Purpose of the compressor hose

A modern compressor hose acts as an air line, which is designed to directly transfer air from the injection element to the spray gun. In most cases, a twisted version is used, which is characterized by high efficiency in use. Among other features, we note the following points:

- Can be used to connect to a rivet device, which, due to the pressure created, ensures reliable fastening.

- The impact wrench is also often powered by a compressor.

- The spray gun has become very widespread today. It can be used to spray a wide variety of substances over a surface.

- A special tool can be called airbrushes, the purpose of which is to accurately distribute paint.

- There are simply a huge number of different pistols designed for construction work.

Not all compressor equipment is equipped with hoses; in some cases it has to be purchased separately. In addition, such a compressor line has to be purchased if you create the structure yourself.

Pneumatic line

Where to begin?

The first advice to those who have decided to establish a good pneumatic line is to forget about all sorts of handicrafts such as water taps in the mains and homemade filter-moisture separators. Only high-quality additional equipment, shut-off and control valves can ensure longevity of the tool and compressor and high quality of work (especially painting). And petty savings in this matter will inevitably lead to additional costs. Tested by life.

For the same reasons, wiring from flexible hoses is extremely undesirable (due to their low mechanical strength and, as a result, air leaks). An ordinary flexible hose may be sufficient only for domestic conditions, when pneumatic tools are rarely connected, and only for blowing or inflating.

And in conditions of even small production it is impossible to do without a permanently fixed line assembled from pipes specially designed for compressed air. And already to the pipeline, using a flexible hose (minimum possible length), you can connect various pneumatic tools.

So, the pipeline. What materials should it be made from?

Pipe material

Steel and galvanized

It would seem that there is nothing wrong with the fact that standard steel water pipes are used as the material for pipelines. The benefit is obvious: “black” pipes (as well as all kinds of valves and angles for them) can be found on any construction market, the costs of their purchase and installation are minimal.

However, not all so simple. As we know, the main enemy of pneumatic networks is condensate, which causes internal corrosion of pipelines. And iron oxide, which occurs as a result of corrosion, is a powerful abrasive that can grind anything into powder, even the nitrided or carbon-saturated surface layer of the metal of pneumatic tool drive mechanisms.

That is why the pneumatic line must be assembled from materials that are resistant to corrosion. As a rule, galvanized steel, plastic or aluminum are used.

Although, as practice shows, galvanized pipes should also be treated with caution. The fact is that galvanizing can be applied only on one side, the outer side. And if not, and the pipes are completely galvanized, corrosion products will still appear in them over time. Under compressed air conditions, the resistance of galvanized zinc coating is not that high, although it is higher than that of ordinary steel.

Plastic

The main advantage of plastic (various types are used) is mobility and ease of installation. A pneumatic line from plastic pipes can be assembled literally “on the knee”; any geometric shapes can be given to pipelines in a matter of minutes. Such a pipeline can be easily expanded or moved. In addition, plastic pipes are not subject to corrosion, and their resistance to air flow is much lower than that of steel.

At the same time, plastic has low strength and heat resistance; over time, such pipes become severely deformed. Hence the air leaks.

In addition, there is a high probability of accidental damage. In practice, there have been cases of careless touching with a grinder or carrying out welding work near a pipe, with all the ensuing (and blown out) consequences.

Aluminum

The best material for pneumatic lines today is aluminum pipe with a polymer coating. Such pipes are not subject to corrosion, are sealed, and easy to install and maintain. Aluminum pipes have the lowest gas-dynamic resistance compared to any other pipeline materials. Their inner surface is polished to a mirror level, so nothing interferes with the air flow.

The costs of such pipes are more than compensated by the high quality of air, the durability of pneumatic tools and filters, the absence of leaks and, as a result, energy savings.

All other elements of the pneumatic network, such as couplings, bends, tees, shut-off and control valves, must also be made of non-corrosive materials.

Pipe diameter

We decided on the pipe material. The next important point is the choice of the diameter of these pipes. The average pneumatic line is a rather long system, and we remember that with distance from the source of compressed air injection, the pressure in the line drops. And the smaller the diameter of the pipelines, the greater the pressure loss will occur.

