In the metallurgical industry, one of the main areas is the casting of metals and their alloys due to the low cost and relative simplicity of the process. Molds with any shape and various dimensions can be cast, from small to large; It is suitable for both mass and customized production.

Casting is one of the oldest areas of working with metals, and begins around the Bronze Age: 7-3 millennium BC. e. Since then, many materials have been discovered, leading to advancements in technology and increased demands on the foundry industry.

Nowadays, there are many directions and types of casting, differing in technological process. One thing remains unchanged - the physical property of metals to pass from a solid to a liquid state, and it is important to know at what temperature the melting of different types of metals and their alloys begins.

What is melting point

Each metal has unique properties, and this list includes its melting point.

When melting, the metal changes from one state to another, namely, from solid to liquid. To fuse a metal, you need to bring heat closer to it and heat it to the required temperature - this process is called the melting point. At the moment when the temperature reaches the desired level, it can still remain in a solid state. If you continue the impact, the metal or alloy will begin to melt. Melting and boiling are not the same thing. The point at which a substance transitions from solid to liquid is often referred to as the melting point of the metal. In the molten state, the molecules do not have a specific arrangement, but attraction holds them close together; in liquid form, the crystalline body leaves volume, but the shape is lost.

During boiling, the volume is lost, the molecules interact very weakly with each other, move chaotically in different directions, and separate from the surface. Boiling point is the process by which the pressure of metal vapor is equal to the pressure of the external environment.

In order to simplify the difference between critical heating points, we have prepared a simple table for you:

| Property | Melting temperature | Boiling temperature |

| Physical state | The alloy transforms into a melt, the crystalline structure is destroyed, and granularity passes through | Transforms into a gas state, some molecules can fly away outside the melt |

| Phase transition | Equilibrium between solid and liquid | Pressure equilibrium between metal vapor and air |

| Influence of external pressure | No changes | There are changes, the temperature decreases with discharge |

How the process works

Elements, whatever they are: gold, iron, cast iron, steel or any other, melt approximately the same. This occurs due to external or internal heating. External heating is carried out in a thermal furnace. For internal purposes, resistive heating is used, passing electric current or induction heating in a high-frequency electromagnetic field

. The impact is approximately the same.

When does heating occur

, the amplitude of thermal vibrations of molecules increases.

Structural lattice defects

appear , accompanied by the rupture of interatomic bonds. The period of lattice destruction and accumulation of defects is called melting.

Depending on the degree at which metals melt, they are divided into:

- low-melting - up to 600 °C: lead, zinc, tin;

- medium-melting – from 600 °C to 1600 °C: gold, copper, aluminum, cast iron, iron and most of all elements and compounds;

- refractory – from 1600 °C: chromium, tungsten, molybdenum, titanium.

Depending on what the maximum degree is, the melting apparatus is selected. It should be stronger the stronger the heating.

The second important value is the boiling degree. This is the parameter at which liquids begin to boil. As a rule, it is twice the melting point. These values are directly proportional to each other and are usually given at normal pressure.

If the pressure increases, the amount of melting also increases. If the pressure decreases, then it decreases.

Difference between melting and boiling points

The melting point of metals is the point at which a solid crystalline substance transitions into a liquid state. In the composition of the melt, the molecules do not have their own location; they are held due to the force of attraction, therefore, in a liquefied state, the volume is retained, but the shape is lost.

During the boiling process, a loss of molecular volume occurs, and the molecules interact sluggishly with each other, moving chaotically in different directions, lagging behind the surface. Boiling point is the process by which the pressure level of metal vapor is balanced with the pressure of the external environment.

Boiling and melting points of metals

The table shows the melting point of metals tmelt, their boiling point tk at atmospheric pressure, the density of metals ρ at 25°C and thermal conductivity λ at 27°C.

The melting point of metals, as well as their density and thermal conductivity are given in the table for the following metals: actinium Ac, silver Ag, aluminum Al, gold Au, barium Ba, beryllium Be, bismuth Bi, calcium Ca, cadmium Cd, cobalt Co, chromium Cr, cesium Cs, copper Cu, iron Fe, gallium Ga, hafnium Hf, mercury Hg, indium In, iridium Ir, potassium K, lithium Li, magnesium Mg, manganese Mn, molybdenum Mo, sodium Na, niobium Nb, nickel Ni, neptunium Np , osmium Os, protactinium Pa, lead Pb, palladium Pd, polonium Po, platinum Pt, plutonium Pu, radium Ra, rubidium Pb, rhenium Re, rhodium Rh, ruthenium Ru, antimony Sb, tin Sn, strontium Sr, tantalum Ta, technetium Tc, thorium Th, titanium Ti, thallium Tl, uranium U, vanadium V, tungsten W, zinc Zn, zirconium Zr.

According to the table, it can be seen that the melting point of metals varies over a wide range (from -38.83°C for mercury to 3422°C for tungsten). Metals such as lithium (18.05°C), cesium (28.44°C), rubidium (39.3°C) and other alkali metals have a low positive melting point.

The most refractory metals are the following: hafnium, iridium, molybdenum, niobium, osmium, rhenium, ruthenium, tantalum, technetium, tungsten. The melting point of these metals is above 2000°C.

Here are examples of the melting point of metals widely used in industry and everyday life:

- melting point of aluminum 660.32 °C;

- copper melting point 1084.62 °C;

- melting point of lead 327.46 °C;

- melting point of gold 1064.18 °C;

- melting point of tin 231.93 °C;

- the melting point of silver is 961.78 °C;

- The melting point of mercury is -38.83°C.

