Depending on the area of application, all professional sheets are divided into three categories. In the first case, the sheets are used only for roofing and are marked with the letter “H”. In the second case, the corrugated sheeting is intended for vertical installation during the construction of fences and walls - it is marked with the letter “C”. Finally, in the third case, the sheet can be used for both roofs and vertical structures - it is simply labeled “NS”. In addition, there is a profiled sheet with alternating wide and narrow stripes - it is labeled as MP, and it can be used in both roofing and wall work.

| Table of main characteristics of steel corrugated sheets | |||

| Drawing | Corrugation height, mm | Metal thickness, mm | Standard |

S21 wall | 21 | 0,5 – 0,8 | GOST 24045-2016 |

NS35 roofing wall | 35 | 0,5 – 0,8 | GOST 24045-2016 |

H60 roofing | 60 | 0,7 – 1,0 | GOST 24045-2016 |

The industry produces corrugated sheets in sizes that satisfy almost any needs of developers. In length “H” profiles are produced from 3 to 12 meters with a difference of 250 mm between types. “C” profiles have a difference of no more than 300 mm with a total length of 2.4 to 12 meters. In this case, it is allowed that the length of the profiled sheet is determined by agreement between the manufacturer and the customer.

The height of the profile (corrugation) is indicated in a short marking - usually the letter is followed by a number in millimeters. Accordingly, C21 has a height of 21 mm. Corrugations are regulated for roofing coverings in height from 15 to 160 mm, and for wall coverings from 8 to 44 mm, although in the latter case an increase is allowed by agreement with the customer.

The width can vary from 1200 mm for C8 to 653 for profiled sheet H114. In addition to the total width, there is a working width, which is obtained during the process of laying the sheet on the surface when the outer corrugations coincide, forming a rigid connection into the lock. The thickness of the sheet is greater for type “H” - it is in the range of 0.5 - 0.9 mm. “NS” and “C” have 0.55 – 0.8 mm and 0.55 – 0.7 mm, respectively. However, today “C” type corrugated sheets with thicknesses of 0.45 and even 0.4 mm have appeared on the market. For H60, the thickness can reach even 1.2 mm. Thus, the size range largely depends on the manufacturer and the needs of a large customer.

Corrugated sheeting can be protected with a special polymer coating of any color, or it can simply be galvanized. The color of the coating on different sides of the sheet may be different. The manufacturer is recommended to produce sheets with a capillary groove to remove unnecessary moisture.

We calculate the weight of rolled sheets

Calculating the weight of rolled metal is a fairly simple task of this class. Simplicity is determined by the shape of the sample being studied. To begin calculations, you need to know the following characteristics:

- geometric dimensions of the test sample;

- metal density (for steel you can use the average indicator, which is 7850 kg/m3);

The first stage involves calculating the weight of a sheet of metal with an area of one square meter and a thickness of one millimeter. The volume of this sample is calculated and multiplied by the density of the steel. It is obtained by standard multiplication of three geometric parameters: length, width, height. Multiplying the result by the density, we get a value equal to 7.8 kg/m3. It will allow you to calculate the weight of a sheet of any geometric size and shape. Convenient because it does not depend on length, width, thickness. You can get the final value without resorting to preliminary recalculation. Therefore, the main task will be to calculate the volume of the selected sheet.

Sheet metal

For example, the weight of a sheet whose size is one meter long, two meters wide, 0.35 mm thick will weigh 5.5 kg. A sheet 5 mm thick, measuring 1.5 m wide and 6 meters long will weigh 353.25 kg.

Before using a metal sheet as a ceiling or building structure, you should evaluate its weight.

Sheet weight

According to reference books

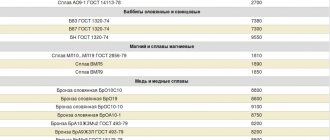

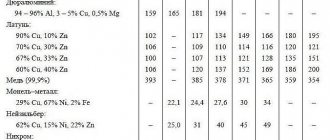

The collection of reference materials contains tables of metals, from which it is easy to determine the weight of rolled metal of any type, from ferrous and non-ferrous metals or alloys. In addition, the collection contains formulas for calculating the weight of metal by size for workpieces of various configurations, data on the specific gravity of metals.

You have to refer to the reference book when performing mathematical calculations on your own, for example, to a table of metal densities. To calculate the mass of a non-ferrous metal part, you will need a conversion factor.

With the finished table it is easy to independently calculate the weight of a sheet of metal. For a given thickness and grade of steel, the theoretical weight of 1 m2 is found, the desired value is multiplied by the area of the sheet. This is especially convenient for steel with corrugations, protrusions, zinc coating, and the rolling method (cold or hot) is also taken into account.

