For threaded connections of steel pipelines, couplings with internal threads are used, but even if sections of the pipeline fit closely to each other, it will not be possible to connect them with one part (unless it is an American one with a union nut) due to the same thread direction. For these purposes, intermediate sections are used - pipe bends, the dimensions and material of which are regulated by GOST.

When installing a water or gas main from metal pipes yourself, you will need to connect the pipelines to plumbing fixtures or gas equipment. For safe and correct installation of the system, it is useful to know the basic dimensions, materials and methods of manufacturing this element of plumbing fixtures.

Fig. 1 Surges in heating systems, water supply and gas pipelines

Pipe bends - dimensions according to GOST

A squeegee is a piece of pipe with a double-sided thread of different lengths, its average size on the short side is 5 threads, the long side has a length of at least 20 turns. Metal or galvanized leads with a short thread end are connected to equipment (gas stoves, heating radiators, boilers), and a coupling of the appropriate length and a lock nut move along the long thread. When joining, a long coupling with a sealing seal (linen tow, plumbing thread, FUM tape) is screwed onto another pipe; on the other side of the coupling, the wound seal is pressed with a lock nut.

The parameters of the bends are regulated by GOST 8969-75, which indicates their size, the length of the threaded sections, and the thread diameter in inches.

Rice. 2 Squeegee - appearance and materials of manufacture

Specifications

The squeegee looks like a piece of pipe with threads on both sides. The segment must be straight or angular. On the short side, the thread consists of 5 turns, and on the long side, it consists of 20 turns or more, up to 30. The short end of the thread is connected to the pipe of the equipment, for example, a gas boiler or battery, and the long end is connected to another pipe. A coupling of a selected size with a lock nut also “goes” along the long thread.

A coupling with a seal is placed on the other pipe to seal it, which is pressed with a lock nut. The latter can be linen tow, plumbing thread or other materials.

The bends are made of metal, often “reinforced” with a zinc coating. If you require a decent appearance of pipes, it is possible to purchase elements with nickel plating. Often two numbers are indicated on the marking of the run, for example, 75/76. This says that the outer diameter of the product is 76 millimeters and the inner diameter is 75 millimeters.

Where are squeegees used and installed?

Squeegees are used in water supply systems, heating systems, gas pipelines, they are installed:

- In water supply and heating lines after the valve on the riser. This allows the shut-off valves to be removed from the pipeline in the event of a malfunction for repair or replacement.

- When connecting old-style cast iron pipes to a heating radiator, their use also allows you to clean the pipeline from lime deposits and rust.

- For the supply line when connecting autonomous equipment for heating water - gas boilers, boilers, expansion tanks and plumbing fittings (faucets with a herringbone connector).

- To the pipeline for supplying gas to household and water heating equipment - stoves, boilers.

- Sometimes surges are used in sections of the system to obtain additional outlet, while the coupling is replaced with a tee, and the distance between the pipes is increased.

Rice. 3 Steel cylindrical bend - dimensions according to GOST 8969-75.

Purpose

The method of connecting pipeline elements depends on several factors, for example, the material of the pipes, the type of transported substance, as well as the conditions of the working environment. The main purpose of pipe fittings is to connect them to plumbing or gas appliances. Welding is not suitable here, because the connection must be detachable: if necessary, some element may have to be dismantled. For example, it is recommended to use squeegees in heating networks after the valve on the riser.

In the event of a breakdown, the presence of a squeegee will make it easy to get the shut-off valve element to repair or replace it. Squeegees are also useful for old cast iron radiators; their presence will help clean the pipeline. This element is used to connect various heating equipment: tanks and gas boilers, as well as mixers. In the kitchen, the squeegee is useful when connecting the stove. Finally, it can be used to create an additional pipeline branch.

