Owners of most types of businesses know firsthand how much space paper waste .

Boxes, paper and documents, even when neatly folded, fill a lot of usable space, despite their low overall density and light weight.

Unpressed waste paper is extremely inconvenient to store and even more inconvenient to transport .

To eliminate these inconveniences, entrepreneurs acquire waste paper presses.

Features of application

The main purpose of a waste paper press is to prepare various paper and plastic waste from production, trade, scientific and administrative activities for recycling.

The waste paper press works with materials such as:

- Paper in all types: single sheets, brochures, books, drawings of various formats, posters.

- Used wrapping paper.

- Boxes made of regular and corrugated cardboard.

- Plastic bottles and canisters.

A cardboard and paper press can also prepare other materials characterized by low bulk density and low strength for recycling.

Pressed waste paper

Tightly compressed bags of standard size are convenient to store - they occupy up to 20 times less area and volume compared to uncompressed waste.

The transportation of such waste to the disposal site is also significantly easier and cheaper.

Technological capabilities of hydraulic presses for waste paper

When choosing a waste paper press, it is necessary to analyze the following parameters:

- Volume of the bale chamber.

- Performance.

- Drive power (for hydraulic and mechanical systems).

- Pressing force.

- Maximum density of pressed materials.

- Energy consumption per unit of production.

- Dimensions and possibility of transportation.

The maximum density depends on the force. The higher the force, the denser the material the cardboard and paper press can handle.

Machine device

To turn a pile of paper waste into small bales, you need to use a waste paper press. Then entrepreneurs hand them over to specialized companies that process recyclable materials. This brings additional income to the company, but it is worth sorting the garbage first. The equipment is a large container for receiving paper, with a piston that descends from above.

The device is equipped with the following additional components:

durable frame;- electric hydraulic pump;

- powerful pressure distributor;

- special locking mechanism;

- electromagnetic starter;

- emergency limit switch.

The main functional part of the pressing device consists of sliders and hydraulic cylinders, and a special handle allows you to control the machine. Using a pressure gauge, the pressure inside the device is monitored. Larger industrial hydraulic cardboard presses have more parts and a more complex design.

Kinds

Over many years of working with paper waste, engineers have developed many designs of waste paper presses. They differ:

- By drive type.

- By size.

- By download type.

- By pressing force.

- By volume and effective area of working chambers.

- According to the degree of mobility.

According to the type of drive, which determines other design features, a cardboard press can be:

- hydraulic;

- mechanical;

- hydromechanical.

Mechanical presses include manually driven presses.

By size they are distinguished:

- compact;

- standard;

- professional.

The loading method can be horizontal or vertical.

Most small and standard size devices use a vertical loading method. Horizontal is more typical for large-sized stationary high-power devices that use a continuous operating cycle.

Mobile press for waste paper

Installations are also divided into stationary and mobile. Stationary ones are distinguished by greater power and a permanent place of work; paper is transported to the place of their installation. Mobile ones, on the contrary, deliver to places where paper waste accumulates and they work where it is needed.

Horizontal

Hydraulically driven devices on the market are small in size and have modest performance, but they can easily cope with waste paper from a small enterprise, institution or retail outlet.

Their performance characteristics are as follows:

- Press force is approximately 2 tons.

- Productivity up to 90 kilograms of paper per hour.

- Power supply: 220 volts, single phase.

- Operating temperature range: -25 +40 °C.

- Occupied area is 2×2 meters.

- The dimensions of the loading window are 0.5×0.5 meters, height 1 meter.

- The dimensions of the bale after pressing are 0.4×0.5×0.35 m, weight – from 10 to 20 kg.

Horizontal press Statiko-40

Its large size and ease of use make it possible to install such a press in the corner of a warehouse; one person can handle the work; no loading devices are required. Such devices cost from 60 thousand rubles.

Vertical

A vertical waste paper press is a more serious device with better performance characteristics:

- Press force is approximately 6 tons.

- Productivity: 3-6 bales per hour.

- Power supply: 220 volts, single phase.

- Operating temperature range: -25 +40 °C.

- Occupied area - 2x2 meters, height - 2 meters.

- The dimensions of the loading window are 0.5×0.5 meters.

- The dimensions of the bale after pressing are 0.4×0.5×0.35 m, weight – from 10 to 20 kg.

