Metal-cutting machines are a broad group of industrial equipment for processing metal workpieces. In addition to working with metal, they are suitable for cutting metal, plastic, and other materials. Due to the diversity of attitudes, they are divided into separate groups according to different factors.

Metal cutting machine for processing workpieces

Types of machines

All metal cutting units belong to one of the following groups:

- Lathes.

- Boring and drilling.

- Lapping, polishing, grinding.

- Combined, also known as special purpose units.

- Gear and thread processing.

- Milling.

- Broaching, planing, slotting.

- Split.

- Different.

Each group has a generally accepted numerical designation. It corresponds to her number in this list.

Japanese Okuma

Popular manufacturers of CNC machines. Japanese Okuma

With over a century of experience and the largest distribution network in America, it's safe to say that Okuma is one of the largest players in the engineering industry. Notably, the company is the only supplier in the industry that has CNC machines, drives, motors, encoders, spindles and CNC systems that are manufactured in-house. Okuma has always been an innovator, remaining at the forefront of development of all technologies, including CNC routers.

They provide the following services:

- CNC lathe

- CNC Machining Center

- CNC grinding machine

- CNC Laser Machine

- Double Column CNC Router

Metal cutting machines

Regardless of the group, type and model of the device, processing consists in the fact that the workpiece and cutting tool perform shaping movements. Due to these movements, the dimensions and configuration of the object are set. For CNC models, a program is prescribed in advance, taking into account all the nuances of a particular object, and it is loaded into the controller using a programmer. From the controller, commands are sent to the operating components of the unit. At the end of the program, the device turns off automatically.

Computer numerical control devices provide significantly higher processing speed and accuracy compared to traditional analogues. They are purchased for large-scale production, since such models are successfully integrated into large automated lines.

A technology that involves removing a certain part of material from an object’s body in order to obtain the desired geometry is known as subtractive. The object to which the impact is applied can be either sheet metal or solid metal. From sheet metal, flat objects of various configurations are obtained, from massive material - three-dimensional objects with any desired number of surfaces.

From a physics point of view, metal can be cut if its crystal lattice is disrupted. When a cutting tool plunges into an object and moves along its surface, it breaks the atomic bonds in the structure of the object with its hard, sharp edges. During plasma or laser cutting, the bond between atoms breaks down due to high temperatures. During guillotine cutting or stamping, the crystal lattice is destroyed due to shear deformation. The advantage of this method is that it leaves no waste behind.

Sawdust poses a major problem in the metalworking process. Metal shavings getting inside the machine can lead to breakdowns. Therefore, the equipment must be covered with safety covers, and the chips must be removed in a timely manner. Operators of outdated machine models collect sawdust by hand. Modern models have conveyor belts that transport the chips to a disposal container. Dust extractors are installed on the grinding and sharpening units, which remove waste from the processing area.

Advanced Metalworking Techniques

In industrial conditions, both the latest and long-known methods are used for metal processing. Modern types of metalworking equipment meet the following requirements:

- productivity – industrial volumes require high speed of operations;

- accuracy - you need to maintain dimensions when manufacturing even the smallest parts;

- reliability and wear resistance.

Industrial equipment for metalworking is divided according to the type of impact on the material. Cutting can rightfully be considered the most common operation at metalworking enterprises.

Gas metal cutting

This method has been known for a long time, but the machines currently produced are fully automated. This eliminates inaccuracies when cutting sheets, which can be caused by the human factor. The disadvantages of the method are low accuracy and heat shrinkage of the metal. Pros: low cost of equipment and high speed of execution.

Plasma cutting machines

Cutting occurs using a narrow plasma jet, which allows for high precision and arbitrary shapes of the workpiece. The high quality of the surface at the cut site, productivity and the ability to cut almost any part are offset by one drawback - plasma machines are not cheap.

Laser processing

Laser cutting machines are precise and prevent loss of material at the cut site due to its small width. This type of equipment is used for processing soft non-ferrous metals: aluminum, brass, bronze (including valuable ones). Laser cutting machines are often used to produce blanks for electronic circuit boards and parts for modern household appliances.

Waterjet and electroerosive machines

These types of equipment are used for precise cutting of any metal of any thickness. The relatively low processing speed is compensated by quality. Both methods guarantee high accuracy and very low cutting allowance consumption. Waterjet and electroerosive machines are used in space, electronics and other types of industries.

Gantry metal gas cutting machines

When processing industrial volumes of metal, modern enterprises use portal gas cutting machines. The design of the machine allows you to place sheets ranging in size from 1.5x3 m to 3x12 m in the working area.

This cutting method is economical, but there is also a small drawback. When processing sheet metal of small thickness, heat shrinkage and a decrease in cutting accuracy are possible. The operator will need maximum care and experience when working with a gantry gas cutting machine.

