Calculation of angle for deflection and bending

This online calculator is designed to allow you to easily and quickly select the dimensions of the corner depending on the load on it. Its peculiarity is that on one page it is possible to compare equal (GOST 8509-93) and unequal (GOST 8510-86) corners. The latter, in turn, can be selected depending on its location in space, i.e. depending on how it will be oriented relative to the load.

The corners are calculated for bending and deflection (in terms of strength and deformation) for the following design schemes:

Type 1 – single-span simply supported beam with a uniformly distributed load. Example: a corner lintel that carries floor slabs and a low masonry height. (For more information on calculating corner jumpers, see this calculator).

Type 2 – cantilever beam with rigid embedding and uniformly distributed load. Example: a reinforced concrete canopy made using an angle that is rigidly (using stiffeners that limit any turns) welded to a reinforced concrete wall.

Type 3 – single-span hinged beam with a cantilever with a uniformly distributed load. Example: the same canopy as in the previous diagram, only here the corner is inserted into the wall on one side and rests on a brace on the other (blue in the picture).

Type 4 – single-span simply supported beam with one concentrated force. Example: a lintel on which one floor beam rests.

Type 5 is a single-span simply supported beam with two concentrated forces. Example: a bridge supported by two concentrated forces.

Type 6 – cantilever beam with one concentrated force. Example: the canopy of a house with a brick wall on it, built in an African republic (where it never snows) according to the imagination of an African architect. The corners of this canopy are firmly embedded in the wall, as described in the second diagram.

Note: the calculated angle in the example drawings is colored red.

Calculation of angle for deflection and bending

Using this calculator, you can not only easily calculate the angle for deflection and bending, but also select the optimal one from equal and unequal angles.

Calculation of the mass of steel angle

Calculator for calculating the mass of angles made of carbon steel, stainless steel, aluminum or nickel alloy, brass, cast iron and other metals. The densities of metals are taken as the average value for a given group of metal or alloy.

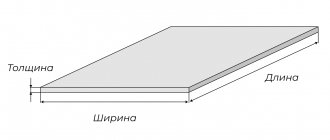

If you know the density of the material, enter the value in the form field, the calculation will be made taking into account the entered density. To calculate, measure the dimensions of the corner shelves, the thickness of the shelves and the length, and fill out the form fields.

Angle steel profiles are a fairly common type of rolled metal and can be used both in construction and in the manufacture of various metal structures. By type, the corner is divided into equal and unequal, depending on whether the shelves are equal in width or not.

The proposed calculation of the weight of a steel angle is not suitable for calculating hot-rolled angles because to calculate their theoretical weight, in addition to the width of the flanges and their thickness, it is necessary to know the radii of the internal and external rounding. The tables show the mass values of a linear meter of hot-rolled angles, data taken from GOST 8905-93.

Theoretical mass per linear meter of hot-rolled steel equal-flange angle GOST 8905-93

| Name, size | Weight per linear meter, kg | Meters per ton |

| Corner 20×3 | 0.890 | 1123.6 |

| Corner 20×4 | 1.150 | 869.57 |

| Corner 25×3 | 1.120 | 892.86 |

| Corner 25×4 | 1.460 | 684.93 |

| Corner 25×5 | 1.780 | 561.8 |

| Corner 28×3 | 1.270 | 787.4 |

| Corner 30×3 | 1.360 | 735.29 |

| Corner 30×4 | 1.780 | 561.8 |

| Corner 30×5 | 2.180 | 458.72 |

| Corner 32×3 | 1.460 | 684.93 |

| Corner 32×4 | 1.910 | 523.56 |

| Corner 35×3 | 1.600 | 625 |

| Corner 35×4 | 2.100 | 476.19 |

| Corner 35×5 | 2.580 | 387.6 |

| Corner 40×3 | 1.850 | 540.54 |

| Corner 40×4 | 2.420 | 413.22 |

| Corner 40×5 | 2.980 | 335.57 |

| Corner 40×6 | 3.520 | 284.09 |

| Corner 45×3 | 2.080 | 480.77 |

| Corner 45×4 | 2.730 | 366.3 |

| Corner 45×5 | 3.370 | 296.74 |

| Corner 45×6 | 3.990 | 250.63 |

| Corner 50×3 | 2.320 | 431.03 |

| Corner 50×4 | 3.050 | 327.87 |

| Corner 50×5 | 3.770 | 265.25 |

| Corner 50×6 | 4.470 | 223.71 |

| Corner 50×7 | 5.150 | 194.17 |

| Corner 50×8 | 5.820 | 171.82 |

| Corner 56×4 | 3.440 | 290.7 |

| Corner 56×5 | 4.250 | 235.29 |

| Corner 60×4 | 3.710 | 269.54 |

| Corner 60×5 | 4.580 | 218.34 |

| Corner 60×6 | 5.430 | 184.16 |

| Corner 60×8 | 7.100 | 140.85 |

| Corner 60×0 | 8.700 | 114.94 |

| Corner 63×4 | 3.900 | 256.41 |

| Corner 63×5 | 4.810 | 207.9 |

| Corner 63×6 | 5.720 | 174.83 |

| Corner 65×6 | 5.910 | 169.2 |

| Corner 65×8 | 7.730 | 129.37 |

| Corner 70×4 | 4.870 | 205.34 |

| Corner 70×5 | 5.380 | 185.87 |

| Corner 70×6 | 6.390 | 156.49 |

| Corner 70×7 | 7.390 | 135.32 |

| Corner 70×8 | 8.370 | 119.47 |

| Corner 70×0 | 10.290 | 97.18 |

| Corner 75×5 | 5.800 | 172.41 |

| Corner 75×6 | 6.890 | 145.14 |

| Corner 75×7 | 7.960 | 125.63 |

| Corner 75×8 | 9.020 | 110.86 |

| Corner 75×9 | 10.070 | 99.3 |

| Corner 80×5 | 6.780 | 147.49 |

| Corner 80×6 | 7.360 | 135.87 |

| Corner 80×7 | 8.510 | 117.51 |

| Corner 80×8 | 9.650 | 103.63 |

| Corner 80×10 | 11.880 | 84.18 |

| Corner 80×12 | 14.050 | 71.17 |

| Corner 90×6 | 8.330 | 120.05 |

| Corner 90×7 | 9.640 | 103.73 |

| Corner 90×8 | 10.930 | 91.49 |

| Corner 90×9 | 12.200 | 81.97 |

| Corner 90×10 | 13.480 | 74.18 |

| Corner 90×12 | 15.960 | 62.66 |

| Corner 100×6.5 | 10.060 | 99.4 |

| Corner 100×7 | 10.790 | 92.68 |

| Corner 100×8 | 12.250 | 81.63 |

| Corner 100×10 | 15.100 | 66.23 |

| Corner 100×12 | 17.900 | 55.87 |

| Corner 100×14 | 20.630 | 48.47 |

| Corner 100×15 | 21.970 | 45.52 |

| Corner 100×16 | 23.300 | 42.92 |

| Corner 110×7 | 11.890 | 84.1 |

| Corner 110×8 | 13.500 | 74.07 |

| Corner 120×8 | 14.760 | 67.75 |

| Corner 120×10 | 18.240 | 54.82 |

| Corner 120×12 | 21.670 | 46.15 |

| Corner 120×15 | 26.680 | 37.48 |

| Corner 125×8 | 15.460 | 64.68 |

| Corner 125×9 | 17.300 | 57.8 |

| Corner 125×10 | 19.100 | 52.36 |

| Corner 125×12 | 22.680 | 44.09 |

| Corner 125×14 | 26.200 | 38.17 |

| Corner 125×16 | 29.650 | 33.73 |

| Corner 140×9 | 19.410 | 51.52 |

| Corner 140×10 | 21.450 | 46.62 |

| Corner 140×12 | 25.500 | 39.22 |

| Corner 150×10 | 23.020 | 43.44 |

| Corner 150×12 | 27.390 | 36.51 |

| Corner 150×15 | 33.820 | 29.57 |

| Corner 150×18 | 40.110 | 24.93 |

| Corner 160×10 | 24.670 | 40.54 |

| Corner 160×11 | 27.020 | 37.01 |

| Corner 160×12 | 28.350 | 35.27 |

| Corner 160×14 | 33.970 | 29.44 |

| Corner 160×16 | 38.520 | 25.96 |

| Corner 160×18 | 43.010 | 23.25 |

| Corner 160×20 | 47.440 | 21.08 |

| Corner 180×11 | 30.470 | 32.82 |

| Corner 180×12 | 33.120 | 30.19 |

| Corner 180×15 | 40.960 | 24.41 |

| Corner 180×18 | 48.660 | 20.55 |

| Corner 180×20 | 53.720 | 18.62 |

| Corner 200×12 | 36.970 | 27.05 |

| Corner 200×13 | 39.920 | 25.05 |

| Corner 200×14 | 42.800 | 23.36 |

| Corner 200×16 | 48.650 | 20.55 |

| Corner 200×18 | 54.400 | 18.38 |

| Corner 200×20 | 60.080 | 16.64 |

| Corner 200×24 | 71.260 | 14.03 |

| Corner 200×25 | 74.020 | 13.51 |

| Corner 200×30 | 87.560 | 11.42 |

| Corner 220×14 | 47.400 | 21.1 |

| Corner 220×16 | 53.830 | 18.58 |

| Corner 250×16 | 61.550 | 16.25 |

| Corner 250×18 | 68.860 | 14.52 |

| Corner 250×20 | 76.110 | 13.14 |

| Corner 250×22 | 83.310 | 12 |

| Corner 250×25 | 93.970 | 10.64 |

| Corner 250×28 | 104.500 | 9.57 |

| Corner 250×30 | 111.440 | 8.97 |

| Corner 250×35 | 128.510 | 7.78 |

Theoretical weight of a linear meter of hot-rolled unequal steel angle GOST 8905-93