Connection device to the outlet and its designation

Steel couplings with or without zinc coating, having double-sided threads, are intended for connecting water and gas pipes in heating systems, gas pipelines, water pipelines and other lines with a non-aggressive working fluid at temperatures up to +175 C. and pressure less than 1, 6 MPa. (16 atm. or bar.). To connect the pipeline with plumbing and gas equipment, the fitting includes a coupling (has lateral longitudinal ribs for engagement with a gas wrench) and a lock nut with standard dimensions corresponding to the external pipe thread of the fitting in accordance with GOST 8969-75.

The fitting marking according to GOST 8969-75 includes the name of the part (squeeze), nominal diameter, material of manufacture (letter C for galvanized steel) and an indication of the above standard. An example of marking is Sgon 25-Ts GOST 8969-75.

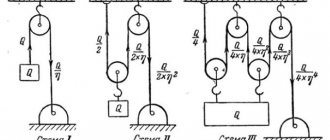

Rice. 4 Installation of the drive

Materials for production

Shaped elements are made from various metal alloys and polymers, but threaded fittings are made only from metal, since plastic threads are easily damaged.

The modern plumbing market offers the following options for threaded type connecting elements:

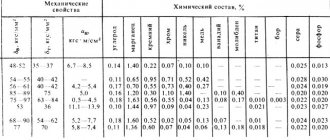

| Material | Advantages of fittings | Flaws |

| stainless steel | suitable for pipes made of any materials, resistant to corrosion, low temperatures, ultraviolet radiation, as well as water hammer, chemical and mechanical stress, chemically inert and suitable for drinking water pipelines, durable, weigh little; | high cost, sticking during long-term use without prevention; |

| brass with chrome plated, bronze | low cost, ease of dismantling, strength and stability at the level of stainless steel; | cannot be installed on pipelines transporting a working medium with a temperature above 150ºC; without preventive maintenance, the unit weakens, becomes loose, and loses its tightness; |

| copper | resistant to temperature, corrosion and water hammer, do not chemically interact with the working environment; | high cost, not compatible with pipes made of galvanized and chrome-plated non-alloy steel, |

| cast iron | longest service life, low cost; | heavy weight, low corrosion resistance, fouling of reaction products with the working environment and a decrease in the throughput of the unit. |

How to install the flow into the system

Steel connecting couplings for installation and installation of water pipelines installed after valves are installed in compliance with the following rules:

- Fittings must have a clearance length between pipes of no more than 5 mm. taking into account the recess of the side with a short thread into the connected equipment or fittings.

- On the side with a thread of at least 20 threads in length, a steel lock nut and a coupling are screwed in succession.

- Flax fiber or thread is wound along the thread

- When installing, flax fiber is wound on the short side, lubricated with a special paste, and the drive pipe is screwed into the outlet pipe of the valve manually, and then pressed with a gas wrench. For convenience, use a second key to hold the valve body with it to avoid turning on the pipeline.

Rice. 5 Steel connecting parts according to GOST 8965-75

- Screw the connecting parts onto the long side: the locknut until it stops and the coupling; flax is wound onto the connected pipe along the thread.

- Drive the long coupling down and screw it onto the pipe, pressing it with a gas wrench.

- Wind flax fiber from the other end of the coupling, coat it with paste and tighten the locknut.

It is necessary to understand that the winding from the other end does not fall under the thread of the coupling, therefore the sealing and sealing of the connection will be carried out by squeezing the fiber with a locknut. Therefore, a larger number of turns of flax fiber should be wound so that the locknut fits the coupling or there is a small gap between them (no more than 1 mm) after strong tightening with a large applied force.

Is it possible to make a squeegee yourself and how to do it?

When installing a pipeline with your own hands, sometimes a situation arises when you need to select the required length of pipes - factory products, according to standards, cover only a narrow range of sizes and diameters. In this case, a self-made pipe is used, and the clamping locknut and coupling of the required diameter are taken from another workpiece. For manufacturing, you need to use a piece of gas pipe of suitable length; to carry out the work, you will need a die with a holder or clamp, oil, a vice for clamping the workpiece, a hacksaw for metal or a grinder for cutting the pipe.

