Non-ferrous is a group of different metals and their alloys.

Let's take a closer look at what non-ferrous metal scrap is.

There are two groups of metals:

- colored;

- black.

Iron and its alloys are called black

The rest are non-ferrous or non-ferrous.

Their list is diverse:

- aluminum;

- copper;

- nickel;

- manganese;

- titanium;

- zirconium, etc.

are in demand today both in production and in scientific activities . Their areas of application are varied.

Scrap metal collection points are happy to buy non-ferrous metal scrap at competitive prices, and in order to avoid getting into trouble when handing it over, you need to be familiar with the types and know the standard classification of non-ferrous metals.

Classification of non-ferrous metals according to GOST

The current GOST 1639-2009 clearly indicates what belongs to non-ferrous metal scrap.

The classification of scrap is divided into four main sections that characterize it:

- Name;

- physical parameters;

- chemical composition;

- quality.

GOST metals and their alloys.

The section displays 13 types that are accepted in organizations for receiving recyclable materials.

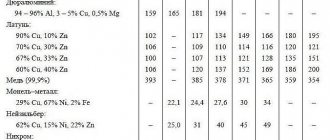

Below is a table in which you can see a list of non-ferrous metals in one list and the number of individual types of scrap:

| Metal | Types of scrap |

| Aluminum | 32 |

| Tungsten | 17 |

| Cadmium | 2 |

| Cobalt | 3 |

| Magnesium | 8 |

| Copper | 13 |

| Brass | 23 |

| Bronze | 15 |

| Molybdenum | 9 |

| Lead | 11 |

| Mercury | 6 |

| Tin | 10 |

| Nickel | 26 |

Pure metal can rarely be found , since most scrap is made up of alloys.

Upon acceptance, belonging to one or another type is assessed by the element that is greater in percentage terms in recyclable materials.

This ratio can be determined using special equipment.

Steel grades

| steel grade | Substitute | Weldability |

| GOST 380-2005 | ||

| St0 | — | Weldable without restrictions |

| St2kp | — | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St2ps | St2sp | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St2sp | St2ps | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St3Gps | St3ps, 18Gps | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St3Gsp | — | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St3kp | St3ps | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St3ps | St3sp | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St3sp | St3ps | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St4kp | — | Limited weldability. Preheating and subsequent heat treatment is recommended |

| St4ps | — | Limited weldability. Preheating and subsequent heat treatment is recommended |

| St5ps | — | Limited weldability. Preheating and subsequent heat treatment is recommended |

| St5sp | St4sp, St6sp | Limited weldability. Preheating and subsequent heat treatment is recommended |

| St6ps | — | Limited weldability. Preheating and subsequent heat treatment is recommended |

| St6sp | St5sp | Limited weldability. Preheating and subsequent heat treatment is recommended |

| GOST 801-78 | ||

| ШХ15 | 9Х, 9Х1, ШХ15СГ | Difficult to weld |

| SHH15SG | 9ХС, ХВГ, ХВСГ, ШХ15 | Difficult to weld |

| GOST 1050-88 | ||

| 8 | 10 | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 08kp | 8 | Weldable without restrictions |

| 10 | 08, 15, 08kp | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 10kp | 08kp, 15kp, 10 | Weldable without restrictions |

| 15 | 10, 20 | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 15kp | 10kp, 20kp | Weldable without restrictions |

| 20 | 15, 20 | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 20kp | 15kp | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 25 | 20, 30 | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 30 | 25, 35 | Limited weldability. Preheating and subsequent heat treatment is recommended |

| 35 | 30, 40, 35G | Limited weldability. Preheating and subsequent heat treatment is recommended |

| 40 | 35, 45, 40G | Limited weldability. Preheating and subsequent heat treatment is recommended |

| 45 | 40Х, 50, 50Г2 | Difficult to weld. Requires heating and subsequent heat treatment |

| 50 | 45, 50G, 50G2, 55 | Difficult to weld. Requires heating and subsequent heat treatment |

| 55 | 50, 60, 50G | Not applicable for welded structures |

| 60 | 55, 65G | Not applicable for welded structures |

| GOST 1414-75 | ||

| A12 | A20 | Not applicable for welded structures |

| A20 | A12 | Not applicable for welded structures |

| A35 | — | Difficult to weld |

| GOST 1435-99 | ||

| U7 | U8 | Not applicable for welded structures |

| U7A | U8 | Not applicable for welded structures |

| U8 | U7, U7A, U10, U10A | Not applicable for welded structures |

| U8A | U7, U7A, U10, U10A | Not applicable for welded structures |

| U9 | U7, U7A, U8, U8A | Not applicable for welded structures |

| U9A | U7, U7A, U8, U8A | Not applicable for welded structures |

| U10 | U12, U12A | Not applicable for welded structures |

| U10A | U12, U12A | Not applicable for welded structures |

| U12 | U10, U10A | Not applicable for welded structures |

| U12A | U10, U10A | Not applicable for welded structures |

| GOST 4543-71 | ||

| 09G2S | 10G2S, 09G2 | Weldable without restrictions |

| 10G2 | 09G2 | Weldable without restrictions |

| 10G2S1 | 10G2S1D | Weldable without restrictions |

| 12Х2Н4А | 20ХГНР, 12ХН2, 20ХГР, 12ХН3А, 20Х2Н4А | Limited weldability |

| 12ХН2 | 20ХНР, 20ХГНР, 12ХН3А, 20Х2Н4А | Limited weldability |

| 12ХН3А | 12ХН2, 20ХН3А, 25ХГТ, 12Х2НР, 20ХНР | Limited weldability |

| 14Х2Н3МА | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 14ХГС | 15HSND, 16GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 15G | 20G | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 15X | 20X | Weldable without restrictions, except for parts after chemical-thermal treatment |