Rhenium Re has the maximum boiling point of the metals presented in the table - it is 5596°C. Also, metals belonging to the group with a high melting point have high boiling points.

The density of the metals in the table ranges from 0.534 to 22.59 g/cm 3 , that is, the lightest metal is lithium, and the heaviest metal is osmium. It should be noted that osmium has a density greater than that of uranium and even plutonium at room temperature.

The thermal conductivity of metals in the table varies from 6.3 to 427 W/(m deg), thus the worst conductor of heat is a metal such as neptunium, and the best heat-conducting metal is silver.

Characteristics table

Metals and alloys are an indispensable basis for forging , foundry, jewelry and many other areas of production. Whatever the craftsman does ( gold jewelry , cast iron fences, steel knives or copper bracelets) , in order to work correctly, he needs to know the temperatures at which this or that element melts.

To find out this parameter, you need to refer to the table. In the table you can also find the boiling degree.

Among the most commonly used elements in everyday life, the melting point indicators are as follows:

- aluminum - 660 °C;

- copper melting point - 1083 °C;

- melting point of gold - 1063 °C;

- silver - 960 °C;

- tin - 232 °C. Tin is often used for soldering, since the temperature of a working soldering iron is exactly 250–400 degrees;

- lead - 327 °C;

- melting point of iron - 1539 °C;

- the melting point of steel (an alloy of iron and carbon) is from 1300 °C to 1500 °C. It varies depending on the saturation of the steel with components;

- melting point of cast iron (also an alloy of iron and carbon) - from 1100 °C to 1300 °C;

- mercury - -38.9 °C.

As is clear from this part of the table, the most fusible metal is mercury, which at positive temperatures is already in a liquid state.

The boiling point of all these elements is almost twice, and sometimes even higher than the melting point. For example, for gold it is 2660 °C, for aluminum - 2519 °C , for iron - 2900 °C, for copper - 2580 °C, for mercury - 356.73 °C.

For alloys such as steel, cast iron and other metals, the calculation is approximately the same and depends on the ratio of components in the alloy.

Read also: How to connect a DRL via a button

The maximum boiling point of metals is rhenium - 5596 ° C. The highest boiling point is for the most refractory materials.

There are tables that also indicate the density of metals . The lightest metal is lithium, the heaviest is osmium. Osmium has a higher density than uranium and plutonium when viewed at room temperature. Light metals include: magnesium, aluminum, titanium. Heavy metals include most common metals: iron, copper, zinc, tin and many others. The last group is very heavy metals, these include: tungsten, gold, lead and others.

Another indicator found in the tables is the thermal conductivity of metals . Neptunium is the worst conductor of heat, and the best metal in terms of thermal conductivity is silver. Gold, steel, iron, cast iron and other elements are in the middle between these two extremes. Clear characteristics for each can be found in the required table.

Each metal or alloy has unique properties, including its melting point. In this case, the object passes from one state to another, in a particular case, it becomes liquid from solid. To melt it, you need to apply heat to it and heat it until the desired temperature is reached. At the moment when the desired temperature point of a given alloy is reached, it may still remain in a solid state. As exposure continues, it begins to melt.

Mercury has the lowest melting point - it melts even at -39 °C, tungsten has the highest - 3422 °C. For alloys (steel and others) it is extremely difficult to determine the exact figure. It all depends on the ratio of the components in them. For alloys it is written as a numerical interval.

Melting point prediction (Lindemann criterion)

An attempt to predict the melting point of crystalline materials was made in 1910 by Frederick Lindemann [6]. The idea was the observation that the average amplitude of thermal fluctuations increases with increasing temperature. Melting begins when the vibration amplitude becomes large enough for neighboring atoms to partially occupy the same space.

The Lindeman criterion states that melting is expected when the rms value of the oscillation amplitude exceeds a threshold value.

The melting point of crystals is described quite well by the Lindemann formula [7]:

Tλ=xm29ℏ2MkBθrs2{displaystyle T_{lambda }={frac {x_{m}^{2}}{9hbar ^{2}}}Mk_{B}theta r_{s}^{2}}

where rs{displaystyle r_{s}} is the average radius of the unit cell, θ{displaystyle theta } is the Debye temperature, and the parameter xm{displaystyle x_{m}} for most materials varies in the range of 0.15-0.3.

Melting point - calculation

Lindemann's formula served as a theoretical basis for melting for almost a hundred years, but was not developed due to low accuracy.

What does melting temperature depend on?

For different substances, the temperature at which the structure is completely reconstructed to the liquid state is different. If we take into account metals and alloys, then it is worth noting the following points:

- Metals are not often found in their pure form. The temperature directly depends on its composition. As an example, we will indicate tin, to which other substances (for example, silver) can be added. Impurities make the material more or less resistant to heat.

- There are alloys that, due to their chemical composition, can transform into a liquid state at temperatures above one hundred and fifty degrees. There are also alloys that can “hold” when heated to three thousand degrees and above. Taking into account the fact that when the crystal lattice changes, the physical and mechanical qualities change, and operating conditions can be determined by the heating temperature. It is worth noting that the melting point of a metal is an important property of a substance. An example of this is aviation equipment.

Heat treatment, in most cases, almost does not change the resistance to heat. The only sure way to increase resistance to heat is to make changes to the chemical composition; this is why steel is alloyed.

