the part falls back into the line that it cuts. For a more efficient harrowing process, a more powerful walk-behind tractor is required, otherwise pulling the hiller will seem harder than working with a hoe or hoe.

Hand hiller. Manual potato hiller

Potatoes have always been considered one of the main vegetables in the kitchen. It is used for preparing first and second courses, desserts, etc. Growing this vegetable requires a lot of labor, because to get a good harvest you need to hill up the potato bushes several times a season.

Thanks to hilling, oxygen access to the roots improves, channels in the ground are destroyed, as a result of which less moisture evaporates, and the number of tubers increases.

Hilling up bushes is carried out in summer cottages mechanically using a hoe. However, this is a long and difficult process.

To help farmers and gardeners specializing in growing potatoes, a special tool called a hiller has been created.

Advantages and disadvantages of hillers

The use of mechanisms always allows you to increase labor productivity on farms and summer cottages.

Manual hiller

Advantages:

- reduces labor costs and increases farmer efficiency;

- can be a multifunctional tool that can additionally be used for loosening the soil, planting potatoes, and also during harvesting;

- in order to use the device, you need to purchase it, which means that material costs will be required for the purchase and further maintenance;

- When working with the device, you must follow safety regulations.

Flaws:

Types of potato hillers

Depending on the design, the following types of devices are distinguished:

Disc hiller

Propeller mechanisms make it possible to move the soil between the rows into the furrows.

The most common are lister and disk devices.

Lister mechanisms

Interesting! Devices of this type are available with a fixed working width. Otherwise they are called plows, as they look like a plow.

They are produced with an adjustable angle of attack (the angle of inclination of the cutting part of the hiller to the ground) and fixed.

Adjustable ones allow you to change the depth of loosening and, accordingly, the gripping area.

Advantages of the device:

- consumes less energy compared to disk devices;

- simpler in design;

- the price is less than for a disk device;

- It is light in weight, so it works great on low-power machines (walk-behind tractors and cultivators).

Lister hiller

Flaws:

- does not work well on wet and heavy soil;

- Potato planting should only be level, with strictly fixed row spacing.

Disc hillers

Structurally, they consist of two disks with a sharpened edge. As the hiller moves, the discs rotate and crush the soil. They have a convex shape. Due to this shape, the soil is simultaneously loosened and an earthen ridge is formed.

The disks are attached through ball bearings to the racks, which are located on a horizontal holding frame.

Note! They can be adjusted vertically, less often horizontally. With vertical adjustment, the angle of rotation of the disks changes, due to which the amount of earth needed to form the ridge also changes. Horizontal adjustment moves the discs vertically (raises or lowers). In this way, the angle of attack is adjusted.

Advantages:

- better performance of hilling, the ridges are smoother and higher;

- can be used with different row spacings;

- allows hilling on heavier soil.

The disc hiller can be used with different row spacings

Flaws:

- higher price;

- higher fuel consumption.

Depending on the volume of work performed and the degree of mechanization, the potato hiller can be:

- manual;

- automated.

Fact! Manual - designed to perform only hilling, automated - used to perform several types of work: hilling, loosening, planting, harvesting.

Manual - moves due to the fact that a person pushes or pulls the mechanism.

An automated potato hiller is an additional hanging device for a walk-behind tractor, cultivator or tractor.

Manual potato hiller

Allows you to process potato beds, regardless of the presence of a walk-behind tractor or a tractor. For manual types, the most common designs are lister and disk mechanisms.

Tips and recommendations regarding choosing a device

Many people mistakenly believe that price is the main criterion when choosing a manual hiller. Actually this is not true. You can pay several tens of thousands for a product that will not work well in a certain type of soil.

What kind of potato hiller do you use?

ManualHinged

Therefore, before purchasing, it is extremely important to pay attention to the following characteristics:

- Number of operators - single options are easy to operate, but push-pull hillers are better suited for deeper cultivation. One person completely controls the depth of the hiller, and the second exclusively pulls the plow.

- The size of the cultivated area - if it is 5-6 acres, then one can easily cope with the work. It is recommended to process 30-50 acres with a trailed hiller, which is mounted on a walk-behind tractor or mini-tractor.

- Soil type – for soft and loose soils a disc hiller is suitable, while for denser soils a plow is needed.

Always pay attention to the thickness of the metal and its quality. If too much pressure is applied, flimsy structures can sag and become deformed, which will cause difficulties in operation.

Always loosen the soil after heavy irrigation. It is more difficult to work on dried soil, especially when using a manual hiller.