What is a pipeline installation run?

A squeegee is a connecting plumbing piece designed for joining pipes when laying a communications system. The reliability and unity of a huge system depends on this detail. In addition, fittings greatly facilitate the process of combining individual components into a complete pipeline.

Plumbers, when mentioning a steel pipe squeegee, mean:

- A pipe with a short thread of 5 turns on one end and a long thread of 20 or more turns on the other side.

- A long thread that is cut on the connection to the communication equipment.

This connecting fitting makes it possible to dismantle a certain section of the pipeline in the area where non-rotating elements are joined. But it is not worth using a drive in a place where the workpiece can be unscrewed from the coupling, since this increases the likelihood of a leak in an area with a large number of threaded combinations.

It is worth mentioning the coupling connection. This is a plumbing blank with the same size of outer and inner pipe diameters. The coupling has internal threads on both sides, which requires that the threaded thread on the device be twice as short. In this case, you can screw the pipes into the fitting from both sides at an equal distance.

Thus, a squeegee is a plumbing fitting in the form of a short tube with a short thread at one end and a long thread at the other. The entire coupling and locknut are screwed onto it.

At the same time, experts recommend choosing squeegees with the longest threaded thread so that all the parts fit on it. Otherwise, the distance between the outlet and the ends of the pipeline will have to be increased, and this will significantly reduce the strength and reliability of such a connection.

Where are surges most often used:

- On the connection to the radiators of the heating system, primarily to old-style cast iron radiators.

- On steel connections, water supply and heating risers after valves, which makes it easy to replace the pipe or remove it for cleaning or repair.

- On the rigid liner for kitchen faucets of the Soviet period there is a herringbone pattern.

Since this fitting is usually used for laying a water supply network, the metal pipe must be periodically treated with anti-corrosion agents.

What are the advantages of connecting pipes with bends?

Connecting a fixed communication system with spurs has many advantages:

- during installation work, you can refuse to use a special device for welding metal pipes;

- Any owner can assemble all the parts together without special education or installation qualifications;

- it is easy to follow technological recommendations for connecting various pipe elements;

- strong and reliable joining of workpieces and tubes without a welding machine;

- during installation, a collapsible block is created for ease of repair work and replacement of the main elements of the site.

Experts note one important drawback - the possible occurrence of a leak in the event of a leaky joint using a lock nut.

Important! The main condition for a reliable connection is the exact matching of the dimensions of all elements, therefore the parameters of the pipes at the junction are very important. Plumbers recommend making sure that the run is slightly longer than the break.

What types of connecting fittings are there?

Based on the metal of manufacture, experts divide pipeline pipes into products made from:

- Nickel. Such products make connections more attractive from an aesthetic point of view, therefore, as a rule, they are used in residential premises.

- Become. They are installed in a pipeline that is laid in the ground. To protect the connections from corrosion, they are painted before immersion in the ground.

- Galvanized. Often used in open sections of pipelines that are exposed to various atmospheric phenomena.

Gosstandart has determined the following types of sizes of connecting blanks:

the first parameter is the length, the second is the internal diameter, the third is the length of one threaded area, the last is the length of another threaded area.

How to make a squeegee with your own hands?

Unfortunately, in practice it often happens that the length of fittings on risers and connections differs from the standard dimensions, so you have to measure and select parts several times in each specific case separately.

If you can’t find a squeegee of the right size, you can make it yourself. For this you need:

- water and gas pipe;

- vice;

- die with holder;

- file for chamfering;

- grinder or hacksaw;

- any oil for lubrication.

Instructions for making your own metal strip:

- Cut the pipe to length.

- Remove external chamfers using a file on both sides.

- Clamp a piece of tube in a vice.

- Lubricate the pipe with oil to reduce the effort when cutting threads.

- Place the die with the guide frame onto the pipe and press them together as much as possible.