It simplifies the calculation of the mass of the channel and I-beam - products with a complex cross-section. There is a table for them indicating the profile number and the corresponding weight 1 linear meter. m to kg. You don’t need to bother calculating the weight of steel reinforcement; besides, the table shows the number of linear meters per 1 ton.

Similar tables exist for L-shaped metal profiles: the weight of 1 m of corner is indicated for a specific thickness and width of the shelf. True, such calculations differ from the actual weight, since the tables are compiled on the basis of GOST. In reality, rentals do not always meet state standards.

The density of steel depends on temperature indicators. All table data corresponds to a temperature of 20°C. This note does not apply to non-ferrous rolled products.

What is a conversion factor?

It allows you to calculate the weight of products made of any material. It is obtained as the ratio of the density of the selected material to the density of steel. Next, to calculate the required parameter, it is enough to calculate such a parameter of a steel product of a given shape. The resulting result will be multiplied by the conversion factor for this material.

The coefficient is a dimensionless quantity. It has its own specific meanings for various metals and alloys. For example, aluminum has 0.34, copper - 1.14, and 1.12 is used for OTS5-5-5 bronze.

To calculate the weight of a sheet made of the specified bronze, it is necessary to obtain the parameter of the same sheet of steel, multiplying with a conversion factor.

Metal conversion factor

The same calculation method, the use of a conversion factor, can be fairly applied to non-metallic rectangular products. For example, to textolite with a coefficient of 0.18, organic glass - 0.15. The results obtained will satisfy the accuracy requirements.

Calculation of weight using mathematical formulas

The weight of any product is found as follows: M = ρV ( ρ – density, V – volume of the product) or by the mass formula through the cross-sectional area: M = ρSL ( S – cross-sectional area, L – length). For carbon steel, it is customary to use an average value of ρ equal to 7850 kg/m3 or 0.00785 g/mm3, or 7.85 g/cm3 (depending on the selected units of measurement). The simplest calculation is the mass of a steel cube with a side of 1 m. It is equal to 7850 kg, or 7.85 tons.

There are practical and theoretical formulas for mass. The former are adapted to certain conditions in order to facilitate and speed up calculations.

Sheet metal

To calculate the weight of sheet metal, you need to multiply 3 dimensions - the length, width and thickness of the product, and multiply the resulting result by the density of the metal. For example: rolled length is 1 m, width is 2 m, thickness is 2 mm, then M = 1 × 2 × 0.002 × 7850 = 31.4 (kg).

When determining the mass of several identical sheets of iron, it is enough to calculate the weight of 1 sheet and multiply by the quantity.

Rod, wire and fittings

To determine the mass of a rod or any product of round cross-section, the following theoretical formula is used: M= πR2Lρ , where L is the length, R is the radius of the workpiece, π = 3.14, ρ is the density of the metal. Another practical formula: M = (0.02466R2)L . It can also be used for corrugated fittings.

Finding the mass of a rectangular rod from the volume is quite simple. You need to multiply the length, width and thickness (this is the volume V ), then find the corresponding density in the reference book and multiply it by V: M = ABLρ , where A, B are the width and thickness.

Circle

To find the weight of a metal circle, you need to substitute the numerical values into the formula: M = πR2dρ ( R – radius, d – thickness).

Hexagonal rod

It is best to turn to ready-made tables for help, but in their absence, you can do the calculations yourself:

M = (3√3/2)а2Lρ,

where a is the length of the hexagon side (mm), L is the length of the rod (mm), ρ = 0.00785 g/mm3.

Rectangular profile

You can find out the mass of a rectangular profile pipe as follows:

M = 2(a+b)sLρ,

where a and b are the width and height of the section (mm), s is the wall thickness (mm), L is the length of the pipe (mm), ρ = 0.00785 g/mm3. If the walls are of different thicknesses, several measurements are taken and the average value is found.

Weight of round pipe

The weight of the pipe is calculated using the following formulas:

M = π(R2 – r2)Lρ, M = 2πRsLρ, M = (Ds)s×0.2466

where M is mass, R2 is outer radius, r2 is inner radius, L is pipe length, ρ. – steel density, s – wall thickness, 0.2466 – constant corresponding to the density of carbon steel ρ = 7.85 g/cm3.

A pipe with a closed end can be considered as a barrel and the formulas presented above for a pipe and a circle can be used to find its weight.

Weight of figured products

It is possible to calculate the mass, knowing the volume and density, for products of any configuration. You just need to correctly calculate the volume and substitute the value into the well-known formula M = Vρ .