Do-it-yourself manual plow for planting potatoes. Planting plow

A hand plow will help you plant potatoes without a shovel. To make it yourself, you will have to put in some effort. But they are worth spending, since the device turns out to be universal - the plow is used not only for planting potato beds, but also for subsequent hilling of bushes and loosening row spacing.

Since hollow pipes and sheet metal are used in the manufacture of the structure, you will need welding equipment, a gas torch or blowtorch, and an angle grinder.

To create a universal method of planting potatoes, follow this algorithm:

- a meter pipe with a diameter of 2.5 cm is filled with sand and closed with plugs;

- bend at an angle of 10-15 degrees at a distance of 30 cm from the edge, using a blowtorch; a stand is obtained, indicated in the drawing by position 3;

- Having removed the plugs, pour out sand (it is only necessary for neat bending of the pipe);

- a double-blade working element with a trimming knife is formed from pieces of metal and secured from the bottom of the rack with bolts, for which holes are pre-drilled in the pipe;

- control handle 4 is inserted into the pipe from above and secured with bolt 12; there should be several holes on the handle to create a telescopic retractable system;

- the front link 5 is shaped as shown in the drawing and welded to the rack; positions 9, 10 indicate the presence of a horny handle;

- Using brackets 7 and 8, a lanyard 6 is attached to the rod and riser, allowing you to adjust the level of attack of the knife.

Manual plow with traction

For ease of control of the plow, a strong neck-axillary tape can be attached to the base of the draft handles (position 11). It will allow the lead worker to evenly distribute his efforts when walking with the plow across the site.

Variety of models

On the market for agricultural products you can find a manual hiller “Druzhba”. It is equipped with adjustable wings that allow you to change the working width, and the addition of a front iron support wheel. The equipment is controlled by two operators. The dimensions of the product are 55 cm width and 48 cm height. The weight of the unit is 17 kg. It is produced in the city of Cheboksary, and its cost varies from 3,000 to 4,000 rubles.

Another version of the hiller is “Pull-Push”, which is popularly called a hand plow. It is unregulated. The design of the tool allows it to cut furrows, weed weeds, and hill up planted potatoes. The width of the product is 45 cm, and the height is 90 cm (including the handle). The unit weighs 7 kg. It is lightweight due to rubberized handles. The price of the tool is from 1500 rubles. It was produced in Kyiv.

A popular hand-held tool is the “Phenom”. The design provides the ability to work with both two and one operator. The hiller is adjustable both in the height of the handles and in the width of the processed ridge. As an additional tool for the hiller, a flat cutter is offered, which is connected with a handle using ordinary bolts. The dimensions of the product are 16x40x40 cm, and the weight is 10 kg.

Modern manufacturers offer flat cutters. This tool is a bent plate with sharpened edges. Using the equipment, you can remove weeds and loosen the soil. To weed several rows at the same time, several flat cutters are combined on a special hitch. On sale it is called a wide-row weeder.

Among the hand tools for loosening, the Tornado cultivator became famous. It has a simple design, which consists of curved teeth connected to the handle. In relation to the base they are turned counterclockwise. To work with the tool, it is enough to rotate it around its axis in a vertical position.

Manual hiller for potatoes. Homemade manual hiller from a bicycle

It is very difficult to hill up potatoes and beds with your own hands, but a homemade hiller makes life much easier for the farmer. The scheme for creating the unit is very simple.

Operating principle

The key part of a manual hiller is the cultivator or plow. It is he who will do what is done manually with a hoe or hoe - plow the soil. This plow, using its sharp end (“nose”), digs slightly into the soil and distributes it on its sides, covering the potato rows with soil.

If the hiller is a homemade model made from a bicycle, then the cultivator will be mounted on its frame. By slightly changing the structure of the unit, grabbing the steering wheel, you can control the device, directing it in the desired direction. The movement of the hiller itself is carried out due to a single wheel in the front part of the frame.

The essence of the work of a manual hiller can be summarized more briefly using the following algorithm:

- the cultivator crashes into the ground;

- the operator of the apparatus, using the steering wheel, directs the hiller in the desired direction and moves it forward;

- movement is carried out due to the existing wheel.

What is needed to create a hiller?

First of all, you will need certain equipment and materials:

- frame of an unnecessary bicycle (necessarily with a handlebar and one wheel 26-28 inches);

- welding fixtures;

- wrenches for nuts and bolts (if the cultivator will be screwed to the mount).

At the same time, you will need a little patience and the ability to work with a welding machine.

Preliminary actions

To begin with, prepare the bicycle frame: handlebars, saddle, pedals, and remove the rear wheel. The second wheel is disassembled and cleaned - only a metal rim is needed.

