INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION (IGS)

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION (ISC)

| INTERSTATE STANDARD | GOST 12595-2003 (ISO 702-1:2001) |

METAL CUTTING MACHINES

FLANGED SPINDLE ENDS TYPEAA AND CLAMPING DEVICE FLANGES

MAIN AND CONNECTING DIMENSIONS

ISO 702-1:2001

Machine tools — Connecting dimensions of spindle noses and work holding chucks — Part 1: Conical connection

MOD

Moscow

IPC Publishing House of Standards

2005

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-97 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Procedure for development, adoption, application, updating and cancellation."

Information about the standard

1 DEVELOPED by the open joint-stock company “Experimental Research Institute of Metal-Cutting Machine Tools” (JSC “ENIMS”)

2 INTRODUCED byStandard of Russia

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Protocol No. 24 of December 5, 2003)

Acceptancevoted:

| Short name of the country according to MK (ISO 3166) 004-97 | PoMK country code (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

| Azerbaijan | AZ | Azstandard |

| Armenia | A.M. | Armstandard |

| Belarus | BY | State Standard of the Republic of Belarus |

| Kazakhstan | KZ | Gosstandart of the Republic of Kazakhstan |

| Kyrgyzstan | KG | Kyrgyzstandard |

| Moldova | M.D. | Moldova-Standard |

| Russian Federation | RU | Federal Agency for Technical Regulation of Metrology |

| Tajikistan | T.J. | Tajikstandard |

| Turkmenistan | TM | Main State Service "Turkmenstandartlary" |

| Uzbekistan | UZ | Uzstandard |

| Ukraine | U.A. | Gospotrebstandart of Ukraine |

4 This standard is modified in relation to the international standard ISO 702-1: 2001 “Metal-cutting machines. Connecting dimensions of the ends of the spindles and flanges for fastening the workpiece. Part 1. Conical connections" (ISO 702-1:2001 "Machine tools-Connecting dimensions of spindle noses and work holding chucks-Part 1: Conical connection"). The name of this standard has been changed relative to the name of the specified international standard to bring it into compliance with GOST 1.5 (subsection 3.6). At the same time, additional provisions that take into account the needs of the national economy of the above-stated features of interstate standardization are given in the section and appendix, highlighted in italics

5 By Order of the Federal Agency for Technical Regulation and Metrology dated December 1, 2004 No. 96-st, the interstate standard GOST 12595-2003 (ISO 702-1: 2001) was put into effect directly as a national standard of the Russian Federation from July 1, 2005.

6 VZAMENGOST 12595-85

GOST 12595-2003 (ISO 702-1:2001)

INTERSTATE STANDARD

Metal cutting machines

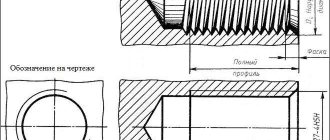

SPINDLE ENDS TYPE A FLANGE AND CLAMPING DEVICE FLANGES

Main and connecting dimensions

Metal-cutting machine tools. Flanked spindle noses of A type and flanges of fixtures. Basic and coupling dimensions

Date of introduction - 2005-07-01

Other GOSTs

GOST 17252-71 Ends of mandrels for fastening countersinks during reverse trimming. Design and dimensions GOST 9400-81 Threaded connecting ends for fittings, connecting parts and pipelines for lens seals at PN 20-100 MPa (200-1000 kgf/cm2). Dimensions GOST 13954-74 Flared pipe ends for connecting pipelines along an outer cone. Design and dimensions GOST 2822-78 Pin and fitting ends of ship fittings and connecting parts of pipelines. Main parameters, dimensions and technical requirements GOST 2324-77 Ends of grinding spindles with internal base surfaces. Connecting dimensions GOST 2323-76 Grinding spindle ends with an external base cone. Connecting dimensions GOST 13876-87 Spindle ends of aggregate machines. Main dimensions GOST 22357-87 Figure skating skates. General technical conditions GOST 22358-87 Cross-country and hockey skates. General technical specifications GOST 12593-72 The ends of the spindles are flanged for a rotary washer. Dimensions GOST R 50101-92 Ends of spindles of drilling, boring and milling machines. Dimensions. Technical requirements GOST 30064-93 Ends of spindles of drilling, boring and milling machines. Dimensions. Technical requirements GOST 16868-71 The ends of the spindles are threaded. Dimensions GOST 17547-80 Spindle ends of gear cutting machines for bevel gears. Main Dimensions

Our events —>

Sections

- home

- News

- Articles

- ads

- Forum

- Organizations

- Directories

- Documentation

- Events

- Editions

- Industry faces

About the portal

Services

- WAREHOUSE, Tenders, Market

- Cable weight calculation

- Decoding the cable brand

- Calculation of checkpoint loading scheme

- Photo, Video

- On the map

- GOSTs, SNiP

- Vacancies, resume

- Site rating

- Mobile applications

- Mobile version

- RSS feeds

- English version

Media holding "RusCable"

- Portal "RusCable.Ru"

- RusCable Insider Digest

- ENERGOSMI

- ElektroPortal.Ru

- Search system "1EL.ru"

- RCWA Award

- Electrical Engineering Yellow Page

- Project "PUNP.RF"

- Project "FIRE RESISTANCE.RF"

- Cabex Chronicles

- Meeting December 8

- “RusCableCLUB” (club anthem)

- Production calendar 2022 (pdf, 1.4 MB)

