Portable devices are important in industry and today there are many manufacturers and types of devices, so it is worth being able to understand the principles of their operation, applications and features of a particular type of equipment.

Where are metal and alloy analyzers used?

X-ray fluorescence and laser spectrometers are used in laboratories, in production and at metal collection points (at the stage of determining the composition of the alloy). In addition, analysis equipment is widely used:

- when working with secondary raw materials, scrap and various alloys (tool, titanium, ferrite, low-alloy, aluminum and others);

- to analyze non-ferrous, precious and ferrous metals and identify their exact value;

- when controlling the quality of alloy structures at factories;

- in other areas.

The mobile spectrometer can be used to inspect, among other things, ingots, billets, small parts and metal dust and carry out sorting. Moreover, prices for portable metal analyzers depend on a number of factors. These are the original manufacturers (who sell their products at different prices), the type of device, and the measurement accuracy of the equipment.

What types of devices are there?

The autonomous device works depending on what type it is (X-ray or laser).

Laser. The operating principle of the device is optical emission. Laser analyzers of chemical composition operate using quantum laser radiation. They allow you to identify many chemical elements at once, determining their percentage. It is distinguished by high accuracy and the ability to detect substances even with the smallest content (from 0.0005 percent and below). When working with a laser, the object becomes hot and emits light. Laser analysis requires a metal sample.

X-ray. Although such devices do not have such high accuracy as lasers, they are also excellent for working with crowbar. Portable X-ray fluorescent chemical composition analyzers detect all substances at once and accurately identify the alloy. The object is not damaged during analysis.

There are portable devices of various models:

- Olympus Vanta;

- Olympus Delta;

- Vulcan;

- Professional Spectrum;

- Bruker Turbo, Sorter, Laser and others.

Among the mobile spectrometers the following can be distinguished:

- Q4 MOBILE;

- PMI-MASTER UVR;

- Spectro SPECTROPORT;

- Belec Compact Port;

- E3 EsaPort, and others.

The difference between hand-held spectrometers lies in the operating methods. Some use X-ray fluorescence to determine chemical elements, while others use laser. Each specific model has its own characteristics that will help you determine what kind of work it will be suitable for and how much the price will be.

Advantages of devices

The mobile analyzer of metals and alloys has undeniable advantages:

- compliance with modern equipment standards;

- high accuracy of the equipment (on average 0.1%), thanks to which it is possible to accurately identify an expensive alloy;

- work with any complex structures

- a variety of types of instruments that are suitable for solving different problems (gas analyzers, spectrophotometers, steeloscopes, etc.);

- small weight of the device (from 1.5 kg and above);

- convenient interface, autonomy, LCD display;

- ability to save research results.

Buy a metal analyzer in Moscow

You can order equipment for research on our website by filling out an application. There is also the possibility of automatically selecting a metal analyzer for your tasks. The price of an individual device is influenced not only by the company by which it was manufactured, but also by its characteristics. For example, the accuracy of determining the alloy, the type of device and the range of elements being determined. The price set by NKPROM is fully consistent with the market average.

Source: nkprom.ru

How to check the chemical composition of a metal

Control of the chemical composition of steels and alloys makes it possible to predict the properties of finished products and is an important component of a comprehensive check of metal quality.

Instruments for analyzing the chemical composition of metals

Currently, the following devices are most widely used:

- Steeloscopes

- Portable X-ray fluorescence spectrometers

- Portable laser spectrometers

- Optical emission spectrometers

Steeloscopes

Steeloscopes are the simplest spectral instruments. The essence of the method is the evaporation of metal under the action of a discharge and the operator observing the resulting glow. Based on the brightness of the spectral lines, one can judge the concentration of various elements.

Steeloscopes are inexpensive, but working with them is quite complicated and requires special skills, training for which takes from several months to several years. In addition, steeloscopes are evaluative instruments; the results of the analysis depend on the subjective assessment of the operator.

This feature does not allow the use of these devices in many technological processes when accurate data on the elemental composition of the metal is required.