| Name, size | Weight per linear meter, kg | Meters per ton |

| Corner 25×16×3 | 0.910 | 1098.9 |

| Corner 30×20×3 | 1.120 | 892.86 |

| Corner 30×20×4 | 1.450 | 689.66 |

| Corner 32×20×3 | 1.170 | 854.7 |

| Corner 32×20×4 | 1.520 | 657.89 |

| Corner 40×25×3 | 1.480 | 675.68 |

| Corner 40×25×4 | 1.940 | 515.46 |

| Corner 40×25×5 | 2.370 | 421.94 |

| Corner 40×30×4 | 2.260 | 442.48 |

| Corner 40×30×5 | 2.460 | 406.5 |

| Corner 45×28×3 | 1.680 | 595.24 |

| Corner 45×28×4 | 2.200 | 454.55 |

| Corner 50×32×3 | 1.900 | 526.32 |

| Corner 50×32×4 | 2.400 | 416.67 |

| Corner 56×36×4 | 2.810 | 355.87 |

| Corner 56×36×5 | 3.460 | 289.02 |

| Corner 63×40×4 | 3.170 | 315.46 |

| Corner 63×40×5 | 3.910 | 255.75 |

| Corner 63×40×6 | 4.630 | 215.98 |

| Corner 63×40×8 | 6.030 | 165.84 |

| Corner 65×50×5 | 4.360 | 229.36 |

| Corner 65×50×6 | 5.180 | 193.05 |

| Corner 65×50×7 | 5.930 | 168.63 |

| Corner 65×50×8 | 6.770 | 147.71 |

| Corner 70×45×5 | 4.300 | 232.56 |

| Corner 75×60×5 | 4.790 | 208.77 |

| Corner 75×60×6 | 5.690 | 175.75 |

| Corner 75×60×7 | 6.570 | 152.21 |

| Corner 75×60×8 | 7.430 | 134.59 |

| Corner 80×50×5 | 4.490 | 222.72 |

| Corner 80×50×6 | 5.920 | 168.92 |

| Corner 80×60×6 | 6.390 | 156.49 |

| Corner 80×60×7 | 7.390 | 135.32 |

| Corner 80×60×8 | 8.370 | 119.47 |

| Corner 90×56×5 | 6.170 | 162.07 |

| Corner 90×56×6 | 6.700 | 149.25 |

| Corner 90×56×8 | 8.770 | 114.03 |

| Corner 100×63×6 | 7.530 | 132.8 |

| Corner 100×63×7 | 8.700 | 114.94 |

| Corner 100×63×8 | 9.870 | 101.32 |

| Corner 100×63×10 | 12.140 | 82.37 |

| Corner 100×65×7 | 8.810 | 113.51 |

| Corner 100×65×8 | 9.990 | 100.1 |

| Corner 100×65×10 | 12.300 | 81.3 |

| Corner 110×70×6 | 8.980 | 111.36 |

| Corner 110×70×8 | 10.930 | 91.49 |

| Corner 125×80×7 | 11.040 | 90.58 |

| Corner 125×80×8 | 12.580 | 79.49 |

| Corner 125×80×10 | 15.470 | 64.64 |

| Corner 125×80×12 | 18.340 | 54.53 |

| Corner 140×90×8 | 14.130 | 70.77 |

| Corner 140×90×10 | 17.460 | 57.27 |

| Corner 160×100×9 | 17.960 | 55.68 |

| Corner 160×100×10 | 19.850 | 50.38 |

| Corner 160×100×12 | 23.580 | 42.41 |

| Corner 160×100×14 | 27.260 | 36.68 |

| Corner 180×110×10 | 22.200 | 45.05 |

| Corner 180×110×12 | 26.400 | 37.88 |

| Corner 200×125×11 | 27.370 | 36.54 |

| Corner 200×125×12 | 29.740 | 33.62 |

| Corner 200×125×14 | 34.430 | 29.04 |

| Corner 200×125×16 | 39.070 | 25.6 |

How to independently determine the weight of a 50 mm corner and other types of products?

Steel corners are classified according to the width of the sides. According to this indicator, all parts are divided into two types: equal-flange and unequal-flange. In the first case, the product has identical sides, and in the second, one of the sides prevails in width.

Equal steel angles have the same side sizes

The weight of steel angles is a necessary parameter for carrying out construction and transport calculations. This indicator is influenced by many factors. First of all, the mass of parts belonging to this group of rolled metal products depends on the dimensions of the products. And also the method that was used in the production of these parts has a great influence on the amount of weight.

In order to determine the weight of a metal corner, you must first find the mass of 1 meter of the product. This calculation is made using two indicators: cross-sectional area and specific gravity. These values need to be multiplied. Each standard size of steel parts has its own specific gravity, which is determined in different ways. Another common method for finding this parameter is using special tables that can be found in the relevant GOSTs.

For unequal metal corners, one of the sides is larger in size

The exact weight of a steel product of this type can only be determined by weighing. However, this method is not always convenient. To find the estimated mass of a batch of corners, you must first calculate the weight of 1 meter. The easiest way is to use special tables that contain data on all standard sizes of steel products of this type. First of all, you need to measure the width of the sides (shelves). It is also necessary to determine the thickness of these same sides.

To determine the exact mass of a batch of corners, you must first calculate the weight of 1 meter

Using the above data, you can easily find the standard size you are interested in in the table and see the weight of 1 linear meter. m of product (for example, the weight of a corner is 50x50 mm). Then you need to divide the resulting theoretical mass by the density of the steel, the average value of which is 7850 kg/m³. The next step is to multiply the result by the density of the steel grade.

If necessary, you can carry out an independent calculation in full. However, this calculation may be inaccurate because it does not take into account the radii of curvature between the sides. The process of independently calculating the weight of a 63 mm corner (or any other) consists of several stages.

First of all, it is necessary to determine the cross-sectional area of the part. To do this, you will need to measure the length of one side (shelf) and multiply the resulting figure by the thickness. Next, you need to subtract the thickness of the product from the length of the second side, after which the resulting number is multiplied by the thickness. This determines the cross-sectional area of one and the other side.

After calculating the area of the sides, you need to add these two indicators. The result is the total theoretical cross-sectional area of the steel angle. All that remains is to multiply this value by the density and 1 m. This way the theoretical weight of 1 m of the steel part is determined.

You can determine the weight of the corner yourself, but the calculation may be inaccurate

Table of weight of equal-flange angle, number of meters in 1 ton

The table below shows all parameters in accordance with GOST 8509-93 . Also, for complete convenience, the number of meters in one ton of different sizes is given.

| Angle section size, mm. | Weight of 1 meter, kg. | Number of meters of angle in 1 ton, m. |

