Niobium price

Since the element does not have large deposits on earth and has a complex production technology, its price has always been very high and with the growth of the development of the automotive industry, energy, aircraft construction and space technology, its price has been steadily rising.

At the same time, there were periods when it remained low due to crisis phenomena in the global economy. Nb price on the world market in thousands of dollars per metric ton by year:

- 1940 – 0.77162;

- 1950 -13.991;

- 2004 – 48.372;

- 2010 – 41.500;

- 2018 – 42.280.

The Asia-Pacific region has begun to dominate the global market in Nb consumption since 2022, driven by increased use of structural steels in the automotive and aerospace industries in countries such as China, India and Japan.

In the global Nb market, the major producer is CBMM (Brazil), which has a monopoly on its supplies with 84% of the world market share.

Other famous companies:

- China Molybdenum Co. Ltd, China NIOBEC (Magris Resources Company), Canada.

- Alkane Resources Ltd, USA.

- Modern Russian Nb manufacturing enterprise at the end.

- Enterprises that stopped production: Malyshevskoye mine department, Zabaikalsky GOK OJSC, Stalmag LLC, Vishnegorsky GOK OJSC.\

The price of niobium is $42,280 thousand per metric ton

Today, projects with investments in the restoration of rare earth deposits and the development of the niobium industry are being implemented in Russia:

- Tomtorproekt.

- Beloziminskoye field.

- Katuginskoe deposit.

- Chuktukonskoe deposit.

- Zashikhinskoe deposit.

- Ulug-Tanzekskoye field.

The global niobium market is expected to register a CAGR of 5.90% from 2019-2024. The main factors influencing it are the high consumption of Nb in structural steel and the widespread use of alloys in the production of aircraft engines.

General properties of refractory metals

Refractory metals and their alloys attract the attention of researchers due to their unusual properties and future prospects for application.

The physical properties of refractory metals such as molybdenum, tantalum and tungsten, their hardness and stability at high temperatures make them a material used for hot metal processing of materials both in vacuum and without it. Many parts are based on their unique properties: for example, tungsten filaments can withstand temperatures up to 3073 K

.

However, their resistance to oxidation up to 500 °C

making them one of the main weaknesses of this group. Contact with air can significantly affect their high temperature performance. That is why they are used in materials in which they are isolated from oxygen (for example, a light bulb).

Alloys of refractory metals - molybdenum, tantalum and tungsten - are used in parts of space nuclear technologies. These components have been specially created as a material capable of withstanding high temperatures (from 1350 K

up to 1900

K

). As stated above, they should not come into contact with oxygen.

List and characteristics of refractory metals

Refractoriness is characterized by an increased value of the transition temperature from the solid state to the liquid phase. Metals that melt at 1875 ºC and above are classified as refractory metals. In order of increasing melting temperature, these include the following types:

- Vanadium

- Chromium

- Rhodium

- Hafnium

- Ruthenium

- Tungsten

- Iridium

- Tantalum

- Molybdenum

- Osmium

- Rhenium

- Niobium.

Modern production in terms of the number of deposits and the level of production is satisfied only by tungsten, molybdenum, vanadium and chromium. Ruthenium, iridium, rhodium and osmium are quite rare in natural conditions. Their annual production does not exceed 1.6 tons.

Heat-resistant metals have the following main disadvantages:

- Increased cold brittleness. It is especially pronounced in tungsten, molybdenum and chromium. The transition temperature of a metal from a ductile to a brittle state is slightly above 100 ºC, which creates inconvenience when processing them under pressure.

- Instability to oxidation. Because of this, at temperatures above 1000 ºC, refractory metals are used only with preliminary application of galvanic coatings to their surface. Chromium is the most resistant to oxidation processes, but as a refractory metal it has the lowest melting point.

The most promising refractory metals include niobium and molybdenum. This is due to their prevalence in nature, and, consequently, low cost in comparison with other elements of this group.

In addition, niobium has established itself as a metal with a relatively low density, increased manufacturability and fairly high refractoriness. Molybdenum is valuable, first of all, for its specific strength and heat resistance.

Physical and mechanical properties

Metals with a high melting point (refractory) are transition elements. According to the periodic table, there are 2 types of them:

- Subgroup 5A – tantalum, vanadium and niobium.

- Subgroup 6A – tungsten, chromium and molybdenum.

Vanadium has the lowest density - 6100 kg/m3, tungsten has the highest density - 19300 kg/m3. The specific gravity of the remaining metals is within these values. These metals are characterized by a low coefficient of linear expansion, reduced elasticity and thermal conductivity.

These metals do not conduct electricity well, but have the quality of superconductivity. The temperature of the superconducting regime is 0.05-9 K based on the type of metal.