Portable X-ray fluorescence spectrometers

Portable X-ray fluorescence spectrometers are widely used due to their light weight and ease of handling. The devices are often called “pistols” because of their external similarity - the device has a handle, a trigger and a “barrel” that contains an X-ray tube and detector.

When the trigger is pressed, the tube begins to generate X-ray radiation, which causes response characteristic radiation from the atoms of the sample, which is recorded by the detector. Small size and weight allow such devices to be used outside the laboratory.

No sample preparation is required - you just need to clean the metal surface from dirt, rust, paint, and scale.

Portable X-ray fluorescence spectrometers are unpretentious, do not require periodic recalibration, and can be trained to operate them in a few hours; however, a significant limitation is the inability to analyze carbon, as well as the high detection limits of sulfur and phosphorus.

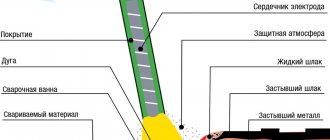

Optical emission spectrometers

Optical emission spectrometers make it possible to analyze all the main alloying elements in steels and alloys, including carbon, sulfur, phosphorus, etc. Based on the operating principle, these devices are similar to steeloscopes, but the spectral lines are analyzed by special detectors.

Scouring must occur in an inert environment, so optical emission spectrometers require argon to operate. Spectrometers of this type are usually quite massive and are tabletop or floor-standing devices, while mobile (mobile) models are placed on special carts.

Despite these disadvantages, optical emission spectrometers are reliable, easy to operate, relatively low cost and require only simple sample preparation, which is why today this method is the main one for analyzing the chemical composition of metals in most industrial, expert and research laboratories.

Portable laser spectrometers

In recent years, a large number of portable laser devices have appeared on the market. In shape and size they are similar to portable X-ray fluorescence spectrometers, and in essence they are similar to optical emission devices.

The analysis occurs by measuring the intensity of spectral lines in the optical range, but their appearance is caused by the action of a laser. Portable laser spectrometers are advantageous to use when analyzing large flows of light non-ferrous alloys (aluminum, magnesium, titanium), because

their analysis is faster and more accurate than with portable analyzers.

However, laser analyzers are much more demanding than X-ray fluorescence spectrometers - they are temperature dependent, require regular recalibration and periodic maintenance, and carbon, a key element in the analysis of steels, is analyzed with too large an error.

Analyzer of metals and alloys - main types and principles of operation

The most important and pressing task at all points of receipt of raw materials (pawnshop, metal depot, metal reception point, incoming control shop) is the process of separation (identification) of raw materials by grade and chemical composition. Based on appearance and primary characteristics, it is currently impossible to correctly identify the copper and titanium from alloys based on them. Some even more difficult to determine elements, such as nickel in stainless steel, are simply not possible to determine without special instruments

Therefore, analyzers and spectrometers are becoming increasingly popular.

As of 2022, the most advanced methods of chemical control of metal and alloys are the optical emission method

(optical emission, atomic abstraction, energy dispersive) and X-ray fluorescence (X-ray method). Also in this article we will talk about portable laser analyzers and reveal the principle of operation and talk about all the pros and cons of this method.

Operating principle of X-ray fluorescence analyzers and spectrometers

Spectrometers and analyzers operate on the basis of a miniature X-ray tube and detector. Using the fluorescence method, atoms of different chemical elements are exposed, after which the photon emission is read. The most advanced portable analyzers use voltages up to 50,000 V.

Today, more and more enterprises in Russia and the CIS countries are replacing their old stationary instruments, which are used in specially equipped laboratories (including premises, personnel certification, and so on) with portable analyzers, spectrometers, which do not require special certification and preparation of the premises, replacing the outdated ones devices.

The main distinguishing feature inherent in all modern analyzers is portability, which allows you to use the analyzer directly where it is needed (street, workshop, mine, warehouse, field, laboratory, and so on). The second distinctive advantage can be considered the speed of analysis. For a routine task of identifying the grade of metal and alloy, 2-5 seconds will be enough

, if you need to determine the gold content in a rock or find thousandths of grams of platinum, rhodium and palladium in ground automobile catalysts, then for a more accurate measurement the analysis time is increased to the required value. In this case, we will get an accuracy of up to 1-2 grams per tone for the elements we need.