| 20x20x3 | 0,89 | 1123,60 |

| 20x20x4 | 1,15 | 869,57 |

| 25x25x3 | 1,12 | 892,86 |

| 25x25x4 | 1,46 | 684,93 |

| 28x28x3 | 1,27 | 787,40 |

| 30x30x3 | 1,36 | 735,29 |

| 30x30x4 | 1,78 | 561,80 |

| 32x32x3 | 1,46 | 684,93 |

| 32x32x4 | 1,91 | 523,56 |

| 35x35x3 | 1,60 | 625,00 |

| 35x35x4 | 2,10 | 476,19 |

| 35x35x5 | 2,58 | 387,60 |

| 40x40x3 | 1,85 | 540,54 |

| 40x40x4 | 2,42 | 413,22 |

| 40x40x5 | 2,98 | 335,57 |

| 45x45x3 | 2,08 | 480,77 |

| 45x45x4 | 2,73 | 366,30 |

| 45x45x5 | 3,37 | 296,74 |

| 50x50x3 | 2,32 | 431,03 |

| 50x50x4 | 3,05 | 327,87 |

| 50x50x5 | 3,77 | 265,25 |

| 50x50x6 | 4,42 | 226,24 |

| 56x56x4 | 3,44 | 290,70 |

| 56x56x5 | 4,25 | 235,29 |

| 63x63x4 | 3,90 | 256,41 |

| 63x63x5 | 4,81 | 207,90 |

| 63x63x6 | 5,72 | 174,83 |

| 70x70x4.5 | 4,87 | 205,34 |

| 70x70x5 | 5,38 | 185,87 |

| 70x70x6 | 6,39 | 156,49 |

| 70x70x7 | 7,39 | 135,32 |

| 70x70x8 | 8,37 | 119,47 |

| 75x75x5 | 5,80 | 172,41 |

| 75x75x6 | 6,89 | 145,14 |

| 75x75x7 | 7,96 | 125,63 |

| 75x75x8 | 9,02 | 110,86 |

| 75x75x9 | 10,07 | 99,30 |

| 80x80x5.5 | 6,78 | 147,49 |

| 80x80x6 | 7,36 | 135,87 |

| 80x80x7 | 8,51 | 117,51 |

| 80x80x8 | 9,65 | 103,63 |

| 90x90x6 | 8,33 | 120,05 |

| 90x90x7 | 9,64 | 103,73 |

| 90x90x8 | 10,93 | 91,49 |

| 90x90x9 | 12,20 | 81,97 |

| 100x100x6.5 | 10,06 | 99,40 |

| 100x100x7 | 10,79 | 92,68 |

| 100x100x8 | 12,25 | 81,63 |

| 100x100x10 | 15,10 | 66,23 |

| 100x100x12 | 17,90 | 55,87 |

| 100x100x14 | 20,63 | 48,47 |

| 100x100x16 | 23,30 | 42,92 |

| 110x110x7 | 11,89 | 84,10 |

| 110x110x8 | 13,50 | 74,07 |

| 125x125x8 | 15,46 | 64,68 |

| 125x125x9 | 17,30 | 57,80 |

| 125x125x10 | 19,10 | 52,36 |

| 125x125x12 | 22,68 | 44,09 |

| 125x125x14 | 26,20 | 38,17 |

| 125x125x16 | 29,65 | 33,73 |

| 140x140x9 | 19,41 | 51,52 |

| 140x140x10 | 21,45 | 46,62 |

| 140x140x12 | 25,50 | 39,22 |

| 160x160x10 | 24,67 | 40,54 |

| 160x160x11 | 27,02 | 37,01 |

| 160x160x12 | 29,35 | 34,07 |

| 160x160x14 | 34,20 | 29,24 |

| 160x160x16 | 38,52 | 25,96 |

| 160x160x18 | 43,01 | 23,25 |

| 160x160x20 | 47,41 | 21,09 |

| 180x180x11 | 30,47 | 32,82 |

| 180x180x12 | 33,12 | 30,19 |

| 200x200x12 | 36,97 | 27,05 |

| 200x200x13 | 39,92 | 25,05 |

| 200x200x14 | 42,80 | 23,36 |

| 200x200x16 | 48,65 | 20,55 |

| 200x200x20 | 60,08 | 16,64 |

| 200x200x25 | 74,02 | 13,51 |

| 200x200x30 | 87,56 | 11,42 |

| 220x220x14 | 47,40 | 21,10 |

| 220x220x16 | 53,83 | 18,58 |

| 250x250x16 | 61,55 | 16,25 |

| 250x250x18 | 68,86 | 14,52 |

| 250x250x20 | 76,11 | 13,14 |

| 250x250x22 | 83,31 | 12,00 |

| 250x250x25 | 93,97 | 10,64 |

| 250x250x28 | 104,50 | 9,57 |

| 250x250x30 | 111,44 | 8,97 |

| 250x250x35 | 128,51 | 7,78 |

Beam calculator - calculation for different types of structures

Beams in a house usually belong to the rafter system or floor, and in order to get a reliable structure that can be operated without any fear, you need to use a beam calculator.

What is the beam calculator based on?

When the walls have already been brought under the second floor or under the roof, it is necessary to make a ceiling, in the second case smoothly turning into rafters. In this case, the materials must be selected so that the load on the brick or log walls does not exceed the permissible value, and the strength of the structure is at the proper level. Therefore, if you are going to use wood, you need to choose the right beams from it and make calculations to determine the required thickness and sufficient length.

Beam calculator

The subsidence or partial destruction of the ceiling can be due to various reasons, for example, too large a step between the lags, deflection of the cross members, too small their cross-sectional area or defects in the structure. To eliminate possible excesses, you should find out the expected load on the floor, be it basement or interfloor, and then use a beam calculator, taking into account their own weight. The latter can change in concrete lintels, the weight of which depends on the density of the reinforcement; for wood and metal, with a certain geometry, the weight is constant. The exception is damp wood, which is not used in construction work without first drying it.

Beam systems in floors and rafter structures are loaded by forces acting on section bending, torsion, and lengthwise deflection. For rafters, it is also necessary to provide for snow and wind loads, which also create certain forces applied to the beams. You also need to accurately determine the required step between the jumpers, since too many crossbars will lead to excess weight of the floor (or roof), and too little, as mentioned above, will weaken the structure.

How to calculate the load on a floor beam

The distance between the walls is called a span, and there are two of them in the room, and one span will necessarily be smaller than the other if the shape of the room is not square. Interfloor or attic floor lintels should be laid along a shorter span, the optimal length of which is from 3 to 4 meters. Larger spacing may require non-standard sized beams, which will result in some unsteadiness of the deck. The best solution in this case would be to use metal crossbars.

Regarding the cross-section of a wooden beam, there is a certain standard that requires that the sides of the beam have a ratio of 7:5, that is, the height is divided into 7 parts, and 5 of them must make up the width of the profile. In this case, deformation of the section is excluded, but if you deviate from the above indicators, then if the width exceeds the height, you will get a deflection, or, if the opposite discrepancy occurs, a bend to the side. To prevent this from happening due to the excessive length of the beam, you need to know how to calculate the load on the beam. In particular, the permissible deflection is calculated from the ratio to the length of the lintel as 1:200, that is, it should be 2 centimeters per 4 meters.

To prevent the beam from sagging under the weight of logs and flooring, as well as interior items, you can grind it from below a few centimeters, giving it the shape of an arch; in this case, its height should have an appropriate margin.

Now let's turn to the formulas. The same deflection mentioned earlier is calculated as follows: fnor = L/200, where L is the span length, and 200 is the permissible distance in centimeters for each unit of beam subsidence. For a reinforced concrete beam, the distributed load q on which is usually equal to 400 kg/m 2, the calculation of the maximum bending moment is performed using the formula Mmax = (q · L 2)/8. In this case, the amount of reinforcement and its weight is determined according to the following table:

Cross-sectional areas and mass of reinforcing bars

Beam calculator - calculation for different types of structures

Security in the house is not only video surveillance, but also strong walls and ceilings, which means that during construction it’s a good idea to use a beam calculator

Weight of unequal corners

Depending on the size and thickness, the corners can have different weights. You can find out the weight from the table, which is presented in the GOST 8510-86 table. The leftmost column shows the number of the corner, and the rightmost column shows the mass of 1 meter of the product with these parameters. The table also shows all dimensions and characteristics of the product.

| Table of mass of unequal angle | |||

| Number | Size, mm | Meter, kg | In a ton of meters |

| 2.5/1.6 | 25x16x3 | 0,91 | 1098,9 |

| 3/2 | 30x20x3 | 1,12 | 892,9 |

| 3/2 | 30x20x4 | 1,46 | 684,9 |

| 3.2/2 | 32x20x3 | 1,17 | 854,7 |

| 3.2/2 | 32x20x4 | 1,52 | 657,9 |

| 4/2.5 | 40x25x3 | 1,48 | 675,7 |

| 4/2.5 | 40x25x4 | 1,94 | 515,5 |

| 4/2.5 | 40x25x5 | 2,37 | 421,9 |

| 4/3 | 40x30x4 | 2,26 | 442,5 |

| 4/3 | 40x30x4 | 2,46 | 406,5 |

| 4.5/2.8 | 45x28x3 | 1,68 | 595,2 |

| 4.5/2.8 | 45x28x4 | 2,2 | 454,5 |

| 5/3.2 | 50x32x3 | 1,9 | 526,3 |

| 5/3.2 | 50x32x4 | 2,4 | 416,7 |

| 5.6/3.6 | 56x36x4 | 2,81 | 355,9 |

| 5.6/3.6 | 56x36x5 | 3,46 | 289,0 |

| 6.3/4.0 | 63x40x4 | 3,17 | 315,5 |

| 6.3/4.0 | 63x40x5 | 3,91 | 255,8 |

| 6.3/4.0 | 63x40x6 | 4,63 | 215,9 |

| 6.3/4.0 | 63x40x8 | 6,03 | 165,8 |

| 6.5/5 | 65x50x5 | 4,36 | 229,4 |

| 6.5/5 | 65x50x6 | 5,18 | 193,1 |

| 6.5/5 | 65x50x4 | 5,98 | 167,2 |

| 6.5/5 | 65x50x4 | 6,77 | 147,7 |

| 7/4.5 | 70x45x5 | 4,39 | 227,8 |

| 7.5/5 | 75x50x5 | 4,79 | 208,8 |

| 7.5/5 | 75x50x6 | 5,69 | 175,7 |

| 7.5/5 | 75x50x7 | 6,57 | 152,2 |

| 7.5/5 | 75x50x8 | 7,43 | 134,6 |

| 8/5 | 80x50x5 | 4,49 | 222,7 |

| 8/5 | 80x60x6 | 5,92 | 168,9 |

| 8/5 | 80x50x6 | 6,39 | 156,5 |

| 8/6 | 80x60x7 | 7,39 | 135,3 |

| 8/6 | 80x60x8 | 8,37 | 119,5 |

| 9/5.6 | 90x56x5.5 | 6,17 | 162,1 |

| 9/5.6 | 90x56x6 | 6,7 | 149,3 |

| 9/5.6 | 90x56x8 | 8,77 | 114,0 |

| 10/6.3 | 100x63x6 | 7,53 | 132,8 |

| 10/6.3 | 100x63x7 | 8,7 | 114,9 |

| 10/6.3 | 100x63x8 | 9,87 | 101,3 |

| 10/6.3 | 100x63x10 | 12,14 | 82,4 |

| 10/6.3 | 100x63x7 | 8,81 | 113,5 |

| 10/6.5 | 100x65x8 | 9,99 | 100,1 |

| 10/6.5 | 100x65x10 | 12,3 | 81,3 |

| 11/7 | 110x70x6.5 | 8,98 | 111,4 |

| 11/7 | 110x70x8 | 10,93 | 91,5 |

| 12.5/8 | 125x80x7 | 11,04 | 90,6 |

| 12.5/8 | 125x80x8 | 12,58 | 79,5 |

| 12.5/8 | 125x80x10 | 15,47 | 64,6 |

| 12.5/8 | 125x80x12 | 18,34 | 54,5 |

| 14/9 | 140x90x8 | 14,13 | 70,8 |

| 14/9 | 140x90x10 | 17,46 | 57,3 |

| 16/10 | 160x100x9 | 17,96 | 55,7 |

| 16/10 | 160x100x10 | 19,85 | 50,4 |

| 16/10 | 160x100x12 | 23,58 | 42,4 |

| 16/10 | 160x100x14 | 27,26 | 36,7 |

| 18/11 | 180x110x10 | 22,2 | 45,0 |

| 18/11 | 180x110x12 | 26,4 | 37,9 |

| 18/11 | 180x110x11 | 27,37 | 36,5 |

| 20/12.5 | 200x125x12 | 29,74 | 33,6 |

| 20/12.5 | 200x125x14 | 34,43 | 29,0 |

| 20/12.5 | 200x125x16 | 39,07 | 25,6 |

The weight of 1 meter of corner is from 0.91 kg (for number 2.5/1.6) to 39.07 kg (for number 20/12.5). Products with greater weight have greater strength and, accordingly, can be used under heavy loads. In the table it is easy to find a model of unequal angles that is suitable for use in solving a specific problem.

