Polycarbonate is a popular building material from which greenhouses, canopies, gazebos, decorative partitions in rooms, as well as advertising structures are made. The material is popular due to its good performance characteristics. These include strength, good light transmission and durability. At the same time, sheet panels can be bent, which makes them in demand not only for the manufacture of straight, but also arched structures. They do not withstand snow loads well, so the roofs of buildings must be made sloping. This is especially true for areas with snowy winters.

When using panels as cladding for structures, it is necessary to take into account that this sheet material must be correctly fixed to the frame. Fastening polycarbonate is a fairly simple job, and the tool for doing it is available in almost every home. You can quickly learn how to attach polycarbonate to metal frames; for this purpose, below is a description of almost all methods existing today. With a properly selected design, high-quality installation of sheet material and its sealing, the structure will serve flawlessly for many years.

Types of polycarbonate fastening

Fastening polycarbonate to the frame can be done in four ways: point, profile (using special profiles), galvanized tape (suitable for arched structures) and mixed (considered professional).

Spot

More often they use a point method of attaching sheets to a metal frame. To do this, use self-tapping screws and washers for fastening polycarbonate. Moreover, ordinary self-tapping screws are used extremely rarely in installation (only in warm rooms).

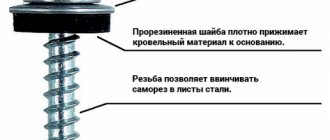

You need to fasten polycarbonate to metal using roofing screws with a gasket (also called EPDM washer), as well as self-tapping screws with a rubber thermal washer or screws and thermal washers with a leg. The screws used in fastening must be for metal, because only such hardware can reliably cut into an iron profile and fix the sheet material.

It is necessary to disassemble in detail each of the above types of fasteners in order to understand how best to attach polycarbonate to a metal frame.

A roofing screw with an EPDM washer is the simplest and most affordable fastening of polycarbonate sheets to a steel frame. To avoid the consequences of frequent wetting, this self-tapping screw is coated with a very reliable anti-corrosion layer. It comes with an EPDM washer, which looks like a rubber gasket with an iron cap. This washer allows you to hermetically close the hole under the screw and evenly distribute the load on the sheet.

Due to the small diameter and thin gasket, the screws are sometimes overtightened during the screwing process. Therefore, dents appear in the area of the fastenings, which violate the tightness of the hole and moisture, dirt and microbes penetrate into the honeycomb panels. When using roofing screws in installation, there is no need to make holes in the panels and iron frame, but experts still recommend drilling them. To install colored SPC, it is better to use painted screws.

A self-tapping screw with a rubber thermal washer is also a reliable fastener for sheet panels. It looks like a roofing screw, but is equipped with a large and rather thick silicone or rubber thermal washer. When screwing a screw into a sheet, the thermal washer is flattened by pressure and at the same time evenly transfers the load to the material. This reduces the risk of overtightening the screw and causing a dent.

A metal self-tapping screw and a thermal washer with a leg are a new type of fastener, specially designed for sheet cellular panels. Thermal washer for polycarbonate looks like a washer with a cylindrical leg, which fits into a hole drilled in the cellular panels and rests against the frame. The leg contains a self-tapping screw that is screwed into the iron, and the thermal washer head evenly presses the sheet to the metal. When choosing this type of fastener, you need to take into account that the length of the leg should be selected depending on the thickness of the material. To seal the fastening, a special sealing ring is placed under the thermal washer, and the top is sealed with a cap. Thanks to this technology, the washer does not cut into the sheet and it is impossible to tighten the screw.

Holes for self-tapping screws for fastening polycarbonate must be made 2-3 mm larger than the width of the thermal washer leg, so that after thermal expansion of the sheet the attachment point does not deform. High-quality thermal washers are made of polycarbonate so that it has the same expansion coefficient as the casing.

There is another type of fastener - universal thermal washers . They don't have legs. This worsens the quality of fastening, but at the same time you do not have to look for a thermal washer with a leg of the required length. This fastening is often used in wooden structures, when working with which you need to remember how to fasten polycarbonate to wood. In some cases, the casing material breaks under the gasket (if the screw is overtightened).