The most fusible metals: properties, features, physical characteristics

Melting point is an important characteristic that is most often applied specifically to metals. It depends on many physical properties of substances - their purity and crystal structure. Which metal is the most fusible: Li, Al, Hg, Cu? Let's find out which of them can really be called such.

The most fusible metals

Melting is the process of transition from a solid to a liquid state. It occurs under the influence of heat, but also depends on a number of physical factors, such as pressure. An important role in how easily and hard a substance can be melted is also played by its composition, the size of the crystals in the lattice, and the strength of the bonds between the atoms.

The melting point of metals varies greatly and can even have sub-zero values. It ranges from -39 to +3410 degrees Celsius. Molybdenum, tungsten, chromium, and titanium are the hardest to transform into liquid. For this process they need to be heated to a temperature of at least 2000 degrees.

The most fusible metals are gallium, mercury, lithium, tin, lead, zinc, indium, bismuth, and thallium. Read more about some of them below.

Mercury

Useful in many areas, but poisonous metal was known even before our era. Mercury was used by ancient and medieval physicians to treat venereal and many other diseases; alchemists tried to make gold from it. Today it is used in electrical engineering, instrument making and organic chemistry.

Ruth is the most fusible metal on the planet. Under normal room conditions, it is always liquid, since its melting point is -39 degrees. Its vapors are very dangerous, so mercury is contained only in containers and special glass flasks. It acts like a poison on the body, poisoning it and disabling the nervous, immune, respiratory and digestive systems.

Gallium

The second most fusible metal is gallium. It becomes liquid at temperatures above 29.5 degrees Celsius, and can be softened simply by holding it in your hands for a while. Under normal conditions, gallium is very brittle, easily amenable to mechanical action, and has a light silver, somewhat bluish tint.

The metal is very dispersed in the earth's crust and is not found in the form of nuggets. In nature, it is found in various minerals, such as garnet, muscovite, tourmaline, chlorite, and feldspar. In addition, it is found in sea water. Gallium is used in high-frequency electronics, for the manufacture of mirrors and various alloys.

Tin

Tin melts at temperatures above 231 degrees Celsius. It is a ductile and soft metal, light silver in color. It exists in four allotropic modifications, two of which appear only at high pressure.

Tin is fairly dispersed in nature, but can form its own minerals, such as stannine and cassiterite. It is used as a coating for metals to enhance their resistance to corrosion, as well as for the production of tin, foil, various alloys, tableware and parts for musical instruments.

Lithium

Lithium is the most fusible metal, becoming a liquid at a temperature of 180 degrees. It is soft, easily forged and machined. It belongs to the alkali metals, but is much less active than other members of the group. It reacts slowly with moist air, and remains practically stable in a dry atmosphere

The metal is found in spodumene, lepidolite, in deposits with tin, bismuth and tungsten, found in sea water and in stellar space objects. Lithium is often used for the manufacture of galvanic cells, batteries, as an oxidizer, and also in pyrotechnics. In alloys with cadmium, copper and aluminum it is used in space, military and aviation technology.

Metal melting process

This process refers to the transition of a substance from a solid to a liquid state.

When the melting point is reached, the metal can be in either a solid or liquid state; further increase will lead to the complete transition of the material into a liquid. The same thing happens during solidification - when the melting point is reached, the substance will begin to transition from a liquid to a solid state, and the temperature will not change until complete crystallization.

It should be remembered that this rule applies only to pure metal. Alloys do not have a clear temperature boundary and undergo state transitions in a certain range:

- Solidus is the temperature line at which the most fusible component of the alloy begins to melt.

- Liquidus is the final melting point of all components, below which the first alloy crystals begin to appear.

It is impossible to accurately measure the melting point of such substances; the point of transition of states is indicated by a numerical interval.

Depending on the temperature at which metals begin to melt, they are usually divided into:

- Low-melting, up to 600 °C. These include tin, zinc, lead and others.

- Medium melting, up to 1600 °C. Most common alloys, and metals such as gold, silver, copper, iron, aluminum.

- Refractory, over 1600 °C. Titanium, molybdenum, tungsten, chromium.

There is also a boiling point - the point at which the molten metal begins to transition into a gaseous state. This is a very high temperature, typically 2 times the melting point.

Effect of pressure

The melting temperature and the equal solidification temperature depend on pressure, increasing with its increase.

This is due to the fact that with increasing pressure the atoms come closer to each other, and in order to destroy the crystal lattice they need to be moved away. At increased pressure, greater thermal energy is required and the corresponding melting temperature increases. There are exceptions when the temperature required to transform into a liquid state decreases with increased pressure. Such substances include ice, bismuth, germanium and antimony.

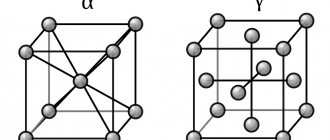

Metal crystal lattices

In its ideal form, it is generally accepted that metals have a cubic lattice (real substances may have flaws). There are equal distances between molecules horizontally and vertically.

A solid substance is characterized by constancy:

- shapes, the object retains linear dimensions in different conditions;

- volume, the object does not change the amount of substance it occupies;

- mass, the amount of a substance expressed in grams (kilograms, tons);

- density, unit volume contains constant mass.

When transitioning into a liquid state, having reached a certain temperature, the crystal lattices are destroyed. Now we can’t talk about constancy of form. The liquid will take the form in which it is poured.