Absolutely all refractory metals are characterized by increased ductility under room conditions. Tungsten and molybdenum also stand out from other metals due to their higher heat resistance.

Corrosion resistance

Heat-resistant metals are characterized by high resistance to most types of aggressive environments. The corrosion resistance of elements of subgroups 5A increases from vanadium to tantalum. As an example, at 25 ºC vanadium dissolves in aqua regia, while niobium is completely inert towards this acid.

Tantalum, vanadium and niobium are resistant to molten alkali metals. Provided there is no oxygen in their composition, which significantly increases the intensity of the chemical reaction.

Molybdenum, chromium and tungsten have greater resistance to corrosion. Thus, nitric acid, which actively dissolves vanadium, has a much less effect on molybdenum. At a temperature of 20 ºC this reaction completely stops.

All refractory metals readily enter into chemical bonds with gases. The absorption of hydrogen from the environment by niobium occurs at 250 ºC. Tantalum at 500 ºC. The only way to stop these processes is to carry out vacuum annealing at 1000 ºC. It is worth noting that tungsten, chromium and molybdenum are much less prone to interact with gases.

As mentioned earlier, only chromium is resistant to oxidation. This property is due to its ability to form a solid film of chromium oxide on its surface. The dissolution of oxygen by chromium occurs only at 700 C. For other refractory metals, oxidation processes begin approximately at 550 ºC.

Cold brittleness

The spread of the use of heat-resistant metals in production is hampered by their increased tendency to cold brittleness. This means that when the temperature drops below a certain level, the brittleness of the metal sharply increases. For vanadium this temperature is -195 ºC, for niobium -120 ºC, and tungsten +330 ºC.

The presence of cold brittleness in heat-resistant metals is due to the content of impurities in their composition. Molybdenum of special purity (99.995%) retains increased plastic properties up to the temperature of liquid nitrogen. But the introduction of only 0.1% oxygen shifts the cold brittleness point to -20 C.

Physical properties of metals

The characteristics of metals by physical properties can be expressed in the form of four main points.

- Metallic luster - all have approximately the same silvery-white beautiful characteristic luster, except for copper and gold. They have a reddish and yellow tint, respectively. Calcium is silvery blue.

- Physical state - all are solid under ordinary conditions, except for mercury, which is in the form of a liquid.

- Electrical and thermal conductivity is characteristic of all metals, but is expressed to varying degrees.

- Malleability and ductility are also parameters common to all metals, which can vary depending on the specific representative.

- Melting and boiling points determine which metal is refractory and which is fusible. This parameter is different for all elements.

All physical properties are explained by the special structure of the metal crystal lattice. Its spatial arrangement, shape and strength.

Niobium and its alloys

Nb, or niobium, is a silvery-white shiny metal under normal conditions. It is also refractory, since the temperature of transition to the liquid state for it is 2477 °C. It is this quality, as well as the combination of low chemical activity and superconductivity, that allows niobium to become increasingly popular in human practice every year. Today this metal is used in industries such as:

- rocket science;

- aviation and space industry;

- nuclear power;

- chemical apparatus engineering;

- radio engineering.

This metal retains its physical properties even at very low temperatures. Products based on it are characterized by corrosion resistance, heat resistance, strength, and excellent conductivity.

This metal is added to aluminum materials to improve chemical resistance. Cathodes and anodes are made from it, and non-ferrous alloys are alloyed with it. Even coins in some countries are made with niobium content.

Where and how to apply

For all applications, the decisive advantage of this group is its low melting point.

Features of use

Based on this property of low-melting metals, methods of use have been determined:

- Soft alloys are a material for soldering microcircuits. Soldering with regular solder is excluded, as it creates overheating that will melt them.

- Alloys are much more often used. They are fusible, but dense, tensile strength, and chemically inert.

- The most popular compounds: lead, tin, cadmium, zinc, mercury. And also with bismuth, thallium, indium, gallium as the basic component.

Areas of use

Areas of application of the material: energy, mechanical engineering, electrical and radio engineering, chemical industry:

- The basis of coolant fluids, lubricant.

- Melting of models of complex configuration.

- Fire segment: temperature sensors, fire extinguishing valves, other fire early warning equipment.

- The basis of thermometers of different types and purposes.

- Top layer, fuses, thermal sensors of microelectronics.

- Medicine. Prosthetic material, fixator for fractures.

These are also conductors, anti-corrosion coatings, and a component of anti-friction alloys.

The unique properties of individual items from the list of light alloys are used:

- Lead is the material of bearings, fuses, batteries, cable sheathing. This is a shield against radioactive radiation.

- Tin is the protective layer of steel.

- Zinc is a component of brass, an anodic coating of steel products with high efficiency.

- Gallium is a mercury substitute that maintains vacuum in equipment.

Alkali metals also form easily melting alloys. In practice, such materials are rarely used due to excessive chemical activity.