For example, when using a ten-meter hose with an internal diameter of 9 mm at a pressure of 6 bar, the pressure drop will be 1.7 bar (at the inlet to the gun the pressure will no longer be 6, but 4.3 bar). And if you use a hose with a diameter of 6 mm, the drop will be as much as 3.5 bar.

The same applies to all other “bottlenecks” of the pneumosistema. After all, sometimes even a powerful compressor and large receivers are not able to provide air to the spray gun due to the fact that somewhere at the pipe connections or at the entrance to the gun there is an adapter with a narrowed internal diameter. Air simply cannot pass through it in the required volume.

There is a universal rule that should be followed when choosing the diameter of the main pipeline: the internal diameter of the pipes must be no less than the internal diameter of the outlet fitting of the compressor or receiver. That is, if the compressor has a valve with an internal diameter of 1 inch (25 millimeters), then the pipelines must have an internal diameter of at least 1 inch.

A common mistake in this regard is to misunderstand the difference between the outer and inner diameter of pipes. Most often, such mistakes are made when installing plastic pipes: a pipe is purchased with the same outer diameter as the valve on the compressor.

A plastic pipe, like all pipes, is marked based on its outer diameter, but there is a catch: the wall thickness. For example, for a PVC pipe it is 4 mm (and for a reinforced one it is even more). Therefore, the total wall thickness will be: 4 + 4 = 8 mm. This means that a PVC pipe marked 25 mm will have a flow section diameter of only 17 mm.

It is more correct to select the diameter of the pipes as follows: the compressor has a fitting with an internal diameter of 1 inch (25 millimeters), which means the pipes must also have a flow diameter of at least an inch. Now we take the total thickness of the pipe walls (in our case with a PVC pipe it is 8 mm) and add 25 millimeters. Thus, we need a pipe with an outer diameter of at least 33 mm.

If you are already using a plastic pneumatic line, just for fun, you can go to the equipment and see how your pipe is selected. In most cases, the outer diameter of the pipe will be equal to the diameter of the compressor valve.

But by using an aluminum pipe, you save yourself from such mistakes, use the basic rule and immediately get what you need.

Accurate calculation of pipeline diameter

Accurately calculating the diameter of the main pipeline is a rather difficult task, which comes down to calculating air velocities and flow rates in various sections of the pipeline, as well as pressure drop values. Due to the fact that air is highly compressible, this calculation is much more complex than, for example, the calculation of hydraulic systems. As a rule, it is performed only in the most critical cases, and in practice, special nomograms or tables are more often used to calculate the pneumatic system.

There is another, relatively simple way to calculate the diameter of the main pipeline. This calculation is based on the equivalent pipe length method, which shows how many additional meters must be added to the length of a straight section of pipeline when installing each “local resistance” (fitting, tap, etc.).

The calculation is carried out as follows: based on the length of the pipeline and the performance of the compressor, the initial diameter of the pipe is selected from a special table. Next, the number of all fittings is calculated and, using a conversion table, the reserve length is calculated, which must be added to the length of the main pipeline to compensate for losses. At the last stage, we check again, using a new length, whether the initially selected diameter is suitable. If not, we increase it.

It is important to remember that:

- half of its nominal length is taken as the basis for calculating the parameters of the ring pipeline;

- The basis for calculating the parameters of a dead-end pipeline is its full nominal length.

Calculation example

Let's try to calculate the diameter of the pipeline for a pneumatic network with the following parameters:

- compressor capacity: 800 l/m;

- 1/2 length of ring pipeline: 100 m.

From the table below we see that the required diameter is 1 inch (25 mm).

Let's say to install this pneumatic network we need the following fittings:

- 4 ball valves;

- 12 corners 90°;

- 8 tees.

Using the following table, we correlate the diameter with the corresponding values of equivalent pipe lengths (different pipe manufacturers may give their own values of equivalent lengths).