The analysis occurs simultaneously from 45 to 79 positions to determine the chemical composition of metals and alloys, depending on the type of device. Each individual element is analyzed at a different voltage to more accurately determine the content, after which we receive the result on the device screen.

Operating principle and description of a portable X-ray spectrometer

What does the analyzer consist of?

The most important components of the analyzer are a miniature X-ray tube and a detector

, also the screen, motherboard and recording device. Batteries, case with external radiator for heat removal. At the same time, the entire structure inside is filled with special plastic, it is a monolithic base, which completely eliminates loosening, loose wires, accumulation of dust and moisture, and protects against falls and impacts. The device is completely sealed and has no openings for dust and moisture to enter, heat is removed to an external radiator and the spout of the device, so the analyzer may become warm after a long time of operation - this is completely normal, do not be alarmed, there are special sensors installed there to prevent overheating.

The technology is developing and in the future, compact portable metal analyzers will completely replace large stationary spectrometers.

Possibilities and advantages of the X-ray fluorescence method:

- Complete absence of dangerous radioisotopes.

- Regardless of the atomic mass of the elements, the analyzer can simultaneously analyze from 24-67 elements, depending on the model and manufacturer. Here I would like to say that the devices of the Vanta line are the undisputed leader both in accuracy and in the number of elements determined.

- the ability to display results in percentage terms, compare all brands with each other and determine compliance with GOST and brand.

- the ability to work anywhere (workshop, street, field, mine, in the mountains, forests, landfills, etc.) and receive research results in a few seconds. With subsequent saving and the ability to transfer data to a computer and printer. Modern software also allows you to generate convenient reports, which can later be attached to products.

- The analysis area is 5 times larger than that of laser and optical emission methods and is up to 1.5 cm², which makes it possible to search for any minerals

- — the most important thing, of course, is the ability to analyze fractions up to 50 microns, slag, dust, shavings, waste, sand and determine the content of rare elements. Another key feature is minimal sample preparation before analysis. Just go through it with a sander and you can begin the analysis.

- - no tuning is required using special tuning samples, no need to know the basis in advance, modern analyzers are equipped with all sorts of functions for auto-detection of the basis, which of course significantly saves time, effort and money

- - a completely universal device. The size does not matter, as well as the condition: liquid, oil, sand, dry mixture, shavings, metal, plastic and so on. The ability to customize the device for almost any task.

These devices have been successfully used for more than 15 years at the largest enterprises and in a wide variety of industries. At the beginning, this method was considered not accurate enough, and it was widely used only at metal collection points, pawn shops and other places where operational analysis was required. Much time has passed since then, and technology, coupled with the experience of technical specialists, has made it possible to increase accuracy to thousandths and ten thousandths for some elements, which allowed these devices to take a leading position in sales.

We have no doubt that soon portable spectrometers and analyzers will completely replace stationary installations and instruments.

Here is an example of the work of a portable analyzer in a metal warehouse in Russia (the work was carried out at the end of November, using the most budget portable analyzer Delta Element)

Spectrometer for sorting metal and alloys

Portable Olympus Delta Element spectrometer for incoming inspection of metals and alloys.

Source: pvp-snk.ru

How to find out the composition of a metal - Metalist's Handbook

A labor-intensive problem at many scrap metal collection points is the process of separating incoming raw materials by grade and type of metal. Sometimes it is difficult to distinguish copper from alloys with a high copper content, and it is absolutely impossible to determine the nickel content in stainless steel. Therefore, when the incoming metal waste is heterogeneous, metal composition analyzers are used.

Two types of such devices have received practical application - those based on the use of the phenomenon of optical emission (laser) , and those using x-ray radiation .

Optical analyzers

Analyzers of metals and alloys of this type make it possible to determine with a high degree of accuracy the presence and content of light chemical elements - sulfur, phosphorus, carbon, i.e., those elements that are necessarily present in the chemical composition of any steel.

