How often during construction you have to lift heavy loads to a decent height. Concrete slabs, beams and logs. All this has a lot of mass. You can't do it without special tools. You will have to use ropes and chains. But how to connect them together into a single whole?

A rigging bracket is designed for this: its dimensions start from 3.5 × 14 × 7 mm. Here 3.5 is the diameter, and 14 and 7 are the depth and width of the passage, respectively. In everyday life, the product was called a lobe, a shakl and an earring.

Rigging shackle: types, sizes and features of choosing a standard size

Often, when working with various types of lifting devices, a rigging or, as it is often called, an omega-shaped shackle is used.

The purpose of this device is to ensure reliable fixation of various components of lifting devices, be it ropes, cables, etc.

And although the design of the rigging shackle is not something complicated, nevertheless, the dimensions and manufacturing process are regulated by several foreign standards, departmental norms and GOST.

Types of staples

The device can be classified according to the following parameters:

- By the type of protective coating on the surface, which, depending on the type, makes it possible to work with hot workpieces or in a chemically active environment;

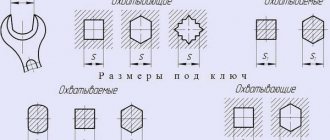

- In shape - omega-shaped (with a curved shape, which is where the second name comes from) and straight (like the letter U);

- According to the permitted temperature operating conditions. There are polar ones, which are able to maintain their original characteristics at temperatures down to minus 40, and ordinary ones;

- For additional fixing elements . The most common is a bolt equipped with a castle nut. It prevents accidental unscrewing of the bolt during operation;

- According to the size of the hole for the fixing part - a finger or a pin.

The carrying capacity of rigging shackles can vary from 330 to 150 thousand kilograms depending on the mode of strengthening heat treatment, the geometric characteristics of the product, namely the cross-sectional diameter and arc length, as well as the materials used in the production process.

The production of domestic designs and standard sizes is carried out in accordance with GOST 2224-72 (GOST 2224-93), which regulates the following points:

- Conservation technology when long-term storage of rigging brackets is necessary;

- Steel grades acceptable for use in the manufacture of parts;

- Methods for quality control of finished products;

- Technological process from forging to hot or cold bending;

- Places where the marking is applied, as well as information that must be reflected in it;

- Requirements for surface quality.

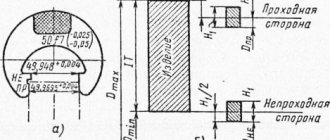

Product sizes

The dimensions of domestic omega-shaped brackets are always strictly consistent with the dimensional parameters of cargo slings manufactured in accordance with GOST 25573-82.

The regulatory document regulates the thickness of the staples used with slings 2SK and higher, and the distance between the section of the rope branch and the grip.

The above is especially important to consider when using the part in conjunction with rope branches that have a transition link. In this case, the main importance is given to the following dimensional values:

- Total length of the part;

- The height of the product to the axis of the fixing element;

- The jaw of the staple, which in turn depends on the dimensions of the mating part of the thimble and the thickness of the rope.

Based on the dimensions considered, a conclusion is drawn regarding whether the practical use of an omega-shaped (anchor) or straight bracket is acceptable.

The first is used for multi-arm rigging and in cases where the distance for mounting the fastening bolt is insufficient.

The second is taken when the load is not expected to be clamped and with sufficient space for the free arrangement of all elements.

It is also necessary to determine the standard size of the rigging brackets based on the type of material being lifted. As a rule, parts are made from rolled steel St.5 and St.

3 according to GOST 380, although in some cases high-quality case-hardened steels, such as steel 20, can be used.

However, when lifting objects made of magnetic materials, it is worth using stainless steel brackets, such as 10X17H13M2 or 08X18H10.

Features of choosing a standard size

The main criteria for choosing the standard size of an omega-shaped bracket are the operating conditions of the part, the dimensions of the product in plan and the maximum load capacity (the standard safety factor should not be less than 5).

At the same time, products that have even small areas of corrosion on their surface are not allowed to work.