- home

- News

- Articles

- ads

- Forum

- Organizations

- Directories

- Documentation

- Events

- Editions

- Industry faces

- About RusCable

- Reviews

- Media kit (pdf, 4.8 MB)

- Presentation (pdf, 6 MB)

- Corporate calendar (pdf, 15 MB)

- Advertising on the portal

- Special project “Survival of the fittest”

- Site Map

- Site search

- Administration message

- FacebookVKontakteTwitterYouTubeInstagramTelegram+7 (999) 003-33-36

- WAREHOUSE, Tenders, Market

- Cable weight calculation

- Decoding the cable brand

- Calculation of checkpoint loading scheme

- Photo, Video

- On the map

- GOSTs, SNiP

- Vacancies, resume

- Site rating

- Mobile applications

- Mobile version

- RSS feeds

- English version

- Portal "RusCable.Ru"

- RusCable Insider Digest

- ENERGOSMI

- ElektroPortal.Ru

- Search system "1EL.ru"

- RCWA Award

- Electrical Engineering Yellow Page

- Project "PUNP.RF"

- Project "FIRE RESISTANCE.RF"

- Cabex Chronicles

- Meeting December 8

- “RusCableCLUB” (club anthem)

- Production calendar 2022 (pdf, 1.4 MB)

Online reception of the “Cable Industry” section of the Advisory Council under the Chairman of the Energy Committee of the State Duma of the Russian Federation

Video reviews

Video review of installation on the machine:

Video review, disassembly, cleaning, polishing:

Video review of a wood lathe chuck:

Video review of a homemade lathe chuck made of wood (cheap option):

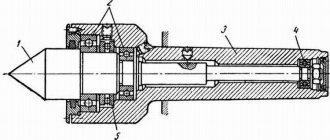

Installing a chuck on a lathe can be done using several methods, it all depends on the specific type of this element that you will be dealing with.

There are two types of chuck mounting on a lathe spindle:

Threaded fastening is used on small machines with light types of chucks, flanged on medium and heavy machines.

If it is light, it is quite easy to install on the machine without outside help, then heavy ones (more than 20 kg) are installed with the help of auxiliary lifting mechanisms, or in tandem with a partner. Let's consider the procedure for installing a heavy flange-mounted chuck on a lathe.

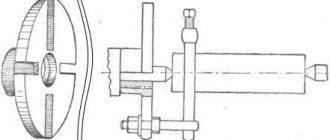

To install a heavy chuck, you need to prepare two mounting fixtures.

- mounting stand;

- guide

The mounting stand is made from a board approximately 50 mm thick. The width is equal to 1.5 times the width of the installed cartridge, the length of the stand L- corresponds to the width of the bed-B and the radius-D.

The blocks are attached to the bottom of the stand. Through vertical through holes, the stand is bolted to the movable rest of the machine support. The height of the stand is adjusted by the thickness of the bars.

Between the steady rest with the stand attached to it and the chuck still installed on the machine, the gap should be 1-3 mm.

The guide is a cylindrical shaft with a diameter of 25-40 mm, with a shank in the form of a Morse cone of at least number three. The length of the cylindrical part of the guide is equal to 1.5-2.0 times the width of the installed cartridge.

Download document

INTERSTATE

COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION (ISC

)

INTERSTATE STANDARD

GOST 12595-2003

(ISO 702-1:2001)

METAL CUTTING MACHINES

TYPE A FLANGED SPINDLE ENDS AND CLAMPING DEVICE FLANGES

BASIC AND CONNECTING

DIMENSIONS

ISO 702-1:2001

Machine tools — Connecting dimensions of spindle noses and work holding chucks

— Part 1: Conical connection

IPK Standards Publishing House

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-97 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Procedure for development, adoption, application, updating and cancellation."

Standard information

1 DEVELOPED by the Open Joint Stock Company "Experimental Research Institute of Metal-Cutting Machine Tools" (JSC "ENIMS")

2 INTRODUCED by Gosstandart of Russia

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Protocol No. 24 of December 5, 2003)

The following voted for adoption:

Short name of the country according to MK (ISO 3166) 004-97

Country code according to MK (ISO 3166) 004-97

Abbreviated name of the national standardization body

State Standard of the Republic of Belarus

Gosstandart of the Republic of Kazakhstan

Federal Agency for Technical Regulation and Metrology

4 This standard is modified in relation to the international standard ISO 702-1:2001 “Metal-cutting machines. Connecting dimensions of the ends of spindles and flanges for fastening the workpiece. Part 1. Conical connections" (ISO 702-1:2001 "Machine tools-Connecting dimensions of spindle noses and work holding chucks-Part 1: Conical connection"). The name of this standard has been changed relative to the name of the specified international standard to bring it into compliance with GOST 1.5 (subsection 3.6). At the same time, additional provisions that take into account the needs of the national economy of the above states and the features of interstate standardization are given in Section 3 and Appendix A, highlighted in italics

5 By Order of the Federal Agency for Technical Regulation and Metrology dated December 1, 2004 No. 96-st, the interstate standard GOST 12595-2003 (ISO 702-1:2001) was put into effect directly as a national standard of the Russian Federation from July 1, 2005.

6 INSTEAD GOST 12595-85

GOST 12595-2003 (ISO 702-1:2001)

INTERSTATE STANDARD

Metal cutting machines

TYPE A FLANGED SPINDLE ENDS and CLAMPING DEVICE FLANGES

Main and connecting dimensions

Metal-cutting machine tools. Flanked spindle noses of A type and flanges of fixtures. Basic and coupling dimensions

Date of introduction - 2005-07-01