The volume of the pyramid is calculated by the formula: V = 1/3 SH , where S is the base area, H is the height of the pyramid.

For a truncated pyramid, V = 1/3 h(F + f + √Ff) , where F and f are the areas of the larger and smaller base.

Cylinder volume: V = πR2H.

Volume of a cone: V = 1/3 πR2H , volume of a truncated cone: V = 1/3 πH(R2 + Rr + r2) , where H is the height, R and r are the radii of the larger and smaller base.

Sphere volume: V = πD3/6 ( D – diameter).

For a corner: V = s(h1 + h2)L , where L is the length of the corner, s is the thickness of the metal, h1 and h2 are the width of the shelves.

The volume of a product with an ornate shape and small dimensions is determined by the amount of displaced liquid by placing it in a container of water.

If a structure is made of different metals and alloys, then its mass can be found through the weight of individual parts.

Theoretical weight is calculated using formulas, practical (actual) is determined by weighing. Naturally, there will always be a discrepancy between these values. Calculation of the mass of the workpiece, made independently using mathematical formulas, may also differ from the tabular ones or those given by the calculator.

To obtain more accurate results, it is advisable to use data from reference books or electronic computing devices.

What makes calculating the weight of metal more difficult?

A serious difference in the data obtained for calculating the mass of a steel product is the technology of its production. The difference between cold-rolled metal and hot-rolled metal can be quite significant. We are talking about the accuracy of geometric characteristics while maintaining density along the entire length of the product.

The use of continuous heating and subsequent cooling leads to such negative phenomena as oxidation and recrystallization. The unevenness of these processes causes a change in such a parameter as thickness.

Metal weight

The accuracy of calculations for cold-rolled and hot-rolled metal profiles will differ. The error caused by thickness instability requires obtaining some average value.

Why is it better to use a metal calculation calculator?

Rolled metal is used everywhere: in construction, housing and communal services, etc. It often requires transportation. However, machines have a certain carrying capacity, exceeding which is unacceptable. Here the question arises: how to find out the tonnage of the metal if it cannot be placed on the scales due to its large volume? This calculation is performed by a special calculator designed in such a way that it is able to take into account all the features of rolled metal, including non-standard shapes.

Without calculating the weight of rolled metal, you risk overpaying for cargo delivery. If you call a truck that is too large to transport, you will definitely overpay. Shipping costs will be high. If you decide to save money, you risk registering a car with a smaller carrying capacity. As a result, you will either have to order another truck or arrange for a larger cargo transport. The result will be the same - overpayment and loss of time.

Previously, people independently calculated the mass of a certain amount of rolled metal. However, they were extremely complex and often led to errors. With the popularization of the Internet, calculating the weight of rolled metal is not difficult.

How to calculate the mass of a rectangular profile?

A rectangular profile is a parallelepiped with a given wall thickness. The wall thickness is specified in the technical documentation for a specific sample.

Square profile

Mass calculation can be done in two ways. In the first method, the cross-sectional area is calculated: for a sheet of a given thickness. Calculate the mass of a rectangular parallelepiped based on its external dimensions. Then the same calculations are made for a parallelepiped with internal dimensions. The difference between the two values will be the desired characteristic.

In the second method, the weight of one wall of the structure is calculated. If the cross-section is square, multiply by four. If it is rectangular, the sizes of the smaller and larger walls will be calculated separately. Then multiply each value by two and add the results to get the final figure.

Square profile weight

To simplify the process, special tables have been developed.

Advantages of online payment

The metal calculator is an online tool to help supply engineers and others in calculating the required mass, volume, and linear meters of the required material. It is based on elementary formulas for the volumes of figures and the densities of materials, facilitating repeated manual substitutions of the same type. The result shown by this calculator is only indicative, but it can help you choose a machine of the required tonnage for transportation or determine the length of the required workpiece, etc.

Basic formula for calculating weight: m = ρ × V

- ρ – material density, kg/m3 (see tables below)

- V – volume, m3 (calculated individually using formulas for each product)

When you need to buy rolled metal, you need to know which transport will be more convenient to transport it. The tonnage of cars or other vehicles for delivery depends on the total mass of metal products. Therefore, the question arises of how to calculate the mass of the required amount of rolled metal.

Once upon a time, solving this issue took a lot of time even for highly qualified specialists. After all, to perform the necessary calculations, it was necessary to know the theoretical mass of the weight of various metals, formulas for calculating the volume of various rolling forms, etc. Such computational complexity required the search for new solutions. This solution was the online metal calculator.