When evaporation occurs, only the mass of the substance remains constant. Gas will take up the entire volume that will be provided to it. Here we cannot say that density is a constant value.

When liquids combine, the following options are possible:

- Liquids completely dissolve in one another, as do water and alcohol. The concentration of substances will be the same throughout the entire volume.

- Liquids are stratified by density, the connection occurs only at the interface. It is only temporarily possible to obtain a mechanical mixture. Mix liquids with different properties. An example is oil and water.

Metals form alloys in the liquid state. To obtain an alloy, each of the components must be in a liquid state. With alloys, phenomena of complete dissolution of one in another are possible. Options cannot be excluded when the alloy will be obtained only as a result of intensive mixing. In this case, the quality of the alloy is not guaranteed, so they try not to mix components that do not allow obtaining stable alloys.

The resulting substances, soluble in each other, when solidified, form crystal lattices of a new type. Define:

- Heliocentered crystal lattices are also called body-centered. In the middle there is a molecule of one substance, and four more molecules of another are located around it. It is customary to call such lattices loose, since the bonds between metal molecules in them are weaker.

- Face-centered crystal lattices form compounds in which the component molecules are located on the faces. Metallurgists call such crystalline alloys dense. In reality, the density of the alloy can be higher than that of each of the components included in the composition (alchemists of the Middle Ages were looking for options for alloys in which the density would correspond to the density of gold).

Strength of metals

In addition to the ability to transition from a solid to a liquid state, one of the important properties of a material is its strength - the ability of a solid body to resist destruction and irreversible changes in shape. The main indicator of strength is the resistance that occurs when a pre-annealed workpiece breaks. The concept of strength does not apply to mercury because it is in a liquid state. The designation of strength is accepted in MPa - Mega Pascals.

There are the following strength groups of metals:

- Fragile. Their resistance does not exceed 50MPa. These include tin, lead, soft-alkaline metals

- Durable, 50−500 MPa. Copper, aluminum, iron, titanium. Materials of this group are the basis of many structural alloys.

- High strength, over 500 MPa. For example, molybdenum and tungsten.

How the process works

Elements, whatever they are: gold, iron, cast iron, steel or any other, melt approximately the same. This occurs due to external or internal heating. External heating is carried out in a thermal furnace. For internal applications, resistive heating is used, passing an electric current or induction heating in a high-frequency electromagnetic field . The impact is approximately the same.

When heating occurs , the amplitude of thermal vibrations of molecules increases. Structural lattice defects appear , accompanied by the rupture of interatomic bonds. The period of lattice destruction and accumulation of defects is called melting.

Depending on the degree at which metals melt, they are divided into:

- low-melting - up to 600 °C: lead, zinc, tin;

- medium-melting - from 600 °C to 1600 °C: gold, copper, aluminum, cast iron, iron and most of all elements and compounds;

- refractory - from 1600 °C: chromium, tungsten, molybdenum, titanium.

Depending on what the maximum degree is, the melting apparatus is selected. It should be stronger the stronger the heating.

The second important value is the boiling degree. This is the parameter at which liquids begin to boil. As a rule, it is twice the melting point. These values are directly proportional to each other and are usually given at normal pressure.

If the pressure increases, the amount of melting also increases. If the pressure decreases, then it decreases.

Classification of metals by melting point

In physics, the transition of a solid into a liquid state is characteristic only of substances with a crystalline structure. The melting point of metals is often indicated by a range of values; for alloys, it is difficult to accurately determine heating to the boundary phase state. For pure elements, every degree matters, especially if these are fusible elements,

doesn't matter. The summary table of t indicators is usually divided into 3 groups. In addition to low-melting elements, which heat up to a maximum of +600°C, there are refractory elements that can withstand heating above +1600°C, and medium-melting ones. This group includes alloys that form a melt pool at temperatures from +600 to 1600°C.

Low-melting metals

Low-melting metals have a melting point below 600°C. These are zinc, tin, bismuth. Such metals can be melted at home by heating them on the stove, or using a soldering iron. Low-melting metals are used in electronics and technology to connect metal elements and wires for the movement of electric current. The melting point of tin is 232 degrees, and zinc is 419.

Table of low-melting metals and alloys (up to 600C o)

| Item name | Latin designation | Temperatures | |

| Melting | Boiling | ||

| Tin | Sn | 232 Co | 2600 So |

| Lead | Pb | 327 Co | 1750 So |

| Zinc | Zn | 420 Co | 907 Co |

| Potassium | K | 63.6 Co | 759 Co |

| Sodium | Na | 97.8 Co | 883 Co |

| Mercury | Hg | — 38.9 Co | 356.73 Co |

| Cesium | Cs | 28.4 Co | 667.5 Co |

| Bismuth | Bi | 271.4 Co | 1564 Co |

| Palladium | Pd | 327.5 Co | 1749 Co |

| Polonium | Po | 254 Co | 962 Co |

| Cadmium | Cd | 321.07 Co | 767 Co |

| Rubidium | Rb | 39.3 Co | 688 Co |

| Gallium | Ga | 29.76 So | 2204 Co |

| Indium | In | 156.6 Co | 2072 Co |

| Thallium | Tl | 304 Co | 1473 Co |

| Lithium | Li | 18.05 So | 1342 Co |

Medium melting metals

Medium-melting metals begin to transform from solid to liquid at temperatures from 600°C to 1600°C. They are used to make slabs, reinforcements, blocks and other metal structures suitable for construction. This group of metals includes iron, copper, aluminum, and they are also part of many alloys. Copper is added to alloys of precious metals such as gold, silver, and platinum. 750 gold consists of 25% alloy metals, including copper, which gives it a reddish tint. The melting point of this material is 1084 °C. And aluminum begins to melt at a relatively low temperature of 660 degrees Celsius. This is a lightweight, ductile and inexpensive metal that does not oxidize or rust, therefore it is widely used in the manufacture of tableware. The melting point of iron is 1539 degrees. This is one of the most popular and affordable metals, its use is widespread in the construction and automotive industries. But due to the fact that iron is subject to corrosion, it must be additionally processed and covered with a protective layer of paint, drying oil, or prevent moisture from entering.