- At the same time, turn the frame clockwise. You can stop pressing the die only after cutting two turns;

- Five threads are cut on a short thread section, and twenty on a long section.

After the entry is made, you can turn the die over to make its wear even.

How to properly assemble a pipeline?

To connect the pipeline system, you need to do a few simple steps step by step:

- First of all, you need to screw the coupling onto the section of the tube.

- After this, the short side of the drive must be screwed into the coupling all the way so that the connection is strong.

- It is necessary to screw a lock nut onto a long section of the sweep.

- Then the connecting fitting is screwed on.

- Attach the end of the drive to the pipe and tighten the coupling so that it is secured to the pipe.

- Then you need to secure the fitting using a lock nut, tightening it to the coupling so that there is a distance of about 2.5-3 cm between the workpieces.

- The parts must be screwed in the direction of rotation of the locknut, which should be screwed in until it stops using a wrench to seal the connection and prevent leakage in this place.

To make the joints of all elements airtight, FUM tape is wound onto the threads.

Correct installation of the American

American plumbing is installed using adjustable, open-end and universal wrenches. Also, sometimes you may need a special round key, which American women use to tighten them from the inside. The use of gas keys is prohibited. Excessive force applied to the handles of the gas wrench can deform the union nut.

Let's look at how to install an American pipe onto a pipe.

An American with internal thread is installed on two sections of the existing pipeline. If there is no thread on the pipe, then it is cut using a die. A sealant is wound onto the threads of one section. This can be FUM tape, flax fibers or other materials. After this, one part of the American is screwed onto the pipe using a wrench. Then a sealant is applied to the second threaded section, after which the second American fitting with a nut is screwed onto it. After which the two sections of the pipeline are connected to each other by tightening the union nut of the fitting.

Installation of an American with external thread is carried out almost the same way. The difference is that the seal is screwed onto the American thread itself.

As you can see, the use of American-type connecting elements can significantly speed up and simplify the process of installation and possible dismantling of pipelines and other plumbing fixtures.

How to dismantle threaded connections?

To protect gas or plumbing from metal corrosion, it is painted, thereby increasing its service life. But after painting work, it is very difficult to dismantle the threaded connections. Therefore, experts recommend not to paint fittings multiple times; once is enough.

If the connecting parts have been painted multiple times, then before dismantling work you need to remove the paint using a knife or a blowtorch.

Then the disassembled section of the pipeline must be lubricated with grease to make the disassembly process easier.

The difficulty of disassembly is affected by the material used to make the workpieces. For example, cast iron elements screwed onto a steel pipeline can be easily unscrewed with a regular wrench. But it is almost impossible for them to unscrew a steel coupling. To do this, you need to heat the connection with a blowtorch or gas torch for 20-50 minutes, depending on the diameter of the tubes and fittings.

Thus, when using couplings and bends, it is possible to create a prefabricated connection of a section of the pipeline, which, if repair work is necessary, allows you to dismantle a certain part of the system without completely disassembling the pipeline.

Installation of any pipeline is a task that requires certain knowledge, skills and abilities.

As a rule, the installation of a pipeline, in addition to the pipes themselves, requires special additional components.

After a certain period of time, the system may fail, sooner or later it needs repair work.

Recommendations for use

To extend the service life of any pipeline part, it must be painted regularly. This reduces the likelihood of rust on the metal pipe. However, if it becomes necessary to disassemble the painted area, the paint layer must first be removed from the squeegees. This can be done using an ordinary knife or a blowtorch.

If rust still appears even with an anti-corrosion coating, this problem can be most easily solved by replacing the hose made of stainless material. Brass elements last a long time and do not rust.

Another common problem is the locknut leaking. This situation occurs regardless of how correctly the parts were selected. The reason for this is most often simple: the seal has become unusable.

Linen thread winding tends to burn out or rot. In this case, the old seal should be replaced. It is advisable to treat new linen thread with a special quick-drying varnish before winding. This coating will create a protective layer that prevents overheating or getting wet.

