“Iron casting” has been known to mankind since time immemorial. Nowadays, it is widely used in many areas of the national economy and is called cast iron. And while the average person may not know about crankshafts, gear housings, wheel hubs, fittings, everyone knows about frying pans, cast iron pots, radiators, bathtubs, grates and other cast iron products.

The metallurgical industry produces various simple and special types of cast iron, each of which has its own scope of application.

Features of cast iron

Cast iron is an iron-carbon alloy, smelted using fuel from magnetic, red or brown iron ore, with the addition of special inorganic substances - fluxes.

Many people do not see the fundamental differences between steel and cast iron, mistakenly assuming that they are the same thing.

Both metallurgical products are alloys - they consist of several components, one of which is iron.

Cast iron is the raw material for steel production.

Technological properties:

- for steel – deformation (stamping, rolling, forging);

- for cast iron - foundries.

Presence of carbon:

- steel – 0.02 – 2.14%;

- cast iron - 2.14 - 6.67%.

External differences:

- cast iron is dark and matte;

- the steel is silvery and shiny.

Various physical characteristics

For cast iron:

- higher casting qualities;

- easy to cut;

- has less weight;

- lower melting point.

The disadvantages of cast iron include:

- low plasticity;

- fragility;

- weakly susceptible to forging and welding.

Cast iron has a low cost and is cheaper than steel.

Additives and impurities

All supplied cast iron is regulated by GOSTs in terms of its chemical composition and impurity content. Cast iron casting, in addition to iron, contains some “ingredients” that affect the final product and add certain features:

- carbons – increase the hardness of the alloy;

- silicon – improves casting qualities;

- manganese – gives strength;

- sulfur - “thickens” and limits the fluidity of cast iron.

- Phosphorus causes cracks to form when cold and reduces mechanical parameters.

In order to improve the starting material, cast iron is alloyed, that is, various alloying additives are introduced that change the physical and/or chemical properties.

Alloying additives:

- zirconium;

- aluminum;

- molybdenum;

- titanium;

- vanadium;

- copper;

- chromium.

Cast irons with a high content of silicon and manganese in their composition are classified as alloyed.

What is

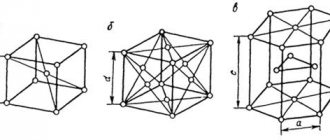

Cast iron is an iron-based alloy. Belongs to the group of ferrous metals.

Ferrous metals are iron, alloys based on it (steel, cast iron, ferroalloys), manganese. According to some classifications, chromium is included in the group.

In terms of composition, cast iron is a conglomerate of iron, carbon, plus other metals. The steel formula could contain the same basic components.

The difference between these alloys is the amount of carbon. If it is less than 2.14%, it is steel. More - cast iron.

Other components are alloys and impurities (sulfur, silicon, phosphorus, manganese).

Carbon in the structure of cast iron is represented by inclusions of graphite or cementite (iron carbide, formula - Fe3C ).

You can distinguish cast iron from steel visually. Steel is lighter and shiny, cast iron is dark matte.

Classification of cast irons

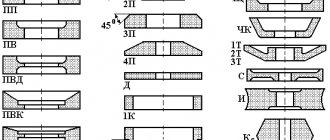

The metallurgical industry produces different types of cast iron. The grade depends on the forms of graphite or cementite and other components involved in the alloy.

Gray cast iron (GC)

Designated by the letters SCH. In cross-section it is grayish-black, which is due to the presence of graphite, this natural color. The composition also contains various impurities, including silicon. This type of cast iron, which can be easily cut and is often used in the engineering industry for “minor” parts, becomes fluid when phosphorus is added. Suitable for all types of casting, including artistic.

White cast iron

The cut is light due to the presence of iron carbide. Subject to further processing into ductile iron and steel. That's why the variety is called reprocessing. Properties – brittleness and hardness, poorly processed, not suitable for independent use. Hard, poorly processed, fragile - these properties make it unsuitable for independent use.

Malleable iron

Designation - KCH. With prolonged annealing, white cast iron becomes malleable.

Properties - not amenable to pressure treatment, but at the same time it has increased impact resistance and tensile strength. Malleable cast iron is suitable for the manufacture of parts with complex configurations.

High strength

Marked with the letters HF. It is obtained by introducing special additives into gray liquid cast iron to give the graphite a spheroidal shape. High-strength cast iron is used for the manufacture of critical parts - gears, crankshafts, pistons, which must have high wear resistance.

The form of production of conversion and foundry types is special forms - ingots. Modern technologies make it possible to obtain semi-finished products, square, sheet, plate, and bar blanks of various types of cast iron.

Depending on the purpose and chemical composition, the following types of cast iron are distinguished:

- ferroalloys

- alloyed.

They have names corresponding to the metal additives:

- zirconium;

- chromium;

- vanadium;

- copper;

- titanium.

Alloyed types are most in demand in the production of units, mechanisms, components and parts operating in particularly unfavorable environments and conditions.

Cast iron, characterized by an increased percentage of ferromanganese or ferrosilicon, is classified as a special ferroalloy. They are added in steelmaking for the release of oxygen - deoxidation.

Alloyed cast irons include:

- Antifriction;

- Heat resistant;

- Heat resistant;

- Corrosion resistant.

Antifriction types are marked with the first letters АЧ. For example, ASF is anti-friction gray cast iron. You can also see the markings AChV - anti-friction high-strength cast iron and AChK - anti-friction malleable.