This is the main reason why we mainly use staples that are resistant to high air humidity and have been painted and galvanized! It is important to note that the cost of galvanized parts is always higher than that of painted ones.

Upon completion of deformation, the hot-stamped rigging shackle is thoroughly cleaned of scale and then subjected to heat treatment again. Thanks to this, the strength of such products reaches its standard indicators - HB 280-310 for stainless steels and HB 155-160 for ordinary ones.

The functionality of the element is checked using the following dependency:

Q=Mmax/280r

Wherein:

- Q – design load on the workpiece;

- r – radius of curvature from the walls to the jaw of the bracket;

- Mmax is the maximum bending moment during the lifting process.

Many years of practice have made it possible to derive practical relationships between the maximum load and the diameter of the part. So for a carbon straight bracket the ratios are as follows:

- Q=1500 kg at d=22 mm;

- Q=800 kg at d=16 mm;

- Q=300 kg at d=10 mm;

- Q=80 kg at d=5 mm;

For omega bracket:

- Q=9500 kg at d=32 mm;

- Q=6500 kg at d=25 mm;

- Q=2000 kg at d=16 mm;

- Q=750 kg at d=10 mm;

- Q=330 kg at d=6 mm;

Based on the size, type of design and production method, the cost of such products can vary in the region of 80-5000 rubles.

- TAGS

- tools

- Shackle

Source: https://ProStrouky.ru/instrumenty-i-oborudovanie/omegoobraznaya-pryamaya-skoba-raznovidnosti-i-tiporazmery-detali.html

Materials for fasteners

Since the purpose of the staples will be different, the material used for their manufacture is also different:

- aluminum;

- copper;

- steel;

- galvanized stainless steel.

Fasteners made of aluminum are the cheapest. It is used almost everywhere, as it practically does not rust. But with hard materials, as well as in places where there is a large load, it is better not to use it.

Copper staples are used on non-rigid materials. Although they do not rust at all, their price limits their distribution. They are used in construction, mainly under wallpaper or under plaster, since they do not cause any stains or drips.

Steel fasteners are available in hardened and unhardened types. A hardened product costs a little more, but during use it is much stronger and more reliable. The disadvantage of steel products is that during operation they tend to oxidize and rust.

Stainless steel and galvanized products are the most durable and reliable fasteners. Almost all branded staples from stapler manufacturers are made from this material.

Despite the material from which the fasteners can be made, there are products with regular legs and with sharpened ones. The sharpened ones will penetrate any material more easily, so they require less impact force. When working with a manual staple gun and using sharpened staples, you will have to apply little effort. If you use unsharpened material, then you will need to press hard on the tool so that the bracket fully enters the material and makes the desired clamp. When hammering several hundred, maybe even thousands of staples a day, it’s worth thinking about the shape of the leg to make your work easier.

Shackle sizes

home ⇒ construction mat ⇒ hardware ⇒ staples

When loading and unloading operations using lifting equipment, lifting shackles with a diameter of 14 (mm) and a distance to the fixing pin of 64 (mm) are often used.

Product dimensions are indicated in the format “cross-section diameter of the staple/diameter of the fixing pin/distance between the pin and the staple/distance between the pins of the staple.”

- 3.5x3.5x14x7 (mm), 5x5x20x10 (mm), 6x6x24x12 (mm), 8x8x32x16 (mm), 10x10x40x20 (mm), 12x12x48x24 (mm), 14x14x64x32 (mm), 16x16x76x38 (mm), 18x18x88x44 (mm), 19x19x76x38 ( mm), 22x22x88x44 (mm), 25x25x100x50 (mm), 28x28x112x56 (mm), 32x32x127x64 (mm).

Scope of application: workshop, construction site, shipbuilding and so on.

Important: in the manufacture of rigging shackles, various grades of carbon steel are used to protect the product from corrosion and maximize its service life - a zinc coating is used.