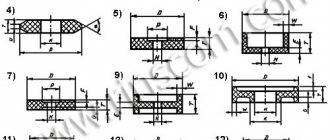

Types of metal cutting machines

Units for cutting metal are very diverse. Here are their main categories:

- Milling group machines. Among the non-console ones there are engraving, copying, longitudinal and vertical installations. Among the console ones there are widely universal, horizontal and vertical devices.

- Lathes. They can be rotary, frontal, drilling and cutting, revolving, multi-cut copying, single or multi-spindle, as well as specialized (that is, automatic or semi-automatic).

- Grinding. They can be cylindrical, internal or surface grinding. This also includes different types of sharpening and specialized units, polishing and roughing equipment.

- Planing. These are broaching devices of vertical or horizontal type, as well as longitudinal models with one or two posts.

- Split. These are straightening cutting devices, as well as machines equipped with smooth metal discs or abrasive wheels. Models with cutters or saws - hacksaws, disks, and bands - fall into the same category.

- Units for processing components of threaded and gear connections. They can be gear-finishing, gear-milling, thread-milling, thread-cutting, thread- and gear-grinding, checking, for processing elements of worm pairs and the ends of teeth, as well as gear-planing for cylindrical gears or gear-cutting for working with bevel wheels.

- Models for drilling and boring. They are equipped with one or more spindles. Boring units are horizontal, diamond or coordinate, drilling machines are radial, horizontal or vertical.

There are other types of units that do not belong to any of the above categories. For example, machines can be sawing machines, filing machines, dividing machines, balancing machines, centerless and leveling machines, and so on.

Germany MAG

MAG is a leading manufacturing technology group for milling and turning for production systems and turnkey machines with customized application technologies. The firm has become a global player since its founding in 2005. MAG serves the automotive and trucking industries and their suppliers. unrivaled technology and experience.

Popular manufacturers of CNC machines. German MAG

MAG offers machines, production systems and services including turning, milling, honing, system integration, automation, software, maintenance, upgrades, e-learning and core components for machine tools. As a full-scale supplier, MAG's manufacturing solutions include processing technology, process capabilities, systems engineering and turnkey systems.

Classification of metal-cutting machines by parameters

In addition to the above characteristics, units can be classified according to the following parameters:

- Weight and dimensions. The installation may be heavy, large or unique.

- Degree of specialization. Models capable of working with workpieces of various shapes and sizes are universal. Devices that process workpieces with the same dimensions are special. Units that process workpieces of different but similar dimensions are called specialized.

- Processing precision. Normal accuracy is designated by the letter N, increased - P, high - B, especially high - A.

Separately, there are precision units, designated by the letter C. They are designed for particularly precise processing.

According to another classification by weight, machines are light (less than 1 ton), medium (from 1 to 10 tons), heavy (from 10 to 16 tons), large (from 16 to 30 tons), and heavy (from 30 to 100 tons) ), especially heavy (over 100 tons).

Japanese Toyoda

Clever engineering has been the cornerstone of Toyoda machines since the company was founded in 1941 as Toyoda Machine Works. Originally produced for the production lines of a major Japanese automobile company, Toyoda grinding machines were designed to operate in high-productivity environments.

Over the years, Toyoda has maintained this level of craftsmanship to ensure that its production is of the highest quality standards. In 1968, Toyoda expanded its product line to horizontal machining centers and later included automation systems, vertical machining centers and lathes, TOP centers, bridge machines and boring machines in Toyoda Americas Corporation's JTEKT product line.

Popular manufacturers of CNC machines. Japanese Toyoda

Toyoda understands tight tolerances, superior speed and maximum productivity. Every detail is carefully considered - from the durable cast iron base to the operator-friendly ergonomic design - to help maximize productivity in the metalworking industries.

Classification by automation level

Depending on how active operator intervention should be, all models are divided into:

- To automatic. Their actions are controlled by the program, but the operator must set processing parameters in them.

- CNC. The entire range of processes is controlled by a program into which a coded system of numerical values is introduced.

- Semi-automatic. The operator is required to manually install the workpiece, start the device, and remove the finished object. Automatic control in such models applies only to auxiliary operations.

- Manual. The operator operates the unit entirely manually.

Flexible automated modules are separately distinguished.

General design features of all types of metal-cutting machines

No matter how the machines differ in their functionality, their design invariably contains a number of common elements:

- Operator console, also known as remote control. It is needed to enter control and monitoring software into the unit. The console allows you to control all aspects of the device’s operation manually as well.

- Controller. It generates control commands that are sent to the working elements of the unit and monitors the correctness of their execution. The controller is also responsible for calculations. Depending on how complex the machine is, its controller can be either a regular microprocessor or a powerful compressor.

- Display, also known as a panel for controlling and monitoring the machine. Through this screen you can watch the operation of the unit in real time, adjusting its settings and parameters if necessary.