| 15ХМ | — | Weldable without restrictions. Preheating and subsequent heat treatment are recommended |

| 15HF | 20HF | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 16GS | 17GS | Weldable without restrictions |

| 17G1S | 17GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 17GS | 16GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 18Х2Н4МА (18Х2Н4ВА) | 20Х2Н4А | Limited weldability. Requires heating and subsequent heat treatment |

| 28ХГТ | 30ХГТ, 25ХГТ, 12ХН3А, 12Х2Н4А, 20ХН2М, 20ХГР | Weldable without restrictions, except for parts after chemical-thermal |

| 20G | 20, 30G | Weldable without restrictions, except for parts after chemical-thermal |

| 20X | 15Х, 20ХН, 18ХГТ | Weldable without restrictions, except for parts after chemical-thermal |

| 20Х2Н4А | 20HGNR, 20HGNTR | Limited weldability. Requires heating and subsequent heat treatment |

| 20ХГНР | 20ХН3А, 12ХН2, 12ХН3А | Limited weldability |

| 20ХГР | 20ХН3А, 20ХН24, 18Х1Т, 12ХН2, 12ХН3А | Limited weldability |

| 20ХГСА | 30ХГСА | Weldable without restrictions |

| 20HGT | — | Subsequent heat treatment required |

| 20ХМ | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 20ХН | 15ХГ, 20ХНР, 18 ХГТ | Limited weldability |

| 20ХН2М (20ХНМ) | 20ХГР, 15ХР, 20ХНР, 20ХГНР | Heating and subsequent heat treatment |

| 20ХН3А | 20ХГНР, 20ХНГ, 38ХА, 20ХГР | Limited weldability |

| 20ХН4FA | 18Х2Н4МА | Difficult to weld. Requires heating and subsequent heat treatment |

| 20ХНР | 20ХН | Requires heating and subsequent heat treatment |

| 25x2N4MA (25x2N4VA) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 25ХГМ | — | Limited weldability |

| 25ХГСА | 20ХГСА | Weldable without restrictions |

| 27ХГР | — | Limited weldability |

| 30G | 35.40G | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30X | 35X | Limited weldability |

| 30Х3МФ | — | Limited weldability. Requires heating and subsequent heat treatment |

| 30ХГС | 40HFA, 35ХМ, 40ХН, 35ХГСА | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30ХГСА | 40HFA, 35ХМ, 40ХН, 35ХГСА | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30KhGSN2A (30KhGSNA) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 30ХГТ | 18ХГТ, 20ХН2М, 25ХГТ, 12Х2Н4А | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30ХМ | 35ХМ, 35ХРА | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30ХМА | 35ХМ, 35ХРА | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30ХН2МА | 40HFA, 35ХМ, 40ХН, 35ХГСА | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 30HN2MFA (30HN2VFA) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 30ХН3А | 30Х2ГН2, 34ХН2М | Limited weldability. Requires heating and subsequent heat treatment |

| 33ХС | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 35G2 | 40X | Limited weldability. Requires heating and subsequent heat treatment |

| 35X | 40X | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 35ХГСА | 30ХГС, 30ХГСА, 30ХГТ, 35ХМ | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 35ХМ | 40Х, 40ХН, 30ХН, 35ХГСА | Limited weldability. Requires heating and subsequent heat treatment |

| 36Kh2N2MFA (36KhN1MFA) | — | Difficult to weld |

| 38Х2МУА (38ХМУА) | 38Х2УА, 38ХВФУ, 38Х2У, 20Х3МВФ | Not applicable for welded structures |

| 38Х2Н2МА(38ХНМА) | — | Not applicable for welded structures |

| 38ХА | 40Х, 35Х | Difficult to weld. Requires heating and subsequent heat treatment |

| 38ХГН | 38ХГНМ | Difficult to weld. Requires heating and subsequent heat treatment |

| 38ХН3МА | 38ХН3ВА | Not applicable for welded structures |

| 38ХН3МФА | — | Not applicable for welded structures |

| 38ХС | 40ХС | Difficult to weld. Requires heating and subsequent heat treatment |

| 40G | 45, 40Х | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 40G2 | 45G2, 60G | Difficult to weld. Requires heating and subsequent heat treatment |

| 40X | 45Х, 38ХА, 40ХС | Difficult to weld. Requires heating and subsequent heat treatment |

| 40Х2Н2МА (40Х1НВА) | 38Х2Н2МА | Difficult to weld. Requires heating and subsequent heat treatment |

| 40ХН | 45ХН, 50ХН, 38ХГН, 40Х, 35ХГФ, 40ХНР, 40ХНМ, 30ХГВТ | Difficult to weld. Requires heating and subsequent heat treatment |

| 40ХН2МА (40ХНМА) | 40HGT, 40HGR, 30H3MF, 45HN2MFA | Difficult to weld. Requires heating and subsequent heat treatment |