Self-tapping screws for thermal washers come with hexagonal and round heads. In addition, they can be used with a regular or Phillips screwdriver. The quality of the connection is the same, but it is still more comfortable to work with a hex head - when working with a screwdriver, the bit practically does not slip off the screw and therefore the sheathing material is less likely to be damaged.

Mostly, self-tapping screws with a width of 4.8 - 8 mm are used, but the length depends on the thickness of the sheets and iron. The selection of screws using an example looks like this: in the arrangement of greenhouses, panels with a thickness of 4 mm and a galvanized pipe with a cross-section of 20×20 and a thickness of 1 mm are used. In this case, it is better to fasten the cellular polycarbonate to the frame using roofing screws measuring 4.8×19 mm, and if you overlap the material, it is better to use screws measuring 4.8×25 mm.

This method of fastening honeycomb panels has a drawback - protruding screws are often visible from inside the structure, which do not fall on the frame elements.

Profile

In addition to point fastening with self-tapping screws, sheet material is attached to an iron frame with polycarbonate and aluminum connecting profiles, which are rigidly fixed to the frame. After that, sheet material of the required length is placed in them, while its width should not be more than 1.05 m. Sheets with a width of 0.7-1.05 m are more often used; for this, the sheet material is cut into pieces, with virtually no waste. This method is used to attach polycarbonate to wood and metal.

Profiles are divided into two types:

- detachable;

- one-piece.

A one-piece profile is a monolithic connecting profile for fastening polycarbonate, the cross-section of which is similar to an I-beam. The ends of this profile are slightly bent inward, so they form a secure latch. The meaning of installing a one-piece connecting profile is simple - the sheet is inserted into the grooves of the profile and secured with latches. Then the profile for fastening the polycarbonate is fixed to the iron frame with roofing screws or screws with thermal washers.

Connecting profile

A special profile is used to attach the sheets to each other and to the frame. It is made from the same material as polycarbonate sheets. The industry produces profiles for sheets of standard thickness - 4,6,8,10, 16 mm.

Profiles for polycarbonate

Important! There should be a gap of 3 mm between the inner wall of the profile and the sheet inserted into it. It is designed to prevent polycarbonate, which expands in the summer heat, from warping and deforming the structure.

The profile can be detachable or non-detachable. The sheets are inserted into the grooves of the profile and secured there. The canvas can be fixed in a polycarbonate, plastic or aluminum profile. Profiles of different sections have different markings - H, HP, HCP, U, RP, UP, FP, SP, L.

Polycarbonate profiles

Types of aluminum profiles for polycarbonate

Aluminum end profile

Important! It is necessary to use sealing and perforated tapes to seal the ends of the sheet, and after that the sheets are fixed inside the profile.

The panels attached to the grille can be sealed together with sealant. But such a connection will not be strong enough in strong winds. You should select a high-quality sealant that retains strength and elasticity for several years.

Docking profiles for polycarbonate with snaps

Accessories for fastening polycarbonate

Let's take a closer look at the components for fastening polycarbonate.

Profiles

For all methods of fastening polycarbonate to metal, profiles are used, and they differ in the material of manufacture and configuration: one-piece, detachable and end.

Connecting one-piece profiles for fastening polycarbonate (HP) are made of polycarbonate, they can be matched to the color of the honeycomb material. The result is not only a strong connection, but also a beautiful one.

The design of the connecting split profile (NSP) consists of a cover and a base. It uses legs rounded inward, so to fix the material, the profile is pulled between the sheets.

End profile (U-shaped) - needed to cover the ends of the honeycomb panels so that dirt, dust and moisture do not get inside the cells.

Ridge profiles allow for floating fastening, which is necessary for arched structures.

Solid corner profile - this plastic sealing profile securely connects two sheets at an angle of 90°. They can be used to connect panels of different thicknesses.

