What to do when the bolt seat falls off during work? It will not be possible to remove it with improvised tools. You need an extractor for unscrewing broken bolts, a device with which anyone can do this operation.

It is necessary to secure it in the body of the broken part, and then turn it out in the usual way. The industry offers several types of products, each of which has its own advantages.

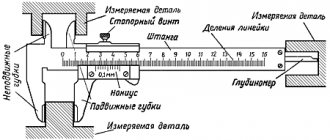

Device and types of extractor

To remove the remainder of the stuck part, it needs to be built up in some way. Savvy craftsmen use several methods. You can weld another fastening bolt with a head or drill a hole, then hammer the handle of a triangular file into it, and try to remove the fragment in this way.

However, this is not so convenient. The work requires significant effort, skill, and in some cases luck, since it is not always possible to complete this operation. It is much wiser to use a device, which comes in three types:

- Wedge-shaped. Due to the sharp edges, the device is securely held in a pre-drilled hole. All that remains is to unscrew the bolt with a regular wrench.

- Rod. The operating principle is the same as the wedge type. The only difference is the wedge shape.

- Screw spiral. Convenient device. Unlike the previous two types, the product is not driven in, but screwed into the hole. A conical shape with notches resembling a thread when rotated enters the bolt and jams. You need to continue twisting in the same direction until the fragment is completely removed.

Video: Types of “unscrewer” of broken bolts

The standard sizes of the extractor allow you to select the optimal model for the stuck debris. They are sold both individually and in sets. The set contains additional elements to make work easier. It may be difficult to remove the broken piece from the fixture. It can get stuck very firmly. Then you need to clamp it in a vice and carefully remove the device.

Principle of operation. Instructions for use

It is better to purchase the device as a kit. There is a wide range of extractors on the market for removing broken bolts. How to use them is described in detail in the instructions to help the user. Along with the main part, there are:

- unscrewing bushings with a wrench head;

- drills of the required diameter;

- bushings for correct drilling of the part.

The kit contains everything needed for operation, including user instructions. The recommended modes of operation are indicated there. The process is described step by step. First, the broken area is cleared of dirt and foreign substances.

Then, using a guide sleeve, a hole is drilled with the drill specified for this extractor. The device is driven in with a hammer, after which the bolt is unscrewed with a wrench. If a screw product is used, then the kit includes a special bushing with which it is rotated.

Methods for removing broken bolts using an extractor

There are three possible types of failure: flush, internal and external, when the upper part of the damaged part is higher. The area where you need to drill a hole is never level. It's difficult to work on. The drill goes away.

Even with the help of an additional bushing, this operation is not easy. It's easiest when the bolt protrudes from the structure. You need to use a grinder and a file to level the surface. Mark the center of the hole and start working.

When performing the operation, you need to accurately drill and drive in the device to ensure alignment of the direction. This ensures the strength of the connection. Screw devices tend to be correctly oriented. You need to start screwing in the extractor effortlessly.

When the approach is made, the load is increased. After jamming, continue unscrewing the part. If rotation is difficult, then you need to make a movement in the opposite direction, and then continue extraction again. Otherwise, there is a risk of breaking the instrument.

Benefits of using the tool

Compared to traditional methods, the device has a significant advantage. Once installed, the fixture practically becomes part of the broken part, but with higher strength. The tool was developed by professionals. Then serious tests were carried out. The optimal shape of the product, pitch of notches, sharpness and number of edges were calculated.

It is impossible to achieve a similar result with improvised means. Only an extractor for unscrewing broken bolts has unique characteristics for holding a broken part. The advantages include minimal time for the procedure. With skill and ordinary auxiliary tools, you can remove the fragment in a minute.

Useful tips

The work is nothing unusual for an experienced craftsman with experience working with metal. But for beginners it will be useful to know how to make this work more productive.

For example, if an extractor for unscrewing broken bolts does not hold the broken part and breaks off under significant force, then after installing it, liquid is dripped into the thread gap of the damaged bolt, making it easier to remove. If there is none, you can use machine oil, kerosene, or solvent. Leave the part for 10-15 minutes and it will probably come out.