Optical metal analyzer - spark research method

Their action is based on the following: the fragment under study is exposed to a spark discharge in air. The resulting spark contains all of the above elements in ionized form, the emission of which is captured by the sensitive element of the device and displayed on the display.

The optical emission method makes it possible to quickly identify scrap metal without causing any noticeable destruction. Sometimes, in order to reduce the risk of explosion or fire, an inert gas, mainly argon, is used instead of air. Changing the research mode is carried out by simply reinstalling the nozzle.

— optical metal analyzer M5000 — description, characteristics:

The chemical composition of the metal is fixed in three ways:

- Branded, when the actual composition is compared with that indicated in the reference table. The method is relatively cumbersome because it requires human intervention;

- By imprint, when the emission spectra of the metal under study and the reference ones are compared;

- According to the “yes/no” principle, when it is necessary to answer the question of whether the sample under study is the metal or alloy that needs to be determined.

The scope of application of analyzers of the type considered is the study of low-carbon steels of the ferritic class, as well as stainless steels containing titanium, nickel, cobalt - elements whose emission spectrum is quite characteristic. Such devices are not widely used due to their increased sensitivity to the external conditions of the site where they are installed.

X-ray metal analyzers

Analyzers operating using X-ray radiation use the phenomenon of fluorescence, in which atoms of chemical elements emit photons of a strictly defined energy. A tube operating at a voltage of 45,000 V is used as a source of X-ray radiation.

In such conditions, it is necessary to allocate a special room for the analyzer to operate and equip it with a reliable lead protective screen.

Stationary devices operate in a similar way, which are used for the chemical analysis of large fragments of metal, but such analyzers are an anachronism; they can still be used in old laboratories left over from Soviet times, but are now becoming less and less common.

Now wearable, compact devices have become widespread - portable metal analyzers , intended for use directly at scrap metal collection points. They do not use radioisotopes and are therefore considered safer.

X-Ray Handheld Metal Analyzer - Can do chip analysis easily

With the X-ray method of determining the chemical composition of a metal, it is analyzed at 45 positions, which are determined by the different energy levels of the emitted electrons. Accordingly, a similar number of elements is determined, which is the main advantage of the method.

In addition, such analyzers are compact, easy to use, and constantly updated software allows you to improve the processing of the results obtained.

Description of the operation of a portable X-ray analyzer

X-ray analyzers of chemical composition consist of a fluorescent X-ray tube, a detector, a recording device and a control unit. The detectors are adapted for solid-state operation, and therefore are very convenient for use at large collection points for ferrous and non-ferrous scrap metals.

Portable Metal X-Ray Spectrometer

Technological capabilities of X-ray analyzers:

- The determination method is multicomponent (the percentage content of several chemical elements is simultaneously determined);

- Radioisotope sources – absent;

- The number of simultaneously determined parameters is up to 33 (regardless of the atomic mass of the element);

- The type of initial sample for analysis is any, including slag and dust fractions up to 50 microns (can be used to determine rare and rare earth elements in industrial waste, shavings, etc.);

- Visualization of research results - color display and registration in the base file of a special computer (it is also possible to connect to a regular computer via a USB connector).

Such characteristics allow the analyzers to be used in determining the type of metal, identifying the grade of non-ferrous alloy, technological control in the process of metal smelting, etc.

X-ray analyzers work quite quickly because they do not require preliminary setup of the device. Calibration will be performed only when solving special research problems.

Laser analyzers of the chemical composition of metals and alloys

in English - test of the Sciaps Laser-Z300 laser analyzer

These devices appeared relatively recently. They use the principle of deep scanning of a sample using quantum laser radiation. Since the laser radiation spectrum can be tuned much more finely than the X-ray spectrum, analyzers of this type have a number of operational advantages:

- The number of determined chemical elements increases significantly (up to 90, and therefore such installations are recommended to be used to determine the chemical composition of complex multicomponent alloys);

- The accuracy of recording a particular chemical element increases, which makes it possible to identify an alloy even with a percentage of the element less than 0.0005%;

- The device is suitable for the quantitative determination of the radioactive component, which is especially important for the radiation safety of equipment and workers. The possibility of receiving scrap that is “dirty” in radioactive terms is cut off;

- Laser-type devices consume significantly less energy, which allows them to be used for a long time without recharging the batteries;

- Since the laser scanning speed is very high, the process of determining the chemical composition of even a multicomponent alloy takes a fraction of a second.