The most refractory metal in the world - Metalist's Handbook

Since ancient times, man has learned to process and use metals in his life.

Some of them are suitable for making dishes and other consumer goods, while others, such as stainless steel, are used to make weapons and medical instruments.

And some metals and alloys are used to build complex technical mechanisms, such as a spaceship or an airplane

One of the characteristics that people pay attention to when choosing a particular material is its refractoriness.

The most refractory metal is tungsten

Refractoriness of metals

All engineers and designers working in mechanical engineering pay attention to this characteristic. Depending on the value of this characteristic, a person can calculate and determine in which design certain refractory materials can be used

Materials whose melting point is higher than the melting point of iron, equal to 1539 ° C, are called refractory. The most refractory materials:

- tantalum;

- niobium;

- molybdenum;

- rhenium;

- tungsten.

TantalumMolybdenum

The full list contains more chemical elements, but not all of them are widely used in production and some have lower melting points or are radioactive.

Tungsten is the most refractory metal. It looks light gray in color and is quite hard and heavy. However, it becomes brittle at low temperatures and is easy to break (cold brittleness). If you heat tungsten above 400 °C, it will become ductile. Tungsten does not combine well with other substances. It is extracted from complex and rare ore minerals, such as:

- scheelitis;

- ferberite;

- wolframite;

- hübnerite.

Ore processing is a very complex and expensive process. The extracted material is formed into bars or finished parts.

Huebnerite

Tungsten was discovered in the 18th century, but for a long time there were no furnaces capable of heating to the melting point of this refractory metal.

It is worth noting that according to one of the theories, seaborgium has a high melting point, but it is not possible to conduct a sufficient number of studies, because it is radioactive and unstable.

Adding tungsten to steel increases its hardness, so it began to be used in the manufacture of cutting tools, which increased cutting speed and thereby led to an increase in production.

The high cost and difficulty of processing this refractory metal affect its areas of application. It is used in cases where it is not possible to use another. Its advantages:

- resistant to high temperatures;

- increased hardness;

- durable or resilient at certain temperatures;

Metal ore processing

All these characteristics help tungsten find wide application in various fields, such as:

- metallurgy, for alloy steels;

- electrical engineering, for filaments, electrodes, etc.;

- mechanical engineering, in the manufacture of gear units and shafts, gearboxes and much more;

- aviation production, in the manufacture of engines;

- space industry, used in rocket nozzles and jet engines;

- military-industrial complex, for armor-piercing shells and cartridges, armor of military equipment, in the design of torpedoes and grenades;

- chemical industry, tungsten has good corrosion resistance to acids, which is why filter meshes are made from it. In addition, compounds with tungsten are used as fabric dyes, in the production of clothing for firefighters, and much more.

Such a list of industries where this refractory metal is used suggests that its importance for humanity is very great. Every year, tens of thousands of tons of pure tungsten are produced around the world, and every year the demand for it grows.

Application and presence in nature

The most fusible metal in the world is found very scattered in nature. Its total concentration in the earth's crust is approximately 83 mg/t, which makes it a rather rare element. It is found in large quantities in shales and sulfide minerals, especially sphalerites and stibnites. Found in livingstonites and metacinnabarites.

Despite its toxicity, mercury is used in many fields, for example, in metallurgy, medicine, the chemical industry, mechanical engineering, electrical engineering and even agriculture. The most fusible metal is suitable for filling energy-saving lamps, thermometers and barometers.

In heavy industry, the substance is used for mercury steam turbines, vacuum units and diffusion pumps. It is used to fill measuring instruments, batteries, and dry batteries. Mercury is involved in the production of air conditioners, refrigerators and washing machines. In agriculture, it is used as part of pesticides.

Properties of niobium (table): temperature, density, pressure, etc.:

| 100 | General information | |

| 101 | Name | Niobium |

| 102 | Former name | Columbia |

| 103 | Latin name | Niobium |

| 104 | English name | Niobium |

| 105 | Symbol | Nb |

| 106 | Atomic number (number in table) | 41 |

| 107 | Type | Metal |

| 108 | Group | Transition metal |

| 109 | Open | Charles Hatchet, UK, 1801 |

| 110 | Opening year | 1801 |

| 111 | Appearance, etc. | Shiny silver-gray metal |

| 112 | Origin | Natural material |

| 113 | Modifications | |

| 114 | Allotropic modifications | |

| 115 | Temperature and other conditions for the transition of allotropic modifications into each other | |