Wall profiles secure the sheets to the wall and protect the ends facing the walls.

You can easily purchase polycarbonate profiles in Anapa in specialized stores that sell building materials and construction equipment. You can also order them online.

Thermal washers

Thermal washer for fastening polycarbonate allows you to securely fix the sheets to the frame. Its design consists of 3 elements:

- a convex plastic washer with a leg that fills a hole in the sheet;

- sealing ring made of plastic polymer or rubber;

- plug protects the self-tapping screw from moisture.

The self-tapping screw for fastening polycarbonate is most often not equipped with a thermal washer, so it must be purchased separately. Thermal washers for fastening polycarbonate gently and reliably press the sheet to the frame of the building, while protecting the material from moisture penetration. They allow the building to look aesthetically pleasing. Moreover, the steps for fastening polycarbonate directly depend on the expected snow, wind and other loads.

Thermal washers come in three types:

- polypropylene;

- polycarbonate;

- made of stainless steel.

For any polycarbonate greenhouses, a thermal washer is an integral element of fastening the coating, because this type of structure must be well sealed.

Mini washers

Mini washers differ from regular thermal washers in their small size. They are used in confined spaces and when it is necessary to make the fastener less noticeable if it is located on a clearly visible part of the sheet. They are also made from different materials. The use of such washers for fastening polycarbonate allows you to make the entire structure more attractive and beautiful.

Galvanized strip

Galvanized tapes for fastening polycarbonate are intended only for arched structures. Thanks to them, the material remains intact, since there is no need to drill or cut it. They allow you to tighten the sheets anywhere, which is necessary for fixing carbonate sheets over long distances.

Stubs

A type of profile for cellular panels is the L-shaped plug with micropores, it is very similar in appearance to the panel guide. This profile must be used with cellular material - it reliably closes the holes at the ends of the sheets, while preventing moisture and dirt from getting inside the panels. It is important to remember which side to attach the polycarbonate to the structure.

The plug profile can be not only L-shaped, but also F-shaped. And in this case, it is also similar to a guide for cellular panels. For arranging heifers, the first option is mainly used, because the ends of the sheet polymer are buried in the ground. Both options are suitable for roof installation - everything will depend on the roof structure and the materials to which the PCs are attached.

Thanks to these plugs, it is possible to prevent a decrease in the transparency of the cellular material, because dirt and moisture will not get into it. During the greenhouse effect, water passes from a liquid state into steam, so it penetrates into the cellular material, making it cloudy. It will be extremely difficult to get rid of it, which is why safety plugs must be installed at the ends of the panels.

The tightness of the plugs can be increased by using a transparent film with micropores.

Types of washers

For the production of thermal washers, various materials are used, differing from each other in various parameters (strength level, transparency and service life).

There are three main materials used in the manufacture of this product:

- stainless steel (stainless steel);

- polycarbonate;

- polypropylene.

The service life of manufactured fasteners may vary. This will depend on the material chosen for production. For example, products made of polypropylene will last no more than 4 years, those made of polycarbonate - up to 15 years.

Steel thermal washers

Stainless steel thermal insulation washers are usually used for work in windy areas. They are also used if the coverage area of the object being constructed is too large. Often steel is installed on a profile made of metal. This gives the structure a beautiful and organic look. The thickness of the thermal washer reaches 0.8 mm, and the diameter is 33 mm. The inner part of the washer, intended for the self-tapping screw, has a diameter of no more than 6 mm.

General installation rules

The installation of panels is divided into the following stages; all of the specified methods of fastening polycarbonate are used in their work by professionals.

The first stage is cutting the panels

The procedure for attaching polycarbonate to wood begins with cutting the material. Cellular panels with a thickness of 4 - 10 mm are cut with a regular knife; a hacksaw is also often used as a cutting tool. But for fast and accurate cutting, you need to use electric saws with a stop, equipped with a blade made of hard alloys. In this case, the teeth of the circular saw should be small.