Models for single or small-scale production may have a unique design or differ significantly from standard analogues. Devices for large-scale and mass production are called aggregate, and their design is more uniform. In this case, units mean similar units from which machines are assembled: tables, beds, working heads, and so on.

Content

- Application area

- Classification of machines by type

- Classification by degree of versatility

- Classification by parameters

- Classification by accuracy

- Classification by degree of automation

- Marking of metal-cutting machines

Metalworking equipment

is a large group of industrial machines and machines for processing metal workpieces. This technique is suitable not only for working with metal products. It is also used for cutting plastic and other materials. The variety of machines is due to the need to carry out various types of work with metal. In addition, different models differ in internal structure, size, drive type and other parameters.

Design of metal-cutting machines equipped with CNC

Any machine model contains key elements responsible for its functioning. They provide the movement through which cutting occurs and the feed movement performed by the workpiece or cutting tool. To perform both functions, the unit must contain the following three components:

- Control system. It starts and stops the device, controls all stages of its operation.

- Drive - hydraulic, pneumatic, mechanical or electric.

- A unit that transforms movement from an electric motor and transmits it to the actuator.

Separately, it is worth mentioning the units of metal-cutting equipment on which cutting tools are placed. They are present on all machines, since without them the units would not cope with their function.

Application area

Metalworking equipment

- This is the basis of various industries. This is an integral part of many areas of technical production and economic activity. Devices for mechanical processing of metal speed up the work process, reduce labor costs, reduce production costs and help optimize production.

Machines and production lines with metalworking equipment are used in the following manufacturing industries:

- mechanical engineering (precision and heavy);

- space and aircraft construction;

- shipbuilding;

- instrument making;

- bridge construction;

- automotive industry;

- construction of metal structures;

- military industry.

Metalworking machines are used in almost all industrial enterprises. The production process requires constant improvement of equipment, and modern mechanisms make it possible to create new parts. That is why technical devices for metalworking are of great importance for the economy of any country in the world.

Marking of metal-cutting machines

The marking of units is an alphanumeric combination that allows you to understand at which enterprise the device was manufactured and what its main characteristics are.

There are two types of markings:

- For serial production units. The first digit indicates the device group, the second - the type, the third and fourth - the standard size. The letter after the first two digits indicates that the model has been modernized. It is followed by a pair of digits of the service number. Then comes a combination of one letter and a number - this is a type of numerical control. The final combination of letter and number characterizes the computing device.

- For specialized units. The first two letters indicate the name of the manufacturer in the abbreviated version. Then there are three digits of the main operational number, and after them - a letter modification. The final letter and number characterize the computing device.

The marking has two purposes: to facilitate the search for a specific model in catalogs and the selection of components for it in the event of a breakdown or scheduled maintenance.

So, now you know what metal cutting machines are, by what parameters they are classified and what nuances you should pay attention to when choosing them. Any CNC units perform their duties better, faster and more efficiently than traditional counterparts. Purchasing such a device will be a significant investment in your business and will quickly pay for itself

- 05 September 2020

- 2345

Exhibition of metalworking equipment

The metalworking exhibition is a serious, highly specialized event that brings together professionals in this field. Progressive equipment, new surface treatment techniques, modern software, components - all this is presented at the organized exhibition. Here you will find: information about the latest scientific achievements, meaningful communication with experts and a thoughtful business program.

Participants and visitors

The participants of the event are world-famous companies and little-known manufacturers/suppliers who strive to increase demand and effective product promotion. The main task is to demonstrate high-performance machine tools, tools, materials and the latest developments in this industry.

Among visitors :

- general directors and deputies;

- leading technologists;

- chief engineers.

Professionals in such industrial sectors as shipbuilding and mechanical engineering, metallurgy, energy, construction and so on gather here. Managers of manufacturing companies and factories choose high-performance machine tools to efficiently complete their tasks.

Advantages of exhibitions

Each side receives beneficial positive aspects, which we will discuss in more detail.

Event participants can, as soon as possible,:

- find potential buyers willing to purchase specialized equipment and tools for metalworking;

- increase the number of sales;

- expand the territorial boundaries of sales;

- arrange a demonstration of modern technological solutions and innovative developments of the company;

- learn an unbiased analysis of the technical characteristics and performance indicators of the exhibited equipment;

- establish communication with intermediary organizations and company managers using the proposed machine systems.

The benefits for visitors will be:

- a wide range of high-performance devices;

- direct analysis of technical indicators;

- studying the latest developments;

- testing of modern technologies in operating mode;

- execution of transactions on favorable terms;

- expert recommendations on the correct choice of metalworking products.

The conditions of highly specialized exhibitions allow participants and visitors to begin business relationships, which will subsequently lead to long-term mutually beneficial cooperation.