Angle weight table (equal flange GOST 8509-93)

| Angle dimensions | Shelf size (mm.) | Metal thickness (mm.) | Weight per linear meter (kg.) | Meters per ton |

| 20×3 | 20 | 3 | 0.89 | 1123.6 |

| 20×4 | 20 | 4 | 1.15 | 869.57 |

| 25×3 | 25 | 3 | 1.12 | 892.86 |

| 25×4 | 25 | 4 | 1.46 | 684.93 |

| 25×5 | 25 | 5 | 1.78 | 561.8 |

| 28×3 | 28 | 3 | 1.27 | 787.4 |

| 30×3 | 30 | 3 | 1.36 | 735.29 |

| 30×4 | 30 | 4 | 1.78 | 561.8 |

| 30×5 | 30 | 5 | 2.18 | 458.72 |

| 32×3 | 32 | 3 | 1.46 | 684.93 |

| 32×4 | 32 | 4 | 1.91 | 523.56 |

| 35×3 | 35 | 3 | 1.6 | 625 |

| 35×4 | 35 | 4 | 2.1 | 476.19 |

| 35×5 | 35 | 5 | 2.58 | 387.6 |

| 40×3 | 40 | 3 | 1.85 | 540.54 |

| 40×4 | 40 | 4 | 2.42 | 413.22 |

| 40×5 | 40 | 5 | 2.98 | 335.57 |

| 40×6 | 40 | 6 | 3.52 | 284.09 |

| 45×3 | 45 | 3 | 2.08 | 480.77 |

| 45×4 | 45 | 4 | 2.73 | 366.3 |

| 45×5 | 45 | 5 | 3.37 | 296.74 |

| 45×6 | 45 | 6 | 3.99 | 250.63 |

| 50×3 | 50 | 3 | 2.32 | 431.03 |

| 50×4 | 50 | 4 | 3.05 | 327.87 |

| 50×5 | 50 | 5 | 3.77 | 265.25 |

| 50×6 | 50 | 6 | 4.47 | 223.71 |

| 50×7 | 50 | 7 | 5.15 | 194.17 |

| 50×8 | 50 | 8 | 5.82 | 171.82 |

| 56×4 | 56 | 4 | 3.44 | 290.7 |

| 56×5 | 56 | 5 | 4.25 | 235.29 |

| 60×4 | 60 | 4 | 3.71 | 269.54 |

| 60×5 | 60 | 5 | 4.58 | 218.34 |

| 60×6 | 60 | 6 | 5.43 | 184.16 |

| 60×8 | 60 | 8 | 7.1 | 140.85 |

| 60×0 | 60 | 10 | 8.7 | 114.94 |

| 63×4 | 63 | 4 | 3.9 | 256.41 |

| 63×5 | 63 | 5 | 4.81 | 207.9 |

| 63×6 | 63 | 6 | 5.72 | 174.83 |

| 65×6 | 65 | 6 | 5.91 | 169.2 |

| 65×8 | 65 | 8 | 7.73 | 129.37 |

| 70×4 | 70 | 4.5 | 4.87 | 205.34 |

| 70×5 | 70 | 5 | 5.38 | 185.87 |

| 70×6 | 70 | 6 | 6.39 | 156.49 |

| 70×7 | 70 | 7 | 7.39 | 135.32 |

| 70×8 | 70 | 8 | 8.37 | 119.47 |

| 70×0 | 70 | 10 | 10.29 | 97.18 |

| 75×5 | 75 | 5 | 5.8 | 172.41 |

| 75×6 | 75 | 6 | 6.89 | 145.14 |

| 75×7 | 75 | 7 | 7.96 | 125.63 |

| 75×8 | 75 | 8 | 9.02 | 110.86 |

| 75×9 | 75 | 9 | 10.07 | 99.3 |

| 80×5 | 80 | 5.5 | 6.78 | 147.49 |

| 80×6 | 80 | 6 | 7.36 | 135.87 |

| 80×7 | 80 | 7 | 8.51 | 117.51 |

| 80×8 | 80 | 8 | 9.65 | 103.63 |

| 80×10 | 80 | 10 | 11.88 | 84.18 |

| 80×12 | 80 | 12 | 14.05 | 71.17 |

| 90×6 | 90 | 6 | 8.33 | 120.05 |

| 90×7 | 90 | 7 | 9.64 | 103.73 |

| 90×8 | 90 | 8 | 10.93 | 91.49 |

| 90×9 | 90 | 9 | 12.2 | 81.97 |

| 90×10 | 90 | 10 | 13.48 | 74.18 |

| 90×12 | 90 | 12 | 15.96 | 62.66 |

| 100×6.5 | 100 | 6.5 | 10.06 | 99.4 |

| 100×7 | 100 | 7 | 10.79 | 92.68 |

| 100×8 | 100 | 8 | 12.25 | 81.63 |

| 100×10 | 100 | 10 | 15.1 | 66.23 |

| 100×12 | 100 | 12 | 17.9 | 55.87 |

| 100×14 | 100 | 14 | 20.63 | 48.47 |

| 100×15 | 100 | 15 | 21.97 | 45.52 |

| 100×16 | 100 | 16 | 23.3 | 42.92 |

| 110×7 | 110 | 7 | 11.89 | 84.1 |

| 110×8 | 110 | 8 | 13.5 | 74.07 |

| 120×8 | 120 | 8 | 14.76 | 67.75 |

| 120×10 | 120 | 10 | 18.24 | 54.82 |

| 120×12 | 120 | 12 | 21.67 | 46.15 |

| 120×15 | 120 | 15 | 26.68 | 37.48 |

| 125×8 | 125 | 8 | 15.46 | 64.68 |

| 125×9 | 125 | 9 | 17.3 | 57.8 |

| 125×10 | 125 | 10 | 19.1 | 52.36 |

| 125×12 | 125 | 12 | 22.68 | 44.09 |

| 125×14 | 125 | 14 | 26.2 | 38.17 |

| 125×16 | 125 | 16 | 29.65 | 33.73 |

| 140×9 | 140 | 9 | 19.41 | 51.52 |

| 140×10 | 140 | 10 | 21.45 | 46.62 |

| 140×12 | 140 | 12 | 25.5 | 39.22 |

| 150×10 | 150 | 10 | 23.02 | 43.44 |

| 150×12 | 150 | 12 | 27.39 | 36.51 |

| 150×15 | 150 | 15 | 33.82 | 29.57 |

| 150×18 | 150 | 18 | 40.11 | 24.93 |

| 160×10 | 160 | 10 | 24.67 | 40.54 |

| 160×11 | 160 | 11 | 27.02 | 37.01 |

| 160×12 | 160 | 12 | 28.35 | 35.27 |

| 160×14 | 160 | 14 | 33.97 | 29.44 |

| 160×16 | 160 | 16 | 38.52 | 25.96 |

| 160×18 | 160 | 18 | 43.01 | 23.25 |

| 160×20 | 160 | 20 | 47.44 | 42968 |

| 180×11 | 180 | 11 | 30.47 | 32.82 |

| 180×12 | 180 | 12 | 33.12 | 30.19 |

| 180×15 | 180 | 15 | 40.96 | 24.41 |

| 180×18 | 180 | 18 | 48.66 | 20.55 |

| 180×20 | 180 | 20 | 53.72 | 18.62 |

| 200×12 | 200 | 12 | 36.97 | 42882 |

| 200×13 | 200 | 13 | 39.92 | 42880 |

| 200×14 | 200 | 14 | 42.8 | 23.36 |

| 200×16 | 200 | 16 | 48.65 | 20.55 |

| 200×18 | 200 | 18 | 54.4 | 18.38 |

| 200×20 | 200 | 20 | 60.08 | 16.64 |

| 200×24 | 200 | 24 | 71.26 | 42808 |

| 200×25 | 200 | 25 | 74.02 | 13.51 |

| 200×30 | 200 | 30 | 87.56 | 15646 |

| 220×14 | 220 | 14 | 47.4 | 42756 |

| 220×16 | 220 | 16 | 53.83 | 18.58 |

| 250×16 | 250 | 16 | 61.55 | 16.25 |

| 250×18 | 250 | 18 | 68.86 | 14.52 |

| 250×20 | 250 | 20 | 76.11 | 13.14 |

| 250×22 | 250 | 22 | 83.31 | 12 |

| 250×25 | 250 | 25 | 93.97 | 23651 |

| 250×28 | 250 | 28 | 104.5 | 21064 |

| 250×30 | 250 | 30 | 111.44 | 35643 |

| 250×35 | 250 | 35 | 128.51 | 28672 |

Weight of steel unequal angle (GOST 8510-96)

| Angle dimensions | Corner flange size A (mm.) | Corner flange size B (mm.) | Metal thickness (mm.) | Weight per meter | Meters per ton |