We get:

| Equivalent pipe length | Nominal length | |

| 4 ball valves Ø 25 | 6 m | 24 m |

| 12 corners 90° Ø 25 | 0.5 m | 6 m |

| 8 tees Ø 25 | 0.2 m | 1.6 m |

| Total (stock length) | 31.6 m |

Thus, the length of the main pipeline, taking into account all fittings and shut-off valves, is:

100 + 31.6 = 131.6 m

Re-checking the first table shows that using a main pipe with a diameter of 25 mm is acceptable. Otherwise, the diameter of the pipeline would have to be increased.

This is some simple arithmetic.

Hoses and connectors

Often, it is the hoses (and their connections), due to improper selection and maintenance, that become the “weakest link” of the pneumatic system and the main point of leaks. Therefore, ordinary rubber hoses for water or gas welding are not suitable here. You need special compressed air hoses: flexible and durable, made of material resistant to aggressive environments. The currently popular spiral hoses or reinforced polyurethane hoses are suitable.

Although spiral hoses are still not an acquired taste. Their cheap models are not resistant to low temperatures and do not tolerate large stretches and “biting”. In addition, spiral hoses are kind of energy “eaters”. Often the culprit for a lack of air when operating a pneumatic tool is a spiral hose of insufficient diameter. In this case, you should use a spiral hose of a larger diameter, or select a smooth hose.

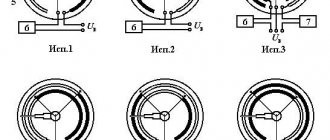

This is illustrated below.

When using a spiral hose at 6 bar pressure the pressure drop will be 2 bar

Pressure drop in smooth hoses is minimal

To keep pressure losses to a minimum, all hoses and connectors must have a sufficient internal diameter (at least 9 mm), and for hoses longer than 7 meters - at least 10 mm. To keep pressure losses to a minimum, try not to use hoses longer than 10 meters. Optimally - 3-5 meters.

As for connections, for ease of operation you should use quick-release fittings and adapters, which are produced in abundance by compressor equipment manufacturers.

Sleeve types

Like many other components, the compressor hose is classified according to a fairly large number of criteria. The rubber version is the most widespread, since it is not expensive and costs much less. The following main types of compressor hoses are distinguished:

- Straight for creating a pneumatic line.

- Twisted or spiral.

In addition, the air hose for a compressor can be classified according to the type of material used in manufacturing. Many operational characteristics of the highway, including service life, depend on it.

Choosing a hose for irrigation: 7 useful tips that will help you avoid mistakes

July and August are traditionally considered the driest months of the summer, and the efforts of many gardeners are now aimed not only at getting a good harvest, but also at preserving decorative flowers and lawns that suffer from drought.

In this difficult task it is simply impossible to do without high-quality watering, which in turn cannot do without the use of a watering hose, the range of which is now simply huge. Let's try to figure out which hose is really worth choosing for watering your summer cottage and garden.

Material selection

If you plan to use a hose not only for irrigation, but also for pumping drinking water or filling a swimming pool, then you should pay attention to what materials the hose is made of and whether it uses various harmful fillers that contain heavy metals.

Direct for organizing a pneumatic line

Modern direct-type pneumatic hose has become very widespread. We will name the following points as features:

- This design option is characterized by the largest diameter and throughput.

- Area of application: high pressure systems.

- In the production of straight compressor hoses, a reinforced housing is used, which is characterized by high resistance to temperature changes.

- Most often, straight pneumatic lines are found in industry.

In general, we can say that such a hose for a compressor is a universal design, suitable for achieving various goals.

Which material to choose?