Fasteners

The best option when installing a polycarbonate structure is to use thermal washers, with the help of which it is possible to solve the following problems:

- strong and reliable fixation of the canvas to the supporting structure;

- sealing of holes drilled in polycarbonate for installing washers, which prevents dust, liquid and cold from entering the structure;

- polycarbonate and the material from which the thermal washers are made expand and contract simultaneously;

- The color range makes it possible to select fasteners to match the color of the structure itself.

Features of corner connection of panels

If you need to install and fasten polycarbonate sheets at right angles, then you need to use corner profiles. They will allow you to securely connect the panels and make the corner connection almost invisible.

Features of installation of monolithic polycarbonate

Sometimes monolithic polycarbonate is attached to metal using an iron frame made in the form of a frame. The frame must have special grooves up to 25 mm deep. Sheets in the frame are fixed in two ways:

Wet method. In this case, a special silicone-based putty or sealant is applied to the edges of the frame and seal. This method can be used for wooden and iron structures. Compact structures are sheathed with monolithic polycarbonate using glue or special tape. External work is carried out with glue, which is not afraid of adverse atmospheric influences. If good transparency of the fastening is required, then you need to use polyurethane glue. Before applying it, the surfaces are degreased with alcohol.

Dry method. Use screws, bolts, nuts, self-tapping screws and press washers. In any case, be sure to use rubber gaskets or plastic profiles that do not contain plasticizers. Do not glue the sealant directly to the panels. Fastening elements must be placed in increments of 50 cm. It is recommended to retreat from the edge of the material at a distance of at least 2 cm.

This type of fastening of monolithic polycarbonate is used for covering canopies and large structures.

Important! Whatever fastening method you choose, you need to remember at what distance to fasten the polycarbonate (monolithic - after 50 cm, cellular - with point fastening after 30-40 cm).

External side

The installation of polycarbonate has strict restrictions, which are associated with the sensitivity of the slabs to ultraviolet radiation. If installed incorrectly, plastic will last for several years, but properly installed high-quality material can be used for more than 15 years.

Removing the protective film from the outside of the plastic Source zavodecoteplic.ru

The outer side of the slabs is covered with a transparent film to protect the material. Low-quality, inexpensive polycarbonate models can block no more than 70% of ultraviolet radiation, and high-quality models can block up to 99%. To hide the destruction, slabs are sometimes covered with smoky and milky tones. But it’s better to immediately purchase high-quality plastic and save yourself from unnecessary problems.

Standard boards use polyvinyl chloride film. It is completely transparent. You can learn how to attach polycarbonate when purchasing it. You need to ask a specialist for help or do it yourself, paying attention to the following characteristics that relate to the outside:

- the thickness of the honeycomb walls is measured with a caliper - on the outside they are 0.1 mm thicker;

- the film is harder and tougher on the outside; a good specialist can determine it by touch.

Polycarbonate – which side to mount it towards the sun:

- If both sides are marked, it does not matter since polycarbonate has two-sided protection.

- If only one side is marked, then it is this side that needs to be turned towards the sun.

It is important to remember that incorrect installation of slabs can lead to destruction of slabs and breakage of wooden elements.

Arched greenhouse Source teplica-exp.ru

Protective coatings

Sheets of cellular slabs are covered with a protective film, which does not need to be removed during installation work, otherwise the light-conducting qualities of the polycarbonate will deteriorate. This protective film protects the material from damage and premature aging. The film is not removed until all work is completed.

Key points before installation

There are several types of polycarbonate

- monolithic, reminiscent of glass, only its weight is much lower;

- honeycomb, having a hollow and multilayer structure with additional transverse stiffeners.

Before purchasing, you should more accurately determine the dimensions; this will make it easier to fit the sheets during work. Do not forget that polycarbonate can be deformed in the heat. This feature should be taken into account before installing the greenhouse.

Materials that do not destroy polycarbonate

Polymer materials that are compatible with polycarbonate include:

- ethylene propylene rubber;

- polychloroprene;

- polyethylene;

- polytetrafluoroethylene (Teflon);

- neoprene;

- silicone;

- rubber sealant.

