Variety of models

On the market for agricultural products you can find a manual hiller “Druzhba”. It is equipped with adjustable wings that allow you to change the working width, and the addition of a front iron support wheel. The equipment is controlled by two operators. The dimensions of the product are 55 cm width and 48 cm height. The weight of the unit is 17 kg. It is produced in the city of Cheboksary, and its cost varies from 3,000 to 4,000 rubles.

Another version of the hiller is “Pull-Push”, which is popularly called a hand plow. It is unregulated. The design of the tool allows it to cut furrows, weed weeds, and hill up planted potatoes. The width of the product is 45 cm, and the height is 90 cm (including the handle). The unit weighs 7 kg. It is lightweight due to rubberized handles. The price of the tool is from 1500 rubles. It was produced in Kyiv.

A popular hand-held tool is the “Phenom”. The design provides the ability to work with both two and one operator. The hiller is adjustable both in the height of the handles and in the width of the processed ridge. As an additional tool for the hiller, a flat cutter is offered, which is connected with a handle using ordinary bolts. The dimensions of the product are 16x40x40 cm, and the weight is 10 kg.

Modern manufacturers offer flat cutters. This tool is a bent plate with sharpened edges. Using the equipment, you can remove weeds and loosen the soil. To weed several rows at the same time, several flat cutters are combined on a special hitch. On sale it is called a wide-row weeder.

Among the hand tools for loosening, the Tornado cultivator became famous. It has a simple design, which consists of curved teeth connected to the handle. In relation to the base they are turned counterclockwise. To work with the tool, it is enough to rotate it around its axis in a vertical position.

The best options for manual models

The gardening equipment market offers a lot of options for hillers, from the simplest in the form of a hoe to more advanced ones. Each of them has its own characteristics that need to be taken into account before purchasing.

Tornadica

The latest development, which makes hilling potatoes ten times easier. It consists of long teeth twisted in a whirlwind, a handle that rotates and drives the teeth, and a connecting pipe.

To hill up, you need to place the device between the rows, lightly press the handle, adjusting the depth of cultivation, and turn it 60°. Processing one hundred square meters of potatoes takes about 20 minutes.

| Advantages | Flaws |

| Durable metal that does not corrode or deform | Fixed handle height |

| Easy to use, even an elderly person can handle it | |

| Removes weeds from the soil | |

| Suitable for all types of soil | |

| Not afraid of stones | |

| Used for all types of gardening work |

The average price of a hiller is 1800 rubles. Reviews about it are only positive. Customers note that the tornadika can be used for all types of garden work; it does a good job of uprooting weeds along with the roots.

Miracle hiller

It works on the “push-pull” principle; maximum efficiency is achieved when operated in pairs. It has discs located at an angle, which speeds up the hilling process. Used on all types of soil, including loams and sandstones. It is recommended to carry out work after the soil has been well irrigated.

| Advantages | Flaws |

| High-strength steel, does not deform under strong pressure | Not identified |

| Possibility of adjusting the height of the handles and the angle of inclination of the disks relative to the axis | |

| Productivity up to 10 acres per hour with pair control | |

| Takes up little space when assembled | |

| Does not corrode | |

| Does not require special treatments |

The average cost of such a hiller is about 2800 rubles. In reviews, buyers note that the unit performs well in soils that are particularly overgrown with weeds.

Farmhand

It is a structure consisting of a handle-holder, a support-moving wheel and a direct attachment for hilling. Suitable for single use, it shows excellent performance. Service life is more than 20 years.

| Advantages | Flaws |

| Durable stainless steel, unpretentious to storage conditions | Relatively high price |

| Includes 3 nozzles, used depending on soil type | |

| Easy to operate, no need to involve a second person | |

| In 1 hour you can process about 15 acres without straining | |

| All parameters are adjustable for ease of operation |

The cost of the hiller is about 4,000 rubles, but it is so simple and fast to operate that it pays for itself in the first season. In reviews, buyers indicate its versatility and the possibility of use in wetlands.

Manual hiller

The simplest, most affordable and most primitive to use manual hiller. Presented in the form of a hoe with a long handle. Suitable for working in small areas, since for good hilling you need to apply force.

| Advantages | Flaws |

| Primitive design | Non-adjustable handle |

| Low price | You need to apply force |

| Wooden handle | |

| Good quality metal work element | |

| No requirements for storage conditions |

This option costs about 800 rubles; buyers note its versatility, but often complain about poor fastening of the working element to the handle.

Manual hiller for potatoes: purpose

A potato hiller is an indispensable household assistant for anyone who has a vegetable garden. With its help, you can hill up a large plot of several hundred square meters in a short time. Its main advantage is that you can do it yourself

Important! In regions with low temperatures and high humidity, frequent hilling of potatoes is required. This is necessary so that excess water is removed, the soil is heated and the vegetables are saturated with air.