If the pipe bend is selected the right size and is made of high-quality material suitable for a specific pipeline and operating conditions, it will last a long time and will not cause problems during use. By choosing the best option, you can save yourself from possible problems.

To put it briefly, what a squeegee is is a small piece of pipe with threads cut at both ends. The threads are cut to different lengths for ease of disassembly during operation, if necessary.

The length of the thread on the product depends on the diameter. The smaller the diameter of the product, the greater the coefficient that determines the length. The minimum values are as follows: short thread of at least 5 threads, long thread of at least 20 threads.

All products are GOST certified and the definition is as follows. A squeegee is a connecting part with a cylindrical thread intended for pipelines. Regulatory document number – 8969-2010. installed on water supply systems, heating systems, gas pipelines and others that operate with non-aggressive media, such as water, steam, gas, at temperatures up to 175°C and pressure not exceeding 1.6 MPa.

Steel products can be classified as follows:

Useful accessories

Replacing a certain part in an entire structure can sometimes be very difficult or even practically impossible.

This is associated with a number of difficulties (electric welded fittings for HDPE pipes).

It is for this reason that when constructing many systems, threaded connections are used through couplings (connecting for HDPE pipes) and bends.

This is a connecting fitting, which is a small tube with a thread for joining hollow objects.

At one end the length of the thread is, as usual, much shorter than at the opposite.

Since the shorter end (5-6 threads) is intended for the coupling, and the second, consisting of 20 - 30 threads, is for the clamping device and locknut.

A stainless steel pipe with a lock nut is usually used to connect two fixed pipes that cannot be rotated.

Also, this part can be used in conjunction with a ball valve of any cross-section (how to connect a valve to a polypropylene pipe is written here).

Experts prefer products with fairly long threads.

Because if a situation arises when there is no alternative to placing the desired part in the area with grooves, it is necessary to increase the gap between the joining sides of the pipe and the fitting.

And this will lead to a decrease in the strength of the connection.

What do you know about the construction of a drainage ditch? Read this useful article on how to properly drain groundwater from your garden plot.

The amount of the fine for a well on the site is written on this page.

You should know that this connecting part, in most cases, is used for water supply systems (watch a video on how to connect HDPE pipes without welding here).

Therefore, it must have good corrosion protection.

Application benefits

The main positive aspects from using squeegees are:

- A design made in this way allows the joining of pipeline components to be carried out quite simply and at the same time very reliably.

- The contact of the parts is dismountable, and this greatly simplifies the process of cleaning pipes and repair work to replace the failed section.

- For installation there is no need to use special equipment or invite specialists. The whole process can be done with your own hands (read about the rules for the technical operation of water supply and sanitation systems here). The main thing is to follow the installation recommendations and the sequence of your actions.

As for the shortcomings, I would like to say the following:

- If the locknut is handled improperly, a leak may occur.

But this is not a “minus” of the product itself, but most likely of the installation.

Therefore, a flaw of this kind is a consequence of inept handling of mechanisms.

When choosing products, you need to understand the designations.

Previously, manufacturers applied markings in inches.

At the moment, the metric system is increasingly used.

When choosing, you need to pay attention to the price of products . This parameter will directly affect the cost of the work as a whole.

If desired, you can purchase devices complete with other elements (couplings, nuts).

Saturday, October 7, 2022

What is a squeegee in plumbing?

Note!

Squeegees are required to receive certification in accordance with the international standard DIN 16961. The most commonly used products are with a nominal diameter of 0.5 to 2 inches

Note!

When choosing, it is important to remember that the reliability of the connection directly depends on whether the size of the outlet is selected correctly in accordance with the parameters of the pipe

Note!

It will be necessary to replace the drive only if the leak has started directly along the axis of the thread. This means that the parts did not line up correctly during installation.

Source

Installation features

The drives are placed in the right place, using special couplings.