Large diameter bolts are removed using large extractors. It is necessary to make a hole with a suitable drill. A labor-intensive and time-consuming operation. Using one drill in this case is not reasonable. The work will go much faster if you first make a hole with a diameter of less than 5 mm. And only then repeat the procedure with the required drill size.

How often in the process of repairing a car, furniture or equipment do situations arise that require unscrewing an old bolt or stud? And no matter how durable the metal from which these parts are made, the possibility of failure cannot be ruled out at the most inopportune moment.

When trying to unscrew an old bolt, you may encounter the fact that the fastening element cannot withstand the load and breaks, as a result of which one part of it remains in the object being unscrewed, and the second remains in the hands. The situation, to put it mildly, is very unpleasant, because if everything is left as is, the equipment can break down.

To quickly solve a problem, it is not at all necessary to throw away the item being repaired. You just need to use a special tool - an extractor for unscrewing broken fasteners, designed specifically for such cases.

Description of the extractor

As you know, in order to remove a stuck part of a fastener from an object, you first need to somehow pick it up and then try to unscrew it. Doing this with a broken bolt that is very stuck inside is extremely problematic. Therefore, for such purposes there is a convenient tool - an extractor, with which you can easily remove fragments of heavily stuck studs, screws or bolts.

Using this tool, you can simply hook a part that is stuck in an object, and then unscrew it from there. The unscrewing process boils down to preliminary drilling a small depression in the very center of the stuck element. After that, an extractor of the desired shape is inserted there - conical or cylindrical, depending on the type of part that is stuck and broken in the object, and then part of this part is easily unscrewed.

Main characteristics of devices

It is worth noting that extractors are designed to perform strictly defined tasks. They help remove a fastener with a broken head from an object. An indispensable item for car repairs. Much attention should be paid to such properties as the reliability and strength of the material used in manufacturing. The product is produced from high-carbon steel, carbide metals, and high-speed steel. S2 tool steel, oxidized steel, high-strength chrome vanadium steel and other similar alloys are often used.

It is worth noting that underground manufacturers use soft metals to manufacture products, which makes the use of these tools for their intended purpose impossible. Therefore, it is necessary to pay special attention to the manufacturer and labeling. You should not contact little-known companies or those whose products have complaints. This is fraught with loss of money.

The weight of the device depends on the metal used in its manufacture, as well as on the parameters and type. Internal extractors have lengths from 26 to 150 mm. Conical tip in the range of 1.5 - 26 mm. The weight of the structure is 8 – 150 grams. External products are available in lengths from 16 to 26 mm, weighing about 100 - 150 grams.

There are no GOST standards for these locksmith devices. Each manufacturer relies on its own specifications. Well-known brands have personal laboratories where specialists develop the best composition of materials for the manufacture of professional-level instruments. Product markings are either missing or the diameter for which the tool is suitable is indicated.

Device types

There are three different types of extractors for removing stuck fasteners, which differ slightly in the way they are used.

- Spiral screw. They are considered the most effective and reliable for removing broken parts. They are distinguished by their cone-shaped shape. Extractors of this type have a special thread, different on both sides. The threads on the right side are designed to remove bolts and studs whose threads are located on the left side. And the left-hand thread on the extractor is necessary for extracting parts whose threads are on the right side. This tool works in a special way: it is not driven into the broken part, but simply screwed into a place previously drilled in the center of a screw or bolt stuck in the object. After the extractor is screwed in, it jams and then calmly unscrews simultaneously with the fastening element. To remove a stuck bolt, you will need to put in a lot of effort, so in this case a special tool is always used - a wrench, which is necessary for high-quality clamping and rotation of some metalwork tools and, in particular, objects.