Table of medium-melting metals and alloys (from 600C to 1600C)

| Item name | Latin designation | Temperature | |

| Melting | Boiling | ||

| Aluminum | Al | 660 Co | 2519 So |

| Germanium | Ge | 937 Co | 2830 Co |

| Magnesium | Mg | 650 Co | 1100 So |

| Silver | Ag | 960 Co | 2180 Co |

| Gold | Au | 1063 Co | 2660 Co |

| Copper | Cu | 1083 Co | 2580 Co |

| Iron | Fe | 1539 So | 2900 So |

| Silicon | Si | 1415 Co | 2350 Co |

| Nickel | Ni | 1455 Co | 2913 Co |

| Barium | Ba | 727 Co | 1897 Co |

| Beryllium | Be | 1287 Co | 2471 Co |

| Neptunium | Np | 644 Co | 3901.85 Co |

| Protactinium | Pa | 1572 Co | 4027 Co |

| Plutonium | Pu | 640 Co | 3228 Co |

| Actinium | Ac | 1051 Co | 3198 Co |

| Calcium | Ca | 842 Co | 1484 Co |

| Radium | Ra | 700 Co | 1736.85 So |

| Cobalt | Co | 1495 Co | 2927 Co |

| Antimony | Sb | 630.63 Co | 1587 Co |

| Strontium | Sr | 777 Co | 1382 Co |

| Uranus | U | 1135 Co | 4131 Co |

| Manganese | Mn | 1246 Co | 2061 Co |

| Konstantin | 1260 So | ||

| Duralumin | Alloy of aluminum, magnesium, copper and manganese | 650 Co | |

| Invar | Nickel iron alloy | 1425 Co | |

| Brass | Copper and zinc alloy | 1000 Co | |

| Nickel silver | Alloy of copper, zinc and nickel | 1100 So | |

| Nichrome | Alloy of nickel, chromium, silicon, iron, manganese and aluminum | 1400 So | |

| Steel | Iron-carbon alloy | 1300 Co – 1500 Co | |

| Fechral | Alloy of chromium, iron, aluminum, manganese and silicon | 1460 So | |

| Cast iron | Iron-carbon alloy | 1100 Co – 1300 Co | |

Refractory metals

The temperature of refractory metals is above 1600°C. These are tungsten, titanium, platinum, chromium and others. They are used as light sources, machine parts, lubricants, and in the nuclear industry. They are used to make wires, high-voltage wires, and are used to melt other metals with a lower melting point. Platinum begins to transition from solid to liquid at a temperature of 1769 degrees, and tungsten at a temperature of 3420°C.

Mercury is the only metal that is in a liquid state under normal conditions, namely, normal atmospheric pressure and average ambient temperature. The melting point of mercury is minus 39°C. This metal and its vapors are poisonous, so it is used only in closed containers or in laboratories. A common use of mercury is as a thermometer to measure body temperature.

Each metal and alloy has its own unique set of physical and chemical properties, not least of which is the melting point. The process itself means the transition of a body from one state of aggregation to another, in this case, from a solid crystalline state to a liquid one. To melt a metal, it is necessary to apply heat to it until the melting temperature is reached. With it, it can still remain in a solid state, but with further exposure and increased heat, the metal begins to melt. If the temperature is lowered, that is, some of the heat is removed, the element will harden.

The highest melting point among metals belongs to tungsten: it is 3422C o, the lowest is mercury: the element melts at -39C o. As a rule, it is not possible to determine the exact value for alloys: it can vary significantly depending on the percentage of components. They are usually written as a number interval.

Table of refractory metals and alloys (over 1600C o)

| Item name | Latin designation | Temperatures | |

| Melting | Boiling | ||

| Tungsten | W | 3420 Co | 5555 Co |

| Titanium | Ti | 1680 So | 3300 So |

| Iridium | Ir | 2447 Co | 4428 Co |

| Osmium | Os | 3054 Co | 5012 Co |

| Platinum | Pt | 1769.3 Co | 3825 Co |

| Rhenium | Re | 3186 Co | 5596 Co |

| Chromium | Cr | 1907 Co | 2671 Co |

| Rhodium | Rh | 1964 Co | 3695 Co |

| Ruthenium | Ru | 2334 Co | 4150 Co |

| Hafnium | Hf | 2233 Co | 4603 Co |

| Tantalum | Ta | 3017 Co | 5458 Co |

| Technetium | Tc | 2157 Co | 4265 Co |

| Thorium | Th | 1750 So | 4788 Co |

| Vanadium | V | 1910 Co | 3407 Co |

| Zirconium | Zr | 1855 Co | 4409 Co |

| Niobium | Nb | 2477 Co | 4744 Co |

| Molybdenum | Mo | 2623 Co | 4639 Co |

| Hafnium carbides | 3890 Co | ||

| Niobium carbides | 3760 Co | ||

| Titanium carbides | 3150 Co | ||

| Zirconium carbides | 3530 Co | ||

Characteristics table

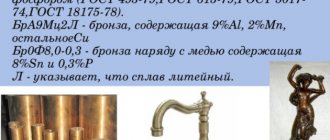

Metals and alloys are an indispensable basis for forging

, foundry production, jewelry production and many other areas of production.