| 25×16×3 | 25 | 16 | 3 | 0.91 | 1098.9 |

| 30×20×3 | 30 | 20 | 3 | 1.12 | 892.86 |

| 30×20×4 | 30 | 20 | 4 | 1.45 | 689.66 |

| 32×20×3 | 32 | 20 | 3 | 1.17 | 854.7 |

| 32×20×4 | 32 | 20 | 4 | 1.52 | 657.89 |

| 40×25×3 | 40 | 25 | 3 | 1.48 | 675.68 |

| 40×25×4 | 40 | 25 | 4 | 1.94 | 515.46 |

| 40×25×5 | 40 | 25 | 5 | 2.37 | 421.94 |

| 40×30×4 | 40 | 30 | 4 | 2.26 | 442.48 |

| 40×30×5 | 40 | 30 | 5 | 2.46 | 406.5 |

| 45×28×3 | 45 | 28 | 3 | 1.68 | 595.24 |

| 45×28×4 | 45 | 28 | 4 | 2.2 | 454.55 |

| 50×32×3 | 50 | 32 | 3 | 1.9 | 526.32 |

| 50×32×4 | 50 | 32 | 4 | 2.4 | 416.67 |

| 56×36×4 | 56 | 36 | 4 | 2.81 | 355.87 |

| 56×36×5 | 56 | 36 | 5 | 3.46 | 289.02 |

| 63×40×4 | 63 | 40 | 4 | 3.17 | 315.46 |

| 63×40×5 | 63 | 40 | 5 | 3.91 | 255.75 |

| 63×40×6 | 63 | 40 | 6 | 4.63 | 215.98 |

| 63×40×8 | 63 | 40 | 8 | 6.03 | 165.84 |

| 65×50×5 | 65 | 50 | 5 | 4.36 | 229.36 |

| 65×50×6 | 65 | 50 | 6 | 5.18 | 193.05 |

| 65×50×7 | 65 | 50 | 7 | 5.93 | 168.63 |

| 65×50×8 | 65 | 50 | 8 | 6.77 | 147.71 |

| 70×45×5 | 70 | 45 | 5 | 4.3 | 232.56 |

| 75×60×5 | 75 | 60 | 5 | 4.79 | 208.77 |

| 75×60×6 | 75 | 60 | 6 | 5.69 | 175.75 |

| 75×60×7 | 75 | 60 | 7 | 6.57 | 152.21 |

| 75×60×8 | 75 | 60 | 8 | 7.43 | 134.59 |

| 80×50×5 | 80 | 50 | 5 | 4.49 | 222.72 |

| 80×50×6 | 80 | 50 | 6 | 5.92 | 168.92 |

| 80×60×6 | 80 | 60 | 6 | 6.39 | 156.49 |

| 80×60×7 | 80 | 60 | 7 | 7.39 | 135.32 |

| 80×60×8 | 80 | 60 | 8 | 8.37 | 119.47 |

| 90×56×5 | 90 | 56 | 5.5 | 6.17 | 162.07 |

| 90×56×6 | 90 | 56 | 6 | 6.7 | 149.25 |

| 90×56×8 | 90 | 56 | 8 | 8.77 | 114.03 |

| 100×63×6 | 100 | 63 | 6 | 7.53 | 132.8 |

| 100×63×7 | 100 | 63 | 7 | 8.7 | 114.94 |

| 100×63×8 | 100 | 63 | 8 | 9.87 | 101.32 |

| 100×63×10 | 100 | 63 | 10 | 12.14 | 82.37 |

| 100×65×7 | 100 | 65 | 7 | 8.81 | 113.51 |

| 100×65×8 | 100 | 65 | 8 | 9.99 | 100.1 |

| 100×65×10 | 100 | 65 | 10 | 12.3 | 81.3 |

| 110×70×6 | 110 | 70 | 6.5 | 8.98 | 111.36 |

| 110×70×8 | 110 | 70 | 8 | 10.93 | 91.49 |

| 125×80×7 | 125 | 80 | 7 | 11.04 | 90.58 |

| 125×80×8 | 125 | 80 | 8 | 12.58 | 79.49 |

| 125×80×10 | 125 | 80 | 10 | 15.47 | 64.64 |

| 125×80×12 | 125 | 80 | 12 | 18.34 | 54.53 |

| 140×90×8 | 140 | 90 | 8 | 14.13 | 70.77 |

| 140×90×10 | 140 | 90 | 10 | 17.46 | 57.27 |

| 160×100×9 | 160 | 100 | 9 | 17.96 | 55.68 |

| 160×100×10 | 160 | 100 | 10 | 19.85 | 50.38 |

| 160×100×12 | 160 | 100 | 12 | 23.58 | 42.41 |

| 160×100×14 | 160 | 100 | 14 | 27.26 | 36.68 |

| 180×110×10 | 180 | 110 | 10 | 22.2 | 45.05 |

| 180×110×12 | 180 | 110 | 12 | 26.4 | 37.88 |

| 200×125×11 | 200 | 125 | 11 | 27.37 | 36.54 |

| 200×125×12 | 200 | 125 | 12 | 29.74 | 33.62 |

| 200×125×14 | 200 | 125 | 14 | 34.43 | 42854 |

| 200×125×16 | 200 | 125 | 16 | 39.07 | 42911 |

How much does a steel angle weigh?

On our website you can buy steel angles in Saratov at a competitive price. We have a large selection of construction and finishing materials, as well as discounts for regular customers!

When planning delivery, customers often ask how much a steel angle weighs. The mass of metal corners can be determined from tables that present the theoretical specific gravity of steel corners with different shelf sizes and thicknesses.

Table 1. “Weight of equal-flange metal angles” (popular sizes)

| Shelf size and corner thickness, mm | Weight of 1 linear meter, kg |

| Steel corner 20x20x3 | 0,89 |

| Steel corner 20x20x4 | 1,15 |

| Steel corner 25x25x3 | 1,12 |

| Steel corner 25x25x4 | 1,46 |

| Steel corner 28x28x3 | 1,27 |

| Steel corner 30x30x3 | 1,36 |

| Steel corner 30x30x4 | 1,78 |

| Steel corner 32x32x3 | 1,46 |

| Steel corner 32x32x4 | 1,91 |

| Steel corner 35x35x3 | 1,60 |

| Steel corner 35x35x4 | 2,10 |

| Steel corner 35x35x5 | 2,58 |

| Steel corner 40x40x3 | 1,85 |

| Steel corner 40x40x4 | 2,42 |

| Steel corner 40x40x5 | 2,98 |

| Steel corner 45x45x3 | 2,08 |

| Steel corner 45x45x4 | 2,73 |

| Steel corner 50x50x4 | 3,05 |

| Steel corner 50x50x5 | 3,77 |

| Steel corner 50x50x6 | 4,47 |

| Steel corner 56x56x4 | 3,44 |

| Steel corner 56x56x5 | 4,25 |

| Steel corner 63x63x4 | 3,90 |

| Steel corner 63x63x5 | 4,81 |

| Steel corner 63x63x6 | 5,72 |

| Steel corner 70x70x4.5 | 4,87 |

| Steel corner 70x70x5 | 5,38 |

| Steel corner 70x70x6 | 6,39 |

| Steel corner 70x70x7 | 7,39 |

| Steel corner 70x70x8 | 8,37 |

| Steel corner 75x75x5 | 5,80 |

| Steel corner 75x75x6 | 6,89 |

| Steel corner 75x75x7 | 7,96 |

| Steel corner 75x75x8 | 9,02 |

| Steel corner 75x75x9 | 10,70 |

| Steel corner 80x80x5.5 | 6,78 |

| Steel corner 80x80x6 | 7,36 |

| Steel corner 80x80x7 | 8,51 |

| Steel corner 80x80x8 | 9,65 |

| Steel corner 90x90x6 | 8,33 |

| Steel corner 90x90x7 | 9,64 |

| Steel corner 90x90x8 | 10,93 |

| Steel corner 90x90x9 | 12,20 |

| Steel corner 100x100x7 | 10,8 |

| Steel corner 125x125x8 | 15,46 |

Table 2. “Weight of unequal metal corners” (popular sizes)

| Shelf size and corner thickness, mm | Weight of 1 linear meter, kg |

| Steel corner 25x16x3 | 0,91 |

| Steel corner 32x20x3 | 1,17 |

| Steel corner 32x20x4 | 1,52 |

| Steel corner 40x25x3 | 1,48 |

| Steel corner 40x25x4 | 1,94 |

| Steel corner 40x25x4 | 2,37 |

| Steel corner 45x28x3 | 1,68 |

| Steel corner 45x28x4 | 2,20 |

| Steel corner 50x32x3 | 1,90 |

| Steel corner 50x32x4 | 2,40 |

| Steel corner 56x36x4 | 2,81 |

| Steel corner 56x36x5 | 3,46 |

| Steel corner 63x40x4 | 3,17 |

| Steel corner 63x40x5 | 3,91 |

| Steel corner 63x40x6 | 4,63 |

| Steel corner 63x40x8 | 6,03 |

| Steel corner 70x45x5 | 4,39 |

| Steel corner 75x50x5 | 4,79 |

| Steel corner 75x50x6 | 5,69 |

| Steel corner 75x50x8 | 7,43 |

| Steel corner 80x50x5 | 4,49 |

| Steel corner 80x50x6 | 5,92 |

| Steel corner 90x56x5.5 | 6,17 |

| Steel corner 90x56x6 | 6,70 |

| Steel corner 90x56x8 | 8,77 |

| Steel corner 100x63x6 | 7,53 |

| Steel corner 100x63x7 | 8,70 |

| Steel corner 100x63x8 | 9,87 |

| Steel corner 100x63x10 | 12,14 |

| Steel corner 110x70x6.5 | 8,98 |

| Steel corner 110x70x8 | 10,93 |

| Steel corner 125x70x7 | 11,04 |

| Steel corner 125x70x8 | 12,58 |

| Steel corner 125x80x10 | 15,47 |

| Steel corner 125x80x12 | 18,34 |

| Steel corner 140x90x8 | 14,13 |

| Steel corner 160x90x10 | 17,46 |

| Steel corner 160x100x9 | 17,96 |

| Steel corner 160x100x10 | 19,85 |

| Steel corner 160x100x12 | 23,58 |

| Steel corner 160x100x14 | 27,26 |

| Steel corner 180x110x10 | 22,20 |

| Steel corner 180x110x12 | 26,40 |

| Steel corner 200x125x11 | 27,37 |

| Steel corner 200x125x12 | 29,74 |

| Steel corner 200x125x14 | 34,43 |

| Steel corner 200x125x16 | 39,07 |

Products on the topic of publication:

- corner 100*100*7 m/d, (12.0) GOST 535-88, GOST 8509-93 11,040 ₽ pcs pcs m.p.

- corner 25*25*3 m/d (6.0) 630 ₽ pcs pcs m.p.

- corner 25*25*4 m/d (6.0) 792 ₽ pcs pcs m.p.

- corner 40*40*4 m/d, (12.0) 2,460 ₽ pcs pcs m.p.