| 40ХС | 38ХС, 35ХГТ | Difficult to weld. Requires heating and subsequent heat treatment |

| 40HFA | 40Х, 65Г, 50ХФА, 30Х3МФ | Difficult to weld. Requires heating and subsequent heat treatment |

| 45G | 40G, 50G | Difficult to weld. Requires heating and subsequent heat treatment |

| 45G2 | 50G2 | Difficult to weld. Requires heating and subsequent heat treatment |

| 45X | 40Х, 50Х | Difficult to weld. Requires heating and subsequent heat treatment |

| 45ХН | 40ХН | Difficult to weld. Requires heating and subsequent heat treatment |

| 50G | 40G, 50 | Limited weldability. Preheating and subsequent heat treatment are recommended. |

| 50G2 | 45G2, 60G | Difficult to weld. Requires heating and subsequent heat treatment |

| 50X | 40Х, 45Х, 50ХН | Difficult to weld. Requires heating and subsequent heat treatment |

| 50ХН | 40ХН, 60ХГ | Not applicable for welded structures |

| GOST 5520-79 | ||

| 15K | — | Weldable without restrictions |

| 16K | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 18K | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 20K | — | Weldable without restrictions |

| 22K | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| GOST 5632-72 | ||

| 06ХН28МДТ (0Х23Н28М3Д3Т, EI 943) | 03ХН28МДТ | Difficult to weld |

| 07Х16Н6 (Х16Н6,ЭП 288) | — | Weldable without restrictions |

| 08Х13 (0Х13, EI 496) | 12Х13, 12Х18Н9Т | Limited weldability. Heating and subsequent heat treatment are used depending on the welding method, type and purpose of the structure |

| 08Х15Н24В4ТР (ЭП 164) | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 08Х16Н13М2Б (EI 405, EI 680) | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 08Х17Н13М2Т (0Х17Н13М2Т) | 10Х17Н13М21 | Weldable without restrictions |

| 08Х17Т (0Х17Т, EI 645) | 12Х17, 08Х18Т1 | Difficult to weld. Subsequent heat treatment is recommended |

| 08Х18Н10 (0Х18Н10) | — | Weldable without restrictions |

| 08Х18Н10Т (0Х18Н10, EI 914) | — | Weldable without restrictions |

| 08Х21 Н6М2Т (0Х21 Н6М2Т, ЭП 54) | — | Weldable without restrictions |

| 08Х22Н6Т (08Х22Н5Т, ЭП 53) | 12Х18Н9Т, 12Х18Н10Т, 08Х18Н10Т | Limited weldability |

| 09X14N19V2BR (EI 695R) | — | Difficult to weld. Subsequent heat treatment is recommended |

| 09X14N19V2BR1 (EI 726) | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 10Х11Н20Т3Р (EI 696) | — | Welds satisfactorily |

| 10Х11Н23Т3МР (ЭП 33) | — | Welds satisfactorily |

| 10Х14Г14Н4Т (Х14Г14Н3Т, EI 711) | 20Х13Н4Г9, 12Х18Н9Т, 12Х18Н10Т, 08Х18Н10Т | Limited weldability |

| 10Х17Н13М2Т (Х17Н13М2Т, EI 448) | — | Weldable without restrictions |

| 10Х17Н13М3Т (Х17Н13М3Т, EI 432) | — | Weldable without restrictions |

| 12Х13 (1Х13) | 20Х13 | Limited weldability. Heating and subsequent heat treatment are used depending on the welding method, type and purpose of the structure |

| 12X17 (X17, EZh 17) | 12Х18Н9Т | Difficult to weld. Subsequent heat treatment is recommended |

| 12Х18Н10Т | 15Х25Т, 08Х17Т, 08Х18Г8Н2Т, 10Х14Г14Н4Т | Weldable without restrictions. Subsequent heat treatment is recommended |

| 12Х18Н12Т (Х18Н12Т) | 12Х18Н9, 12Х18Н9Т, 12Н18Н10Т | Weldable without restrictions |

| 12Х18Н9Т (Х18Н9) | 20Х13Н4Г9, 10Х14Г14Н4Т | Weldable without restrictions |

| 12Х18Н9Т (Х18Н9Т) | 12Х18Н10Т | Weldable without restrictions |

| 12X25N16G7AR (EI 835) | — | Weldable without restrictions |

| 13Х11 Н2В2МФ-Ш (ЭИ 961-Ш) | — | Limited weldability |

| 14Х17Н2 (1Х17Н2, EI 268) | 20Х17Н2 | Limited weldability |

| 15Х11МФ (1Х11МФ) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 15Х12ВНМФ (EI 802, EI 952) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 15Х25Т (Х25Т, EI 439) | 12Х18Н10Т | Difficult to weld. Preheating and subsequent heat treatment are recommended |

| 17Х18Н9 (2Х18Н9) | 20Х13Н4Г9 | Limited weldability |

| 18Х11МНФБ (2Х11МФБН, ЭП 291) | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 18Kh12VMBFR-Sh (EI 993-Sh) | — | Not applicable for welded structures |

| 20N23N18 (Х23Н18, EI 417) | 10Х25Т, 20Х23Н13 | Weldable without restrictions |

| 20Х12ВНМФ (EP 428) | 15Х12ВНМФ, 18Х11 МНФБ | Limited weldability. Requires heating and subsequent heat treatment |