Vertical press

The high drive power allows you to press not only paper, cardboard, but also plastic and waste from rolled ferrous and non-ferrous metals up to 1.5 mm thick. This device can also be operated by one person, but for effective operation it will be necessary to equip the workplace with hoists or a hoist. The unit will cost from 70 thousand rubles.

Baling

Baling systems are purchased by specialized companies for processing and receiving waste paper and secondary raw materials, as well as enterprises with large volumes of paper and cardboard waste.

Horizontal Baling Press

This is powerful equipment with wide capabilities:

- Pressing force from 15 to 50 tons.

- High degree of compression of the material in the bale.

- Package sizes can be customized as needed.

- The package is tied with plastic or steel tapes.

- The weight of the pressed package is from 15 to 800 kg.

Such professional equipment costs from 120 thousand rubles.

Stationary

Stationary units differ:

- permanent installation location;

- large dimensions

- high drive power and working force;

- high performance;

- additional functions and equipment.

They are installed at enterprises for the reception and processing of recyclable materials or where a large volume of paper and cardboard waste is generated daily.

Stationary press at the enterprise

The place of their installation is equipped with lifting and transport equipment, and the logistics flows for the delivery of raw materials and removal of finished packages are carefully thought out.

Mobile

The mobile waste paper press is small in size, has low power and productivity. It does not require special site preparation for its installation; it is often mounted on a wheeled cart or a passenger car trailer.

Such a device is easily delivered to the waste accumulation site and, if necessary, transported to another location.

They are popular among buyers such as:

- enterprises specializing in the removal of waste paper accumulated in other companies and individuals;

- retail outlets with a large turnover of packaging containers;

- small companies recycling recycled materials.

Hydraulic

This waste paper press is driven by a hydraulic drive. They are widely used for pressing waste paper, plastic, rubber, etc. materials.

Based on the degree of automation, control systems are divided into:

- Automatic machines.

- Semi-automatic devices.

- Manual.

Hydraulic presses also differ in characteristics such as:

- Dimensions.

- Performance.

- Pressing force.

- Speed of movement of the working plate.

Hydraulic press for waste paper

Both mobile mini-devices and powerful stationary presses can be equipped with hydraulic drives of different power.

Mechanical

Mechanical waste paper presses are called manual presses. Their distinctive features compared to other types of drives:

- Small dimensions.

- Poor performance.

- Low pressing force.

- No power required.

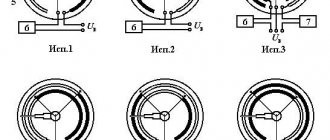

Structurally, hand presses are divided into:

- Screw.

- Rotary.

- Eccentric.

- Lever-cranked.

Screw mechanical press

Such devices are used where the volume of waste is small and there is no economic sense in purchasing a more productive device.

Hydromechanical

These waste paper presses have both hydraulic and lever drive. Their differences are that:

- The beginning of the press stroke is characterized by high speed and low force.

- The end of the working stroke, on the contrary, is at low speed and many times increased pressing force.

- Reduced energy costs.

Such presses are widely used in mechanical engineering for pressing metal waste and are ideal for economical and high-performance processing of waste paper.

Choosing a device: popular models and prices

How much it costs directly depends on the productivity and pressure force of the press. Popular models of presses (domestic and foreign production), their characteristics and approximate prices are given in the table:

| Name | Characteristic | Price, thousand rubles |

| Barinel 1500LP6 | Pressure force – 6 tons. Loading type – vertical. Productivity – 4-5 bales per hour. Dimensions of the press – 160*56*67 cm. Bale size – 50*50*50 cm. Bale weight – from 10 to 30 kg. | 80-85 |

| Statiko-8 "Baby" | Pressure force – 8 tons. Loading type – vertical. Productivity – 3-4 bales per hour. Dimensions of the press – 218*70*84 cm. Bale size – 70*60*50 cm. Bale weight – from 40 to 100 kg (depending on the material being pressed). | 100-110 |

| Hydraulic press PGP-2 mini | Pressure force – 2 tons. Loading type – vertical. Productivity – up to 500 kg in 8 hours. Press dimensions – 200*64*42 cm. Bale size – 50*40*35 cm. Bale weight – from 10 to 20 kg. | 70-80 |

| Orwak 5010E | Pressure force – 3 tons. Loading type – vertical. Productivity – up to 500 kg in 8 hours. Press dimensions – 214*111*91 cm. Bale size – 70*50*70 cm. Bale weight – from 85 to 105 kg. | 85-95 |

This and other equipment can be purchased on the following websites:

- 1-top.ru;

- wallepress.ru (there are Walle X presses here);

- packpress.ru;

- avito.ru (used equipment is also available here).