Displaying laser analyzer results on the screen of an Android smartphone

The result of the laser analyzer can be displayed on the monitor screen, or can be recorded by the built-in video camera or displayed through a special application on the smartphone screen.

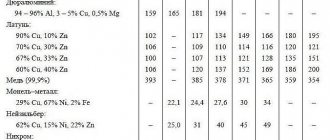

Average market prices for analyzers of metals and alloys

Spark optical emission spectrometers are perhaps the most expensive; the price of such analyzers can reach up to $50,000.

Portable X-ray metal analyzers cost a little less, but the price is also quite high - about $20,000 - $30,000.

Laser spectrometers are the latest generation analyzers, gaining more and more popularity; over time, the price will fall, now the cost is approximately $30,000-$40,000.

On the Internet, even sellers on their websites do not always have the same price. Those. There is a product, there is a description of the analyzer, a large selection of devices is presented, but in the price field it says “Make a request” or “Find out the price”. Where you leave your contact information and wait for a response with a price.

This can be explained this way - a metal analyzer is an expensive device, not every metal receiving facility can afford it. In order not to lose a client and bring the sale to completion, managers prefer to conduct a dialogue directly with the client, varying the price and other bonuses when purchasing an analyzer from them.

In other words, this is a marketing ploy that brings the seller and buyer closer together, which makes selling a metal analyzer easier.

— the most budget metal analyzer Delta Element

How to determine steel grade

There are simply a huge number of different steel options, each grade is characterized by its own specific features. If the manufacturer has not carried out markings, then you can find out the characteristics of the metal only by independently conducting various tests. We'll talk about this in more detail later.

How to determine steel grade

Methods for determining steel grade

A fairly common question is how to determine the grade of steel. There are several common methods:

- The first involves removing chips from the surface, for which a chisel can be used. At high carbon concentrations it will be short and brittle. A decrease in the indicator causes an increase in plasticity. However, it is not possible to accurately determine the brand using this method.

- The second method involves hardening the product, after which it is necessary to make cuts. If the material is simply sawed before and after hardening, then it contains a small amount of carbon. Due to the increase in carbon concentration after treatment, the surface becomes too hard.

- Determining the steel grade by spark is based on a visual inspection of the sparks that are formed when processing the surface with a grinding wheel. With an increase in the size of the sparks and their number, the hardness index increases, which depends directly on the carbon concentration. Such a test does not give an accurate result, since the main characteristics of the flying chips depend on the force of pressing and some other points. You can find tables that decipher the qualities of a material based on chips.

Metal analyzers

Portable analyzers perform express analysis of the chemical composition of metals and their alloys. The operating principle is to evaluate the spectrum of X-ray waves reflected from a metal surface. The source of the latter is a tube with a radioactive isotope built into the device.

Shockproof portable X-ray analyzer of chemical composition from the legendary manufacturer Olympus (the founders of X-ray fluorescence portable devices Innov-X Olympus) Vanta spectrometer. The first shockproof metal analyzer in the World!

The Delta Professional device is an analyzer with an ideal combination of price and quality. It is easily able to study light elements such as magnesium, aluminum, silicon, phosphorus and sulfur.

X-ray fluorescence metal analyzer - portable device Delta Premium is the best analyzer from the entire Delta range. It allows you to accurately determine light elements down to one thousandth of a percent, such as magnesium, silicon, aluminum, sulfur and phosphorus.

The DELTA Element is a decent and durable design with a unique rubber overmold and ergonomic handle to protect the analyzer. To avoid downtime, hot-swappable batteries allow quick replacement while the analyzer is in use. The Delta Element has integrated wide area heatsinks for use in extreme temperatures.