| 116 | Bose-Einstein condensate | |

| 117 | 2D materials | |

| 118 | Content in the atmosphere and air (by mass) | 0 % |

| 119 | Content in the earth's crust (by mass) | 0,0017 % |

| 120 | Content in seas and oceans (by mass) | 1,0·10-10 % |

| 121 | Content in the Universe and space (by mass) | 2,0·10-7 % |

| 122 | Abundance in the Sun (by mass) | 4,0·10-7 % |

| 123 | Content in meteorites (by mass) | 0,000019 % |

| 124 | Content in the human body (by weight) | |

| 200 | Properties of the atom | |

| 201 | Atomic mass (molar mass) | 92.90638(2) a. e.m. (g/mol) |

| 202 | Electronic configuration | 1s2 2s2 2p6 3s2 3p6 3d10 4s2 4p6 4d4 5s1 |

| 203 | Electronic shell | K2 L8 M18 N12 O1 P0 Q0 R0 |

| 204 | Atomic radius (calculated) | 164 pm |

| 205 | Empirical atomic radius* | 145 pm |

| 206 | Covalent radius* | 137 pm |

| 207 | Ion radius (crystalline) | Nb3+ 86 (6) pm, Nb4+ 82 (6) pm, Nb5+ 78 (6) pm (in parentheses the coordination number is indicated - a characteristic that determines the number of nearest particles (ions or atoms) in a molecule or crystal) |

| 208 | Van der Waals radius | |

| 209 | Electrons, Protons, Neutrons | 41 electrons, 41 protons, 52 neutrons |

| 210 | Family (block) | d-family element |

| 211 | Period in the periodic table | 5 |

| 212 | Group on the periodic table | 5th group (according to the old classification - a secondary subgroup of the 5th group) |

| 213 | Emission spectrum | |

| 300 | Chemical properties | |

| 301 | Oxidation states | -3, -1, +1, +2, +3, +4, +5 |

| 302 | Valence | I, II, III, IV, V |

| 303 | Electronegativity | 1.6 (Pauling scale) |

| 304 | Ionization energy (first electron) | 652.13 kJ/mol (6.75885(4) eV) |

| 305 | Electrode potential | Nb3+ + 3e– → Nb, Eo = -1.1 V |

| 306 | Electron affinity energy of an atom | 86.1 kJ/mol |

| 400 | Physical properties | |

| 401 | Density | 8.57 g/cm3 (at 0 °C/20 °C and other standard conditions, state of matter - solid) |

| 402 | Melting temperature* | 2477 °C (2750 K, 4491 °F) |

| 403 | Boiling temperature* | 4742 °C (5015 K, 8567 °F) |

| 404 | Sublimation temperature | |

| 405 | Decomposition temperature | |

| 406 | Self-ignition temperature of a gas-air mixture | |

| 407 | Specific heat of fusion (enthalpy of fusion ΔHpl)* | 30 kJ/mol |

| 408 | Specific heat of evaporation (enthalpy of boiling ΔHboiling)* | 689.9 kJ/mol |

| 409 | Specific heat capacity at constant pressure | 0.265 J/g K (at 25 °C), 0.322 J/g K (at 1000 °C) |

| 410 | Molar heat capacity* | 24.44 J/(K mol) |

| 411 | Molar volume | 10.8 cm³/mol |

| 412 | Thermal conductivity | 53.7 W/(mK) (at standard conditions), 53.7 W/(mK) (at 300 K) |

| 500 | Crystal cell | |

| 511 | Crystal grid #1 | |

| 512 | Lattice structure | Cubic body-centered |

| 513 | Lattice parameters | 3.301 Å |

| 514 | c/a ratio | |

| 515 | Debye temperature | 275 K |

| 516 | Name of space symmetry group | Im_ 3m |

| 517 | Symmetry space group number | 229 |

| 900 | additional information | |

| 901 | CAS number | 7440-03-1 |

Note:

205* The empirical radius of the niobium atom agrees to be 146 pm.

206* The covalent radius of niobium according to and is 164±6 pm and 164 pm, respectively.

402* The melting point of niobium according to and is 2468 °C (2741 K, 4474 °F) and 2470 °C (2743.15 K, 4478 °F), respectively.

403* The boiling point of niobium according to and is 4742 °C (5015 K, 8567 °F) and 4760 °C (5033.15 K, 8600 °F), respectively.

407* The specific heat of fusion (enthalpy of fusion ΔHmelt) of niobium according to and is 26.8 kJ/mol and 28 kJ/mol, respectively.

408* The specific heat of evaporation (enthalpy of boiling ΔHboiling) of niobium according to and is 680 kJ/mol and 662 kJ/mol, respectively.

410* The molar heat capacity of niobium is 24.44 J/(K mol).

Obtaining refractory materials

As noted earlier, the main obstacle to the production of heat-resistant metals is their high chemical activity, which prevents the release of elements in their pure form.

The main production technology remains powder metallurgy. This technique makes it possible to obtain powders of refractory metals in various ways:

- Reduction with hydrogen trioxide. The process is carried out in several stages, inside multi-tube furnaces at 750 – 950 °C. The technology is applicable for powders of refractory metals: tungsten and molybdenum.