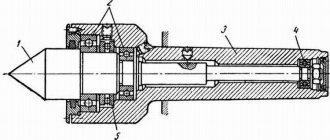

General characteristics of rigging shackles Drawing Drawing and parameters of a typical model D (mm) Diameter of shackle and pin in (mm) C (mm) Depth of shackle passage in (mm) W (mm) Width of shackle passage in (mm)

| Omega-shaped | from 6.5 (mm) to 69 (mm) | from 29 (mm) to 267 (mm) | from 12 (mm) to 105 (mm) |

| Straight | from 6.5 (mm) to 66.5 (mm) | from 22 (mm) to 203 (mm) | from 12 (mm) to 105 (mm) |

Strength classes

The strength classes used for lifting operations are two groups of numbers separated by a dot, on the product labeling - from 3.6 to 12.9. The first number (or two) indicates a hundredth of the tensile strength in MPa. The second group is a tenth of the ratio of yield strength to tensile strength.

For example, a product of strength class 5.8 after simple transformations is characterized as follows: yield strength (deformation) - 40 kgf/mm², tensile strength - 50 kgf/mm². In order not to do your own calculations for a specific bracket, it is easier to use the product certificate, which clearly indicates the maximum permissible load and other operating conditions.

Staples

Home – Lifting shackle

The Krepline company supplies rigging shackles (another name is anchor shackles, since an internal rod is used for connection) of the most common types (straight and omega-shaped) and sizes (3.5 - 45 mm) since 2002. You can buy products from our warehouse in Moscow or order delivery throughout the Russian Federation and the CIS. To receive a wholesale price, contact us by phone. 7(495)784-83-26.

Principle of choosing a rigging shackle:

– load capacity (indicated in the table below)

– long-term connection or often detachable (in the first case, a straight bracket is better suited, in the second - an omega-shaped one with a threaded pin)

– when choosing used products, remember that the degree of wear (abrasion) should not exceed 10% - otherwise it is unsafe to use the product!

| Price list: staples |

| download (format – Excel, 230 Kb). |

Straight rigging shackle

The straight rigging shackle is used for the temporary connection of ropes and cables of all types (galvanized steel and PVC-coated), as well as chains of various rigging mechanisms - primarily where periodic separation of their parts is required, in which case fastening with a threaded pin is best suited.

For a permanent connection, it is recommended to use an omega-shaped bracket, fastened with a bolt with a nut and a cotter pin securing the connection. The bracket is made of carbon steel.

Use - single-arm structures.

Specifications

Maximum load: working load X 5

Calibrated rigging shackle (omega-shaped)

The calibrated rigging bracket is selected to match the required size of the rope (chain). The table shows the cross-sectional diameter of the bracket.

This type of rigging shackle can be used with ropes and cables of any type, including those with PVC coating. Due to the rounded internal arc, rope wear is minimized, which is important for long-term connections (here it is recommended to use a nut and a safety pin).

Use – can be used when lifting loads in a structure consisting of several arms.

Maximum load: working load X 5. The largest shackle, 45 mm, is rated for a working load of 7 tons.

Specifications

maximum load: working load X 5

Fastening and mounting of rigging brackets

As we have already indicated above, for a temporary connection (where the connection is proposed to be periodically or permanently disconnected), a fastening with a threaded screw pin is better suited; otherwise, a “bolt-nut” connection and a safety cotter pin are better suited.

When carrying out lifting operations, special attention should be paid to the geometry of the rigging. If the fastener is incorrectly positioned relative to the axis of the main vibration, this entails chafing of the rope and increased wear of the bracket. Optimal fastening of a load suspended from the slings is so that the main load is distributed along the center line of the shackle.

When securing a load on a cable deflected in a vertical plane, one should take into account the reduced load-carrying capacity coefficients of the shackle, depending on the angle of the cable:

0 g (vertical) – 100%

45 g – 70% load capacity

90g (right angle) – 50% load capacity

When attaching two cables to one bracket, only an omega-shaped bracket is used, and the fastening angle should not exceed 120 degrees.

Particular attention should be paid when constructing loops - make sure that the bracket is secured correctly, is not bent, and the rope will not fray.

You can buy rigging shackles in Moscow by contacting our manager by phone.