First of all, the X-5000 mobile mini-laboratory is ideal for conducting various types of geological exploration, when sorting many soil or rock samples. An excellent tool for seekers of gold nuggets or other rare metals. Also in the mini-lab you can analyze a liquid sample with a high level of acidity. The device is one of the indispensable tools of a professional geochemist, providing the highest accuracy of indicators.

With this device you can easily evaluate gold products; the gold standard is determined in almost a couple of seconds. A pretty good function for detecting toxins or impurities in the subject of research. Another very convenient ability of the analyzer is to conduct a percentage analysis of all kinds of metals that may be present in a gold alloy. Accordingly, and vice versa, you can find out the golden percentage in a pile of metal. A well-thought-out function for analyzing precious items for the amount of palladium or platinum they contain.

A device for determining the chemical composition of a metal is used in modern industry, as well as in production everywhere. It is one of the laser models that are in great demand - the Laser-Z 500 portable spectrometer, a metal analyzer with carbon and 91 other elements.

Portable X-ray fluorescence analyzer of automotive, industrial and radio catalysts, as well as metals and alloys. Equipped with a powerful 40 kV X-ray tube and a modern SiPin detector, which allows analysis with incredible accuracy in a very short period of time (only 3-5 seconds), for more accurate measurements, the number of seconds can be changed at any time.

The Omega Xpress Olympus metal and alloy analyzer is designed specifically for express X-ray analysis. With Omega Xpress Olympus you can easily determine the chemical composition of any metal + the built-in alloy library will tell you the brand of ferrous or non-ferrous metal being determined! The entire analysis takes from 3 to 10 seconds!

Optical emission spectrometer PMI-MASTER UVR is a mobile optical emission spectrometer for metal diagnostics. It can also be called modern and unique, which makes it possible to carry out detailed diagnostics and identify the grade of various steels and alloys, and also allows you to analyze carbon, sulfur, and phosphorus.

On-line chemical testing of pipes of different diameters, rods and rods. Fully automated device for chemical analysis and confirmation of metal grade.

Analysis of metals in harsh workshop conditions. It carries with it a huge number of dimensions without interruption.

The ARC-MET 8000 is ideal for those who expect reliability and detail from devices for incoming inspection and similarity of metals by chemical composition.

The ICP-5000 Inductively Coupled Plasma Spectrometer (ICP-OES) is used in environmental, pharmaceutical, food and many other industries and sectors. The main features of the ICP-5000 atomic emission spectrometer are low cost and unsurpassed accuracy. The ICP-5000 analyzer allows you to analyze up to 72 elements within a few seconds, simultaneously with more than 50,000 spectra in its spectral library.

The Argon-5SF analyzer is an emission analyzer (spectrometer) for measuring the content of elements in samples of metals and alloys. (also determines carbon (c) sulfur (S) phosphorus (P)). The scope of application of the analyzer is practically unlimited - it can be metallurgy, mechanical engineering, metal receiving, incoming inspection and many others. Today, more than 170 analyzers are successfully operating in Russia, which indicates its reliability and quality (the warranty on the analyzer is 2 years)

Portable analyzers are used:

- when sorting scrap metal;

- quality control of manufactured metallurgical products;

- assessing the purity of silver and gold jewelry;

- geological surveys.

The catalog contains mobile devices for laboratory and field research in a wide range of prices:

- Olympus (Vanta series). Portable, shockproof chemical analyzers that can withstand drops of up to 1.2 meters. The housing protects the mechanism from dust and moisture (IP65);

- Delta (Element, Professional and Premium series). These metal analyzers are powered by lithium-ion batteries. Convenient for analyzing metals in open warehouses, construction sites and in the field;

- Olympus X-5000. Mini laboratory in a plastic case, weighs 11.5 kg. Ideal for geological exploration: sorting samples, analyzing nuggets, determining the presence of metals in liquid solutions;

- Laser-Z 500. Spectral analyzer of metals for industrial enterprises. In seconds, determines the full chemical formula of any alloy, including carbon content and another 90 elements of the periodic table.

All analyzers come with a warranty. Delivery of spectrometers to regions of the Russian Federation is possible.