- Reduction of perrhenate with hydrogen. The scheme is implemented in the production of rhenium metal. Operating temperatures are around 500 °C. The final stage involves washing the powder from the alkali. To do this, hot water and a solution of hydrochloric acid are used sequentially.

- Use of metal salts. Technology has been developed to isolate molybdenum. The main raw materials are the ammonium salt of the metal and its metal powder, introduced into the mixture at a level of 5–15% by weight. The composition undergoes heat treatment at 500 – 850 °C in flowing inert gas. The reduction of the metal takes place in a hydrogen atmosphere at temperatures of 800 – 1000 °C.

Production of refractory metals – powder metallurgy

Excursion to production

Methods for producing heat-resistant metals continue to be improved, as does the chemical technology of refractory non-metallic and silicate materials, which is associated with the development of nuclear energy, aircraft construction, and the emergence of new models of rocket engines.

One of the largest tungsten production enterprises in the Russian Federation is the Unech Refractory Metals Plant. This enterprise is relatively young; its construction began in 2007 on the territory of the settlement of Unecha. The plant's production focus is on powders of refractory metals, more precisely tungsten and its carbides.

Subsequently, to obtain ingots, the crumbly mass is sintered or compressed with a press. In a similar way, refractory metal powders are processed to produce heat-resistant products.

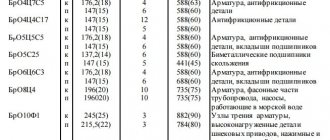

Chromium-based alloys

Chromium-based alloys have high heat resistance in an air atmosphere and are used for the manufacture of parts that operate for a long time in gaseous and liquid aggressive environments at temperatures of 1100...1150 °C, for a short time up to 1500...1600 °C. The most widely used wrought alloys based on chromium are grades VKh-1, VKh-1N. The chemical composition of the alloys is given in table. 13.

The mechanical properties of the VKh-1 alloy are presented in table. 14.

Table 13. Chemical composition of alloys VKh-1, VKh-1N

| Alloy grade | Chemical composition, % | ||||

| Cr | O | N | H | Other impurities | |

| VX-1 | 99,7 | 0,02…0,04 | 0,02…0,04 | 0,001…0,003 | 0,25 |

| VKh-1N | 99,2 | ≤ 0,5 | 0,001…0,03 | ≤ 0,3 | |

Table 14. Mechanical properties of alloy VKh-1

| Alloy grade | Type of semi-finished product | Mechanical properties | |||||

| σв, MPa | σ0.2, MPa | δ, % | Ψ, % | ak, (kgf m)/cm2 | NV | ||

| VX-1 | Rods | 290 | 200 | 4 | 6 | 0,1 | 100…120 |

Properties of the most refractory metals

Thus, the most refractory metal in the world (tungsten) is usually alloyed with rhenium, thorium, nickel with the participation of copper and/or iron. The first makes the alloy more corrosion-resistant, the second - more reliable, and the third - gives unprecedented density

It should be noted that all tungsten alloys contain no more than 4/5. Because tungsten is both hard and refractory, it is commonly used in electrical power supply, instrument construction, and the manufacture of weapons, projectiles, warheads, and missiles.

Denser alloys (nickel-based) are used to produce golf clubs. Tungsten also forms so-called pseudo-alloys. The fact is that the metal in them is not alloyed, but filled with liquid silver or copper. Due to the difference in melt temperatures, better heat and electrical conductivity properties are obtained.

Molybdenum, unlike tungsten, can be alloyed with only a few hundredths of parts and obtain excellent properties. The main alloying elements of molybdenum are: titanium + zirconium and tungsten. With the latter, the alloy turns out to be extremely inert, with great resistance. This makes it possible to use it for the manufacture of molds for casting zinc parts. A special use of molybdenum is as an alloying element in steel alloys. Steel+molybdenum alloys have good wear resistance and low friction values. Steel + molybdenum is used in the manufacture of pipes, pipe structures, automobiles and mechanical engineering.

Niobium and tantalum are like brothers, always nearby. Both are used in the manufacture of electrolytic capacitors. Niobium is also sometimes doped with hafnium and titanium to prevent it from reacting with oxygen during heating. Annealing niobium makes it possible to obtain metal with different elasticity and hardness coefficients. Niobium can be found in power supply, rocket and shipbuilding, nuclear industry, etc. Tantalum, due to its inertness to acids, is used in medicine and the production of high-precision electronics.

The rarest and most expensive metal presented is rhenium. It is difficult to extract, so in alloys it acts not as the main element, but as an alloying element. It is often used with copper and platinum. Rhenium strengthens such formations and improves their ability to forge. Used in nuclear, chemical (catalyst) and electronics industries.