How much pressure is needed to compact waste paper?

The key characteristic of a waste paper press is the force it develops. The most low-power presses with a force of 2 to 10 tons can easily cope only with highly deformable materials - paper, cardboard, polyethylene. To press stronger structural plastics, a force of 10 to 15 tons will be required. And finally, to cope with thin sheet metal, the working force must be from 15 to 30 tons.

For pressing waste paper, more powerful presses are used than 4-10 tons, when high productivity is required. It is important to understand that a more powerful press consumes much more energy, and its use must be economically justified.

Equipment dimensions

The dimensions of the press are determined by the volume of waste paper that needs to be processed.

It is reasonable to use compact devices:

- in households;

- in small institutions;

- in warehouses and retail outlets.

Systems of this class have a modest force of up to 4 tons, and can reduce the initial volume of raw materials up to three times. The system does not require permanent installation, foundation or lifting and transport equipment, it is mobile and can be easily controlled by one operator.

Standard size presses are better suited for:

- retail chains;

- logistics terminals;

- large enterprises and institutions generating large flows of paper and cardboard waste.

These devices are heavy and require reliable fastening to the floor. They develop a force of up to 15 tons and compress raw materials 4-6 times.

VAKKPRESS 2104

Professional installations justify their high cost and high energy consumption in those places where the flow of raw materials for them is very significant - a printing plant or a large logistics and distribution complex with repackaging functions.

These units weigh tens of tons and require a separate foundation and spacious and high rooms for installation. They develop a pressing force of 30 to 60 tons and compress the original waste more than tenfold.

Making a home recycler

The principle of such a device itself is well known. It aims to increase a small force or some kind of energy to be applied to the work plate, which is movable. The mechanisms can be hydraulic or mechanical. They also differ in the type of installation. Making a recycling press with your own hands is relatively easy.

Simple option

This is the simplest waste paper press. Even a novice master can do it. Of course, it would be nice for him to have a basic understanding of welding. For the design, as a rule, what can always be found at hand is taken.

Home (rather, a garage version, installation for a shed) is done like this:

- A drawing is prepared on which future installation parameters are indicated. When determining the dimensions, you need to start from the place where the recycling machine is supposed to be located.

- An iron box is attached to the bottom of the metal channel using gas or electric welding. This will be a chamber for storing raw materials.

- At the bottom of the chamber, a system should be equipped (preferably in the form of a hinged lid) to free the device from the finished product.

- Ventilation holes must be drilled on the sides of the chamber. They can be made in one row on top, but in several pieces.

- You need to attach a working lever to the top of the channel. The longer it is, the less effort will have to be applied later in the pressing process.

- A sheet of metal (stainless steel) must be attached to the lever, which will act as a piston.

- A beam or metal pipe is welded in the center of the piston. Its length should be sufficient for the piston to reach the bottom of the chamber.

The device can be attached to the wall. The mounting height is calculated based on ease of use and human height.

Operating the press

A homemade waste paper press is easy to use. It is important that it is stable and well secured, i.e., that it does not pose a threat to the person working on it. You need to start small, and your work skills will improve with experience.

We recommend: Manufacturing a briquetting press for sawdust pressing

The process itself should be built this way:

- Shred the paper using any available method.

- Place it in a suitable container, fill it with water and let it soak.

- Mix and place in the chamber.

- Operate the lever several times.

- Remove and dry the paper.

This way you can make paper “briquettes” that are suitable for stoves and boilers. When pressing waste paper, you can do without water, although the process itself will be more difficult, since you will have to put in more effort.

Do it yourself

If you have limited financial resources at your disposal, but have welding and plumbing skills and the appropriate tools, then you can make a compact waste paper press with your own hands.