Source: techkontrol.ru

Metal composition analyzer. Range of capabilities of modern models

Non-destructive testing of chemical composition using a metal and alloy analyzer is used in various sectors of economic activity. At metal depots and Vtorchermet enterprises, this is how the grades of alloys used in recycled components are determined.

In metallurgy, the purpose of using this technique is to control the quality of raw materials. Archaeologists use analyzers to roughly determine the age of discovered finds, and geologists use them to determine the quantitative and qualitative composition of soils and minerals.

Classification of modern metal analysis technologies

Chemical analysis of metals makes it possible to quantify the elemental composition of a material, thereby ensuring quality control, investigating the causes of structural failures, etc. Metal-chemical analysis is also used in so-called reverse engineering, when the nature of the failure is examined, which determines whether the correct alloy was used.

The chemical composition and microstructure of most metal samples can be determined in one of the following ways:

- Metallographic analysis and energy-dispersive optical spectrometry. The method is used for mass elemental analysis of steels, stainless steels, cast irons, copper, aluminum, cobalt, nickel, tin and zinc alloys.

- Inductively coupled plasma method. Used for mass analysis of small samples where high accuracy is required even at low element concentrations.

- X-ray photoelectron spectroscopy. The method is used for the analysis of nickel alloys and for the semi-quantitative analysis of all alloy systems.

- Infrared combustion, which is used in the determination of carbon, sulfur, as well as associated oxygen and hydrogen in metal.

If specific elements must be determined with particularly high precision, then tests using all the above methods can be carried out to measure them. If necessary, hardness testers are also used to determine the hardness of samples, which serves as additional confirmation of the presence of certain chemical elements in the metal. For the same purposes, spark tests are carried out on steels.

Types of metal analyzers

Optical emission spectrometers implement a technology that uses the intensity of light (emitted by a flame, plasma, or any other energy source that operates at the desired wavelength) to determine the amount of an element in a sample. Emission spectrometers work like this.

A highly concentrated electrical discharge of high thermal power is passed through the sample, heating it to the temperature at which thermionic emission begins. As a result, light radiation occurs at a certain wavelength, which is captured by a monochromator.

Modern devices are equipped with sources of controlled spark discharge, which allows for quantitative analysis of the composition of metals.

Plasma spectrometers are portable devices. Electrical energy in the form of a spark is generated between the electrode and the metal sample, causing the vaporized atoms to be driven into a high-energy state of discharge plasma.

Atoms and ions excited in plasma create a unique emission spectrum characteristic of each element. Thus, one element generates numerous characteristic emission spectra. This light is separated by a diffraction grating to extract the emission spectrum for the target elements. The intensity of each emission spectrum depends on the concentration of the element in the sample.

Analyzers that operate on the laser principle are used primarily to assess the presence of aluminum and its alloys in metal.

The principle of operation is based on assessing the wavelength of radiation that is activated by a laser beam. The ergonomics of the device is pistol-shaped. The laser analyzer is turned on using buttons located near the trigger. The measurement results are read using a touch screen that can be tilted at any angle.

A special feature of laser analyzers is the presence of a microchip, for which it is necessary to install a special program. With its help, a measurement matrix is selected, the chemical composition itself is produced, and the presence of a certain substance is identified.

X-ray fluorescent metal analyzers are designed to determine alloying components, traces and foreign impurities in various grades of steel.

The sample is exposed to X-ray radiation, with absorbed electrons passing into an electron beam analyzer and reflected electrons into an X-ray spectrometer. There the signal is amplified and displayed on the screen through a pulse magnitude discriminator.

Since two different blocks are used simultaneously for quantitative analysis, the accuracy of the results obtained is the greatest.

What determines the price of devices?

The practical value of any type of analyzer is determined by:

- The range for determining the percentage composition of elements.

- Nomenclature of defined elements.

- Dimensions of the analyzer.

- Difficulty in preparing and operating the device.

The price of a metal analyzer depends on the prestige of the manufacturer, as well as the availability of its service departments in Russia. The most popular metal analyzers in the world are those manufactured in Japan, Germany and the USA.