The use of the beneficial properties of refractory metals and alloys is considered by scientists around the world as a very promising area of scientific research.

Classification

Depending on the melting point, refractory metals are assigned to the main or additional group.

Main group

This segment includes five positions: tungsten, niobium, tantalum, molybdenum, rhenium.

Melts at 2200°C+. Properties of the fourth group of elements

| Name | Niobium | Molybdenum | Tantalum | Tungsten | Rhenium |

| Melting temperature | 2750 K (2477 °C) | 2896 K (2623 °C) | 3290 K (3017 °C) | 3695 K (3422 °C) | 3459 K (3186 °C) |

| Boiling temperature | 5017 K (4744 °C) | 4912 K (4639 °C) | 5731 K (5458 °C) | 5828 K (5555 °C) | 5869 K (5596 °C) |

| Density | 8.57 g cm³ | 10.28 g cm³ | 16.69 g cm³ | 19.25 g cm³ | 21.02 g cm³ |

| Young's modulus | 105 GPa | 329 GPa | 186 GPa | 411 GPa | 463 GPa |

| Vickers hardness | 1320 MPa | 1530 MPa | 873 MPa | 3430 MPa | 2450 MPa |

Molybdenum

The most popular of the refractory elements.

The number one area of use is metallurgy:

- Molybdenum is used to “strengthen” steel to produce a hard alloy.

- Together with stainless steel, it is used as a material for the infrastructure of pipelines, car parts, and other mechanical engineering products.

- Due to its melting point, wear resistance, and low abrasion, it is used as an alloying additive.

For example, half a percent titanium plus 0.08% zirconium creates a molybdenum alloy that does not lose strength up to 1060°C.

Extraordinary friction parameters have led to the use of molybdenum as a long-lasting lubricant with high efficiency.

The material is indispensable for mercury relays, since an amalgam with this metal is not formed by mercury.

Tungsten

Opened at the end of the 18th century. The hardest and most refractory (3422°C) metal.

Refractory durable metal, light gray in color - tungstenTogether with copper and iron, it is used as the basis (up to 80%) of alloys with rhenium, thorium, and nickel. Such additives increase density, rust resistance threshold, and reliability.

It is in demand as a material for power supply systems, instruments, ammunition, and nuclear missile warheads. Nickel alloys are valued by golf fans as club materials.

Tungsten ingots

Tantalum

The most resistant to acids and corrosion from the segment of refractory metals.

Heavy, hard metal of gray color – tantalum

Therefore, it is used in capacitors of smartphones, tablets, and other gadgets.

Compatible with biological organisms (does not change under the influence of natural acids). Because of this, it is used in medicine.

Niobium

Metal with unusual characteristics:

- The lightest (low density) in the segment.

- It is unique due to its ability to change the coefficient of hardness and elasticity depending on the degree of annealing.

- Most common in superconducting alloys.

It is used as a material for capacitors, gas turbines, rockets, and aircraft. As well as an element of nuclear reactors and lamps of electronic devices.

Rhenium

The rarest and most expensive of the refractory metals:

- In alloys it acts as an alloying component, never as a main component.

- As an alloy, it increases the utilitarian qualities of the alloy: strength, malleability (for example, with copper and platinum).

- Found last in the refractory segment.

Alloys with rhenium serve as catalysts, filling electronic equipment, gyroscopes, and reactors of nuclear facilities.

Additional group

This segment of refractory metals includes nine positions. Their common feature is the melting threshold of 1850°C.

This includes nine elements from three groups (fourth – sixth periods) of the periodic table.

Each has its own “zest”:

- Osmium is the densest substance on the planet, the heaviest refractory.

- Iridium is found more often in meteorites than on Earth.

- Metamorphoses of the heat capacity of hafnium are still inexplicable by science.

- Ruthenium is named after Russia.

- Pure vanadium is used to make tokens and medals for collectors.

- Titanium is the only refractory non-ferrous metal. Material of dental and bone prostheses.

- Without zirconium, fireworks and fireworks are impossible. Medical "understudy" of titanium.

A thin layer of chrome and noble rhodium is used to cover the surface of luxury products, including jewelry. The processes are called chrome plating and rhodium plating.

General properties of refractory metals

Refractory metals and their alloys attract the attention of researchers due to their unusual properties and future prospects for application. The physical properties of refractory metals such as molybdenum, tantalum and tungsten, their hardness and stability at high temperatures make them a material used for hot metal working of materials both in vacuum and without it.

Many parts are based on their unique properties: for example, tungsten filaments can withstand temperatures up to 3073 K

The physical properties of refractory metals such as molybdenum, tantalum and tungsten, their hardness and stability at high temperatures make them a material used for hot metal processing of materials both in vacuum and without it. Many parts are based on their unique properties: for example, tungsten filaments can withstand temperatures up to 3073 K

.