Whatever the craftsman does ( gold jewelry

, cast iron fences, steel knives or

copper bracelets)

, in order to work correctly, he needs to know the temperatures at which this or that element melts.

To find out this parameter, you need to refer to the table. In the table you can also find the boiling degree.

Among the most commonly used elements in everyday life, the melting point indicators are as follows:

- aluminum – 660 °C;

- copper melting point – 1083 °C;

- gold melting point – 1063 °C;

- silver – 960 °C;

- tin – 232 °C. Tin is often used for soldering, since the temperature of a working soldering iron is exactly 250–400 degrees;

- lead – 327 °C;

- melting point of iron – 1539 °C;

- the melting point of steel (an alloy of iron and carbon) is from 1300 °C to 1500 °C. It varies depending on the saturation of the steel with components;

- melting point of cast iron (also an alloy of iron and carbon) – from 1100 °C to 1300 °C;

- mercury – -38.9 °C.

As is clear from this part of the table, the most fusible metal is mercury, which at positive temperatures is already in a liquid state.

Read also: What can be made from a refrigeration compressor

The boiling point of all these elements is almost twice, and sometimes even higher than the melting point. For example, for gold it is 2660 °C, for aluminum

- 2519 °C

, for iron - 2900 °C, for copper - 2580 °C, for mercury - 356.73 °C.

For alloys such as steel, cast iron and other metals, the calculation is approximately the same and depends on the ratio of components in the alloy.

The maximum boiling point of metals is rhenium – 5596

°C

. The highest boiling point is for the most refractory materials.

There are tables that also indicate the density of metals

.

The lightest metal is lithium, the heaviest is osmium. Osmium has a higher density than uranium

and plutonium when viewed at room temperature. Light metals include: magnesium, aluminum, titanium. Heavy metals include most common metals: iron, copper, zinc, tin and many others. The last group is very heavy metals, these include: tungsten, gold, lead and others.

Another indicator found in the tables is the thermal conductivity of metals

. Neptunium is the worst conductor of heat, and the best metal in terms of thermal conductivity is silver. Gold, steel, iron, cast iron and other elements are in the middle between these two extremes. Clear characteristics for each can be found in the required table.

Melting point, along with density, refers to the physical characteristics of metals

.

The melting point of a metal

is the temperature at which a metal changes from its normal solid state (except mercury) to a liquid state when heated.

During melting, the volume of the metal practically does not change, so normal atmospheric pressure does not affect

.

The melting point of metals ranges from -39 degrees Celsius to +3410 degrees

. For most metals, the melting point is high, however, some metals can be melted at home by heating on a regular burner (tin, lead).

Classification of metals by melting point

- Low-melting metals

, the melting point of which ranges

up to 600

degrees Celsius, for example

zinc, tin, bismuth

. - Medium-melting metals

that melt at temperatures

from 600 to 1600

degrees Celsius: such as

aluminum, copper, tin, iron

. - Refractory metals

, the melting point of which reaches

more than 1600

degrees Celsius -

tungsten, titanium, chromium

, etc. - - the only metal that is in a liquid state under normal conditions (normal atmospheric pressure, average ambient temperature). The melting point of mercury is about -39 degrees

Celsius.

Table of melting temperatures of metals and alloys

650

1000

| Metal | |

| Aluminum | 660,4 |

| Tungsten | 3420 |

| Duralumin | |

| Iron | 1539 |

| Gold | 1063 |

| Iridium | 2447 |

| Potassium | 63,6 |

| Silicon | 1415 |

| Brass | |

| Low melting alloy | 60,5 |

| Magnesium | 650 |

| Copper | 1084,5 |

| Sodium | 97,8 |

| Nickel | 1455 |

| Tin | 231,9 |

| Platinum | 1769,3 |

| Mercury | –38,9 |

| Lead | 327,4 |

| Silver | 961,9 |

| Steel | 1300-1500 |

| Zinc | 419,5 |

| Cast iron | 1100-1300 |

When melting metal for the manufacture of metal castings, the choice of equipment, material for molding the metal, etc. depends on the melting temperature. It should also be remembered that when alloying the metal with other elements, the melting temperature most often decreases

.

Do not confuse the concepts of “metal melting point” and “metal boiling point” - for many metals these characteristics are significantly different: for example, silver melts at a temperature of 961 degrees Celsius, and boils only when the temperature reaches 2180 degrees.

The melting point of a metal is the minimum temperature at which it changes from solid to liquid. When melting, its volume practically does not change. Metals are classified by melting point depending on the degree of heating.

Which metal has the highest melting point

Tungsten is the most refractory metal, 3422 °C (6170 °F).

A hard, refractory, fairly heavy material of light gray color that has a metallic sheen. It is difficult to machine. At room temperature it is quite fragile and breaks. The fragility of the metal is associated with contamination with carbon and oxygen impurities.