The heat-resistant type is marked with the letters ZhCh. Next, the letter indicating the alloying element is indicated. For example, ZHCH-2.5. This is heat-resistant cast iron with the addition of 2.5% chromium.

Heat-resistant brands include: ChN19ХЗШ.

Corrosion-resistant: marking CHNHT, CHN1MHD

They are also called special cast irons.

Physical properties

Cast iron has become widespread due to its attractive physical properties:

Read also: Disposal of waste of different classes

- The cost of the material is significantly lower than the cost of other alloys. That is why it is used to create a wide variety of products.

- Considering the density of cast iron, we note that this indicator is significantly lower than that of steel, due to which the material becomes much lighter.

- The melting point of cast iron can vary slightly depending on its structure, but in most cases it is 1,200 degrees Celsius. Due to the inclusion of various additives in the composition, the melting point of cast iron can significantly increase or decrease.

- When choosing a material, many pay attention to the fact that the color of cast iron may differ slightly depending on the structure and chemical composition.

The boiling point of cast iron also largely depends on the chemical composition. In order to consider the physical properties of a material, attention should be paid to each of its varieties. A different structure and chemical composition cause different physical and mechanical properties to be imparted.

Production

The technology for the industrial extraction of iron from iron-containing raw materials and the production of cast iron is quite labor-intensive and complex. There is no point in describing all chemical and technological processes and delving into terminology. If you wish, you can study the issue in sources on metallurgy.

Cast iron is smelted from magnetic, red, and brown iron ore at metallurgical plants and in special blast furnaces. The fuel is coke, which can be partially replaced by fuel oil or gas.

The ore undergoes preliminary preparation before entering the blast furnace. In addition to ore and fuel, fluxes are used for smelting - limestones, which are necessary to form slag and remove sulfur from the melt.

Preparation methods depend on the quality of the ore - crushing, sorting, agglomeration, beneficiation and others.

After going through all the complex processes, the ore turns into a charge, which is continuously loaded into the blast furnace.

Through tuyeres in the lower part, hot air enriched with oxygen and natural gas are supplied, which burns under the influence of high temperatures, forming oxygen dioxide. Rising higher, the gas combines with oxygen and unburned carbon, transforming into carbon monoxide CO. It reacts with iron oxides, “taking” oxygen from them.

The result is an almost pure metal. The molten cast iron mass flows into the furnace. Non-combustible residues also flow down.

The finished cast iron is poured at certain intervals into special ladles.

While the smelting process is underway in the furnace, the hole through which the cast iron is released is plugged with a special plug made of a refractory mass. To release the metal, a hole is punched in the cork. Through special channels in the floor of the workshop, the flow of molten metal flows in a “red drain”.

Liquid slag is also discharged from the furnace through another channel.

A sample is taken from each melt. The metal is poured into a special mold and analyzed. All processes are automated. Operators are watching them.

To the average person, a blast furnace appears to be a giant test tube in which the “mystery” of turning iron ore into cast iron takes place.

Application

1) Cast iron is indispensable in mechanical engineering. A large number of parts (pistons, gears, electric motors) are made from it. 2) Cast iron is also valuable in the metallurgical industry. It has excellent casting properties and is also not expensive. 2) Cast iron continues to be widely used to create sewer pipes and plumbing fixtures. It is used to make durable bathtubs, sinks and fittings. Some radiators purchased years ago still continue to serve their owners. 3) The alloy is also used for the production of tableware. Cast iron frying pans are especially popular. 4) Cast iron stoves are not only much cheaper than their analogues, but are also not subject to deformation when heated. 5) Decorative elements or artistic elements are also created from cast iron: openwork fences, gates and gratings.

Recently, due to the high cost of producing cast iron, its use has decreased significantly. To facilitate production, lighter alloys for manufacturing began to be used instead. This trend has been going on for several years now, and for many people, cast iron now seems like a relic of the past. But there are still sectors in which it is not losing ground and is still extremely necessary. Therefore, it is not possible to completely abandon the use of cast iron.

Advantages and disadvantages of the material

It is worth discussing in comparison with steel, although low-quality carbon steel is essentially the same as cast iron.

In some parameters (density, magnetic properties, typical chemical reactions) ferroalloys are almost identical. There are significant differences in the technology of use.

Advantages:

- Moderate cost.

Carbonation is part of the smelting process from ore. A decrease in its content will inevitably increase the price of the metal.

Story

The documented history of cast iron starts from the 1st millennium BC:

- Smelting was mastered by the Chinese and their neighbors.

- From the 5th century BC, the period of decorative iron casting began.

- 600 years later, coins appeared in China.

The appearance of the alloy in Europe dates back to the 14th century, in Russia – two hundred years later. Interest increased due to the suitability of cast iron as a material for cannons and cannonballs.

Eglinton Tournament Bridge (completed c. 1845), North Ayrshire, Scotland, built of cast iron

Since the time of Queen Victoria, fireplaces have become the most popular product in the “civil segment” among the British.

Cast iron charcoal iron

The heyday of the cast iron industry in Russia dates back to the 18th century:

- Bridges and rails appeared.

- Cast iron pots were invented in the Urals - the number one cookware for the Russian stove. Later they were supplemented with frying pans.

- By the end of the century, Russia had become the world leader in the production of cast iron.

The original bridge across the Tey from the north (finished in 1878)

The openwork products of Kasli craftsmen have gained world fame.

The method of molding for casting artistic castings of complex shapes, invented by the Kasli people, is still in demand by machine builders today.