The metal rim penetrates the soil better, which is why the hiller will gain much greater stability and maneuverability than with rubber. Operating such a unit will become much easier.

The process of creating a hiller

The manufacturing process can be divided into 5 stages:

- The mount on the rear wheel is cut so that in the end there is only a “triangle” from the bicycle frame.

- The cultivator will be placed instead of the wheel, and it must be fixed there.

- Screw or weld the cultivator.

This should be done efficiently, because this part of the hiller will bear the greatest load. If the cultivator will be screwed on, then tighten the nuts as tightly as possible, otherwise the manual hiller will not last even a couple of days. This is where both nut and bolt wrenches come in handy. By operating them simultaneously, you will be able to secure the parts firmly and for a long time. - Next, the offset of the cultivator is adjusted (how far/close it is). This is done for the purpose of convenience during the hilling process, so as not to trip over the cultivator blades.

- The previously removed steering wheel is tightly twisted in place of the saddle.

Creation of a cultivator section

Creating a basic cultivator is quite simple. In fact, this is the same plow. Two plates are attached near the base, which form an angle directed forward (towards the wheel). As the hiller moves, the plates will divide the soil into 2 parts and hill up the potato rows with the raised soil.

However, the following requirements for this part should be adhered to:

- the total width of the blades should be equal to 2/3 of the row spacing of the potato bushes;

- the cultivator should go 10-15 cm underground;

- The angle of the blades should be close to 90 degrees - this way they will perfectly pick up the soil.

After carrying out a full range of work, you should end up with a full-fledged manual hiller that does its job perfectly while growing potatoes.

To familiarize yourself with the device in more detail and understand how to properly make such a homemade hiller, you can see the following

Useful tips

If you operate the hiller together, the hilling process will be significantly simplified and the efficiency of the work done will significantly increase. To operate a manual hiller in pairs, you need to attach a regular belt to the front of the unit.

You can attach some kind of weight to the back. This improves penetration into the ground, which, again, increases work efficiency. But at the same time, it will be more difficult for such a unit to move forward due to the increase in mass.

Other types of hillers

There are many schemes for creating hillers. Next we will consider other methods.

From a bicycle wheel and fork

If you have a front bicycle fork and a wheel for it, then you can create a hiller using the following technology:

- 2 pipes need to be welded at an obtuse angle;

- a bicycle handlebar is attached to a long pipe (it would be wiser to weld it so that it does not fall off during operation);

- A cultivator is attached/welded to the junction of both pipes, below.

The final output will look like this:

Creating such a hiller is much simpler than the one mentioned earlier. However, different types of units should be used for different purposes.

How to carry out hilling?

Hilling potatoes with a manual disk hiller is not difficult. The gardener does not need to bend over to the beds or perform any difficult actions - just “guide” the structure where it is needed, adjust the required width between the disks for a more efficient process.

A manual disk hiller not only tucks the soil under the bushes, but also cultivates the row spacing and loosens the soil. It is often used even after harvesting simply to break up lumps of earth and make it soft for subsequent sowings. You can also use the mechanism in the spring; it will make it easy to create smooth, comfortable beds for sowing or planting seedlings.

Do-it-yourself manual plow drawings. DIY hand plow

When planning to make a plow, you must first decide what type of soil you will have to plow with the unit and the type of crop you are going to grow.

During operation, the body of the unit experiences enormous loads, its working surface is exposed to the abrasive effects of the soil. Therefore, for the manufacture of working parts, it is necessary to use steel metal with a thickness of 3-5 mm.

It is advisable to provide a removable design of the ploughshare, so that it can be sharpened.

Considering all these properties of equipment operation, you can begin manufacturing a carbon steel blade. You can do this in three main ways:

- If the surface of the dump is cylindrical, then it is better to use sheet-bending equipment to produce a workpiece of the desired shape. A steel workpiece, cut by gas welding or metal shears, is fed to sheet metal bending equipment at an angle of 23-25 degrees and bent. Then the finishing is carried out strictly according to the template, which is pre-cut from thick cardboard.

- A metal pipe with a diameter of 55–60 mm and a wall thickness of 4–5 mm is also suitable for the manufacture of the unit. Cut out a template from cardboard, place it on the pipe and mark the dimensions. Treat with a hammer and, if necessary, fine-tune with sandpaper.

- This method is the most time-consuming and requires special skill. The workpiece is preheated in any way, but preferably in a forge, and then bent along a matrix.

The unit body is made of sheet steel with a thickness of at least 3 mm.