| 20Х13 (2Х13) | 12Х13, 14Х17Н2 | Limited weldability. Heating and subsequent heat treatment are used depending on the welding method, type and purpose of the structure |

| 20Х20Н14С2 (Х20Н14С2, EI211) | — | Limited weldability. Subsequent heat treatment is recommended. |

| 20Х23Н13 (Х23Н13, EI 319) | — | Limited weldability. |

| 20Х25Н20С2 (Х25Н20С2, EI 283) | — | Limited weldability. |

| 25Х13Н2 (2Х14Н2, EI 474) | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 30Х13 (3Х13) | 40Х13 | Not applicable for welded structures |

| 31Х19Н9МВБТ (ЭИ 572) | — | Difficult to weld. Heat treatment is recommended to relieve welding stresses |

| 36Х18Н25С2 (4Х18Н25С2, ЭЯ 3С) | — | Limited weldability. Subsequent heat treatment is recommended |

| 37Х12Н8Г8МФБ (EI 481) | — | Difficult to weld. Subsequent heat treatment is recommended |

| 40Х10С2М (4Х10С2М, EI 107) | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 40Х13 (4Х13) | 30Х13 | Not applicable for welded structures |

40Х9С2 (4Х9С2, ESH  | — | Not applicable for welded structures |

| 45Х14Н14В2М (EI 69) | — | Difficult to weld. Subsequent heat treatment is recommended to relieve welding stresses. |

| 95х18 (9Х18, EI 229) | — | Not applicable for welded structures |

| ХН32Т (EP 670) | — | Weldable without limitation |

| ХН35ВТ (EI 612) | — | Difficult to weld. Subsequent heat treatment is recommended to relieve welding stresses. |

| KhN35VTYu (EI 787) | — | Difficult to weld. Subsequent heat treatment is recommended to relieve welding stresses. |

| ХН45У (EP 747) | — | Weldable without restrictions |

| HN55VMTKYU (EI 929) | — | Difficult to weld |

| KHN55VMTKYu-VD (EI 929-VD) | — | Difficult to weld |

| ХН60ВТ (EI 868) | — | Limited weldability |

| ХН60У (ЭИ 559А) | — | Weldable without restrictions |

| KHN62MVKYU (EI 867) | — | Difficult to weld |

| ХН62МВКУ-ВД (ЭИ 86-ВД) | — | Difficult to weld |

| KhN65MVTYu (EI 893) | — | Difficult to weld |

| KhN67MVTYu (EP 202, EI 445R) | — | Difficult to weld. Requires heating and subsequent heat treatment |

| KhN70VMTYu (EI 617) | — | Limited weldability |

| KhN70VMTYUF (EI 826) | — | Difficult to weld |

| KhN70VMTYuF-VD (EI 826-VD) | — | Difficult to weld |

| KHN70VMUT (EI 765) | — | Difficult to weld. Subsequent heat treatment is recommended to relieve welding stresses. |

| ХН70У (EI 652) | All types of welding can be carried out in thin sections | |

| ХН75ВМУ (EI 827) | — | Difficult to weld |

| KHN77TYUR (EI 437B) | — | Difficult to weld |

| ХН78Т (EI 435) | 12Х25Н16Г7АР, 20Х23Н18, ХН38Т | Limited weldability |

| KHN80TBYu (EI 607) | — | Difficult to weld |

| GOST 5781-82 | ||

| 18G2S | — | Weldable without restrictions |

| GOST 5950-2000 | ||

| 11Х4В2МФ3С2 (DI 57) | — | Not applicable for welded structures |

| 3X2MNF | — | Not applicable for welded structures |

| 3Х3М3Ф | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 4Х3ВМФ (3И 2) | — | Not applicable for welded structures |

| 4Х4ВМФС (DI 22) | — | Not applicable for welded structures |

| 4Х5В2ФС (EI 958) | — | Not applicable for welded structures |

| 4Х5МФ1С (EP 572) | — | Difficult to weld. Requires heating and subsequent heat treatment |

| 4Х5МФС | — | Not applicable for welded structures |

| 4ХМФС (4ХСМФ) | — | Not applicable for welded structures |

| 5Х2МNF (DI 32) | — | Not applicable for welded structures |

| 5Х3В3МФС (DI 23) | — | Not applicable for welded structures |

| 5ХНМ | 5ХНВ, 5ХГМ, 4ХМФС, 5ХНВС, 4Х5В2ФС | Not applicable for welded structures |