To make a hydraulic press with a force of up to 4 tons you will need:

- welding machine, electrodes or wire;

- metalworking tools;

- Bulgarian;

- steel profile no thinner than 5 mm for the base, frame and traverse;

- steel sheet with a thickness of at least 2 mm for the box;

- a steel plate with a thickness of at least 10 mm is the main working body of the press;

- hydraulic car jack of appropriate force;

- two springs to return the traverse to the upper position;

- design and blueprint reading skills.

First you need to make a rectangular base. Stands are welded to the sides, in the grooves of which the traverse will go. The racks are connected at the top by a crossbar. A traverse is suspended on springs between the posts, a jack is attached to it, and a plate is attached below. The box, open at the top, must be equipped with a securely locking door on one side. If a plate of insufficient thickness is deformed during operation, stiffeners are welded to it on top - longitudinal and transverse.

How to make your own machine

If you want to make a cardboard press with your own hands, you need to carefully familiarize yourself with various videos, instructions and drawings from the network. It is worth giving preference to manual hydraulic equipment, because it processes cardboard much better and more efficiently, acting on it with a working force of up to 3 tons. And also similar models have a high efficiency.

The main part of the homemade device will be a regular automotive hydraulic jack. You need to immediately decide on the dimensions of the product. For this purpose, precise drawings and calculations are carried out. It is also worth considering the length of the piston and the size of the pressed bale.

First, a sturdy platform for the machine is installed, which includes a plate, a large chamber for raw materials and mounts for a hydraulic jack. Experts advise making a unit to adjust the jack. This will allow you to get a universal type machine.

Next, metal racks are placed along which the stop and the plate will move. As they move, the solid waste will be compressed under the pressure of the hydraulic jack. Container doors and walls are made from tin up to 2 mm thick. This material will prevent equipment breakdowns during the production of pressed paper.

Operation and operating conditions

When purchasing medium to large stationary equipment, the manufacturer or its representative will typically provide training to personnel on how to operate their equipment efficiently and safely.

In addition, the presses are equipped with safety and locking systems that prevent the system from being turned on while the operator is adjusting something in the working chamber, and allow the equipment to be stopped instantly in the event of an emergency.

Waste paper presses are capable of operating in a wide range of weather conditions, including subzero temperatures. To do this, they use special all-weather lubricants and working materials.

Equipment maintenance must be carried out in strict accordance with the manufacturer's instructions. This will ensure long and high-performance operation of the device.

Homemade hydraulic press for waste paper

Hydraulic pressing equipment can be easily made independently. To create a pressure device for such a homemade press, a conventional hydraulic jack is suitable, the selection of which is carried out based on the size of the pressing box and the desired force.

Drawing of a hydraulic press for waste paper

It is better to make the frame from construction steel type 12GS, produced according to GOST 19282 standards. Such high-quality material will help to properly weld the frame and give it the shape of a rectangular closed frame.

The crossbar (movable crossbar) and the frame must correspond in size to the capabilities of the jack. The working surface with the container must be provided with vertical adjustment.

The design of homemade pressing equipment should include two springs located symmetrically relative to each other, which will return the traverse to its original position.

The final stage is the installation of an electrically based drive control system. The simplest option is a two-button regulator.

Household hydraulic press designs can provide a pressing force of 100–120 kN, therefore they are practically not inferior to purchased production equipment.

Mechanical press

The main part of the waste paper press is represented by a frame made of metal channels or corners, covered with sheets and supplemented with transverse beams.

Examples of press drawings for DIY assembly

Four bars or corners of metal 800 mm long are taken, and the same number of similar parts 600 mm long are taken and connected to each other by welding to form a structure of two rectangles that will play the role of the lower and upper walls of the box. For a more rigid coupling, you can use bolts or screws.

Then these parts are fastened with vertical type beams in the above manner (welding or bolts). The resulting square box is sheathed with sheets of metal and reinforced with transverse beams. A door is made on the widest side.

Next, a piston is welded from metal channels, the length of which is 450–500 mm. For a more durable state, the part is strengthened with a transverse beam. In its center, a flange is attached by welding, into which a rod with a pre-cut thread is attached.

At the final stage, two channels of at least 100 mm in width are welded to the main box opposite each other on the longest sides. Two beams are fixed to the top side of them, and in the space between them a bearing is attached in a cage. A threaded metal rod is placed in it and attached to the piston flange.

How to use a waste paper press