Polycarbonate, used as a construction and finishing material, can come into contact with the following materials:

- wood;

- rubber and caoutchouc;

- thermoplastic elastomers or thermoplastic elastomers that do not contain PVC;

- glass;

- metals.

Materials not compatible with polycarbonate

The following polymer materials are incompatible with polycarbonate:

- polyvinyl chloride (PVC);

- nitrile;

- all types of polyurethane.

There are also some chemicals that are not compatible with this material. They are:

- solvents, especially acetone;

- alkaloids;

- acids;

- solutions of salts and fats;

- ammonia;

- some types of adhesives and dyes.

Moreover, their influence directly depends on the duration of contact with the material, their concentration and temperature.

Installation instructions

Installation must be carried out in compliance with certain recommendations. Violating them will not only move you away from the desired result, but will also lead to damage to the roofing.

How to drill mounting holes

Table. Step-by-step installation of thermal washers.

| Steps, illustrations | Brief description of actions |

Frame

You can make a frame for monolithic and cellular polycarbonate from many materials. A wood frame looks very elegant, but when choosing this building material, you need to know that it must be glued, otherwise the entire structure will crack and deform. In addition, almost every year the frame will need to be painted and treated with special protective compounds against insects and diseases. At the same time, you need to remember how to securely attach polycarbonate to a wooden frame.

A frame made of thin-walled profile pipes, which has a long service life and increased strength, is considered more unpretentious.

Aluminum and steel materials are suitable for the frame under sheet cladding. Moreover, the sheathing can be made from steel and aluminum directly on the construction site, using a reliable type of fastener. The aluminum frame is distinguished by its anti-corrosion properties. If its design is correctly calculated, then it will retain its physical and aesthetic properties for many decades. But it is very expensive, so it is rarely chosen.

For quick construction and saving money, you can build a thinner sheathing and cover it with thick sheets. In this case, there will be fewer screw fastenings, which will speed up the installation process. You can also save money and purchase a thin covering, but then the lathing will have to be more frequent.

The choice depends on the following aspects:

- roof type;

- the area where the structure is installed;

- arch size;

- span dimensions;

- thickness of sheet material.

In any case, savings must be effective. For example, if you do not take into account the snow load and install sheets that cannot cope with the mass of snow falling in the region, then the surface will not withstand the overload and savings will lead to large losses.

If they are sheathing an already built structure that cannot be changed, then the thickness of the material is selected based on the frequency of the frame sheathing: the thinner it is, the thicker the material should be chosen.

Tools and equipment

To carry out work on fixing the panels, you need tools, main and auxiliary equipment. The choice depends on what frame is attached to and how the material is mounted, as well as on the complexity of the design.

To carry out the work you need:

- screwdriver;

- electric drill (with drills for wood or metal);

- electric jigsaw for cutting polycarbonate;

- a vacuum cleaner for collecting small chips and dust from the honeycombs after cutting;

- device for cutting aluminum profiles;

- self-tapping screws;

- bolts with nuts;

- various washers;

- rubber, plastic, silicone gaskets for washers (umbrella or flat);

- ladder;

- metal ruler;

- measuring tape (roulette);

- level.

Prices for self-tapping screws

self-tapping screws

Choosing a step is the most important stage in frame construction

When installing the frame under the panels, you need to more accurately select the pitch of the sheathing, which depends on the amount of bending of the material, its thickness and the angle of the roof. The roof slope angle cannot be less than 30°. Knowing all the nuances of constructing the frame, you can quickly set the pitch of the sheathing (it is equal to a hundred times the thickness of the material).

For example, for a sheet with a thickness of 4 mm, the step will be 40 cm, for 8 mm - 80 cm. In other words, the greater the thickness of the material, the smaller the step of the sheathing. It should be noted that thick cellular polycarbonate is faster to fasten because the fastener spacing is smaller and the material bends less. For regions with snowy winters, the sheathing pitch is reduced by 10-15%. When a frame with such a step is expensive, it is better to do something different: design the structure in such a way that the snow quickly melts off the roof. To do this, use a roof slope of 30 - 50°. At these degrees, the cellular panels are securely fastened, and the snow melts well.