Experienced craftsmen recommend cutting out all the parts from cardboard and gluing them together, maintaining all sizes and angles. Only after you are completely satisfied with the cardboard model can you begin metal work.

Manufacturing

It is not at all necessary to buy this device in a store. We will tell you how to make different types of hillers for a walk-behind tractor with your own hands, including disk ones, based on drawings with dimensions and photos.

Lister hiller

To make a lister type of nozzle with non-adjustable width, we will use the following drawings and diagrams:

Diagram of a lister attachment.

Structural elements:

Lister hiller for walk-behind tractor.

To cut out the wings of the hiller, use the drawing in the picture below:

Template for cutting out halves of the product.

Step-by-step production:

- From sheets of metal 2 mm thick, you need to cut out two identical parts of the working tool using the template above. Next, the halves are bent and fastened together by welding in several approaches.

- The seams must be processed and cleaned.

- It is necessary to weld the base from three-millimeter sheets of metal.

- From sheets of metal 4-5 mm thick you need to make a bracket and a field board.

- You need to make a stand from a thick sheet of metal.

- For a double-row hiller, you can add a width adjustment function using hinge mechanisms. And to control the angle of inclination of the sheets, use rods.

Important! To make the stand, it is necessary to use metal with a thickness of 8 mm. This part of the structure must be very strong and reliable, since the heaviest loads fall on it. Design of a lister hiller

Design of a lister hiller.

Disc hiller

To create this type of attachment for a walk-behind tractor, you will need a drawing:

Drawing of a disk hiller.

Also prepare materials and tools for work:

- welding machine;

- Grinder;

- emery machine;

- electric drill with a set of drills;

- fasteners (bolts, etc.);

- two metal disks with a diameter of about 50-60 cm, steel thickness - about 3 mm;

- metal pipe 1 m long, 2.5 cm wide;

- adjustable adapters;

- screw lanyards – 2 pcs.;

- bracket;

- gas lamp.

Tip: to make discs, craftsmen often use metal lids from kitchen utensils, old discs from agricultural machinery, and even bottoms from gas cylinders.

Disc hiller at work.

Manufacturing process step by step:

- Sharpen the discs around the entire circumference.

- Using a hammer, the disks need to be given the correct shape - convex on one side and depressed on the opposite. It is due to this that they will be able to collect soil.

- It is necessary to make a T-shaped structure from the pipe. To do this, the elements can be fastened by welding or bolts.

- Using welding, it is necessary to connect the T-shaped leader, racks and tarlaps.

- To make a hiller with a fixed pitch, fasten the disks to a width equal to the row spacing. If it is a type with adjustable width, the discs must be secured using adjustable adapters.

- Secure the device to the walk-behind tractor using brackets, a leash, and bolts.

Important! The discs must be fixed strictly symmetrically. At the slightest deviation, the walk-behind tractor will move to the sides, working with it will be very problematic and ineffective. In this video you can watch how to make a disk hiller:

In this video you can watch about making a disk hiller:

Field plowing equipment

The modern fleet of mini tractors includes about two dozen devices, domestic and imported, differing in functionality, power, and price. Let's look at the most popular of them.

Motoblock "Neva"

A domestic unit from a well-known plant among summer residents. This is a powerful device that can handle any soil.

Among the advantages:

In addition, this type of walk-behind tractor provides the user with ample opportunities to choose the optimal speed and comfortable handle position. At the same time, according to reviews from gardeners, “Neva” has not proven itself very well when working with a plow (short plowing depth).

The disadvantages include high weight (more than 90 kg), insufficient stability on uneven ground, and high cost.

Motoblock "Salute"

The author of this device, the Salyut association (Moscow), did everything to make it as convenient to use as possible. Its center of gravity is low and the engine is moved forward, making it easier to control than the Neva and able to easily maintain balance when connecting a plow.

Another advantage is its low weight and maneuverability, allowing the Salyut to be used in small areas. It should also be noted that the handles of the walk-behind tractor are narrowed and can be rotated 180°, which makes it very convenient for cleaning work.

A significant drawback is the lack of a differential, which makes turning difficult and making the cart inconvenient to use. In addition, some varieties of Salyut are characterized by a high noise level.

Motoblock "MTZ"

The brainchild of the Minsk Tractor Plant attracts with its compactness and maneuverability. Despite its high weight, the device is perfectly balanced and therefore extremely stable.

The latest modification, MT3 09N, will become a universal gardener’s assistant, and if you purchase an additional adapter with a seat, the walk-behind tractor can be turned into a mini tractor. Other advantages include wide functionality, large fuel tank capacity, and high power.