However, their resistance to oxidation up to 500 °C

making them one of the main weaknesses of this group. Contact with air can significantly affect their high temperature performance. That is why they are used in materials in which they are isolated from oxygen (for example, a light bulb).

Alloys of refractory metals - molybdenum, tantalum and tungsten - are used in parts of space nuclear technologies. These components have been specially created as a material capable of withstanding high temperatures (from 1350 K

up to 1900

K

). As stated above, they should not come into contact with oxygen.

Temperature of transition of metals to the superconducting state

| Metal | °K |

| Titanium | 0,53 |

| Vanadium | 5,1 |

| Zirconium | 0,7 |

| Niobium | 9,17 |

| Molybdenum | 0,9-0,98 |

| Hafnium | 0,35 |

| Tantalum | 4,40 |

| Rhenium | 1,7 |

| Tungsten | 0,05 |

Conversion table for hardness numbers

| Rockwell hardness | Vickers hardness (HV) | Brinell Hardness (HB) | |

| C scale (HRC) | Scale A (HRA) | ||

| 70 | 86,5 | 1076 | — |

| 69 | 86,0 | 1004 | — |

| 68 | 85,5 | 942 | — |

| 67 | 85,0 | 894 | — |

| 66 | 84,5 | 854 | — |

| 65 | 84,0 | 820 | — |

| 64 | 83,5 | 769 | — |

| 63 | 83,0 | 763 | — |

| 62 | 82,5 | 739 | — |

| 61 | 81,5 | 715 | — |

| 60 | 81,0 | 695 | — |

| 50 | 76,0 | 513 | — |

| 49 | 75,5 | 498 | — |

| 48 | 74,5 | 485 | — |

| 47 | 74,0 | 471 | 448 |

| 46 | 73,5 | 458 | 437 |

| 45 | 73,0 | 446 | 425 |

| 44 | 72,5 | 435 | 415 |

| 42 | 71,5 | 413 | 393 |

| 40 | 70,5 | 393 | 372 |

| 30 | — | 301 | 283 |

| 28 | — | 285 | 270 |

| 26 | — | 271 | 260 |

| 24 | — | 257 | 250 |

| 22 | — | 246 | 240 |

| 20 | — | 236 | 230 |

Elastic properties of refractory metals

| Metal | Compressibility coefficient, X106 cm2/kg | Modulus of normal elasticity, kg/mm2 | Shear modulus, kg/mm2 | Poisson's ratio |

| Titanium | — | 9000-10000 | — | — |

| Zirconium | 1,097 | 8960 | 3330 | 0,35 |

| Hafnium | — | 9800-14060 | — | — |

| Vanadium | — | 13500 | — | — |

| Niobium | — | 9080 | 8820 | 0,39 |

| Tantalum | 0,52 | 18830 | 7000 | 0,35 |

| Chromium | — | 25000 | — | — |

| Molybdenum | 0,347 | 33630 | 12200 | 0,31 |

| Tungsten | 0,293 | 41500 | 15140 | 0,30 |

| Rhenium | — | 47000 | — | — |

| Ruthenium | — | 42000 | — | — |

| Rhodium | — | 28640 | — | — |

| Osmium | — | 57000 | — | — |

| Iridium | — | 53830 | — | — |

Thermal conductivity coefficient of refractory metals

| Element | T°C | Thermal conductivity coefficient k W/m∙K |

| Vanadium | 20 | 33,2 |

| Tungsten | 27 | 130 |

| Molybdenum | 27 | 162 |

| Niobium | 27 | 53 |

| Tantalum | 27 | 63 |

| Chromium | 27 | 67 |

| Zirconium | 50 | 20,96 |

Thermodynamic properties of refractory metals

| Element | Specific heat capacity, J/K∙mol | Heat of fusion, kJ/mol | Heat of evaporation, kJ/mol |

| Vanadium | 0,485 | 17,5 | 460 |

| Tungsten | 24,8 | 35 | 824 |

| Molybdenum | 0,251 | 28 | 590 |

| Niobium | 0,268 | 26,8 | 680 |

| Tantalum | 0,140 | 24,7 | 758 |

| Chromium | 0,488 | 21 | 342 |

| Zirconium | 0,281 | 19,2 | 567 |

Symbols:

- σв — tensile strength;

- σт—yield strength;

- σ0.2 is the yield strength at which the residual deformation is 0.2% of the length of the test sample;

- δ—relative elongation;

- ψ - relative narrowing;

- k is the thermal conductivity coefficient;

- HB—Brinell hardness;

- HV—Vickers hardness;

- HR - Rockwell hardness.