In regions with high temperatures and low humidity, this procedure, on the contrary, is carried out much less frequently. After all, this removes all the moisture from the soil, which may already be insufficient.

Do I need to hill up potatoes?

Hilling is carried out to maintain moisture and normal soil temperature, where the potato root system is located, which is where the tubers are formed. Humidity and stable temperature are one of the key factors affecting crop yield. During hilling, the soil is simultaneously loosened, and this is also important, because at the same time the soil is saturated with oxygen. A sufficient amount of oxygen helps to increase the mass of tubers.

Previously, a wooden plow was used for hilling and loosening beds; now smaller versions are used - manual hillers.

Materials and tools for work

To make a potato hiller with your own hands, you will need drawings and some materials that are not difficult to obtain.

It is better to prepare everything you need in advance so that you can make a hand plow and start working with it as quickly as possible.

- Be sure to purchase or rent an angle grinder and a welding machine. You will need to grind uneven seams with a grinder, and a welding machine will help connect the individual parts as firmly as possible. Don't forget to wear gloves and a protective mask to make it safe to work with such tools.

- The tube, which is empty inside, will serve as the handle of the plow. It is better to give preference to a water pipe with a diameter of about 1 inch. Its length depends on the height of the person who will work the plow. Practice shows that 1 m is quite enough. But for traction you will need a tube with a cross-section of about ¾ inches.

- So that the pipes can be bent and soldered together, you will need a special apparatus. But if there is none, then an ordinary gas burner is quite suitable, over which you can heat the material and then bend it.

- It will be very good if you can get a lanyard. This part perfectly connects the front link with the vertical post of the plow. But it can also be replaced with a piece of steel plate, on which you need to pre-drill several holes so that you can subsequently adjust the angle of inclination of the hiller.

- For plow moldboards you will need dense pieces of sheet steel. It is best to give preference to steel, the thickness of which is about 2 mm. Thinner sheets will begin to bend after a while, as a result the entire hiller will have to be redone.

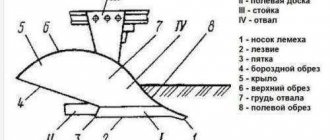

And now regarding the actual process of assembling a potato hiller. First, you need to carefully study the available drawings, which show a diagram of a beam without disks (Figure 1). If the principle of connecting the main parts of the plow is more or less clear, you can safely proceed directly to the assembly process itself.

Other tool types:

- To the tractor - process automation. This design can immediately remove all weeds from the treated area. In practice, it has been proven that after working with this type, potato yield increases.

- for a walk-behind tractor - also for automation of work. In principle, this is not a separate type, but the tool can be installed on this vehicle.

Which device is better is up to you to decide. It depends on your goals, the desired speed of operation and the functionality of the devices.

Why do you need a hiller?

Hilling increases potato yield

Hilling potatoes is a very important procedure for the growth of vegetables. Those who neglect to carry out this process get a low and small harvest. Hilling up using a technical method helps to get rid of most weeds between the rows. The grass between the holes can be pulled by hand. It does not take a lot of time. The remaining weeds between the rows of potatoes from technical processing can be easily removed using a regular hoe.

Advantages of processing potatoes using a technical method, using a manual, tractor plow or hiller for a walk-behind tractor:

- On average, productivity can increase by up to 30%.

- With timely loosening of the soil, it is actively saturated with oxygen. This allows the tubers to absorb more nutrients from the ground.

- Potatoes grow faster with the right air access.

Are there any disadvantages when hilling using additional equipment?

Advantages and disadvantages of hillers

The use of mechanisms always allows you to increase labor productivity on farms and summer cottages.

Manual hiller

Advantages:

- reduces labor costs and increases farmer efficiency;

- can be a multifunctional tool that can additionally be used for loosening the soil, planting potatoes, and also during harvesting;

- You can freely buy a potato hiller in a store or make it yourself.

Flaws:

- in order to use the device, you need to purchase it, which means that material costs will be required for the purchase and further maintenance;

- When working with the device, you must follow safety regulations.

Tips and recommendations regarding choosing a device

Many people mistakenly believe that price is the main criterion when choosing a manual hiller. Actually this is not true. You can pay several tens of thousands for a product that will not work well in a certain type of soil.

What kind of potato hiller do you use?

ManualHinged

Therefore, before purchasing, it is extremely important to pay attention to the following characteristics:

- Number of operators - single options are easy to operate, but push-pull hillers are better suited for deeper cultivation. One person completely controls the depth of the hiller, and the second exclusively pulls the plow.

- The size of the cultivated area - if it is 5-6 acres, then one can easily cope with the work. It is recommended to process 30-50 acres with a trailed hiller, which is mounted on a walk-behind tractor or mini-tractor.

- Soil type – for soft and loose soils a disc hiller is suitable, while for denser soils a plow is needed.