It should be remembered that MTZ is more intended for processing large areas; it is unprofitable to use it in small areas. In addition, the unit is picky about the choice of soil: it is not recommended to use it on heavy soils.

Field plowing equipment

A walk-behind tractor, also known as a motor-cultivator, is widely used to facilitate heavy manual agricultural labor.

Before purchasing equipment for plowing a field, you must choose:

Choosing a walk-behind tractor

A mechanical self-propelled device with an engine is simply indispensable today for the following earthworks:

When choosing a walk-behind tractor, it is necessary to take into account the area of the area being processed.

The modern equipment market offers the following popular types of cultivators:

Choosing trailed equipment

To plant potatoes using a walk-behind tractor, you need trailed equipment.

Trailed equipment for walk-behind tractors:

Planting under the plow

Features of using a plow when planting potatoes:

You can plant potatoes using a plow in the following way:

The video shows how to plant potatoes with a walk-behind tractor under a plow. The video was filmed by the City& Country Style channel.

Planting with a disc hiller

Features of the disc hiller when planting potatoes:

Planting potatoes with a disc hiller

Application of potato planter

The potato planter consists of the following set of structures:

Features of using the potato planter:

Planting with a potato planter

Using a two-row hiller

Features of using a two-row hiller when planting potatoes:

Planting with a two-row hiller

Tuber preparation

The potatoes should be the same size. If the tubers are too large, they need to be cut, which will increase the risk of disease development and open access to pests.

Germination will take about a month. The planting material should be placed in a warm and bright room (+12-15 degrees). If dark spots begin to form on fresh sprouts, this indicates a disease. Tubers that are infected should be discarded.

Before planting, potatoes need to be soaked in stimulating and pickling solutions.

Important! It is not recommended to keep seed in solutions for a long time. It is better to lay the tubers on a flat surface, spray them with preparations and leave them to dry.

After the earth warms up to about +8 degrees, you can begin planting root crops.

Soil preparation

Pre-sowing work should begin with the laying of organic and mineral fertilizers in the autumn.

Stages of sowing in spring

Right before planting, you need to plow the soil to about 15 centimeters. For this procedure you will need a special attachment - a cutter.

Before planting the crop under the Neva walk-behind tractor, it is necessary to remove the wings of the unit. The main thing is to correctly configure all the equipment that is installed on the walk-behind tractor. This is necessary so that the car runs smoothly and requires little effort.

Advice! If you plow the soil well, you will not need to harrow the soil.

Hurming is necessary to ensure that the soil is saturated with moisture and oxygen. In well-loosened soil, the crops will sprout together.

It is at this stage that the walk-behind tractor will help facilitate the process of preparing the soil before sowing.

What is a walk-behind tractor?

A walk-behind tractor is a self-propelled mechanical device that can be used to automate the entire process of growing potatoes.

It is a unit consisting of the following main components:

- internal combustion engine;

- transmissions;

- chassis, consisting of an axle and two wheels;

- handles with which control is carried out.

In order for the walk-behind tractor to perform this or that work, additional equipment is attached to it.

Crop care

A walk-behind tractor and various attachments will make further care of the potato plantation easier.

Treatment after germination

The time from planting to the first potato shoots is the most important for the formation of full-fledged and healthy tubers. Germination will begin from the upper buds. The main thing that should not be allowed is breaking off sprouted branches. This will negatively affect the growth and development of potato fruits.

The role of the plow

After the first shoots appear, a weeder is used to weed and loosen the soil between the rows. It performs the tasks of a conventional plow.

Hilling

Accelerates the development of stems, destroys weeds and protects the plant from possible frosts. Performed 2–3 weeks after germination. A hiller is used for work.

Spraying with a walk-behind tractor

This can be done using a special sprayer, which is equipped with a pump.

Wire harrow for weeding

To remove weeds after sowing, but before the first shoots appear, a mesh weeding harrow is used, which is fixed to the frame of the walk-behind tractor and pulled across the field.

Advantages and disadvantages of homemade structures

A homemade potato hiller has the following advantages:

- Availability. Almost every gardener can do it. This does not require special knowledge or any skills. It is enough to understand the basic tools and be able to use them.

- Saving. Ready-made solutions are always more expensive. And taking into account that a person does not pay himself for the work, then we get a free option.

- Performance. A self-made device is not inferior in efficiency to its automated counterparts.

The only drawback is that safety and quality depend only on you. Therefore, do not be lazy to pay due attention to each stage of work, even if it seems insignificant. To obtain a quality product, use the appropriate parts