- corner 45*45*4 m/d, (12.0) 2,775.60 ₽ pcs pcs m.p.

- corner 50*50*4m/d, (12.0) 3,063.60 ₽ pcs pcs m.p.

- corner 50*50*5 m/d, (12.0) 3,786 ₽ pcs pcs m.p.

- corner 63*63*5 m/d, (12.0) 4,851.60 ₽ pcs pcs m.p.

- corner 75*75*5 m/d, (12.0) 6,057 ₽ pcs pcs m.p.

- corner 90*90*6 m/d, (12.0) 8,400 ₽ pcs pcs m.p.

We calculate the weight of rolled sheets

Calculating the weight of rolled metal is a fairly simple task of this class. Simplicity is determined by the shape of the sample being studied. To begin calculations, you need to know the following characteristics:

- geometric dimensions of the test sample;

- metal density (for steel you can use the average indicator, which is equal to 7850 kg/m 3);

The first stage involves calculating the weight of a sheet of metal with an area of one square meter and a thickness of one millimeter. The volume of this sample is calculated and multiplied by the density of the steel. It is obtained by standard multiplication of three geometric parameters: length, width, height. Multiplying the result by the density, we get a value equal to 7.8 kg/m3. It will allow you to calculate the weight of a sheet of any geometric size and shape. Convenient because it does not depend on length, width, thickness. You can get the final value without resorting to preliminary recalculation. Therefore, the main task will be to calculate the volume of the selected sheet.

For example, the weight of a sheet whose size is one meter long, two meters wide, 0.35 mm thick will weigh 5.5 kg. A sheet 5 mm thick, measuring 1.5 m wide and 6 meters long will weigh 353.25 kg.

Before using a metal sheet as a ceiling or building structure, you should evaluate its weight.

Sheet weight

Weight of hot-rolled steel unequal angle GOST 8510-96

| Angle dimensions | Corner flange size A, mm | Corner flange size B, mm | Metal thickness S, mm | Weight m/p., kg | Number of meters in tons |

| 25×16×3 | 25 | 16 | 3 | 0.91 | 1098.9 |

| 30×20×3 | 30 | 20 | 3 | 1.12 | 892.86 |

| 30×20×4 | 30 | 20 | 4 | 1.45 | 689.66 |

| 32×20×3 | 32 | 20 | 3 | 1.17 | 854.7 |

| 32×20×4 | 32 | 20 | 4 | 1.52 | 657.89 |

| 40×25×3 | 40 | 25 | 3 | 1.48 | 675.68 |

| 40×25×4 | 40 | 25 | 4 | 1.94 | 515.46 |

| 40×25×5 | 40 | 25 | 5 | 2.37 | 421.94 |

| 40×30×4 | 40 | 30 | 4 | 2.26 | 442.48 |

| 40×30×5 | 40 | 30 | 5 | 2.46 | 406.5 |

| 45×28×3 | 45 | 28 | 3 | 1.68 | 595.24 |

| 45×28×4 | 45 | 28 | 4 | 2.2 | 454.55 |

| 50×32×3 | 50 | 32 | 3 | 1.9 | 526.32 |

| 50×32×4 | 50 | 32 | 4 | 2.4 | 416.67 |

| 56×36×4 | 56 | 36 | 4 | 2.81 | 355.87 |

| 56×36×5 | 56 | 36 | 5 | 3.46 | 289.02 |

| 63×40×4 | 63 | 40 | 4 | 3.17 | 315.46 |

| 63×40×5 | 63 | 40 | 5 | 3.91 | 255.75 |

| 63×40×6 | 63 | 40 | 6 | 4.63 | 215.98 |

| 63×40×8 | 63 | 40 | 8 | 6.03 | 165.84 |

| 65×50×5 | 65 | 50 | 5 | 4.36 | 229.36 |

| 65×50×6 | 65 | 50 | 6 | 5.18 | 193.05 |

| 65×50×7 | 65 | 50 | 7 | 5.93 | 168.63 |

| 65×50×8 | 65 | 50 | 8 | 6.77 | 147.71 |

| 70×45×5 | 70 | 45 | 5 | 4.3 | 232.56 |

| 75×60×5 | 75 | 60 | 5 | 4.79 | 208.77 |

| 75×60×6 | 75 | 60 | 6 | 5.69 | 175.75 |

| 75×60×7 | 75 | 60 | 7 | 6.57 | 152.21 |

| 75×60×8 | 75 | 60 | 8 | 7.43 | 134.59 |

| 80×50×5 | 80 | 50 | 5 | 4.49 | 222.72 |

| 80×50×6 | 80 | 50 | 6 | 5.92 | 168.92 |

| 80×60×6 | 80 | 60 | 6 | 6.39 | 156.49 |

| 80×60×7 | 80 | 60 | 7 | 7.39 | 135.32 |

| 80×60×8 | 80 | 60 | 8 | 8.37 | 119.47 |

| 90×56×5 | 90 | 56 | 5.5 | 6.17 | 162.07 |

| 90×56×6 | 90 | 56 | 6 | 6.7 | 149.25 |

| 90×56×8 | 90 | 56 | 8 | 8.77 | 114.03 |

| 100×63×6 | 100 | 63 | 6 | 7.53 | 132.8 |

| 100×63×7 | 100 | 63 | 7 | 8.7 | 114.94 |

| 100×63×8 | 100 | 63 | 8 | 9.87 | 101.32 |

| 100×63×10 | 100 | 63 | 10 | 12.14 | 82.37 |

| 100×65×7 | 100 | 65 | 7 | 8.81 | 113.51 |

| 100×65×8 | 100 | 65 | 8 | 9.99 | 100.1 |

| 100×65×10 | 100 | 65 | 10 | 12.3 | 81.3 |

| 110×70×6 | 110 | 70 | 6.5 | 8.98 | 111.36 |

| 110×70×8 | 110 | 70 | 8 | 10.93 | 91.49 |

| 125×80×7 | 125 | 80 | 7 | 11.04 | 90.58 |

| 125×80×8 | 125 | 80 | 8 | 12.58 | 79.49 |

| 125×80×10 | 125 | 80 | 10 | 15.47 | 64.64 |

| 125×80×12 | 125 | 80 | 12 | 18.34 | 54.53 |

| 140×90×8 | 140 | 90 | 8 | 14.13 | 70.77 |

| 140×90×10 | 140 | 90 | 10 | 17.46 | 57.27 |

| 160×100×9 | 160 | 100 | 9 | 17.96 | 55.68 |

| 160×100×10 | 160 | 100 | 10 | 19.85 | 50.38 |

| 160×100×12 | 160 | 100 | 12 | 23.58 | 42.41 |

| 160×100×14 | 160 | 100 | 14 | 27.26 | 36.68 |

| 180×110×10 | 180 | 110 | 10 | 22.2 | 45.05 |

| 180×110×12 | 180 | 110 | 12 | 26.4 | 37.88 |

| 200×125×11 | 200 | 125 | 11 | 27.37 | 36.54 |

| 200×125×12 | 200 | 125 | 12 | 29.74 | 33.62 |

| 200×125×14 | 200 | 125 | 14 | 34.43 | 42854 |

| 200×125×16 | 200 | 125 | 16 | 39.07 | 42911 |

Specific Gravity Calculation

Today, many methods and algorithms have been developed for measuring and calculating not only density, but also specific gravity, which make it possible to determine this important parameter even without the help of tables. Knowing the specific gravity, which differs between different alloys of copper and pure metal, as well as the density value, you can effectively select materials for the production of parts with given parameters

It is very important to carry out such measures at the design stage of devices in which it is planned to use parts made of copper and its alloys

Specific gravity, the value of which (as well as density) can be seen in the table, is the ratio of the weight of a product made either from metal or from any other homogeneous material to its volume. This relationship is expressed by the formula γ = P/V, where the letter γ denotes specific gravity.

Specific gravity and density, which are inherently different characteristics of a metal, should not be confused, although they have the same meaning for copper.

Knowing the specific gravity of copper and using the formula for calculating this value γ = P/V, you can determine the mass of a copper billet having a different cross-section. To do this, it is necessary to multiply the specific gravity value for copper and the volume of the workpiece in question, which is not particularly difficult to determine by calculation.

Methods for calculating a metal corner, weight table, product features

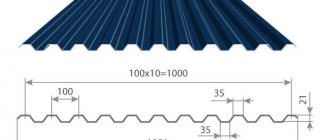

Angle steel is the most popular type of shaped steel. According to the production method, it is divided into hot-rolled and bent. Source materials: ordinary quality carbon steel St3 ps/sp (for ordinary use), high-quality, low-alloy steel 09G2S, 17G1S, 10HSND, 15 KHSND (for products used under high loads, in difficult temperature conditions, in contact with aggressive environments).

Characteristics of hot rolled metal angle

Equal-flanged hot-rolled steel angles are produced in accordance with GOST 8509-93 from a square, which is the original workpiece. The most widely used angular profile of normal accuracy is “B”; for critical structures, high-precision products “A” are used. The shelf dimensions, according to the standard, are from 20 to 250 mm.

The range of unequal corners is determined by GOST 8510-86. The smallest shelf sizes are 16 and 25 mm, the maximum are 125 and 200 mm. These products are used to create structures of complex shapes, such as arches.

Hot-rolled products are characterized by high strength, which allows them to be used in structures designed to operate under high load conditions. In the production of corner profiles, carbon steel of ordinary quality and high quality is widely used. Products made from low-alloy steels are used to create critical structures of housings, frames and other parts of agricultural machinery, locomotives, cars, large-sized construction machines and mechanisms. Products made from this profile can maintain performance characteristics over a wide temperature range - from -70° to +70°C, with serious daily and seasonal temperature changes.

Hot-rolled products are supplied in batches, the size of which usually does not exceed 70 tons. Each batch has a certificate of compliance with regulatory requirements.