| 6Х6В3МФС (55Х6В3СМФ, ЭП 569) | — | Not applicable for welded structures |

| 7Х3 | 8Х3 | Not applicable for welded structures |

| 7ХГ2ВМФ | — | Not applicable for welded structures |

| 8Х4В2МФС2 (EP 761) | — | Not applicable for welded structures |

| 9Х1 (9Х) | 9X2 | Not applicable for welded structures |

| 9Х1Ф | — | Not applicable for welded structures |

| 9X2 | — | Not applicable for welded structures |

| 9ХС | HVG | Not applicable for welded structures |

| 9HF | — | Not applicable for welded structures |

| X12 | X12MF | Not applicable for welded structures |

| X12VMF | X12MF | Not applicable for welded structures |

| X12MF | Kh6VF, Kh12F1, Kh12VMF | Not applicable for welded structures |

| Х12Ф1 | Kh6VF, Kh6F3FM | Not applicable for welded structures |

| Х6ВФ | Х12Ф1, Х12М, 9Х5Ф | Not applicable for welded structures |

| HVG | 9ХС, 9ХВГ, ШХ15СГ | Not applicable for welded structures |

| GOST 14959-79 | ||

| 75 | 70, 80, 85 | Not applicable for welded structures |

| 85 | 70, 75, 80 | Not applicable for welded structures |

| 50HFA | 60С2А, 50ХГ FA, 9ХС | Not applicable for welded structures |

| 55С2 | 50S2, 60S2, 35Х2AF | Not applicable for welded structures |

| 60С2 | 55S2, 50HFA | Not applicable for welded structures |

| 60С2А | 60S2N2A, 60S2G, 50HFA | Not applicable for welded structures |

| 60S2G | — | Not applicable for welded structures |

| 65G | 70, U8A, 70G, 60S2A, 50HFA, 9HS, 60S2, 55S2 | Not applicable for welded structures |

| 65S2VA | 60С2А, 60С2ХА | |

| 70С2ХА | — | |

| GOST 19265-73 | ||

| P18 | — | Not applicable for welded structures |

| 11R3AM3F2 | — | Not applicable for welded structures |

| R18K5F2 | — | Not applicable for welded structures |

| R6M5 | — | Not applicable for welded structures |

| R6M5K5 | — | Not applicable for welded structures |

| R9M4K8 | — | Not applicable for welded structures |

| GOST 19281-89 | ||

| 09G2 | 09G2S, 10G2 | Weldable without restrictions |

| 09G2S | 10G2S, 09G2 | Weldable without restrictions |

| 10G2S1 | 10G2S1D | Weldable without restrictions |

| 10HSND | 16G2AF | Weldable without restrictions |

| 14G2 | 15HSND | Weldable without restrictions |

| 14ХГС | 15HSND, 16GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 15HSND | 16G2AF, 14HGS, 16GS | Weldable without restrictions |

| 16GS | 17GS | Weldable without restrictions |

| 17G1S | 17GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 17GS | 16GS | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 18G2AFps | 15G2AFDps, 16G2AF, 10HSND, 15HSND | Limited weldability |

| GOST 20072-72 | ||

| 12MH | — | Weldable without restrictions. Preheating and subsequent heat treatment are recommended |

| 12Х1МФ (EI 575) | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 15ХМ (12Х5МА, Х5М) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 15Х5МФ | — | Limited weldability. Preheating and subsequent heat treatment are recommended |

| 20Х1М1Ф1БР (ЭП 44) | — | Not applicable for welded structures |

| 20Х1М1Ф1ТР (ЭП 182) | — | Not applicable for welded structures |

| 20Х3МВФ (EI 415, EI 579) | — | Limited weldability. Requires heating and subsequent heat treatment |

| 25Х1МФ (EI 10) | — | Limited weldability |

| GOST 28393-89 | ||

| R6M5F3-MP (DI 99-MP) | — | Not applicable for welded structures |

| R12M3K5F2-MP (DI 103-MP) | — | Not applicable for welded structures |

Marking of materials of various groups

Types

Non-ferrous metal scrap is divided into types according to the following criteria :

- origin;

- chemical composition;

- physical state.

The origin of the scrap may be as follows:

- industrial waste;

- marriage;

- substandard;

- scrap of finished products.

The chemical composition of non-ferrous metal scrap, which is determined in the laboratory, shows which metal or alloy it belongs to.

The most valuable recyclable materials are unalloyed metals with a low content of impurities. Physical parameters are just as important when passing as chemical ones.

According to these characteristics, scrap is divided into the following classes :

- A – directly refers to scrap and lump waste;

- B – includes shavings, tangled wire and small pieces;

- B - powdered waste (mainly found only in rare metals: tungsten, cobalt, molybdenum and titanium);

- G - other recyclables.

How does marking happen in practice?

Before smelting any grade of metal, the charge materials are calculated. Then the desired composition is poured into the oven, boiled and poured. All necessary elements are verified using a ladle sample in accordance with GOST or TU tables. They check for harmful impurities (they get into the melt with the charge and from the lining). If all components are within the normal range, then the melt is marked as expected.

It also happens that chemical composition standards are not met. Then the metal is marked with a different brand. The customer must be sure that he will receive exactly the products he ordered. The quality of the products depends on this. 's technical control system strictly monitors this.

Safety

All non-ferrous scrap must be checked for:

- presence of radiation and harmful chemical contamination;

- explosion hazard.

When transporting scrap metal, it must be accompanied by documentation on radiation and explosion safety.

The concentration of harmful substances must not exceed the values specified in GOST 12.1.005.

The Russian Ministry of Natural Resources has identified five classes of chemical, radiation and explosion hazards of non-ferrous metal scrap:

- Hazardous waste with great harm to the ecosystem. These include mercury, polonium and plutonium.

- Highly hazardous waste, the consequences of which take nature thirty years to remove. These are alloys of lead, cobalt and molybdenum.

- Moderate danger , in which it takes ten years to restore the ecology. This is scrap mixed with copper, nickel, iron, zinc, aluminum and silver.

- Low hazardous waste, removal of the consequences takes three years. This includes scrap bronze.