Always pay attention to the thickness of the metal and its quality. If too much pressure is applied, flimsy structures can sag and become deformed, which will cause difficulties in operation.

Always loosen the soil after heavy irrigation. It is more difficult to work on dried soil, especially when using a manual hiller.

Varieties and features

Depending on the method of operation, potato hillers are:

- Manual - consist of a working mechanism and a holder. By pressing on the handle, the desired hilling depth is selected, while the human movement determines the speed of work.

- Mounted (semi-automatic) - they are a ready-made structure that is attached to a walk-behind tractor or mini-tractor.

The most common are manual ones, since they are cheaper and simpler in design, and do the same job. The difference with mounted ones is only in the need to use manual labor, while semi-automatic machines do the main work without the participation (but with control) of the gardener.

Taking into account the design features, hillers come in the following types:

- Plow – has 1, 2, 3 mini-plows that go deep into the soil and loosen it.

- Disc – the design contains 2 discs, which, when moving, crush the soil, making it looser.

- A tine is a working mechanism in the form of closely spaced metal rods, which, without lifting the soil layer, saturate it with oxygen.

Depending on the number of hiller operators, they can be single or double. In the first case, the mechanism is designed in such a way that all the work is done by one person. Paired options suggest that one person adjusts the depth of the hiller by pressing on the working mechanism, and the other sets the mechanism in motion (traction force).

Manual hiller for potatoes. Homemade manual hiller from a bicycle

It is very difficult to hill up potatoes and beds with your own hands, but a homemade hiller makes life much easier for the farmer. The scheme for creating the unit is very simple.

Operating principle

The key part of a manual hiller is the cultivator or plow. It is he who will do what is done manually with a hoe or hoe - plow the soil. This plow, using its sharp end (“nose”), digs slightly into the soil and distributes it on its sides, covering the potato rows with soil.

If the hiller is a homemade model made from a bicycle, then the cultivator will be mounted on its frame. By slightly changing the structure of the unit, grabbing the steering wheel, you can control the device, directing it in the desired direction. The movement of the hiller itself is carried out due to a single wheel in the front part of the frame.

The essence of the work of a manual hiller can be summarized more briefly using the following algorithm:

- the cultivator crashes into the ground;

- the operator of the apparatus, using the steering wheel, directs the hiller in the desired direction and moves it forward;

- movement is carried out due to the existing wheel.

What is needed to create a hiller?

First of all, you will need certain equipment and materials:

- frame of an unnecessary bicycle (necessarily with a handlebar and one wheel 26-28 inches);

- welding fixtures;

- wrenches for nuts and bolts (if the cultivator will be screwed to the mount).

At the same time, you will need a little patience and the ability to work with a welding machine.

Preliminary actions

To begin with, prepare the bicycle frame: handlebars, saddle, pedals, and remove the rear wheel. The second wheel is disassembled and cleaned - only a metal rim is needed.

The metal rim penetrates the soil better, which is why the hiller will gain much greater stability and maneuverability than with rubber. Operating such a unit will become much easier.

The process of creating a hiller

The manufacturing process can be divided into 5 stages:

- The mount on the rear wheel is cut so that in the end there is only a “triangle” from the bicycle frame.

- The cultivator will be placed instead of the wheel, and it must be fixed there.

- Screw or weld the cultivator.

This should be done efficiently, because this part of the hiller will bear the greatest load. If the cultivator will be screwed on, then tighten the nuts as tightly as possible, otherwise the manual hiller will not last even a couple of days. This is where both nut and bolt wrenches come in handy. By operating them simultaneously, you will be able to secure the parts firmly and for a long time. - Next, the offset of the cultivator is adjusted (how far/close it is). This is done for the purpose of convenience during the hilling process, so as not to trip over the cultivator blades.

- The previously removed steering wheel is tightly twisted in place of the saddle.

Creation of a cultivator section

Creating a basic cultivator is quite simple. In fact, this is the same plow. Two plates are attached near the base, which form an angle directed forward (towards the wheel). As the hiller moves, the plates will divide the soil into 2 parts and hill up the potato rows with the raised soil.

However, the following requirements for this part should be adhered to:

- the total width of the blades should be equal to 2/3 of the row spacing of the potato bushes;

- the cultivator should go 10-15 cm underground;

- The angle of the blades should be close to 90 degrees - this way they will perfectly pick up the soil.

After carrying out a full range of work, you should end up with a full-fledged manual hiller that does its job perfectly while growing potatoes.

To familiarize yourself with the device in more detail and understand how to properly make such a homemade hiller, you can see the following

Useful tips

If you operate the hiller together, the hilling process will be significantly simplified and the efficiency of the work done will significantly increase. To operate a manual hiller in pairs, you need to attach a regular belt to the front of the unit.