- As for wedge-shaped extractors, they are made in the form of a cone with small edges. It is used very simply: the tool needs to be carefully driven using a regular hammer into a pre-drilled hole in a broken fastener. After the device is driven in, it needs to be jammed and then unscrewed with a wrench. This type of extractor is very easy to use; no special effort is required to unscrew a stuck bolt. However, in order to do the job efficiently, the extractor must always be driven exactly into the center of the broken part, otherwise pulling it out will be extremely problematic. Moreover, while using the tool, it can sometimes be difficult to remove an already unscrewed bolt from the device itself.

- And the last type of extractor is the rod one. It has the shape of a rod with very sharp edges. This device is used on the same principle as the other two types: first, a small hole is drilled in the center of the part, after which the device itself is wedged in it. The process of unscrewing the part is carried out using a suitable wrench. This type of device has one significant drawback: fasteners that have already been unscrewed from an object are extremely difficult to reach from the tool itself.

Read also: Alloying element that gives steel heat resistance

As you can see, each type of device has its own specific features, which must be taken into account when choosing a tool .

Design features and specifications of individual devices

In addition to the main types of extractors, there are other types of designs. What are they? On store shelves you can find the following products:

- Rod. An analogue of a cylindrical rod with longitudinal cutting edges. There are grooves between them. Drives into the center of the broken fastener. No pre-drilling required. The sharp edges fit tightly into the damaged hardware, which leads to reliable engagement. The other edge is equipped with a special nozzle with a tetrahedral shank, which is grasped with a wrench or wrench to deal with broken fasteners. According to buyers, the device is not very convenient, since it gets very stuck in the element being pulled out.

- Extractor – drill. The working end of the screwdriver resembles a left-handed drill. Faces – with cutting edges. It cuts into damaged screw fasteners on its own. After a tight jam, it is possible to remove the broken object.

- For a screwdriver. What to look for when choosing? The models are compact and are available in single-sided and double-sided versions. The body resembles a hexagonal rod. Can be used as a separate hand tool or as an attachment to a screwdriver. They are sold in sets that also contain guide bushings, knobs and drills.

- Combined. The set of characteristics of the rod and wedge-shaped analogues. The shape is wedge-shaped. The grip is excellent due to the presence of a large number of sharp edges. The device is driven into the center of the hardware being removed using a hammer. Once engaged, it can be twisted both to the right and to the left.

- Eccentric. The second name is a stud gun. Produced with an offset center. Area of use: unscrewing studs. The device is interesting. Allows you to unscrew a screw type fastener with a head with worn edges or without a head. Belongs to the category of specialized devices. The only limitation when using the device is that it will cope with the task if there is a place to grab onto. If the bolt body is completely embedded in the object, the eccentric product will be powerless to do anything.

- Secret extractor. The characteristics resemble an extractor in appearance - the best for extracting secret bolts from car wheels. A distinctive feature is the thickness of the walls. They are thinner so that they can be placed freely on the head of the wheel bolt without damaging the alloy wheels.

- Reinforced. A distinctive feature is the material of manufacture. The composition contains special additives that increase the strength index. This allows you to extend the life of the device and make it more reliable.

- For pipes. The main purpose is to remove pipe scraps, as well as various adapters in the sewer system. A conventional tool will not achieve the desired result. In appearance and operating principle it resembles a screw extractor, only the dimensions are significant. There is no need to drill a hole in the pipe. It is present initially and the device is screwed into it. After jamming, it is unscrewed together with the broken part of the pipe.

- Universal. With the function of extracting pipes or individual parts thereof, if it is not possible to get hold of it with another tool. Copes with all pipes, regardless of their diameter. The main thing is that the maximum size of the device itself is sufficient. Works in a similar way to an internal thread extractor. Suitable for other uses.

- Hydraulic. Belongs to the category of professional tools. The main purpose is to turn out rolled pipes. Belongs to the manual category. The dimensions are significant. Place of use: industrial production facilities.

How to choose the right product? It is necessary to decide on the scope of its use. This is the main selection criterion. Which product is better to buy depends on many factors, including the user’s personal preferences. You cannot make mistakes when choosing. Otherwise, a positive result will not be achieved.