- Low danger , such scrap does not harm the environment. This is the most common class among colored scrap.

Due to the expected harm to humans and nature, all operations with non-ferrous scrap require a license from the points accepting secondary non-ferrous metals. Checking for all types of hazards is carried out according to the following scheme:

What do the numbers mean in hair dye numbers?

When choosing paint, each woman is guided by her own criteria. For one, the decisive factor is brand awareness, for another - the price criterion, for the third - the originality and attractiveness of the packaging or the presence of a balm in the kit.

But as for choosing the shade itself, everyone is guided by the photo posted on the packaging. At least, on the name. And rarely will anyone pay attention to the small numbers that are printed next to the beautiful (like “chocolate smoothie”) name of the shade. Although these numbers give us a complete picture of the presented shade.

On the main part of the shades presented by various brands, the tones are indicated by 2-3 numbers. For example, “5.00 Dark Blonde”.

- The 1st number refers to the depth of the main color (approx. - usually from 1 to 10).

- Under the 2nd number is the main color tone (note - the number comes after the dot or fraction).

- Under the 3rd number is an additional shade (approx. 30-50% of the main shade).

- When marked with only one or two numbers, it is assumed that there are no shades in the composition, and the tone is exceptionally pure.

Let's decipher the depth of the main color:

- 1 - refers to the color black.

- 2 - to dark-dark chestnut.

- 3 - to dark chestnut.

- 4 - to chestnut.

- 5 - to light chestnut.

- 6 - to dark blond.

- 7 - to fair-haired.

- 8 - to light brown.

- 9 - to very light brown.

- 10 - to light light brown (that is, light blond).

Some manufacturers can also add an 11th or 12th tone - these are already super-lightening hair dyes.

Deciphering the number of the main shade

- Under the number 1: there is a blue-violet pigment (approx. - ash row).

- Under the number 2: there is a green pigment (approx. - matte row).

- Under the number 3: there is a yellow-orange pigment (approx. - golden row).

- Under the number 4: there is a copper pigment (note - red row).

- Under the number 5: there is a red-violet pigment (approx. - mahogany row).

- Under the number 6: there is a blue-violet pigment (approx. - purple row).

- Under the number 7: there is a red-brown pigment (note - natural base).

- It should be remembered that the 1st and 2nd shades are classified as cold, the others - warm.

Marking

According to GOST, all transported scrap must be marked with the following indication:

- names;

- GOST designations;

- designations of the type of recyclable materials;

- alloy grades.

Marking of non-ferrous metals and alloys must be firmly attached to the cargo during transportation and storage.

To determine the grade of metal, you need to look at the stamp book , a special document with all the markings of the metal or alloy you are interested in.

Decoding the numbers on the packaging

Color. The box and tube are marked by the manufacturer with a code or paint number consisting of several numbers. Numerical characters can be separated by a fraction or a dot.

The first part of the number, located before the dot or fraction, means the main tone of the dye; it is also called the lightening level. It is numbered from 1 to 11 (sometimes 12), from dark to light: 1 - the darkest, black color; 2 - black-brown; 3 - dark brown; 4 - medium brown; 5 - light brown; 6 - dark blond; 7 - medium brown; 8 - light brown; 9 - light blond; 10 is the lightest.

When applying markings 11 and 12, different manufacturers designate the blonde as “ultra” or “extra”. Numbers from 1 to 5 are black and brown, 6 and above indicate different degrees of blonde.

Tone or additional pigment. When determining hair color, we talk about color and tone. The tone belongs to one of three groups: neutral, warm, cold. A combination of color and tone is used to create the perfect customized formula. Manufacturers mark additional pigmentation of dyes with the first number after the fraction or dot: /0 - natural shade; /1 - pearl, gray, ash; /2 /3 - golden, yellow; /4 - copper, orange; /5 - fiery, red; /6 - purple; /7 - brown; /8 /9. If there are two numbers after the fraction, then the manufacturer has designated the pigment additive. For example, the numbers 7/73 indicate medium blond, a shade of brownish-golden.

In addition to giving hair different shades, pigments neutralize or enhance the color of natural or dyed hair.

Labeling of additional shades may not be the same from different manufacturers. But there is an international system - the International Color Chart (ICC), where coloring is standardized. This numerical system is used throughout the world to classify the range of hair. Typically, hairdressers choose one professional brand and train by working with it, studying the numbering system and combination options.

Palette of shades

Knowing the meaning of the marking, it is very easy to read the palette album supplied by the manufacturer with each series of dye in the store. Next to each dyed strand in the album there is a digital color and shade code. Lovers of natural dyes should choose zero additional pigmentation.

The main tone has a greater influence on the final hair color than the additional tone. For example, 8/1 is a light blonde with a cool ash tone, and 8/13 is also a light blonde with a cool ash tone, but with a hint of warm gold as the background.

Red tones. Red shades are added to change the base of the medium brown. The zero after the fraction is used to mark the intensity of the tone. For example, 4/06 is a medium brown with just a hint of red, like warm coffee. While 4/60 is the same moderate brown, with a more obvious red tint. And 4/66 is a strong red tone on medium brown hair color.

The shade Mahogany is a mixture of red and purple shades. It is usually used in conjunction with another tone rather than on its own. Mahogany itself is neither a warm nor a cool shade. Its paired tone determines whether the hair color will be warm or cool. For example, 4/15 (chocolate brown) is cool, and 4/56 is warm.