You should be wary of measuring equipment that is produced in countries such as China, Malaysia or the Philippines: using licensed components, such installations do not always have the proper build quality, although their price is quite attractive.

The cost is also related to the dimensions of the device. Stationary metal analyzers are mains powered and easier to maintain, while the reliability of portable models is highly dependent on the quality of the batteries, which are often supplied by companies with a lower trust rating.

The most reliable and popular models on the domestic market of metal and alloy analyzers are:

- Of the stationary devices, the M5000 analyzer, made in China, costs from 1 million rubles.

- Portable devices include X-ray fluorescence analyzers of the DELTA line from the Olympus brand (Japan), the price of which, depending on the capabilities of the device, ranges from 1 to 2 million rubles.

- Multifunctional hand-held laser analyzers Elanik from the Russian LLC Laser-Export. Price on request.

Portable metal and alloy analyzers

Portable metal and alloy analyzers

We present the latest technologies for express analysis of the composition of metals and alloys - laser LIBS and X-ray XRF

SciAps Laser Z series - safety and super laser capabilities, Li, Be, B, Al, Si, Mg, Na, any alloys - lightning fast

SciAps X series - the lightest, most accurate and fastest XRF in the world, double detector protection, new generation nanotube

Ostek-ArtTool is the official distributor of SciAps Inc. USA on the territory of the Russian Federation

New SCIAPS X and Z Series Metal Analyzers

The SciAps team pioneered portable XRF technology during the early days of the Niton and Innov-X handheld analyzers, and today has decades of industrial development experience.

Users of portable metal analyzers have long been waiting for the new generation of this unique device. First of all, a new concept of the case and hardware and software base.

The answer was SciAps analyzers: X-ray and laser Z-series. Two newest models solve the problem of incoming, repair and technological control of metals and express analysis of chemical composition with an innovative approach.

SciAps was the first to find a way to improve the method by combining high-precision portable analysis and cloud computing, and thanks to this it reached a new level comparable to the laboratory.

Source: www.arttool.ru

Determinant of metal grades OMET

The thermoelectric metal analyzer OMET is designed to quickly determine the grade of metal and heat treatment or mechanical processing modes based on thermopower on the surface of metal products of arbitrary shape in relation to copper.

The thermopower analysis in the metal detector is carried out at the same automatically maintained temperature difference between two copper electrodes. This ensures stable readings under different measurement conditions without additional calibration.

The grade of the metal being determined is determined by a comparative analysis of two metal samples based on the value of their thermopower. The voltage values (thermopower) of samples with the same chemical composition and the same microstructure of materials at the measurement points must match in sign and absolute value.

The metal detector automatically finds the beginning of each new measurement and automatically stores the result of the last measurement (grade of material) on the display. In addition, the determinant allows you to save the results of any one measurement in long-term memory when conducting a comparative analysis of metal samples by comparison with a standard.

This determinant allows you to quickly and easily make a decision about the identity of two samples of any grade of metals, and also, using the thermopower database of various known alloys relative to copper, make an assumption about its grade when analyzing a sample from an unknown material.

- ferrous and non-ferrous metallurgy;

- metalworking industry;

- machine tool and tool industry;

- electrical industry and instrument making, etc.

- OMET determinant with two probes (copper electrodes) - 1 pc.;

- set of standards - 1 pc.;

- metallized sponge for cleaning copper electrodes of probes - 1 pc.;

- AC power adapter with DC output (12 V 500 mA) - 1 pc.;

- passport, technical description and instruction manual - 1 pc.;

- case - 1 pc.

Attention! The manufacturer reserves the right to change the delivery package.

50±1

| 2 | ||

| 3. | Range for determining the thermopower value, µV | 0. ±1111 |

| 4. | Time of one measurement, no more, sec. | 1 |

| 5. | terms of Use | ambient temperature from 0 to +40 o C relative humidity up to 80% at 20 o C |

| 6. | Overall dimensions of the determinant, mm | 170x100x50 |

| 7. | Weight of metal detector with electrodes, no more, kg | 1 |

Attention! Specifications are subject to change by the manufacturer without prior notice.

Source: t-ndt.ru