The reliability and durability of the structure depends on the correct choice. It is worth noting that inexpensive devices made in the Middle Kingdom cannot be of high quality.

Where to buy devices? Experts advise visiting specialized retail outlets, getting acquainted with the presented assortment, holding the selected model in your hands, and determining the quality of the assembly and materials used. If necessary, you can get advice from a professional sales manager. You can order tools online in the online store. You need to treat such a purchase carefully, as there is a chance, instead of an expensive device from a leading foreign manufacturer, to become the happy owner of a disposable budget Chinese counterfeit with questionable performance characteristics.

Set contents

As a rule, entire sets of extractors with several attachments are sold - up to five pieces, designed to extract fasteners of various shapes and sizes. It is best to purchase extractors in a set rather than individually, since they include all kinds of attachments and additional elements necessary for the job.

- The set includes drills of various sizes. There are five of them in total. Moreover, each of the five extractors offered in the set has its own unique serial number and diameter.

- Special bushings designed for high-quality unscrewing using a wrench.

- All types of rods.

- Bushings required to center drill bits on a jammed fastener.

As you can see, such tools are very convenient, unlike individual tools , because they are universal.

User manual

To learn how to use this tool, it is enough to understand its basic principle of operation, which is as follows: a small hole must be made in the broken part right in the center. It should be remembered that the diameter of the hole should in no case exceed the diameter of the surface of the broken part. After that, the device itself is inserted into the hole made, screwed into the broken bolt and unscrewed together with it.

Part Retrieval Rules

When removing a part, the following rules should be followed:

- Before starting work, it is best to lubricate the jammed bolt.

- If the bolt is very old and covered with severe rust, then it should be treated with any rust-dissolving agent.

- After this, you need to drill a hole, which is done using a special bushing that comes with the tool kit.

- Then the extractor is screwed into the stuck part or driven in.

- After the device is well wedged into the part, it is unscrewed simultaneously with it using the appropriate wrench.

Of course, the technique for working with the tool will differ slightly depending on where exactly the bolt is stuck.

Methods for removing broken bolts

So, the extraction process will directly depend on where exactly the fragment is stuck.

- In the case when the bolt breaks at the same level with the surface of the object, to remove it you will need an additional tool for marking the central holes, called a center punch. With its help, you can accurately mark a place in the center of the broken part for further drilling. After marking, a hole is drilled into which the extractor rod is then inserted, after which the fragment of the part is quietly unscrewed.

- When the bolt is broken below the surface level of the object, to remove it you will first need to insert the guide sleeve, which is included with the tool kit, into the resulting recess. Then you need to make a deep hole in the stuck part using a drill. If the diameter of the stuck bolt turns out to be very large, you should first use a small drill. A rod of the required size is inserted into the resulting hole and driven in with a hammer. Then the bushing itself is installed and the bolt is unscrewed.

- If the fracture site of the part is above the level of the fastener, then a guide sleeve is first installed, after which a recess is made in the stuck bolt. A rod is inserted into the resulting recess and a piece of the bolt is unscrewed.

Working with bolt extractors is quite simple, and no special skills are required at all. The only thing you should always remember is that you need to drill the hole strictly in the center to avoid displacement in any direction. Otherwise, problems may arise with removing the broken part.

Rating of quality products up to 1000 rubles

Innopax 38294855

A set of tools for unscrewing bolts and studs with damaged heads. It consists of four elements of different parameters, in the manufacture of which hardened stainless steel is used. To remove damaged fasteners, you must first make a small hole in the center using a drill. Afterwards, the extractor itself comes into operation, which is firmly wedged and rotates counterclockwise using a key. Items are packaged in a beautiful black plastic case. The kit includes an instruction manual.

The average price is 964 rubles.

Innopax extractor set

Advantages:

- strength of the material used;

- practicality;

- wear resistance;

- durability;

- functionality;

- ease of storage and transportation.

Flaws:

- not installed.

A-Market 33853549

The set can hardly be called a new product. It is in high demand among locksmiths due to its reliability and value for money. Works with damaged right-hand thread bolts to help remove them safely from objects. Also copes with broken studs. Pre-drilling of the fragment is required. Product length – 51 mm. Number of elements – 5 pieces.