During the installation process, be especially careful about fastening, which is done using washers. If there are few of them, then the sheet material will not be securely fastened. Given its large windage, there is a possibility of the sheet being torn off by strong winds. But you also don’t need to install a lot of washers, because this will increase the load on the panels, and they may not withstand hot weather and become deformed. The same can happen in a snowy winter, when wet snow freezes onto sheets of material and the load on the frame exceeds the maximum permissible limit, as a result of which the sheet material breaks. But in any case, you need to use washers to ensure the fastening is secure.

Some useful tips

- Polycarbonate, with its advantages and characteristics, is plastic. And over time it ages, and cracks appear on the surface. Honeycomb sheets often have dirt and plants trapped inside. When the ends are not sealed, moss and insects are soon found inside. And you will have to fight them with antiseptics.

- When the polycarbonate in a greenhouse is not laid correctly towards the sun or a mistake is made, there is no need to disassemble the entire greenhouse. A simpler option is to cover the greenhouse with a protective film, which is used for restoring car paintwork.

- Monolithic polycarbonate is more reliable, but also more expensive. Small cracks easily appear on it due to sudden temperature changes. Over time, droplets of water and stains appear on the surface of the canvas. Cracks are removed with solution 646, which melts the surface.

- It is important to choose the right type of greenhouse and fastening elements, taking into account the characteristics of the region.

- In some regions, you will need not only a reinforced frame, but also strong fastening of polycarbonate sheets due to constant and strong winds.

- When using carpentry fasteners, it is recommended to first perform several screws on the scraps. This way you can correctly select the required force and tool speed.

It’s easy to figure out the correct installation of polycarbonate sheets. The manufacturers themselves inform the buyer with instructions on the packaging. If it is not there, then the data is decrypted. Polycarbonate is a fragile material and requires careful handling during installation. When you don’t have the skill to work with it, it’s better to hire a professional. But even with high-quality installation of polycarbonate in a greenhouse, it requires annual maintenance, which will ensure its durability.

Temperature recording for installation work

You can work with this unique building material at any time of the year. But experts still do not recommend installing this sheet material in cold weather at temperatures below - 15°C, because it may break when bent.

Working with this material in cold weather requires special care, because in winter it is very fragile. When installing in cold weather, future expansion of the material must be taken into account because it will expand after heating. If this is not taken into account, then the panels installed in cold weather in the spring may come out of the grooves and the entire skin will be deformed. In this case, you need to remember how to properly attach cellular polycarbonate.

Screw consumption calculator

A self-tapping screw, like any other hardware, is a consumable material.

For a certain task, be it mounting a picture on a wall or organizing parquet flooring in an apartment, a certain number of screws are required. Of course, calculating the number of hardware needed to organize the simplest work is very simple. This can be done literally on your fingers. If the work ahead is more complex, then in this case a detailed calculation of the quantities of all consumables, including self-tapping screws, is needed. First, a work plan is made, and then costs are calculated. Using this calculator, you can calculate the required number of self-tapping screws (nails, screws, bolts, ...) for fastening corrugated board (plasterboard, OSB, fiberboard, ...)

Cleaning polycarbonate after installation

After installation work, the surface of the casing must be cleaned of dust and dirt. In this case, taking into account the adverse effects of acids, neutral compositions are selected. It is better to use soap solutions; cleaning the canvas with them will not be difficult. Do not use abrasive compounds or strong solvents. Moisture, drying oil, wax and oil that have penetrated into the honeycomb negatively affect the material. Due to the good properties of the panels, they can be used for cleaning with steam and jets of water.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.84%

No. More answers required. I'll ask in the comments now.

37.31%

Partially. There are still questions. I'll write in the comments now.

15.85%

Voted: 713