If you need to cover your gray hair

If there is a certain percentage of gray hair, when choosing a dye, you should also focus on the numbers, and not on the sample strand in the palette: all dyes related to natural shades completely cover gray hair, this is a range from 1/0 to 10/0; dyes with additional golden pigment cover gray hair by 75%; red, orange and purple pigments can cover only half of the gray hair; To improve this indicator, natural color paint is added to the dye of these shades.

What do the numbers in the paint number mean?

Most tones are designated by one, two or three numbers. So, let's try to figure out what is hidden behind each of them.

The first number indicates the natural color and is responsible for the level of its depth . There is an international scale of natural tones: number 1 corresponds to black; 2 – dark-dark chestnut; 3 – dark chestnut; 4 – chestnut; 5 – light chestnut; 6 – dark blond; 7 – fair-haired; 8 – light brown; 9 – very light brown; 10 – light light brown (or light blond).

Some companies add another 11 and 12 tones, indicating super-lightening paints. If the tone is named with only one number, this means that the color is natural, without other shades. But in the designation of most tones there are second and third numbers that decipher shades of color.

The second number is the main shade:

- 0 – a range of natural tones

- 1 – presence of blue-violet pigment (ash row)

- 2 – presence of green pigment (matte row)

- 3 – presence of yellow-orange pigment (golden row)

- 4 – presence of copper pigment (red row)

- 5 – presence of red-violet pigment (mahogany row)

- 6 – presence of blue-violet pigment (purple row)

- 7 – presence of red-brown pigment, natural base (Havana)

It should be taken into account that the first and second shades are cold, the rest are warm. The third number (if there is one) means an additional shade, which is half as much in the color as the main one (in some paints their ratio is 70% to 30%).

For some manufacturers (for example, Pallet paint), the direction of color is indicated by a letter, and the depth of tone by a number. The meanings of the letters are as follows:

- C – ash color

- PL - platinum

- A - intense lightening

- N - natural

- E - beige

- M - matte

- W - brown

- R - red

- G - golden

- K - copper

- I - intense

- F,V - purple

Kinds

The large number of non-ferrous metals and various characteristics required their classification into separate types.

industrial systematization is in use , reflecting the historically established components of the metallurgical industry and the science of the same name.

The name itself does not fully reflect the essence of non-ferrous metal.

Only gold and copper are colored, while the rest are the usual grey-black shades.

Science usually distinguishes the following types of non-ferrous metals and alloys:

- lungs;

- heavy;

- noble;

- refractory;

- scattered;

- rare earth;

- radioactive.

industry in Russia today is on the rise and includes:

- metal mining;

- ore beneficiation;

- metal smelting

Basic non-ferrous metals

The main non-ferrous metals include:

- copper;

- aluminum.

Aluminum is an excellent electrical conductor. It is flexible, which is both its advantage and disadvantage.

To give it strength add :

- manganese;

- copper;

- magnesium, etc.

Such alloys are used for the production of :

- airplanes;

- sea and river ships;

- space shuttles;

- in construction;

- in the food industry.

Aluminum and its alloys are the cheapest type of non-ferrous metal scrap.

You can find it in a variety of household items, including:

- siding;

- gutters;

- roofing

Copper is a commonly found non-ferrous metal.

It also has good characteristics:

- plastic;

- good electrical conductor;

- good heat conductor.

It is in great demand in alloys and is used in various economic sectors.

Its alloy with zinc and tin is known - brass.

It can be found in:

- cars;

- hours;

- expensive jewelry.

find copper for scrap metal in:

- power cables;

- water pipes;

- household products.

Copper is highly valued at recycling centers.

Rare

Rare earth metals are used to improve the qualities of other metals and became widely used with the development of industrial production in the 20th century.

These are the following metals:

- scandium;

- yttrium;

- lanthanides.

The name itself suggests that there is very little of these non-ferrous metals in the earth's crust. Also, previously, refractory oxides that form rare non-ferrous metals were called “earths” . They are extracted from oxides.

Today, rare earth metals can be found in all digital devices:

- smartphones;

- players;

- computers;

- in hybrid engines;

- in other electronics.

Alloys made from them have high characteristics , for example:

- anti-corrosion;

- strength;

- heat resistant.

Heavy

Let's consider heavy non-ferrous metals, collecting them in several lists.

The heaviest non-ferrous metals on Earth:

- osmium;

- iridium.

Rarely found in soil , it is generally the most expensive non-ferrous metal.

Also included in this group are:

- copper;

- lead;

- zinc;

- tin;

- nickel.

All of them have a high density and, accordingly, a lot of weight, which is why they get the name – heavy.

Lead is widely known and used in many industries , contained in:

- rock

- soil.

It is made from:

- batteries;

- explosives;

Lead is also used to create protective aprons from radiation .

Has the following characteristics:

- low thermal conductivity;

- plastic;

- toxicity.

Therefore, lead must be used carefully, following all safety regulations.

Tin used to be called an alloy of lead and silver.

Today, tin is used in the metallurgical industry and the production of various alloys, which include:

- bearings;

- packaging foil;

- bronze;

- food tin;

- wires

Nickel is a heavy non-ferrous metal with high heat-resistant and anti-corrosion characteristics. Nickel is used in alloys. In stainless steel it is the main component.