The average cost is 870 rubles.

A-Market extractor set

Advantages:

- versatility;

- practicality;

- functionality;

- long service life;

- quality of the material used;

- no defects on sale.

Flaws:

- not defined.

Hairpin driver 6 mm Jonnesway AG 010061-6, 15492076

The device is among the TOP best-selling products. Purchased for installation or dismantling of stud connections. It is convenient and easy to use, reliable and durable. Standard size – 6. Material of manufacture – CrV. Country of origin: Taiwan. The product is sold in convenient packaging. In addition to the tools, the set includes a warranty card and a dealer certificate

The average price is 790 rubles.

Hairpin driver 6 mm Jonnesway AG 010061-6

Advantages:

- increased working resource;

- suitable for regular use;

- lifetime warranty from the manufacturer;

- value for money;

- efficiency.

Flaws:

- none.

Hairpin driver JonnesWay 12 mm AG 010061-12, 15507184

The product is manufactured by a Taiwanese company. There are no complaints about the product. Marriage items are not available for sale. The reviews are only positive. The tools are designed for unscrewing and screwing in threaded rods. High-quality materials are used in the manufacture of the model. Weight – 180 grams. Can be purchased at specialized retail outlets or ordered online in an online store.

How much does the product cost? You will have to pay 820 rubles for it.

Hairpin driver JonnesWay 12 mm AG 010061-12

Advantages:

- durability;

- reliability;

- ease of use;

- lifetime warranty from the manufacturer;

- functionality;

- value for money.

Flaws:

- not found.

Forsage 37826220

A set of extractors in the amount of 6 items M3 – M25. The products are manufactured at Chinese production facilities. Allows you to quickly and easily remove damaged bolts. It is in high demand among novice locksmiths. Sold in all specialized retail outlets. Packaging parameters: 0.08*0.02*0.11 cm.

The average cost is 527 rubles.

Forsage extractor set

Advantages:

- long service life;

- reliability;

- functionality;

- practicality;

- versatility.

Flaws:

- not installed.

Thorvik 25148909

The products are manufactured in Taiwan. It is a set of multi-start threaded tools with a conical shape. Able to deal with broken pins of small diameter, carefully removing them from the object. Alloyed chrome-molybdenum steel is used in the manufacture of this product. The devices are equipped with connecting squares with different parameters for the purpose of transmitting torque. The driver can be an adjustable tap holder, an adjustable wrench, or a twelve-sided socket head of the appropriate size with a drive. Product weight – 160 grams.

Retailers offer the product at a price of 541 rubles.

Thorvik extractor set

Advantages:

- wear resistance;

- durable material;

- high working resource;

- practicality;

- versatility.

Flaws:

- not identified.

Forsage 37826212

The recruitment is made on the territory of the Celestial Empire. Consists of 6 elements. Supplied for sale in a convenient case made of durable plastic. Packaging parameters – 0.1*0.03*0.17 mm. Belongs to the category of new products. It is in high demand not only among novice locksmiths, but also among professional craftsmen. The designs are reliable and easy to work with. No special skills required. The manufacturing material is durable, which makes the tools durable even with active use.

Purchase price – 506 rubles.

Forsage extractor set

Advantages:

- successful set;

- functionality;

- versatility;

- value for money;

- wear resistance.

Flaws:

- none.

Benefits of using the tool

Unlike futile attempts to unscrew a wedged broken part by hand, using an extractor has several undeniable advantages.

- The tool is very easy to use. To use it, you do not need to have any special repair skills.

- Extractor kits are affordable, so everyone can afford them.

- The kit includes all available extractors of various sizes and diameters.

- When using this tool, you can very quickly unscrew any broken fastener stuck in an object, furniture, equipment or car.

- If you purchase high-quality tools made of durable steel, the likelihood of the extractor breaking during the process of unscrewing a stuck part will be minimized.