Note! Technically, pure metal at temperatures above four hundred degrees Celsius becomes very ductile. Demonstrates chemical inertness and is reluctant to react with other elements. It occurs in nature in the form of such complex minerals as: hübnerite, scheelite, ferberite and wolframite.

Tungsten can be obtained from its ore, through complex chemical processing, as a powder. Using pressing and sintering, it is used to create parts of regular shape and bars.

Tungsten is an extremely resistant element to any temperature influences. For this reason, tungsten could not be softened for more than a hundred years. There was no furnace that could heat up to several thousand degrees Celsius. Scientists have been able to prove that this is the most refractory metal. Although there is an opinion that seaborgium, according to some theoretical data, has greater refractoriness, this is only an assumption, since it is a radioactive element and has a short lifespan.

Low-melting metals list - masakarton.com

| H | He | |||||||||||||

| Li | Be | B | C | N | O | F | Ne | |||||||

| Na | Mg | Al | Si | P | S | Cl | Ar | |||||||

| K | Ca | Sc | Mn | Fe | Co | Ni | Cu | Zn | Ga | Ge | As | Se | Br | Kr |

| Rb | Sr | Y | Tc | Pd | Ag | Cd | In | Sn | Sb | Te | I | Xe | ||

| Cs | Ba | La | * | Pt | Au | Hg | Tl | Pb | Bi | Po | At | Rn | ||

| Fr | Ra | Ac | ** | Rf | Db | Sg | Bh | Hs | Mt | Ds | Rg | |||

| * | Ce | Pr | Nd | Pm | Sm | Eu | Gd | Tb | Dy | Ho | Er | Tm | Yb | Lu |

| ** | Th | Pa | U | Np | Pu | Am | Cm | Bk | Cf | Es | Fm | MD | No | Lr |

| Refractory metals | Expanded group of refractory metals[1] |

See also: Refractory alloys

Refractory metals

- a class of chemical elements (metals) that have a very high melting point and resistance to wear. The expression refractory metals

Most often used in disciplines such as materials science, metallurgy and engineering sciences. The definition of refractory metals applies to each element of the group differently.

The main representatives of this class of elements are the elements of the fifth period - niobium and molybdenum; sixth period - tantalum, tungsten and rhenium. All of them have a melting point above 2000 °C, are chemically relatively inert and have an increased density.

Thanks to powder metallurgy, they can be used to produce parts for various industries.

Definition

Most definitions of the term refractory metals

define them as metals having high melting points. By this definition, metals must have a melting point above 4,000 °F

(2,200

°C

). This is necessary for their identification as refractory metals[2]. Five elements - niobium, molybdenum, tantalum, tungsten and rhenium are included in this list as the main ones [3], while a broader definition of these metals allows us to include in this list also elements with a melting point of 2123 K (1850 °C) - titanium, vanadium, chromium, zirconium, hafnium, ruthenium and osmium. Transuranium elements (which are located behind uranium, all isotopes of which are unstable and are very difficult to find on earth) will never be classified as refractory metals[4].

Physical properties

Properties of the fourth group of elements

| Name | Niobium | Molybdenum | Tantalum | Tungsten | Rhenium |

| Melting temperature | 2750 K (2477 °C) | 2896 K (2623 °C) | 3290 K (3017 °C) | 3695 K (3422 °C) | 3459 K (3186 °C) |

| Boiling temperature | 5017 K (4744 °C) | 4912 K (4639 °C) | 5731 K (5458 °C) | 5828 K (5555 °C) | 5869 K (5596 °C) |

| Density | 8.57 g cm³ | 10.28 g cm³ | 16.69 g cm³ | 19.25 g cm³ | 21.02 g cm³ |

| Young's modulus | 105 GPa | 329 GPa | 186 GPa | 411 GPa | 463 GPa |

| Vickers hardness | 1320 MPa | 1530 MPa | 873 MPa | 3430 MPa | 2450 MPa |

The melting point of these elements is the highest, excluding carbon and osmium. This property depends not only on their properties, but also on the properties of their alloys.

Metals have a cubic system, with the exception of rhenium, in which it takes the form of a hexagonal close packing.

Most of the physical properties of the elements in this group vary significantly because they are members of different groups[5][6].

Resistance to creep deformation is a defining property of refractory metals. In ordinary metals, deformation begins at the melting point of the metal, and hence creep deformation in aluminum alloys begins at 200 °C

, while for refractory metals it starts at 1500 °C

. This resistance to deformation and high melting point allows refractory metals to be used, for example, as parts of jet engines or in the forging of various materials[7][8].

Chemical properties

| This section is not completed. You will help the project by correcting and expanding it. |

In open air they undergo oxidation. This reaction slows down due to the formation of a passivated layer. Rhenium oxide is very unstable because when a dense flow of oxygen is passed through, its oxide film evaporates. All are relatively resistant to acids.[5]

Indium

As a simple substance, indium is very light, malleable and soft, so much so that it even leaves a mark if it is passed over paper. It is also one of the most fusible metals, but is only affected by temperatures above 157°C. It boils at 2072 degrees.

Like gallium, indium does not form its own deposits, but is found in various ores. Due to its dispersion in nature, the metal is quite expensive. It is used in microelectronics, for the manufacture of low-melting alloys, solders, and liquid crystal screens for equipment.

View gallery

Application

Refractory metals are used as light sources, parts, lubricants, in the nuclear industry as ARC, and as a catalyst.