You can attach some kind of weight to the back. This improves penetration into the ground, which, again, increases work efficiency. But at the same time, it will be more difficult for such a unit to move forward due to the increase in mass.

From a bicycle wheel and fork

If you have a front bicycle fork and a wheel for it, then you can create a hiller using the following technology:

- 2 pipes need to be welded at an obtuse angle;

- a bicycle handlebar is attached to a long pipe (it would be wiser to weld it so that it does not fall off during operation);

- A cultivator is attached/welded to the junction of both pipes, below.

The final output will look like this:

Creating such a hiller is much simpler than the one mentioned earlier. However, different types of units should be used for different purposes.

Preliminary actions

To begin with, prepare the bicycle frame: handlebars, saddle, pedals, and remove the rear wheel. The second wheel is disassembled and cleaned - only a metal rim is needed.

The metal rim penetrates the soil better, which is why the hiller will gain much greater stability and maneuverability than with rubber. Operating such a unit will become much easier.

How to make a hand plow

Making a simple marker is easy. It is enough to have a regular board and wooden pegs on hand.

A marker for planting potatoes is a wooden stake with a diameter of about 65 mm. The height of the stake must be at least 90 centimeters. A transverse strip is attached at a height of about 15 cm from the sharp edge. It will serve as a stop that limits the depth of the hole.

Before planting with this tool, you must first mark the locations of the holes using a rope. The ropes are pulled along the rows at a distance of 40-80 cm from each other. Everyone sets the distance independently; it depends on whether the hilling will be carried out with a walk-behind tractor or manually.

Why is a homemade device better than a purchased device? In the marker you can set the exact distance, which will be equal to the distance between the wheels of the cultivator or tractor.

Pegs are made from thick spruce branches. They are processed, sharpened, and made into handles. Wooden transverse strips are nailed to them. Make a distance of about 60-65 centimeters between the stakes if the planting will subsequently be processed with a cultivator or mini-tractor. The distance should be no more than 55 cm if the processing is manual.

The bottom board should be with a reserve; a note is made on it using a narrow strip at the same distance as the stakes. It will help determine the beginning of the pits.

How to use this device? Place the device on the ground, holding it by the handles in front of you. Press down to make holes. You immediately get two ridges of holes, the third will become a note, they follow it in the opposite direction. The second person will follow the marker and plant the potatoes.

A hand plow will become a homemade machine for planting, hilling, and loosening the soil. It can be operated by two people. It takes effort to make a plow.

For production you will need:

- Meter-long hollow pipe with a diameter of 2.5 cm.

- Hollow pipe with a diameter of ¾ inch.

- Metal sheet 2 mm thick.

- A metal plate with holes or a lanyard.

- Gas-burner.

- Bulgarian.

- Welding machine.

The large pipe is bent, departing from the beginning by 30 centimeters. To facilitate this procedure, you can use a pipe bender. Use a blowtorch if there is no pipe bender.

The small pipe needs to be bent. To adjust the height, you need to make holes on the vertical post and on the top edge. The height of the stand is made individually so that the person who will hold the plow will be comfortable. It can be adjusted with bolts.

To plant potatoes in a field or bed in a short time, it is best to use automated or manual equipment. In any case, planting with a potato planter takes less time than doing all the work simply by hand.

A preliminary drawing of the devices will visually show how to make a device for planting tubers. Most of the special equipment makes it possible to immediately determine the distance between the holes and the number of rows processed simultaneously. Easy-to-use homemade machines can be carried by hand or attached to a motor cultivator.

You will need:

- steel sheet profile to form the base;

- several pipes with a diameter of 5 centimeters for a “lift” or cone;

- fastenings connecting the device to the walk-behind tractor.

In this case, the marker drawing for the potato planter can be changed depending on the selected size and depth of planting of tubers. The diameter of the “elevator” pipes varies if necessary to fill vegetable gardens with small potato seedlings.

The diameter can be changed using a simple manual planting cone.

Making any potato planter begins with drawing up a drawing. Next, elevators are formed. When the cones are made, the distance that will separate each planted tuber is determined. It will be 25–50 centimeters depending on the selected variety and soil type.

The next step is to determine the height of the stand, depending on the parameters of the beds. If the structure is placed on a platform, it is connected with M8 bolts with nuts and wheels. As a base, you can use a device for a trimmer or a walk-behind tractor, on which platforms with cones and a container for tubers are attached.

To determine the length of the hand-held device used to carry the container with tubers, the height of the owner of the site is taken into account. For ease of use, the handle of automated or manual equipment is placed so that it is convenient for the worker to perform all actions with a straight back.