Of course, you need to take into account that not every bolt can be pulled out using this tool. The main rule to follow is that the body of the stuck part must be an order of magnitude softer than the material from which the tool is made. Therefore, it is best to purchase a high-quality set in a specialized store .

What you need to know about extractors?

The edges of extractors made of soft metals quickly lick off, and such a tool becomes unsuitable for work almost from the first minutes.

Soft metals are most often used in the manufacture of tools by Chinese gray manufacturers, which makes the price of their products even lower.

You shouldn’t chase cheapness; it’s better to buy a professional tool made from quality materials once, which will serve for a long time.

Important!

Chinese instruments can also be of high quality and professional, it all depends on the manufacturer.

Fake extractors with false labeling are often found even in specialized stores; to avoid being deceived, ask the seller for certificates of conformity.

It is more profitable to buy sets of extractors, the kit of which includes several different tool sizes; sometimes there is also a wrench or a special attachment for a tetrahedron or hexagon.

There are also kits that come with a guide sleeve, which makes it much easier and simpler to drill a hole in the stuck hardware strictly in the center.

In addition, the extractor sets are placed in special cases or cases; storing and transporting the tool in such boxes is much more convenient.

Useful tips

In order for the process of unscrewing stuck fasteners to be as fast and efficient as possible, you need to follow certain rules.

- It is always necessary to use cutting oil to significantly increase the life of the extractors.

- To make it easier to remove a stuck screw or bolt, it is enough to slightly heat the stuck product before using the extractor.

- The use of drills with reverse threads greatly simplifies the process of unscrewing stuck debris.

- If the thread of a stuck part has been torn off, then it is best to use a six-sided wrench to unscrew it.

- Before starting work, it is best to first lubricate the broken part with any lubricant, such as solvent or oil.

- When using a drill with reverse rotation, you can pull out a stuck part without an extractor. However, this option may not work, so if you are not sure that everything will go smoothly, it is better not to risk it and use the extractor right away. Otherwise, the situation can significantly worsen.

- It is recommended to always wear safety glasses when working with the extractor. This is due to the fact that when working with metal, the extractor can be damaged or broken, and parts of the broken tool can fly away in different directions and get into your eyes.

- If it was still not possible to pull out the broken element, you will have to re-make a hole of a larger diameter and cut the thread.

- If you use a hammer and a core, you can move the stuck part a little and then pull it out. To do this, you need to place the bench core at an angle of exactly 45 degrees right at the base of the broken part. After this, hit it with a hammer in a circle, in four different places (counterclockwise). If you do everything correctly, the part should loosen and stretch out calmly.

The bolt extractor is a really handy tool that does an excellent job with metal hardware, bolts, screws and studs. However, it can only work in conjunction with a drill or at least a screwdriver. The extractor itself will not help remove the stuck part.

Rating of quality products up to 25,000 rubles

Heads – extractors 1/4″, ½", 6 – 27 mm, 13 pieces Sorokin 40.58, code 15476906

Products from a domestic manufacturer. Designed for pulling out bolts where the edges are completely worn out or damaged. The drive can be cranks, keys, ratchets. The set includes 13 elements. They arrive for sale in a convenient lockable case. The set is in high demand among professional locksmiths. Often purchased by auto repair shops to remove damaged screws.

The average price is 7999 rubles.

Heads – extractors 1/4″, ½", 6 – 27 mm, 13 pieces Sorokin 40.58

Advantages:

- efficiency;

- ease of use;

- high working resource;

- 1 year manufacturer's warranty;

- wear resistance;

- variety of metric thread diameters;

- quality of materials used;

- professional set.

Flaws:

- not identified.

Aist015372

Products of the Russian brand are manufactured in Taiwan. The set of external extractors consists of 12 items, including special heads and ejectors. Everything is packed in a practical case. The tools are suitable for working on damaged bolts and studs. Standard size – 10. CrV steel alloy is used in manufacturing. Package weight – 1.8 kg. The reviews are positive.

Retailers are asking 6,715 rubles for the product.