Now, when drawing up any construction specifications, a rolled metal calculator is used instead of many tables, formulas and painstaking calculations. Using our online rolled metal calculator service, you can calculate the mass of the following metals:

- steel;

- cast iron;

- aluminum;

- bronze;

- brass;

- magnesium;

- nickel;

- copper;

- tin;

- lead;

- titanium;

- zinc.

In order to make the calculation, you need to select the type of metal and type of rental in the drop-down menu of the Free Online Metal Calculator program. The calculation is made for the following types of rental:

- corner;

- sheet;

- pipe;

- circle/wire/wire rod;

- square pipe;

- rental;

- channel;

- tape/strip;

- beam;

- hexagon.

For each type of metal, it is possible to select a specific brand. For example, when steel is selected in the “Metal Type” drop-down menu, then in the “Grade” drop-down menu, to the right of the metal type field, you can select any of the standard steel grades. The program also includes all existing grades of metals from which rolled metal is produced.

Next, having selected the type of rolled product, the type of metal and its grade, all that remains is to indicate the main parameters of the product itself. The program clearly displays which parameter needs to be entered for the calculation. Each type of rolled metal is accompanied by a graphic image of its cut with the name of each face, shelf, etc. displayed in the form of letters. The type of rolled metal itself is also shown. You probably won’t confuse the “sheet” type with the “strip” type, or the “square pipe” with the “square” type. For convenience and ease of measurement, the graphical representation of a rolled metal cut shows the names of each shelf, for example, a, b, c. For example, if you are calculating the mass of an aluminum corner, you need to indicate the height and width of its shelves, as well as the wall thickness (thickness of the metal sheet). To calculate the mass of a copper pipe, you need to indicate its total diameter and wall thickness. The fields in which you need to enter specific dimensions have the same name as the names in the graphic image.

This data is entered into the metal calculator in millimeters. In addition, indicate the length of a specific metal product in the appropriate field; the length is indicated in meters. Now all that remains is to click on the “Calculate” button and in the “Mass” field the program will display the value of the mass of the specified rolled metal in kilograms, accurate to the nearest gram.

To calculate the total mass of various metal products with different dimensions, perform the calculation for each type of product separately. Then simply add up the results - and you will find out the exact mass of the entire amount of rolled metal you need.

It is also possible to specify the required weight of rolled metal (for example, when you know that you can transport metal using a truck with a certain carrying capacity) and, knowing its basic measurements, determine the total length of the product.

Determining the weight of a round profile

Round metal products include solid rods, fittings, and pipes of various diameters. The approach to solving the problem remains the same. If the product is solid, it is necessary to calculate the volume, multiply by the density of the material. The volume of metal is calculated using known geometric formulas.

Round profile weight

If the round workpiece is hollow inside, you need to know the wall thickness. Next, you can use one of the methods applicable to calculate the value of rectangular rolled products. The only difference will be the calculated ratios for finding the volume.

How to find out the mass of a hexagonal profile?

Solid metal rods with a hexagonal cross-section are often used. The calculation method for such products remains the same. It is necessary to remember from the school geometry course how the volume of a regular hexagonal parallelepiped is calculated.

The task is greatly simplified if you know the size or number of such a rental. All numbers are given in a standardized table.

The hexagonal profile with the smallest number 10 weighs only 0.68 kg, the largest number 60 weighs 24.5 kg.

Hexagonal profile

The calculations are based on a formula for calculating the volume of a regular hexagonal prism. Having calculated this volume, it is multiplied by the density of the metal. A mass of hexagonal product is obtained.

It should be remembered that the use of simplified methods gives approximate results. They are used for express assessments. When developing design documentation in detail, more accurate indicators are used.

How much does steel weigh?

Specific gravity of steel

| Specific gravity of the most common steel grades | ||

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| Quality carbon structural steel | 10,20,30,40 | 7,85 |

| Carbon structural steel | St3sp, St3ps | 7,87 |

| Die tool steel | X12MF | 7,7 |

How to find out the mass of a pipe

Finding the parameter of a metal pipe of any diameter is carried out similarly to the method for a round profile. Calculate the difference in the areas of two circles. The first has the outer radius of the pipe. The second has the inner radius of the pipe.

The resulting difference is multiplied by the length of the pipe, calculating the volume of metal. Multiplying by the density of steel, the mass of a pipe of a given length is found. Operations with non-ferrous metal products are simplified through the use of a conversion factor.

Pipe weight

When working with ready-made tables, you should find data for a 1 m bar with a radius equal to the outer diameter. Calculate the diameter of the rod, which is equal to the internal diameter. Subtract the smaller value from the larger value to get the desired result. It should be multiplied by the length of the sample.