Application area

According to the USGS (United States Geological Survey), about 80 percent of Nb is used in the steel industry to create high-strength, low-alloy steels. The properties of niobium make it possible to use it in alloys, which increases mechanical and heat resistance, impact strength and corrosion resistance.

Other uses include pipeline construction, superalloys for heat-resistant equipment, as well as jet engines and jewelry. Niobium, tungsten, molybdenum, tantalum and rhenium are known as the five refractory metals. All of them have very high resistance to heat and wear.

Niobium is used in the steel industry

Industrial use of Nb began in the early 1900s. Niobium's largest market (>80%) is in the high-strength, low-alloy steel industry, where it provides high heat resistance and corrosion resistance for gas pipelines, automotive components, and structural steel.

Nb, like tantalum, allows alternating current to flow in only one direction through the electrolyser. Niobium metal is used in arc welding rods for stabilized grades of stainless steel. Its most interesting applications are in the field of superconductivity. Superconducting magnets are made of Nb-Zr (niobium and zirconium) wire, which maintains superconductivity in strong magnetic fields.

Which metal is considered the most refractory?

Metal has been used by humans in various fields of activity since ancient times.

To obtain a high-quality metal product, it is important to choose a good material, while assessing its characteristics. An important parameter is refractoriness

For the manufacture of some products, only the most refractory metals are suitable.

Definition

Refractory metal is a separate class that includes metal blanks that can withstand exposure to critically high temperatures. Typically, members of this class have a melting point of more than 1600 degrees, which is considered the melting point of iron. These include noble alloys. They are also called representatives of the platinum group.

Properties

To understand where it is best to use a material, you need to know the properties of refractory metals. They are used to make parts for industrial equipment, machinery and electronics. The characteristics of heavy refractory metals will be described below.

Physical properties

Characteristics:

- Density - up to 10000 kg/m3. For tungsten this figure reaches 19,000 kg/m3.

- The average melting point is 2500 degrees Celsius. Tungsten has the highest metal melting point - 3390 degrees.

- Specific heat capacity - 400 J.

Refractory objects cannot withstand impacts and falls.

Chemical properties

Chemical properties:

- These are solid substances with high chemical activity.

- Strong interatomic structure.

- Resistance to long-term exposure to acids and alkalis.

- High paramagnetic index.

These materials have some disadvantages. The main one is the difficult process of processing and manufacturing products from it.

Application

Initially, refractory metals were used in the manufacture of capacitors and transistors for radio electronics. The number of their areas of application increased only by the middle of the 20th century. The industrial complex expanded to produce parts for machine tools, cars, airplanes and missiles.

Alloys that can withstand exposure to critical temperatures began to be used to make tableware. Refractory metals are used in the production of building and connecting materials. They are used to make parts for household appliances and electronics.

Tungsten is considered the most refractory. Its melting point of 3390 degrees exceeds other materials. However, we must not forget that if a tungsten part falls from a height, it will crack or break into separate parts. Tungsten is the most refractory metal on EARTH! Other materials with a high melting index are little different from tungsten. They are used in mechanical engineering, shipbuilding, nuclear energy, and the manufacture of industrial equipment. Their development and research continues to this day.

Which metal is considered the most refractory? Link to main publication

What is the refractoriness of metals?

The essence of the term should be clear from the phrase itself - these are metals that “tightly”/hard to melt. In most scientific and technical literature, the term is assigned based on the minimum melting point of a chemical element - from +2,200 degrees Celsius.

Additional chemical elements belong to the so-called extended group of refractory metals - 9 substances + 5 from the main group. There are other metals whose melting point falls within the range of refractory substances, but they are located in the periodic table behind uranium (transuranium).

Due to the instability of isotopes + small distribution over the earth's surface, transuranium metals are not classified as refractory metals.

Physical/chemical properties of refractory metals:

- if we do not take into account carbon and osmium, the temperature indicators for melting of substances have no competitors in the periodic table;

- a high threshold of resistance to deformation of a substance under constant influence of mechanical pressure (creep deformation). For ordinary metal elements, the specified threshold starts from 220 degrees, and for refractory ones from 15,000 degrees. That is why it is much easier to forge iron than a product made from niobium or other refractory substance;

- due to the ease of reaction of compounds with other chemical elements, it is almost impossible to find refractory metals in their pure form;

- In the open air, refractory metals oxidize very slowly. Almost immediately a protective layer in the form of a film forms on the surface;

- When infusible metals are heated, they become vulnerable to corrosion. Their fragility increases + 50%+ of their properties are lost.

The physical properties of refractory metals vary greatly due to their belonging to different groups. All 100% of the elements are refractory, but only 25% of them can be classified as heat-resistant. This difference is due to a change in physical properties when the chemical element is heated. The metal may become susceptible to aggressive environments such as alkalis and acids. More details on each of the refractory metals will be below.