Calculation of the quantity of steel equal angle angle

When determining the mass of a batch of rolled corner profiles, you need to know the mass of a linear meter, which you can determine from the table, and the total footage.

Weight table for equal flange hot-rolled steel angles of the most common sizes

Methods for calculating a metal corner, weight table, product features

The article describes methods for calculating a metal corner and its characteristics. A table of weights is provided.

Weight table for unequal angle

Below is a table that details the weight of one meter of steel angle of different sizes, and the number of angles in 1 ton. All calculations were made in accordance with GOST 8510-86 .

| Angle section size, mm. | Weight of 1 meter, kg. | Number of meters of angle in 1 ton, m. |

| 25x16x3 | 0,91 | 1098,90 |

| 30x20x3 | 1,12 | 892,86 |

| 30x20x4 | 1,46 | 684,93 |

| 32x20x3 | 1,17 | 854,70 |

| 32x20x4 | 1,52 | 657,89 |

| 40x25x3 | 1,48 | 657,68 |

| 40x25x4 | 1,94 | 515,46 |

| 40x25x5 | 2,37 | 421,94 |

| 40x30x4 | 2,26 | 442,48 |

| 40x30x5 | 2,46 | 406,50 |

| 45x28x3 | 1,68 | 595,24 |

| 45x28x4 | 2,20 | 454,55 |

| 50x32x3 | 1,90 | 526,32 |

| 50x32x4 | 2,40 | 416,67 |

| 56x36x4 | 2,81 | 355,87 |

| 56x36x5 | 3,46 | 289,02 |

| 63x40x4 | 3,17 | 315,46 |

| 63x40x5 | 3,91 | 255,75 |

| 63x40x6 | 4,63 | 215,98 |

| 63x40x8 | 6,03 | 165,84 |

| 65x50x5 | 4,36 | 229,36 |

| 65x50x6 | 5,18 | 193,05 |

| 65x50x7 | 5,98 | 167,22 |

| 65x50x8 | 6,77 | 147,71 |

| 70x45x5 | 4,39 | 227,79 |

| 75x50x5 | 4,79 | 208,77 |

| 75x50x6 | 5,69 | 175,75 |

| 75x50x7 | 6,57 | 152,21 |

| 75x50x8 | 7,43 | 134,59 |

| 80x50x5 | 4,49 | 222,72 |

| 80x50x6 | 5,92 | 168,92 |

| 80x60x6 | 6,39 | 156,49 |

| 80x60x7 | 7,39 | 135,32 |

| 80x60x8 | 8,37 | 119,47 |

| 90x56x5.5 | 6,17 | 162,07 |

| 90x56x6 | 6,70 | 149,25 |

| 90x56x8 | 8,77 | 114,03 |

| 100x63x6 | 7,53 | 132,80 |

| 100x63x7 | 8,70 | 114,94 |

| 100x63x8 | 9,87 | 101,32 |

| 100x63x10 | 12,14 | 82,37 |

| 100x65x7 | 8,81 | 113,51 |

| 100x65x8 | 9,99 | 100,10 |

| 100x65x10 | 12,30 | 81,30 |

| 110x70x6.5 | 8,98 | 111,35 |

| 110x70x8 | 10,93 | 91,49 |

| 125x80x7 | 11,04 | 90,58 |

| 125x80x8 | 12,58 | 79,49 |

| 125x80x10 | 15,47 | 64,64 |

| 125x80x12 | 18,34 | 54,53 |

| 140x90x8 | 14,13 | 70,77 |

| 140x90x10 | 17,46 | 57,27 |

| 160x100x9 | 17,96 | 55,68 |

| 160x100x10 | 19,85 | 50,38 |

| 160x100x12 | 23,58 | 42,41 |

| 160x100x14 | 27,26 | 36,68 |

| 180x110x10 | 22,20 | 45,05 |

| 180x110x12 | 26,40 | 37,88 |

| 200x125x11 | 27,37 | 36,54 |

| 200x125x12 | 29,74 | 33,62 |

| 200x125x14 | 34,43 | 29,04 |

| 200x125x16 | 39,07 | 25,60 |

Production Features

Angle bars are produced on automated production lines. The raw material for hot-rolled angles is steel ingots. The cube-shaped bloom is heated to the temperature of metal recrystallization and fed to rolling rolls. Under the influence of high pressure, soft metal is transformed into a product of the desired shape with specified parameters.

The advantages of this hot rolling technology include the following factors:

- production of rolled products without size restrictions;

- large thickness of processed workpieces;

- high speed of production of products.

Products made using this technology are distinguished by the accuracy of linear parameters and have high quality characteristics. Metal products have a smooth surface without visible or hidden defects and are characterized by increased bending strength. Steel that has undergone heat treatment has a uniform structure and has the necessary ductility. The area of use of hot-rolled angles depends on the type and size of the product.

Assortment of hot rolled angles

The high strength of these products ensures their use in creating structures that operate under severe loads. The range of equal flange hot-rolled angles is regulated by GOST 8509-93. The standard provides for two classes of rolling accuracy:

- A – increased;

- B – ordinary.

In the production of angle steel, carbon steel of ordinary quality and high-quality structural steel are used. For the manufacture of critical structures and elements of machines and mechanisms, angles made of low-alloy steels of type 09G2S, 10HSND are used. Such products can be used in a wide temperature range (-70...+450°C), therefore they are in demand in regions with harsh climates.

Table of dimensions and weight of the most common range of steel equal-flange angles according to GOST 8509-93

| Shelf width, mm | Shelf thickness, mm | Weight of 1 meter, kg | Shelf width, mm | Shelf thickness, mm | Weight of 1 meter, kg |

| 20 | 3 | 0,89 | 63 | 4 | 3,9 |

| 4 | 1,15 | 5 | 4,81 | ||

| 25 | 3 | 1,12 | 6 | 5,72 | |

| 4 | 1,46 | 70 | 5 | 5,38 | |

| 30 | 3 | 1,36 | 6 | 6,39 | |

| 4 | 1,78 | 7 | 7,39 | ||

| 35 | 3 | 1,6 | 75 | 5 | 5,8 |

| 4 | 2,1 | 6 | 6,89 | ||

| 5 | 2,58 | 7 | 7,96 | ||

| 40 | 3 | 1,85 | 8 | 9,02 | |

| 4 | 2,42 | 80 | 6 | 7,36 | |

| 5 | 2,98 | 7 | 8,51 | ||

| 45 | 3 | 2,08 | 8 | 9,65 | |

| 4 | 2,73 | 90 | 7 | 9,64 | |

| 5 | 3,37 | 8 | 10,93 | ||

| 50 | 3 | 2,32 | 9 | 12,2 | |

| 4 | 3,05 | 100 | 7 | 10,79 | |

| 5 | 3,77 | 8 | 12,25 | ||

| 6 | 4,47 | 10 | 15,1 |

Metal weight reference tables – Rolled unequal angles

Metal weight reference tables – Rolled unequal angles

Angles are produced by hot-rolling metal or bending cold-rolled and hot-rolled sheets of metal. In hot rolling, the workpiece is formed to the required dimensions and passed under pressure through a rolling mill. Bent corners are produced on profile bending machines.

Steel angles are used for mounting frames, strengthening concrete structures, and creating platforms for various purposes. In this case, cold-rolled angles made of ordinary steel are used for finishing, and hot-rolled angles are used for load-bearing structures.

Along the length of the edges of the shelves:

equal-flange; unequal.

According to manufacturing accuracy:

high accuracy - A; increased accuracy - B; normal accuracy - B.

By manufacturing method:

hot rolled; cold rolled; bent from sheet metal.

According to the length characteristics:

measured length; length multiple of measured; of unmeasured length.

Theoretical: mass of 1 linear meter of unequal angle and number of meters per ton

| 25x16x3 | 0,91 | 1098,90 |

| 30x20x3 | 1,12 | 892,85 |

| 30x20x4 | 1,46 | 684,92 |

| 32x20x3 | 1,17 | 854,70 |

| 32x20x4 | 1,52 | 657,89 |

| 40x25x3 | 1,48 | 675,67 |

| 40x25x4 | 1,94 | 515,46 |

| 40x25x5 | 2,37 | 421,94 |

| 40x30x4 | 2,26 | 442,48 |

| 40x30x5 | 2,46 | 406,5 |

| 45x28x3 | 1,68 | 595,23 |

| 45x28x4 | 2,2 | 454,54 |

| 50x32x3 | 1,9 | 526,32 |

| 50x32x4 | 2,4 | 416,67 |

| 56x36x4 | 2,81 | 355,87 |

| 56x36x5 | 3,46 | 289,01 |

| 63x40x4 | 3,17 | 315,45 |

| 63x40x5 | 3,91 | 255,75 |

| 63x40x6 | 4,63 | 215,98 |

| 63x40x8 | 6,03 | 165,84 |

| 65x50x5 | 4,36 | 229,36 |

| 65x50x6 | 5,18 | 193,05 |

| 65x50x7 | 5,98 | 167,22 |

| 65x50x8 | 6,77 | 147,71 |

| 70x45x5 | 4,39 | 227,78 |

| 75x60x5 | 4,79 | 208,77 |

| 75x60x6 | 5,69 | 175,75 |

| 75x60x7 | 6,57 | 152,21 |

| 75x60x8 | 7,43 | 134,59 |

| 80x50x5 | 4,49 | 222,72 |

| 80x50x6 | 5,92 | 168,92 |

| 80x60x6 | 6,39 | 156,49 |

| 80x60x7 | 7,39 | 135,32 |

| 80x60x8 | 8,37 | 119,47 |

| 90x56x5.5 | 6,17 | 162,07 |

| 90x56x6 | 6,7 | 149,25 |

| 90x56x8 | 8,77 | 114,03 |

| 100x63x10 | 12,14 | 82,37 |

| 100x63x6 | 7,53 | 132,8 |

| 100x63x7 | 8,7 | 114,94 |

| 100x63x8 | 9,87 | 101,32 |

| 100x65x10 | 12,3 | 81,3 |

| 100x65x7 | 8,81 | 113,51 |

| 100x65x8 | 9,99 | 100,1 |

| 110x70x6.5 | 8,98 | 111,36 |

| 110x70x8 | 10,93 | 91,49 |

| 125x80x10 | 15,47 | 64,64 |

| 125x80x12 | 18,34 | 54,53 |

| 125x80x7 | 11,04 | 90,58 |

| 125x80x8 | 12,53 | 79,81 |

| 140x90x10 | 17,46 | 57,27 |

| 140x90x8 | 14,13 | 70,77 |

| 160x100x10 | 19,85 | 50,38 |

| 160x100x12 | 23,58 | 42,41 |

| 160x100x14 | 27,26 | 36,68 |

| 160x100x9 | 17,96 | 55,68 |

| 180x110x10 | 22,2 | 45,05 |

| 180x110x12 | 26,4 | 37,88 |

| 200x125x11 | 27,37 | 36,54 |

| 200x125x12 | 29,74 | 33,62 |

| 200x125x14 | 34,43 | 29,04 |

| 200x125x16 | 39,07 | 25,6 |

Section articles - equipment for stables Section instructions - equipment for stables Section news - equipment for stables

Section articles - artistic forging Section instructions - artistic forging Section news - artistic forging Video - artistic forging, equipment for stables, metal structures.