The bracket is screwed onto the reinforcement or fastening element, with the side with short grooves. In the process, you need to use sealing tape, paste or flax.

A crimp ring and a nut are screwed onto the opposite side for joining to the end of a pipe with a shortened cut, on which hemp is wound in advance, FUM - tape or a special paste (how to connect a PVC pipe with a metal one is written in this article).

Using rotational movements, we screw the coupling onto the end of the hollow object, connecting it to the drive.

In order to press the nut well against the connecting element, the area between the coupling and the nut must be wrapped in tow.

If the drive needs to be used in conjunction with a ball valve, then the part is attached to the end of the valve.

This solution greatly simplifies the task of dismantling the segment you need, and even an inexperienced home craftsman can handle this.

Most often, dismantling must be done to clean the system from scale and accumulated rust.

Remember! The more accurately the axes of the parts match, the easier you can make the connection.

Product characteristics

Here are the main characteristics of products made from the most common materials.

Table of sizes depending on the inch, steel products:

| Conditional transition, mm | Thread | Thread left, length, mm | Thread right, length, mm | Product length, mm |

| 100 | 4″ | 25 | 100 | 200 |

| 80 | 3″ | 22 | 85 | 180 |

| 65 | 2 ½″ | 19,5 | 75 | 170 |

| 50 | 2″ | 17 | 65 | 150 |

| 40 | 1 ½″ | 15 | 60 | 150 |

| 32 | 1 ¼″ | 13 | 55 | 130 |

| 25 | 1″ | 11 | 50 | 130 |

| 20 | ¾″ | 10,5 | 45 | 110 |

| 15 | ½″ | 9 | 40 | 110 |

| 10 | 3/8″ | 8 | 42 | 90 |

Table of standard sizes of galvanized steel products:

| Du, mm | Length, mm | Weight, kg |

| 50 | 130 | 0,5 |

| 40 | 120 | 0,44 |

| 32 | 120 | 0,26 |

| 25 | 110 | 0,187 |

| 20 | 100 | 0,105 |

| 15 | 100 | 0,83 |

Separately, it is necessary to say about the designations, which is very important to know when choosing. If earlier inch markings were more often used (for example, ¾ inch or 3/2 inch ridge), now the metric system is increasingly used.

And the marking takes on a slightly different look, and let’s say a ½ stainless steel strip will be marked differently. For example, 15/14 instead of stainless steel ½, where 15 is the outer diameter, 14 is the inner diameter.

When making a choice, you can’t help but pay attention to what the price of the cuts will be. After all, this parameter directly affects the cost of the entire work.

You can buy steel bends at different prices, especially taking into account the size of the nominal diameter and the material of manufacture.

Thus, the price of a Du15 drive made of galvanized steel will be $0.3, while a product of the same size made of ordinary steel will cost $0.18. You can buy stainless steel bends at a higher price: the price of pipe bends starts from $0.5.

You can also buy a water squeegee assembled with other elements. In this case, the price of the assembled drive will be even higher - $0.8 - depending on the features of additional fasteners (couplings, nuts).

Installation nuances

The drives are placed in the right places using special couplings. The fitting is screwed onto the fitting with a short thread using sealing tape (paste and flax).

A coupling and nut are screwed onto the other end to connect to the end of a short-threaded pipe on which sealing tape (paste and flax) is pre-wound.

By rotating, the coupling is screwed onto the end of the pipeline, connecting to the outlet. Then, on the product itself, in the area between the nut and the coupling, you should wind flax and spread the paste to press the nut to the coupling.

If the squeegee is used in combination with a ball valve, then the product is attached to the end of such a valve. The solution allows you to simplify the task of dismantling the site, which even a beginner can do.

Dismantling is most often necessary to clean scale and rust that has formed inside the pipeline system. A complete replacement with drive 2 is rarely performed.

As a rule, this procedure is performed for products made of low-carbon steel. First, remove the nut, coupling, pipes, and then the drive itself, using a lever pipe wrench.