Related products:

Source: https://www.krepline.ru/catalog/skoba-takelazhnaja/

Installation and fastening

To assemble the rigging shackle, you need to insert the pin and screw it along the right-hand thread until the shoulder fits snugly against the eye. In brackets with a bolt, after screwing on the nut, it is necessary to secure it with a cotter pin. Operation of the device without a cotter pin is prohibited.

If during assembly it is discovered that the pin does not fit up to the shoulders in the eye due to tight threads, misalignment of the hole and the pin, or the latter being bent, such a bracket cannot be used.

If, when using a straight bracket, the load sags asymmetrically, it is necessary to insert washer gates of equal thickness on both sides and thereby eliminate the eccentricity.

All parts of the bracket must be checked for cracks, deformations, rust, burrs and unusable ones must be excluded from circulation.

Lifting shackles must not be heat treated, welded, changed in shape by any method, or immersed in aggressive solutions.

It should be remembered that the rated load-carrying capacity of the bracket is maintained up to 200 ºС of its surrounding environment; when the temperature rises to 400 ºС, it decreases to 75%; above + 400 ºС the bracket cannot be used.

Omega-shaped brackets, straight lifting

Omega-shaped rigging shackle (earrings, shackles) is an integral part of lifting and static systems. It is also used as removable ties, with the help of which it is possible to attach steel cables, wire chains and other devices to lifting equipment.

Lifting shackles in accordance with GOST, equipped with screw pins, are used, as a rule, irregularly. Those shackles that use safety counterbolts in their design can be used to solve long-term problems.

Also, a rigging shackle, the price of which in our catalog is constantly maintained at an acceptable level that is beneficial for the client (whose device uses a counterbolt), is used in cases where there is a high probability of weights being pushed onto the pin, which can lead to rotation of the pin.

You can select the dimensions of the rigging shackle, as well as its other design characteristics, in strict accordance with the assigned tasks (weight, dimensions of the loads expected to be moved).

In addition to the omega-shaped earrings, we also offer a straight rigging shackle in a wide range of products, whose technical characteristics allow you to quickly and reliably connect cables and chains with its help or connect them to other devices. As a rule, a straight shackle (SA) is used in lifting systems with a single-arm design.

The omega shackles (SI) described above are used in multi-arm lifting systems. You can buy both these and other rigging brackets from our company.

Popular goods

| — omega-shaped rigging shackle g209 load capacity, t: [3.25] packaging, pcs: [1] weight, kg: [0.7] type of pin: [with internal thread] Price, rub: [on request] | — omega-shaped rigging shackle g2130 load capacity, t: [4.75] packaging, pcs: [1] weight, kg: [1.1] type of pin: [safety bolt with nut] Price, rub: [on request] | — straight rigging shackle g210 load capacity, t: [2.0] packaging, pcs: [1] weight, kg: [0.4] type of pin: [with internal thread] Price, rub: [on request] | — straight rigging shackle g2150 load capacity, t: [6.5] packaging, pcs: [1] weight, kg: [1.6] type of pin: [safety bolt with nut] Price, rub: [on request] |

Shackles

Download price list

https://www.youtube.com/watch?v=52g8m6_4YAE

Lifting shackles for securing cargo are omega-shaped elements used for fastening cables and chains for their installation to various structures. Fastening loops are used to create guy wires and move loads of various types. Features: the brackets for securing the load can be quickly removed and ensure secure fastening.

Similar in scope of application, a straight rigging shackle with a screw pin is used for handling cargo and creating temporary ties, while for long-term, permanent connections a shackle or fastening loop for a load with a nut and safety pin is required. In addition, if during production operations the finger experiences forced rotational movements, then it is recommended to use cotter pins to secure the load.

In order to purchase a rigging shackle, buy loops for securing a load with the required characteristics, it is worth studying the features of the products. The loop for securing cargo can have different load capacity (this is the main characteristic). Another equally important criterion is the linear dimensions to which the bracket for securing the load corresponds. In particular, the diameter of the bearing finger in millimeters.

Depending on what kind of cargo securing loop you need, you will certainly find the necessary products in the catalog.