Because they have high melting points, they are never used as an open-air smelting material. In powder form, the material is compacted using melting furnaces.

Refractory metals can be processed into wire, ingot, rebar, tin or foil.

Tungsten and its alloys

Main article: Tungsten

Tungsten was discovered in 1781 by the Swedish chemist Carl Wilhelm Scheele. Tungsten has the highest melting point of all metals - 3422 °C

(6170 °F

)

Tungsten.

Rhenium is used in alloys with tungsten in concentrations up to 22 %

, which improves refractoriness and corrosion resistance. Thorium is used as an alloying component of tungsten. This increases the wear resistance of materials.

In powder metallurgy, components can be used for sintering and subsequent application. To obtain heavy tungsten alloys, nickel and iron or nickel and copper are used. tungsten in these alloys usually does not exceed 90%.

The mixing of the alloying material with it is low even during sintering[9].

Metal alloys

To design products from alloys, their properties are first studied. To study, the metals being studied are melted in small containers in different ratios to each other. Based on the results, graphs are built.

The lower axis represents the concentration of component A with component B. The vertical axis is temperature. Here the values of the maximum temperature are noted when all the metal is in a molten state.

When cooled, one of the components begins to form crystals. In a liquid state, eutectic is an ideal compound of metals in an alloy.

Metallurgists identify a special ratio of components at which the melting point is minimal. When making alloys, they try to select the amount of substances used in order to obtain a eutectoid alloy. Its mechanical properties are the best possible. Crystal lattices form ideal face-centered positions of atoms.

The crystallization process is studied by studying the hardening of samples upon cooling. They build special graphs where they observe how the cooling rate changes. Ready-made diagrams are available for different alloys. By marking the start and end points of crystallization, the composition of the alloy is determined.

Wood's alloy

In 1860, American dental technician Barnabas Wood was looking for optimal ratios of components to produce teeth for clients at minimum melting temperatures. He found an alloy that has a melting point of only 60.2...68.5 ⁰С. Even in hot water, metal melts easily. It includes:

- tin - 12.5...12.7%;

- lead - 24.5...25.0%;

- bismuth - 49.5...50.3%;

- cadmium - 12.5...12.7%.

The alloy is interesting for its low temperature, but has never found practical application. Attention! Cadmium and lead are heavy metals and contact with them is not recommended. Many people can experience poisoning from contact with cadmium.

Soldering alloys

In practice, many people experience melting when soldering parts. If the surfaces of the materials to be joined are cleaned of contaminants and oxides, then they can be easily soldered with solders. It is customary to divide solders into hard and soft. Soft ones are most widespread:

- POS-15 - 278...282 °C;

- POS-25 - 258...262 °C;

- POS-33 - 245...249 °C;

- POS-40 - 236...241 °C;

- POS-61 - 181...185 °C;

- POS-90 - 217...222 °C.

They are produced for enterprises manufacturing various radio equipment.

Brazing alloys based on zinc, copper, silver and bismuth have a higher melting point:

- PSr-10 - 825...835 °C;

- PSr-12 - 780...790 °C;

- PSr-25 - 760...770 °C;

- PSr-45 - 715...721 °C;

- PSr-65 - 738...743 °C;

- PSr-70 - 778...783 °C;

- PMC-36 - 823...828 °C;

- PMC-42 - 830...837 °C;

- PMC-51 - 867...884 °C.

The use of hard solders allows you to obtain strong connections.

Attention! Wed means that silver is used in the solder. Such alloys have minimal electrical resistance.

Melting point of non-metals

Non-metallic materials can be presented in solid and liquid form. Inorganic substances are presented in table. 4.

Table 4, melting point of inorganic non-metals:

In practice, organic materials are of greatest interest to users: polyethylene, polypropylene, wax, paraffin and others. The melting points of some substances are shown in table. 5.

Table 5, melting temperature of polymer materials:

Attention! The glass transition temperature refers to the state at which a material becomes brittle.

Video: melting point of known metals.

Sources

- https://dosaafvlg-kotovo.ru/stanki-drugoe/temperatura-kipeniya-stali.html

- https://tutsvarka.ru/vidy/temperatura-plavleniya-metallov-tablitsa-i-ponyatie

- https://zpu-tmb.ru/metalloprokat/pri-kakoj-temperature-plavitsya-metall.html

- https://ru.wikipedia.org/wiki/%D0%A2%D0%B5%D0%BC%D0%BF%D0%B5%D1%80%D0%B0%D1%82%D1%83%D1 %80%D0%B0_%D0%BF%D0%BB%D0%B0%D0%B2%D0%BB%D0%B5%D0%BD%D0%B8%D1%8F

- https://pressadv.ru/stali/temperatura-plavleniya-metallov-tablica.html

- https://tpspribor.ru/vidy-metalla/pri-kakoy-temperature-plavitsya-metall-v-gradusah.html

- https://metmastanki.ru/temperatura-plavleniya-metallov-i-nemetallov-tablitsy

- https://svarkaprosto.ru/tehnologii/pri-kakoj-temperature-plavitsya-metall

- https://morflot.su/temperatura-plavlenija-metallov-tablica-po/

- https://stanok.guru/stanki/metallorezhuschiy-stanok/temperatura-plavleniya-raznyh-metallov-v-tablice.html

- https://plazmen.ru/kakova-temperatura-plavleniya-zheleza/