Hilling potatoes: when and how to do it on a walk-behind tractor

To increase the yield, farmers strive to apply fertilizers in a timely manner and fight pests and plant diseases. Weeds cause significant damage to agricultural crops, deplete the soil and deprive the plant of moisture. Hilling up potatoes with a cultivator destroys more than half of all weeds and completely destroys their root system

We invite you to learn about the importance of regular loosening of the soil, which includes the following aspects:

- promotes the full growth and development of tubers;

- improves oxygen access to the plant root system;

- helps protect tubers from parasites;

- reduces the likelihood of damage to root crops from sunlight.

Experienced farmers recommend starting to hill up potatoes with a cultivator after rain or heavy watering, when the top layers of the soil have dried out. First, it is worth weeding the weeds on the site and collecting them. When cultivating row spacing with a motor cultivator, you need to adhere to the following sequence of work, namely:

- place equipment between rows of bushes;

- start the engine and engage a lower gear;

- start moving between the plants, adhering to the central location of the device and the desired depth of immersion of the hiller;

- when hilling, you must constantly monitor so that the cultivator does not damage the potato sprouts;

- Having passed the row to the end, they begin to process the next row spacing.

We invite you to watch a video of hilling potatoes with a cultivator:

Agronomists recommend mandatory three-time hilling. We invite you to familiarize yourself with the timing of the procedure:

- It is recommended to carry out the first hilling with a cultivator when the plant branches reach a length of about 10 cm. It is especially worth doing work in the beds if the potatoes were planted early and night frosts are possible. Hilling will protect the shoots from freezing.

- The second procedure is carried out 20 days after the first hilling, before the bushes begin to flower. It is called the budding period. If loose soil surrounds the entire bush, the plant will receive more moisture and the fruits will develop well.

- The third hilling is carried out after the plants have flowered and its purpose is to loosen the soil during the period of tuberization. Chernozem is a heavy soil, and if it is made loose, it will be easier for the tubers to develop and they will have the correct shape and a beautiful presentation.

You need to be very careful when cultivating the soil between rows of potatoes.

A motor cultivator is a fairly powerful device that can cause irreparable harm to a crop if handled carelessly. It is strictly forbidden to run into potato bushes and immerse the hiller too deeply

If the potato tops have grown significantly, you should postpone the procedure and perform hilling manually.

How to make a hiller with your own hands

How to make a potato hiller with your own hands? To do this we need the following tools:

- hollow water pipes: length - 10 cm, diameter 1 inch;

- another similar pipe, but with a diameter of 3/4 inch;

- sheet steel 1-2 mm;

- lanyard or steel plate;

- pipe bender or gas torch;

- welding tools;

- Bulgarians.

This is an approximate list of tools, depending on what type of hiller you want to make, it may change.

The device can be adjusted in several ways:

- By height. Due to the telescopic mechanism in the center. A smaller pipe will be mounted into the central pillar pipe, which will act as a rear linkage. This design is very comfortable to use, because it can adapt to any person’s height.

- We change the angle of attack by tilting the central post relative to the ground. We get this opportunity if we change the angle between the front link and the vertical post. If your design does not have a lanyard, then you can change the angle by changing the position of the plate.

We start making a homemade manual potato hiller with vertical stands

We take a 10 cm pipe and measure about 4 cm from the end. At this distance we should make a slight bend. Approximately - 15 degrees. The most comfortable and easiest way to do this is with a pipe bender - a tool specifically designed for this purpose. Of course, not everyone has such a device, so we’ll tell you about a more affordable way to complete this step.

We fill the pipe tightly with sand or earth - whatever is freely available. We insert plugs so that all the mixture does not spill out. Using a blowtorch or any other heating element, we make the bend we need. Due to the fact that there is a mixture of sand or earth inside the pipe, it will not bend and will maintain its ideal parameters.

Let's move on to making traction

A homemade manual potato hiller has a built-in rear pull. It has the shape of the letter "Pe". In our design it will be of the following dimensions: 5 cm wide and 2 cm long. Note that if you change this value for one engine, you must do the same for the others. We attach a 3 cm long pipe to the center of the fork, vertically. Then we will insert it into the vertical rod

We attach a 3 cm long pipe to the center of the fork, vertically. Then we will insert it into the vertical rod.

We now need to bend a pipe with a diameter of 3/4. This can be done using the method already discussed above. If you have other options, you can use them. In this case, the main thing is one result.

Let's take care of the ability to change the height. We make a hole at the top and in the vertical part of the mechanism. And now, by changing the bolt, we can adjust the height. So, a person of any height will be comfortable working with the tool.

We have made the rear link, now we need to move on to making the front link. It is made in the form of a fork, like the rear link, differing only in size. The handles should be of such length that a person can comfortably stand between the handles.

For ease of use, we will also add an elastic belt that can be worn on the shoulders and chest. This design will reduce the load on the hands and preserve the strength of the person working with the tool.

Dimensions: handles - 6 cm, vertical part - 7 cm. On the vertical part of the fork at its end you need to make a hole with which it can be secured to the rack.