Return to list

Weight of steel hot-rolled equal-flange angle GOST 8509-93

| Angle dimensions | Corner flange size A, mm | Metal thickness S, mm | Weight m/p., kg | Number of meters in tons |

| 20×3 | 20 | 3 | 0.89 | 1123.6 |

| 20×4 | 20 | 4 | 1.15 | 869.57 |

| 25×3 | 25 | 3 | 1.12 | 892.86 |

| 25×4 | 25 | 4 | 1.46 | 684.93 |

| 25×5 | 25 | 5 | 1.78 | 561.8 |

| 28×3 | 28 | 3 | 1.27 | 787.4 |

| 30×3 | 30 | 3 | 1.36 | 735.29 |

| 30×4 | 30 | 4 | 1.78 | 561.8 |

| 30×5 | 30 | 5 | 2.18 | 458.72 |

| 32×3 | 32 | 3 | 1.46 | 684.93 |

| 32×4 | 32 | 4 | 1.91 | 523.56 |

| 35×3 | 35 | 3 | 1.6 | 625 |

| 35×4 | 35 | 4 | 2.1 | 476.19 |

| 35×5 | 35 | 5 | 2.58 | 387.6 |

| 40×3 | 40 | 3 | 1.85 | 540.54 |

| 40×4 | 40 | 4 | 2.42 | 413.22 |

| 40×5 | 40 | 5 | 2.98 | 335.57 |

| 40×6 | 40 | 6 | 3.52 | 284.09 |

| 45×3 | 45 | 3 | 2.08 | 480.77 |

| 45×4 | 45 | 4 | 2.73 | 366.3 |

| 45×5 | 45 | 5 | 3.37 | 296.74 |

| 45×6 | 45 | 6 | 3.99 | 250.63 |

| 50×3 | 50 | 3 | 2.32 | 431.03 |

| 50×4 | 50 | 4 | 3.05 | 327.87 |

| 50×5 | 50 | 5 | 3.77 | 265.25 |

| 50×6 | 50 | 6 | 4.47 | 223.71 |

| 50×7 | 50 | 7 | 5.15 | 194.17 |

| 50×8 | 50 | 8 | 5.82 | 171.82 |

| 56×4 | 56 | 4 | 3.44 | 290.7 |

| 56×5 | 56 | 5 | 4.25 | 235.29 |

| 60×4 | 60 | 4 | 3.71 | 269.54 |

| 60×5 | 60 | 5 | 4.58 | 218.34 |

| 60×6 | 60 | 6 | 5.43 | 184.16 |

| 60×8 | 60 | 8 | 7.1 | 140.85 |

| 60×0 | 60 | 10 | 8.7 | 114.94 |

| 63×4 | 63 | 4 | 3.9 | 256.41 |

| 63×5 | 63 | 5 | 4.81 | 207.9 |

| 63×6 | 63 | 6 | 5.72 | 174.83 |

| 65×6 | 65 | 6 | 5.91 | 169.2 |

| 65×8 | 65 | 8 | 7.73 | 129.37 |

| 70×4 | 70 | 4.5 | 4.87 | 205.34 |

| 70×5 | 70 | 5 | 5.38 | 185.87 |

| 70×6 | 70 | 6 | 6.39 | 156.49 |

| 70×7 | 70 | 7 | 7.39 | 135.32 |

| 70×8 | 70 | 8 | 8.37 | 119.47 |

| 70×0 | 70 | 10 | 10.29 | 97.18 |

| 75×5 | 75 | 5 | 5.8 | 172.41 |

| 75×6 | 75 | 6 | 6.89 | 145.14 |

| 75×7 | 75 | 7 | 7.96 | 125.63 |

| 75×8 | 75 | 8 | 9.02 | 110.86 |

| 75×9 | 75 | 9 | 10.07 | 99.3 |

| 80×5 | 80 | 5.5 | 6.78 | 147.49 |

| 80×6 | 80 | 6 | 7.36 | 135.87 |

| 80×7 | 80 | 7 | 8.51 | 117.51 |

| 80×8 | 80 | 8 | 9.65 | 103.63 |

| 80×10 | 80 | 10 | 11.88 | 84.18 |

| 80×12 | 80 | 12 | 14.05 | 71.17 |

| 90×6 | 90 | 6 | 8.33 | 120.05 |

| 90×7 | 90 | 7 | 9.64 | 103.73 |

| 90×8 | 90 | 8 | 10.93 | 91.49 |

| 90×9 | 90 | 9 | 12.2 | 81.97 |

| 90×10 | 90 | 10 | 13.48 | 74.18 |

| 90×12 | 90 | 12 | 15.96 | 62.66 |

| 100×6.5 | 100 | 6.5 | 10.06 | 99.4 |

| 100×7 | 100 | 7 | 10.79 | 92.68 |

| 100×8 | 100 | 8 | 12.25 | 81.63 |

| 100×10 | 100 | 10 | 15.1 | 66.23 |

| 100×12 | 100 | 12 | 17.9 | 55.87 |

| 100×14 | 100 | 14 | 20.63 | 48.47 |

| 100×15 | 100 | 15 | 21.97 | 45.52 |

| 100×16 | 100 | 16 | 23.3 | 42.92 |

| 110×7 | 110 | 7 | 11.89 | 84.1 |

| 110×8 | 110 | 8 | 13.5 | 74.07 |

| 120×8 | 120 | 8 | 14.76 | 67.75 |

| 120×10 | 120 | 10 | 18.24 | 54.82 |

| 120×12 | 120 | 12 | 21.67 | 46.15 |

| 120×15 | 120 | 15 | 26.68 | 37.48 |

| 125×8 | 125 | 8 | 15.46 | 64.68 |

| 125×9 | 125 | 9 | 17.3 | 57.8 |

| 125×10 | 125 | 10 | 19.1 | 52.36 |

| 125×12 | 125 | 12 | 22.68 | 44.09 |

| 125×14 | 125 | 14 | 26.2 | 38.17 |

| 125×16 | 125 | 16 | 29.65 | 33.73 |

| 140×9 | 140 | 9 | 19.41 | 51.52 |

| 140×10 | 140 | 10 | 21.45 | 46.62 |

| 140×12 | 140 | 12 | 25.5 | 39.22 |

| 150×10 | 150 | 10 | 23.02 | 43.44 |

| 150×12 | 150 | 12 | 27.39 | 36.51 |

| 150×15 | 150 | 15 | 33.82 | 29.57 |

| 150×18 | 150 | 18 | 40.11 | 24.93 |

| 160×10 | 160 | 10 | 24.67 | 40.54 |

| 160×11 | 160 | 11 | 27.02 | 37.01 |

| 160×12 | 160 | 12 | 28.35 | 35.27 |

| 160×14 | 160 | 14 | 33.97 | 29.44 |

| 160×16 | 160 | 16 | 38.52 | 25.96 |

| 160×18 | 160 | 18 | 43.01 | 23.25 |

| 160×20 | 160 | 20 | 47.44 | 42968 |

| 180×11 | 180 | 11 | 30.47 | 32.82 |

| 180×12 | 180 | 12 | 33.12 | 30.19 |

| 180×15 | 180 | 15 | 40.96 | 24.41 |

| 180×18 | 180 | 18 | 48.66 | 20.55 |

| 180×20 | 180 | 20 | 53.72 | 18.62 |

| 200×12 | 200 | 12 | 36.97 | 42882 |

| 200×13 | 200 | 13 | 39.92 | 42880 |

| 200×14 | 200 | 14 | 42.8 | 23.36 |

| 200×16 | 200 | 16 | 48.65 | 20.55 |

| 200×18 | 200 | 18 | 54.4 | 18.38 |

| 200×20 | 200 | 20 | 60.08 | 16.64 |

| 200×24 | 200 | 24 | 71.26 | 42808 |

| 200×25 | 200 | 25 | 74.02 | 13.51 |

| 200×30 | 200 | 30 | 87.56 | 15646 |

| 220×14 | 220 | 14 | 47.4 | 42756 |

| 220×16 | 220 | 16 | 53.83 | 18.58 |

| 250×16 | 250 | 16 | 61.55 | 16.25 |

| 250×18 | 250 | 18 | 68.86 | 14.52 |

| 250×20 | 250 | 20 | 76.11 | 13.14 |

| 250×22 | 250 | 22 | 83.31 | 12 |

| 250×25 | 250 | 25 | 93.97 | 23651 |

| 250×28 | 250 | 28 | 104.5 | 21064 |

| 250×30 | 250 | 30 | 111.44 | 35643 |

| 250×35 | 250 | 35 | 128.51 | 28672 |