Made from nickel :

- coins;

- armor;

- chemical equipment;

- wire;

- foil;

- a thread;

- powder;

- alkaline batteries.

in demand in:

- shipbuilding;

- electrical engineering.

Lungs

The definition of “light non-ferrous metals” includes metals with low density.

List of the most popular light non-ferrous metals:

- aluminum;

- tin;

- magnesium;

- titanium;

- beryllium;

- lithium.

The lightest non-ferrous metal is lithium. It is widely used in various alloys.

is used in:

- chemical industry;

- metallurgical industry;

- military-industrial complex;

- thermonuclear energy.

Lithium is also used in the manufacture of:

- optics;

- alkaline batteries;

- ceramic products.

The ductility of magnesium is not as good as that of copper and aluminum, which affects the welding properties of this metal. But it can be easily cut with a special tool. At the same time, the mechanical properties leave much to be desired. This it to be widely introduced into industrial production .

Foreign standards

Manufacturers in the Russian Federation and post-Soviet countries use labeled methods, thanks to which you can at least roughly understand the composition, purpose and technical properties without the use of special literature. American and European production, on the contrary, does not use this practice. This is due to the many companies that are qualified to standardize metal products.

Most often, European countries and America do not apply a chemical composition to the outer surface, and steel varieties are characterized by letters and numbers. However, to decipher this abbreviation you will need to use reference books or other literature.

For corrosion-resistant steels in Europe and America, the AISI marking system is often used. It requires three numbers and one or more letters. The first digit in the metal marking indicates the steel class. The next two digits correspond to the serial number of the alloy in the group. Meaning of letters used in marking steel alloys:

- carbon content less than 0.03%;

- C content within 0.03-0.08%;

- the alloy contains nitrogen;

- low carbon steels containing nitrogen;

- high concentration of sulfur and phosphorus;

- contains selenium, B – silicon, Cu – copper.

Other labeling systems may be used in the United States. In Europe there is a system that is in many ways similar to the Russian labeling system. Carbon content is indicated in hundredths of a percent. The differences are that alloying elements are listed first, and then their percentages follow in the same order; alloys are indicated in accordance with the periodic table. If any element is present in an amount of more than 5%, then the letter X is placed before the marking. For example: X5CrNi18-10. This steel contains 0.05% carbon, 18% chromium and 10% nickel.

Table of designations of alloy steels in different marking systems

| US Standard ASTM A240 | European standards EN 10088-2 and EN 10095 | Russian standard GOST 5632-2014 | Chemical composition, % | ||||

| Cmax | Cr | Ni | Mo | Ti | |||

| Austenitic class | |||||||

| Corrosion resistant | |||||||

| AISI304 | 1.4301 | 12Х18Н9 | 0,07 | 17-19 | 8-10 | ||

| AISI 304DDQ | 1.4301 | 08Х18Н10 | 0,07 | 17-19 | 9-10 | ||

| AISI 304L | 1.4307 | 04Х18Н10 | 0,03 | 18-19 | 8-10 | ||

| AISI 316 | 1.4401 | 03Х17Н14М2 | 0,03 | 16,5-18,5 | 10-13 | 2-2,5 | |

| AISI 316L | 1.4432 | 03Х17Н14М3 | 0,03 | 16,5-18,5 | 10,5-13 | 2,5-3 | |

| AISI 316Ti | 1.4571 | 08Х17Н13М2Т | 0,08 | 16,5-18,5 | 10,5-13,5 | 2-2,5 | 5*C-0.7 |

| AISI 321 | 1.4541 | 12Х18Н10Т | 0,08 | 17-19 | 9-12 | 5*C-0.7 | |

| Heat resistant and heat resistant | |||||||

| AISI 309S | 1.4833 | 20Х23Н13 | 0,15 | 22-24 | 12-14 | ||

| AISI 310 S | 1.4845 | 20Х23Н18 | 0,10 | 24-26 | 19-22 | ||

| Ferritic class | |||||||

| Corrosion resistant steel alloys | |||||||

| AISI 410S | 1.4000 | 08Х13 | 0,08 | 12-14 | |||

| AISI 430 | 1.4016 | 12Х18 | 0,12 | 16-18 | |||

| AISI 430Ti | 1.4510 | 08Х17Т | 0,08 | 16-18 | Up to 0.8 | ||

| AISI 409 | 1.4512 | 08Х13 | 0,08 | 0,5-11,75 | |||

| Martensitic class | |||||||

| Corrosion resistant steel alloys | |||||||

| AISI 410 | 1.4006 | 12Х13 | 0,08-0,15 | 11,5-13,5 | |||

| AISI 420L | 1.4021 | 20Х13 | 0,16-0,25 | 12-14 | |||

| AISI 420 | 1.4028 | 30Х13 | 0,26-0,35 | 12-14 | |||

| AISI 420 | 1.4031 | 40Х13 | 0,36-0,42 | 12,5-14,5 | |||

| AISI 420 | 1.4034 | 45x13 | 0,43-0,5 | 12,5-14,5 | |||

Popular types at collection points

The most popular non-ferrous metals at collection points:

- aluminum;

- copper;

- brass;

- zinc alloys (for example, TsAM);

- bronze;

- nickel;

- lead;

- titanium;

- tin;

- tungsten.

If you want to find out what is more profitable to rent out, then read this article.