The material from which the air hose is made affects such qualities as flexibility, weight, strength, durability, performance at different ambient temperatures. The table below describes the features, advantages, and disadvantages of the most common materials.

| Types of hoses by material | |||

| Polyurethane | Rubber | Polyvinyl chloride (PVC) | |

| Durability and flexibility | Up to 5 times stronger than rubber and PVC. High resistance to aggressive environments (except some solvents). Low flexibility. | They lie flat and do not bend. Strength and wear resistance are average. | Tendency to twist and bend. |

| Weight | Lungs | The heaviest | Very light - up to 4 times lighter than rubber (depending on the degree of reinforcement). . |

| Behavior in the cold | Frost-resistant - up to -30°C | Average sensitivity to cold. Suitable for working in frost conditions not lower than -20°C | They are afraid of the cold. Deterioration of properties already at temperatures below -5°C |

| Application area | High-pressure hoses. Typically used in twisted form or coils in workshops and workshops. | Industry, agriculture and household. | Pressure-suction or exhaust hoses. Typically used where low weight is important |

| Price | High | Average | Low |

Twisted spiral

Also often found is a twisted or spiral hose for a compressor. It is often found in almost all automobile workshops. Among the features we note the following points:

- Most often, a twisted hose is installed as the main element of pneumatic equipment, of which the compressor is part.

- A special feature of the twisted spiral is that it is manufactured using a technology that does not allow it to straighten during use.

- Due to the self-rolling property, the required compactness is ensured, which simplifies storage and use.

- There is no need to twist the compressor line after each use of the equipment.

However, there is a significant drawback, which is the small diametrical size. Straight main pipes are much cheaper and have greater capacity.

Additional accessories

Today, there are many devices in stores that are needed to connect the line to a paint sprayer, a compressor and a filter that will remove moisture and oil. As a rule, we are talking about quick-release connectors. Such devices are divided into two categories:

Their main difference will be, first of all, in diameter. Fittings will be smaller in size. The reason for this is the type of connection: inserting a fitting into a fitting. You should take into account that if you bought a moisture-oil separating filter that is not equipped with fittings, you will need to buy them separately.

In addition to them, clamps will be needed to secure the line to the compressor connectors. They allow you to make a highly reliable connection that will not bleed air.

There are a number of other ways to connect the line to pneumatic equipment, in addition to the one mentioned above, but this may turn out to be the most correct. Please note that the fitting is included with the spray gun. It will not be superfluous to purchase and attach a pressure gauge to the equipment. This method significantly increases operational convenience: if it is necessary to add paint, the tool is easily disconnected and the material is added inside; there is no need to carry the equipment along with the hoses. This will also apply to storage.

Another additional useful device would be to mount an element called a “Christmas tree” on the adapter tool. A hose is put on it, and the connecting point is secured with a clamp. It should be said that the stores offer several solutions for such adapters, which are needed for painting and have connections for both the compressor and the adapter to the spray gun. A common additional accessory to the hose is the reel that comes with the kit.

The highway turns out to be enclosed in it. The advantage of this option will be to increase the convenience of working with pneumatic tools and to improve the storage conditions for the hose. This design will also increase its durability due to high protection, reduced wear during use, as well as transportation and storage. Typically, reels are made of plastic. They are equipped with a blocking mechanism for the hose that has been pulled out.

Selection characteristics

Quite a lot of attention should be paid to the choice of line for the compressor, since an unsuitable design option significantly reduces the functionality of the device. The most important parameters are the following:

- Length.

- Diameter.

- Type of material used in manufacturing.

- Type of connection used.

- Permissible operating pressure.

When choosing, you should pay quite a lot of attention to each parameter. For example, if the diameter is insufficient, the device will not be able to transfer a sufficient amount of medium at the time of operation.

Length

One of the most important parameters can be considered length. If it is selected incorrectly, the pressure loss will be proportional. Among the features of choosing this indicator, we also note the following points:

- The wrong choice causes a strong or slight drop in pressure in the system.

- With increasing compressor power, the length of the compressor line increases significantly. That is why, when choosing, attention is paid to the recommendations specified by the manufacturer in the operating instructions.

- If the length is not enough, then using the device will be uncomfortable.

Standard lengths are 6, 8, 12 and 15 meters.

At the time of operation, you should not strain the product too much, as this can lead to serious consequences, for example, a decrease in strength.

Diameter

When choosing a compressor hose, it is important to pay attention to the diametrical size. The larger the diameter of the product in question, the greater the throughput, which also needs to be taken into account. As capacity increases, the amount of air the compressor can pump increases. Among the features of choosing such a product by diametrical size, we note the following points:

- As the indicator decreases, the efficiency value decreases.