Let's move on to adjusting the angle of attack. The best option is a lanyard.

We count 3 cm from the bottom of the vertical post and mount a 25x25 cm corner in this place. We count 0.3 cm from the position of the fork and then do the same. And we repeat the procedure to the vertical post above our first corner.

The last step is the trimming knife.

It is this mechanism that takes the entire load and reduces resistance in the soil during operation.

For the knife, choose carbon steel. You need to cut the arrows and sharpen them at an angle of 45 degrees. Such parameters allow our mechanism to remain sharp and fully cope with its tasks.

Now you need to start welding the knife to the lower end of the vertical post. Our DIY potato hiller is now ready!

https://youtube.com/watch?v=1WnBUHf8Ds0

Reviews

A device for hilling potatoes is very popular among summer residents, and especially if it is made with your own hands. Numerous reviews prove this. Let's present you some of them:

“A homemade potato hiller is probably the best thing we have among all the gardening devices. This design saves so much effort and time. Previously, they even wanted to give up having a vegetable garden, because it requires a lot of dedication. A neighbor recommended a hiller to us. Accordingly, they wanted to buy it, but my husband made it himself. They also added a special belt, so now it’s generally comfortable to work with. From practice: this year we got 2 times more harvest than last year, when we used a hoe and, accordingly, did this work in bad faith.”

“I never thought that a potato hiller would bring me so much joy! We discovered this device recently, which we regret: how much time we could have saved. Our vegetable garden is very large; we had to ask our children and grandchildren to do all the work, because we couldn’t do it ourselves. Now we have solved at least one problem - hilling potatoes, which was very difficult if you used a shovel or hoe. We looked at how to make a homemade potato hiller and the next day we tested our invention. It seems to me that our mechanism is even better than the store-bought one. We designed it taking into account our own characteristics.”

I can’t imagine how we managed before without such a structure. A manual plow for hilling potatoes significantly saves time and effort. Of course, there are many outstanding inventions in the world, but for summer residents and gardeners this mechanism is probably the best thing that has been invented in recent years. There is a lot of equipment on the market for professional use, which costs accordingly. And you can make a tool for hilling potatoes yourself, which is what we did. For the second season we can’t do without him. The last time I noticed good progression in increasing the yield.

Remember that a manual potato hiller must be of high quality. Therefore, carry out all stages of work conscientiously and do not forget to select good parts and materials.

Self-production

The tool is simple to make yourself. To make a hiller yourself, you need drawings and skills in working with metal. It is advisable to have the following tools:

- welding machine;

- gas-burner;

- angle grinder;

- drill;

- sharpener

An alternative would be homemade hillers, which can be used with any walk-behind tractor and cultivator. To make a part, you need a steel sheet from which the base is made. The pipe will act as a bracket. The entire load will be borne by an element called a rack. For the wings you need two sheets of the same size. If the hiller is adjustable, then hinges are attached to the base of the wings. For better rigidity, the products are bent at a slight angle. A two-row hiller differs from a simple hiller in the increased size of the bracket. It should be sufficient to attach two pairs of plows (wings).

The process of making a plow hiller

For the simplest plow hiller you will need the following materials:

The hiller is assembled in stages:

It is quite possible to make a plow hiller from scrap materials available at any dacha. An old children's bike will do. The tools you will need are metal scissors or a grinder, a welding machine, a vice and a drill.

Preparing for work

To make a homemade potato hiller, it is recommended to prepare drawings, appropriate materials and tools. If you don’t have a grinder and a welding inverter, you can rent them. A grinder will be needed for grinding uneven seams, and with the help of a welding inverter you can connect individual elements as efficiently as possible.

As the main handle of the hiller, a hollow tube of the required diameter and length is used, which will depend on the height of the person. The best option is to use a water standpipe with a diameter of 1 inch. Often one meter of such a tube is sufficient. For front and rear traction, it is better to take tubes with a diameter of ¾ inches.

In the process of making a hiller, you will need to bend and solder pipes to each other, so you need to prepare a special device. But in the absence of one, you can use a regular gas burner, over which the material is first heated and then bent at a certain angle.

You will also need to find a screw-type lanyard that can connect the front link and the vertical post of the plow. Instead, you can use a fragment of a steel plate, in which several holes are drilled in advance to further adjust the angle of inclination of the homemade unit.

To make dumps, it is recommended to use fragments of sheet steel 2 mm thick. It is not advisable to use thinner steel, since after some time such dumps will begin to deform and the device will have to be made again.

To understand how to make a potato hiller with your own hands, you need to familiarize yourself with the specific drawing in more detail and understand the principle of connecting all the components of the unit.

Making a hand plow

Plant potatoes without straining your back

Homemade manual plows are often used for planting potatoes in small gardens and dachas. The design of such a tool allows you to dig a hole using only one leg and arms, without bending your back.