Prices and specifications

Straight type staples

Screw rigging shackle SA type G-210 G/p, tWeight, kgPrice, rub.

| Read more… | ||

| 0,50 | 0,05 | 30 |

| 0,75 | 0,08 | 34,00 |

| 1,00 | 0,13 | 49,00 |

| 1,50 | 0,20 | 67,00 |

| 2,00 | 0,27 | 80,00 |

| 3,25 | 0,57 | 130,00 |

| 4,75 | 1,20 | 185,00 |

| 6,50 | 1,43 | 275,00 |

| 8,50 | 2,15 | 375,00 |

| 9,50 | 3,06 | 492,00 |

| 12,00 | 4,11 | 780,00 |

| 13,50 | 5,28 | 965,00 |

| 17,00 | 7,23 | 1350,00 |

| 25,00 | 12,10 | 2260,00 |

| 35,00 | 19,20 | 3590,00 |

| 55,00 | 32,50 | 7130,00 |

| 85,00 | 70,00 | Great Dane |

Lifting shackle cotter pin SA type G-2150 G/p, tWeight, kgPrice, rub.

| 0,50 | 0,06 | 40 |

| 0,75 | 0,10 | 45,00 |

| 1,00 | 0,15 | 65,00 |

| 1,50 | 0,22 | 80,00 |

| 2,00 | 0,34 | 90,00 |

| 3,25 | 0,67 | 135,00 |

| 4,75 | 1,14 | 195,00 |

| 6,50 | 1,74 | 318,00 |

| 8,50 | 2,52 | 420,00 |

| 9,50 | 3,45 | 605,00 |

| 12,00 | 4,90 | 840,00 |

| 13,50 | 6,24 | 1100,00 |

| 17,00 | 8,39 | 1555,00 |

| 25,00 | 14,20 | 3520,00 |

| 35,00 | 21,20 | 3980,00 |

| 55,00 | 38,60 | 9250,00 |

| 85,00 | 56,00 | 15000,00 |

| 120,00 | 95,00 | Great Dane |

Omega type staples

Screw rigging shackle SI type G-209 G/p, tWeight, kgPrice, rub.

| Read more… | ||

| 0,50 | 0,05 | 32 |

| 0,75 | 0,09 | 38,00 |

| 1,00 | 0,14 | 53,00 |

| 1,50 | 0,17 | 70,00 |

| 2,00 | 0,33 | 83,00 |

| 3,25 | 0,62 | 135,00 |

| 4,75 | 1,07 | 195,00 |

| 6,50 | 1,64 | 300,00 |

| 8,50 | 2,28 | 425,00 |

| 9,50 | 3,36 | 585,00 |

| 12,00 | 4,31 | 885,00 |

| 13,50 | 6,14 | 1040,00 |

| 17,00 | 7,80 | 1285,00 |

| 25,00 | 12,60 | 2400,00 |

| 35,00 | 20,40 | 3740,00 |

| 55,00 | 38,90 | 7900,00 |

| 85,00 | 70,00 | Great Dane |

Lifting shackle cotter pin SI type G-2130 G/p, tWeight, kgPrice, rub.

| 0,50 | 0,05 | 40 |

| 0,75 | 0,10 | 45,00 |

| 1,00 | 0,15 | 62,00 |

| 1,50 | 0,22 | 83,00 |

| 2,00 | 0,36 | 105,00 |

| 3,25 | 0,76 | 145,00 |

| 4,75 | 1,23 | 217,00 |

| 6,50 | 1,79 | 330,00 |

| 8,50 | 2,57 | 475,00 |

| 9,50 | 3,75 | 600,00 |

| 12,00 | 5,31 | 905,00 |

| 13,50 | 7,18 | 1190,00 |

| 17,00 | 9,43 | 1600,00 |

| 25,00 | 15,40 | 2650,00 |

| 35,00 | 23,70 | 4180,00 |

| 55,00 | 44,61 | 10000,00 |

| 85,00 | 70,00 | 16000,00 |

| 120,00 | 120,0 | Great Dane |

Source: https://www.GruzoZahvat.ru/takelazhnye-izdeliya/skoby-takelazhnye/

Classification

According to the shape, material of manufacture, and design of the bracket, there are the following varieties:

- U-shaped and omega-shaped rigging shackles;

- depending on the diameter of the retainer - under a finger or under a pin;

- by the presence of additional fasteners that prevent arbitrary unscrewing of the finger;

- depending on the range of operating temperatures - whether the product loses the strength properties declared in the passport at temperatures below -40 degrees or not;

- depending on the coating of the bracket - allowing or not allowing work to be done in an aggressive environment or at high temperatures.