- Too large a diameter may cause pressure loss.

- Standard dimensions for the twisted version are 6 by 8 mm. You can find other options.

The recommended diameter can also be found in the operating instructions for a particular device.

Material

A variety of materials can be used in manufacturing. The most widespread are the following:

- Plastic.

- Polyurethane.

- Rubber.

- Reinforced type sleeve.

When choosing a line, it is important to pay attention to the type of material used in manufacturing, since the scope of application and service life depend on this.

Connection type

The backbone can be connected to equipment when using a wide variety of devices. The most widespread are the following:

- Bayonet type connection.

- Air seal element.

Both options are suitable for connecting compressor lines of various diameters and lengths, as well as materials.

Operating pressure

The most important parameter can be called the working pressure. Compressed air can be supplied at different pressures; if the compressor hose does not have sufficient strength, it will simply wear out quickly. High pressure compressor hoses are made of multilayer materials using a reinforcing element. Considering the pressure parameters, we also note the following points:

- The most widely used versions are those designed for 6-8 bar.

- The operating pressure is indicated on the marking.

- The recommended value is indicated in the operating instructions.

As a rule, the indicator in question is indicated in the product labeling.

Fittings and connectors

Almost all coiled hoses and many straight hoses are sold with fittings (ends) installed. This makes it possible to immediately connect to a compressor and pneumatic tools. With the help of fittings, several hoses are also combined into one to expand the coverage area.

Each additional fitting or adapter helps reduce the pressure in the line, so their use should be kept to a minimum.

When purchasing a hose, pay attention to the sizes and types (“male”, “female”) of the installed connectors. Quality, reliable connections are essential to the efficient and safe use of air tools.

Selected hose models

There are quite a large number of hoses that are very popular. Their demand is due to the following points:

- Long service life.

- Wide range of applications.

- Attractive performance characteristics.

Let's take a closer look at some of these products.

Rubberflex straight hose

This version is sold in two versions: 10 and 100 linear meters. Among its features we note:

- The 10-meter coil is equipped with special rotating fittings, which significantly expand the scope of application of the product. In addition, the product on the end side is characterized by increased strength.

- The inner and outer sides are made using EPDM rubber. A mesh made of a special polyamide thread is used for reinforcement.

- The internal diameter is 10 by 55 mm, the burst pressure is 30 bar. This compressor hose can be used to operate at a pressure of 15 bar, the operating range is from -25 to 140 degrees Celsius.

The application of the hose is very extensive. It is suitable for spray gun and other devices.

Flexible Double Rubber Hose SBR ERDM

Spray paint sprayers of the SP type have become quite widespread. A special hose version is suitable for this device, which is characterized by the following features:

- The length is 10 meters.

- The operating pressure is 20 bar.

- A rotary type fitting is used for connection.

In manufacturing, several materials are used that are characterized by increased mechanical stability.

Double hose for SSP

This product has become very widespread. Let's call its features the following points:

- Rubber is used in production.

- There are Rilsan ones, the diameter of which is 8 by 10 mm.

This type of product is characterized by a wide range of applications.

Airbrush hose Graphique

When creating an air main, a variety of hoses can be used. The considered version is suitable for an airbrush:

- The diameter of the product is 4 by 6 mm.

- The product dimensions are relatively small.

This product is designed for fairly high pressure. The airbrush is compact, so a small hose is used for connection.

Voting by our readers

Which hose would you choose or recommend?

Fubag 170105

20.00 % ( 1 )

Caliber SHAKK-21.5

0.00 % ( 0 )

Wester 814

40.00 % ( 2 )

Mighty Seven SD – 23315

0.00 % ( 0 )

NORDBERG 2115-10

0.00 % ( 0 )

MASTAK 680-10110SQ

0.00 % ( 0 )

Rilsan Metabo 0901054940

20.00 % ( 1 )

NEO Tools 12-574

0.00 % ( 0 )

STELS 57021

0.00 % ( 0 )

Polyurethane straight hose with F1/4 connections

This product is manufactured using two rotating fasteners. Other key points include:

- The structure is reinforced with polyester threads, thereby increasing strength.