The most popular option is the Vyatka Plowman plow (Monk Gennady’s shovel)

Such a device can be adjusted in height, which is important for user convenience. It has a wide lever for grasping with your hands and a regular blade, like a shovel

Advantages of the Vyatka plowman

Gennady's father's shovel has the following advantages:

- ease of performing work (the back always remains straight, all actions are performed with the hands);

- digging speed is 4 times higher than when using a conventional shovel;

- one use of the tool “pulls out” 2 times more earth than with conventional devices;

- With a slight turn of the lever, the earth is tilted to the side, which is convenient for such a task.

In addition, the advantage of such a tool is that it is suitable for any type of soil. The main thing is to avoid mistakes when assembling the plow, act step by step according to the instructions and drawings, and also use only high-quality materials during construction.

How to do

To make such a tool, you will need a handlebar from an old bicycle, a metal pipe, fittings and a sheet of cold-rolled stainless steel, 2 mm thick. The tools you will need are a welding machine, as well as a grinder or a metal file. The process of making a plow is as follows:

- The pipe is cut (along the ground). This is the basis of the shovel, its dimensions should be user-friendly. You can also take two pipes of different diameters and install a spring, which will allow you to adjust the height of the frame for several people.

- A bicycle handlebar is welded to one end of the pipe.

- A ploughshare is created. A part of the workpiece is cut out to known dimensions, bent and welded to the bottom of a metal pipe so that the end of the plow base protrudes 5-10 cm.

The process of planting potatoes with a hand plow takes only 10-20 seconds. Under pressure from the foot, the shovel digs into the ground and when the lever is turned, the soil is tilted to the side. For convenience, it is better to throw potatoes into the holes of another person. So, the process of planting potatoes with a plow will go faster.

As a hiller, such a tool is not used. His specialization is narrow. The shovel is carried manually. If you need to plant large areas, it is better to make a device with shares and a wheel. In addition, you can build a two-row tool.

Homemade option

If you have the desire and opportunity, you can make a hiller with your own hands.

To do this, you will need everything that is in the garage or can be bought at a flea market for pennies:

- Wheelbarrow wheel - the larger the diameter, the more convenient it is to work with it in loamy and loose soils.

- Metal pipe - acts as a connection between the handle and the working mechanism.

- A handle that controls the pressure force and the depth of loosening - an ideal option is a bicycle handlebar.

- Working element - it is best to work with plow-type hillers. It can be made from a sheet of stainless steel or purchased separately. As an alternative, use a brush made of metal rods, which you can weld yourself.

- Brackets and hinges - help connect the elements of the hiller and adjust the height and position of the handle relative to the soil surface.

The work cannot be done without a welding machine, grinder and drill. They will help you cut metal, apply seams and connect the necessary elements to each other.

It is not recommended to start work without thinking through the small details and details of the device. You should first work out the drawing, displaying the parameters of all elements.

It is important to consider the following nuances:

- The height of the handle-holder and the possibility of its adjustment - you need to pick up any stick and imagine that it is the handle of a hiller. Lower it to the desired height, determining the maximum comfortable grip width and length to the ground.

- Type of working element - the simplest option would be to take two disks and place them on the axis.

Expert opinion

Mityuk Stefania Bogdanovna

All details should be written down on paper, and then an indicative drawing should be made. According to these data, the hiller will be assembled, and if there are errors and serious errors, this may negatively affect productivity.

When the drawing is ready, it is necessary to adjust all structural parts to the desired size. Next, assembly occurs: the wheel is installed on the shaft, the main pipe and handle are welded. Check the resulting version to ensure that the height is suitable. A vertical hinge is attached to the support shaft and holder, which holds the main hilling element.

Hilling process

The process itself is a treatment between rows of potatoes, when soil is raked onto the stem on both sides, forming a mound. The higher the bush is hilled, the greater the harvest will be. For this process, many devices are used, ranging from a hoe to a tractor. For small home garden beds, a hand tiller will be sufficient. Another option is an electric hiller, namely a walk-behind tractor, but only if the bed is large.

There is no need to rush right away; first you need to understand how the hiller works. Having reached the end of the row, they turn the hiller and return along the new row spacing. All potatoes are processed this way.

Important! The hiller must pass clearly in the center of the row, otherwise there is a risk of damaging the potato stems.

Choosing a prototype

Hilling in general is a type of soil cultivation and is most often carried out with a conventional cultivator with replaceable working parts. The exception is hilling potatoes. In order for potatoes to form more large nutritious tubers, their rows are made wide (0.5-0.6 m), and the bushes are hilled high. Therefore, a potato hiller is a specialized mounted tool. Another specific case is the hilling of crops grown in narrow beds. Specialized cultivators for narrow rows exist, but in private household plots you can almost always get by with a regular cultivator with minor modifications, see for example. selection of videos:

Active or passive?