Omega-shaped rigging shackle SI with cotter pin

Load capacity:

Weight:

- Arrange products on the page in blocks

- or in tabular form

- – 0.75t. / – 0.08kg /

- – 1t. / – 0.14kg /

- – 1.5t. / – 0.22kg /

- – 2t. / – 0.33kg /

- – 3.25t. / – 0.65kg /

- – 4.75t. / – 0.97kg /

- – 6.5t. / – 1.52kg /

- – 8.5t. / – 2.39kg /

- – 9.5t. / – 3.15kg /

- – 12t. / – 4.32kg /

- – 13.5t. / – 5.67kg /

- – 17t. / – 7.79kg /

- – 25t. / – 12.51kg /

- – 35t. / – 18.5kg /

- – 55t. / – 37.6kg /

- – 85t. / – 65kg /

- – 120t. / – 112kg /

supplies omega-shaped lifting shackles of the "SI" type with a cotter pin, the common name is a shackle rigging eyelet - in Yekaterinburg, which complement load-handling devices when fixing or lifting loads:

Omega-shaped rigging shackle with cotter pin type SI – design

- Omega-shaped bracket, reminiscent of the letter of the Greek alphabet - omega " Ω

" - The ends of the SI bracket with a hole for the pin.

- Pin with nut and cotter pin

The differences between omega-shaped mounting brackets are due precisely to the method of attaching the pin.

Omega-shaped bracket with cotter pin

- Hole at the end without thread + pin with nut and safety cotter pin

Omega-shaped staples with a cotter pin are used for long-term connection and fastening during rigging work.

Important!

- When choosing SI omega-shaped rigging shackles, you must first calculate the maximum weight the shackle can lift or hold.

- We will help you calculate and select omega-shaped rigging shackles with a cotter pin to safely solve your problems.

- We guarantee the quality of the rigging products supplied, no doubt about it!

The Strop-Arsenal LLC company invites you to choose from the presented catalogue, order and buy an omega-shaped rigging shackle SI with a cotter pin wholesale and retail inexpensively and at a favorable low price in Yekaterinburg.

The omega-shaped rigging shackle SI with a cotter pin is available, but can be manufactured (or equipped) to order according to your dimensions or technical requirements.

To find out how much it costs and buy an omega-shaped rigging shackle SI with a cotter pin, fill out an application on the website or call by phone in Yekaterinburg.

We produce custom-made products in an average of 1 day. We deliver throughout Yekaterinburg, Tyumen and regions of the Russian Federation.

Now you know where to buy Omega-shaped rigging shackle SI with cotter pin wholesale and retail. Stop doubting, just try to order!

reference Information

Personal data processing policy

Criteria for choosing a construction stapler

When choosing a stapler for work, you should pay attention to whether it is safe. Well-known companies that produce such devices carefully think through this issue.

The main protective function is the inability of the stapler to operate at idle speed. This means that the tool will only release fasteners when it is against the part. Before purchasing a tacker, you need to make sure that it has such protection.

The presence of a viewing window is not only pleasant, but also a convenient feature. Even a cheap Chinese model may have it. In the window you can see how many staples are currently in the device.

The device should have a comfortable handle; manufacturers of well-known brands have taken care of this. The instrument is simply pleasant to hold in your hand.

A model in which the impact force can be adjusted is considered practical. Many devices have this capability, including mechanical ones.

Before purchasing replacement brackets, you need to know what type your appliance works with. This information can be found on the device packaging, in the instructions, or on the case itself. As a last resort, you can write down the model name. An experienced seller will be able to determine the type of bracket you need by name.