- The length is 10 meters.

- The diameter is 6 by 10 mm.

- The line can operate at temperatures from 25 to 60 degrees Celsius.

- The maximum operating pressure is 60 bar.

High strength and a wide temperature range at which the line can be used determine its wide application.

Features of pneumatic hoses

Only special pneumatic lines are suitable for spray guns. This is due to the fact that at the time of operation it should not bend, as this will lead to a break in the connection.

Reinforced versions are made with flexible cord.

In the manufacture of windings, a variety of materials are used, for example, synthetics or fiberglass.

When equipping a device intended for painting a surface, hooks are also purchased. Their purpose is to fix the line so that it cannot touch the surface.

Compressor pipes

Danfoss compressors are usually equipped with thick-walled copper-plated steel pipes, which are soldered to the refrigeration circuit pipes just as well as conventional copper pipes. The pipes are welded to the compressor housing; During the soldering process, the welding seam of the pipes is not damaged.

The pipes are closed with sealed aluminum caps, which ensure good sealing of the compressor housing. The seal on the cap ensures that the compressor has not been opened since leaving the production line. In addition, the caps retain nitrogen in the compressor housing, which is charged at the factory to protect the compressor from moisture.

The seals are easily removed with pliers or a special tool, as shown in the figure. It is no longer possible to put the fillings back. If the pipe caps are removed, the compressor must be installed in the system within 15 minutes so that moisture and dirt do not have time to enter the circuit.

Do not leave seals in the assembled system. Compressor oil coolers, if installed (in compressors with a cylinder volume greater than 7 cm3), are made of copper pipe. The pipe fitting is closed with a rubber cap. The oil cooler heat exchanger is connected to the middle part of the condenser circuit.

Twin SC compressors must have a check valve installed on the discharge line of compressor No. 2. If the firing order of compressors No. 1 and No. 2 is to be changed, a check valve must be installed in both discharge lines.

To ensure optimal soldering conditions and reduce solder consumption, all Danfoss compressor nozzles made from pipe have a collar as shown in the figure.

Hoses for professional equipment

Professional equipment must be equipped with special hoses. Among the features we note:

- The inner diameter is 6 mm.

- Minimum operating pressure 10 bar.

- The length varies over a fairly wide range and is selected depending on what pressure should be at the outlet.

- When choosing, attention is paid to the diameter of the fittings and other connectors that are used to connect equipment.

In some cases, high-quality oxygen tubes are used. They are widely used due to their high reliability and relatively low cost. Other tubes are used extremely rarely, since when exposed to external pressure they bend and can also be heavy, which complicates various work.

Compressor installation location

If there is no extra space and the compressor is allocated the “only free corner”, then there is nowhere to go - we put it there. But if you have the desire and ability to install the compressor correctly, install it in a separate room.

This room must be dry and heated (most compressors are designed for operation in the temperature range from +5 to +40°C). For obvious reasons, the compressor should not be exposed to precipitation. The room must be well ventilated, the sucked air must not contain vapors of toxic substances, explosive gases and solvents. For this reason, the compressor should not be installed directly in the vehicle preparation and painting area.

It is extremely important to ensure low dust levels in the room. Try, if possible, to minimize the number of different “dust-collecting” surfaces - all this dust will ultimately go into the compressor and not all of it will be retained by the filter.

An example of a classic dusty surface is a concrete floor. This floor should at least be painted.

If it is impossible to ensure low dust levels in the compressor room, you will have to pay attention to the condition of the air filter more often. A clogged filter not only reduces compressor output, but also causes valve failure.

The place to install the compressor must be horizontal and level. For ease of maintenance, it is advisable to install the compressor at a certain distance from the walls (0.8 - 1 m).

The compressor is the heart of the pneumatic system. At the same time, without an air line (it can be compared to arteries), it will remain only a part of the general “organism”.