In large agricultural machinery, they often work with active hillers, the working parts of which are driven into rotation by the power take-off shaft of the traction unit. Walk-behind tractors and mini-tractors for private household plots and small farms are on sale, but in practice it turns out that an active hiller for them increases the productivity and quality of work slightly, but its cost and fuel consumption increase significantly, and the life of the engine is exhausted faster.

The reason is the engine. There are no mini-potatoes or tomatoes - we need edible ones. A mini-hiller should turn over soil per meter of row as much as a large one; the same amount of energy is needed for this. Taking 10 kW for a 5-hull hiller from a 100 kW diesel engine is not a problem, but giving 2 kW to a single-hull 6-10 kW engine will be at the limit of possibilities.

There is one more significant circumstance. Tractor diesel engines have a special design, although this is only noticeable to an engine specialist. Their liter power is small, but the engines themselves are very responsive, with a soft external characteristic, so the power output to the mounted unit has little effect on the specific fuel consumption in g/kW*h. It is difficult to install the same motor on a walk-behind tractor because the required performance characteristics are obtained only with a sufficiently large displacement of the engine. But even if this obstacle can be overcome, the motor will still turn out to be too expensive, heavy and bulky.

Large agricultural farms consume tons of fuel; Private household plots and small farms - in liters. But even here the engine of the walk-behind tractor must maintain a uniform traction force, adapting itself to the heterogeneity of the soil, because Processing errors are unacceptable in any case. Therefore, mini-agricultural machinery is equipped with engines, carburetor or with fuel injection, which are obviously power-hungry and designed for the speed of movement of the unit, approx. equal to walking speed. In this way, it is possible to minimize the costs of mechanization as a whole, but the external characteristics of the engine necessary for “painless” power take-off are no longer obtained: the engine is strained, burning an excessive amount of fuel and itself. Therefore, further we will limit ourselves to considering only passive hillers (without transmitting power directly to the working element), which load the source of traction force as little as possible.

Landing technology

A very important point is that when using different types of units for planting potatoes, the distance between the seeds in the row should be 20-30 cm, and their planting depth should be 10-15 cm.

Using a conventional hiller and attaching it to a walk-behind tractor reduces the cost of physical labor. For more comfortable placement of potatoes in the furrows, the grip of the wings is increased. This is achieved by moving the dumps. If you use the Neva walk-behind tractor, the stop and wings are removed from it, but if you use the Salyut, such manipulations are not necessary. A necessary condition when using any walk-behind tractor is to attach lug wheels to it.

If a hand plow is used for planting, the track width should be left at 60 centimeters. Potato tubers are laid out in furrows at an equal distance between them. Rubber wheels are put on a walk-behind tractor of any brand, but the track width should remain the same. A maximum gap is left between the wings of the unit. After all the preparatory work, the rows are filled with fresh soil.

Types of hillers

Manual

Manual hillers (disc) are designed for loosening and hilling. The use of such a tool can guarantee high-quality tillage.

This tool can help the gardener carry out hilling and will avoid energy-consuming and tedious work.

The cost depends on the configuration. On average, a device with two disks costs around 2,500 rubles. The cost of a manual hiller is about 2.5 thousand rubles

To the tractor

They are used for automated processing. The device is capable of immediately removing weeds from the cultivated area and, in fact, successfully hilling the tubers. After manipulating the tractor hiller, the potato yield level increases sharply.

They consist of: a metal frame, an attachment that is responsible for the coupling, two stamped wheels, iron pointed paws and dumps.

The load on the hiller is reduced by tractor wheels, in turn, the paws cut the soil (up to fifteen centimeters). A steel support attaches the legs to the frame. Lattice dumps are used for hilling.

Basically, tractor ones can be attached exclusively to the T-25 tractor, which has a rather small traction force, unlike the MTZ. It is not able to work with a device that has more than 3 cases.

If the gardener’s goal is to simply hill up the potatoes, then he needs to unscrew the pointed paws.

The cost of tractor potato hillers varies from 20,000 to 30,000 rubles. Hiller for tractor T-25

To the walk-behind tractor

The device is installed on the walk-behind tractor in place of the coulter.

How it works: during transitions between rows, the device pours soil with its wings directly onto the tubers. You can attach a disc hiller to the walk-behind tractor.

In fact, “hillers for walk-behind tractors” are not a separate species. We used this to let you know that the device can also be mounted on a tiller.

Disc hiller for walk-behind tractor

Plow

The potato hilling plow is designed to facilitate the work associated with growing potatoes. With the help of such a plow, furrows and beds are cut, the soil is loosened, crops are planted, and hilling is done.

In terms of its configuration and mechanism of action, the plow is similar to a disk hiller. At least their mechanism of action is absolutely identical.

Plow