Aist 67310925 00-00015372

Advantages:

- practicality;

- functionality;

- versatility;

- reliability;

- durable alloy;

- suitable as a gift for a master;

- value for money.

Flaws:

- not installed.

Rennsteig RE-4719003

The set includes specialized tools that make it possible to quickly and smoothly remove damaged unnecessary fasteners from objects. The manufacturer packed the products in a convenient envelope with pockets. With proper use, damage does not occur, so expensive parts remain safe and sound. When working with fasteners made of soft material, the tool is screwed in by hand. If the composition is hard, you will have to use a drill. Dimensions – 1-5. Hardened chrome vanadium steel is used in the manufacture of the device. Metric thread - right - left.

You can purchase the products at a price of 4,540 rubles.

Rennsteig RE-4719003

Advantages:

- strength;

- practicality;

- versatility;

- ease of storage;

- burnished surface;

- no damage occurs during operation;

- polished cutting edges;

- long service life;

- hex head;

- two-year warranty from the manufacturer;

- designed for right-handed and left-handed threads;

- fastener removal speed.

Flaws:

- not found.

Gedore 6755550

Professional set from a German manufacturer. It is in high demand among masters of their craft. It goes on sale in a durable plastic case with separate holders for personal storage of devices. The main purpose is to remove broken screws and threaded rods. Length – 150 mm. The diameter of the drilled hole is M5 – M16. Manufacturing material – tool alloy steel. Weight – 790 grams. The manufacturer provides a 2-year warranty on its products.

The average cost is 23,740 rubles.

Gedore extractor set

Advantages:

- advanced functionality;

- ease of use;

- long service life;

- reliability;

- strength;

- convenient storage case.

Flaws:

- the price is high.

Matrix 13796567

The products are manufactured in the Middle Kingdom. There are no complaints about the product. The devices cope with cutting external threads on pipes with a diameter of 1*4, 1*2, 3*4, 1*1 1*4. The set includes a die holder with a ratchet, as well as a assembled handle. All items are in a plastic case with parameters 37*33*10 cm. The kit is in high demand among novice locksmiths.

Purchase price – 4857 rubles.

Matrix extractor set

Advantages:

- 8 items;

- functionality;

- ease of use;

- practical storage case;

- can be purchased through the online store.

Flaws:

- none.

JonnesWay 37589354

The set consists of five items. This includes conical multi-start threaded extractors with a small spiral angle. They are suitable for working with small diameter studs. Alloy chrome-molybdenum steel is used in the manufacture of devices. Supplied for sale in a durable plastic case. The tools are equipped with connecting squares with various parameters for transmitting torque. The driver is an adjustable tap holder or wrench, as well as a 12-sided socket head. The products are manufactured in Taiwan. Marriage items are not available for sale.

Purchase price – 2574 rubles.

JonnesWay extractor set

Advantages:

- advanced functionality;

- ease of use;

- quality of materials used;

- absence of marriage;

- value for money;

- positive reviews.

Flaws:

- not identified.

How to drill out a broken bolt

During repairs, sometimes something bad happens - something breaks. Sometimes a broken part leads to trouble with a larger device. For example, a broken bolt in the cylinder block. A broken bolt can cause a lot of trouble. Especially when it breaks down in a place where access is limited.

Removing a Broken Bolt

Simple option

The first thing to do is not to panic. At all. A broken bolt can almost always be removed, the main thing is to do it correctly.

Read also: Semi-automatic welding photo

Secondly, inspect the “scene of the incident.” If it breaks when unscrewing it, fill it with WD40, brilliant green or brake fluid - it is required that the broken piece is slid along the threads. You can try to anneal the threads with a blowtorch - you need to look at the circumstances. Let's see where it broke. When a broken piece sticks out above the part, you are very lucky - you can try to unscrew it. If this is possible, screw on two nuts, fixing the lower one with the upper one. We unscrew it by the bottom nut - if the broken bolt left the thread intact, it should come out. There is not enough space for two nuts - we try to unscrew them by the thread with pliers. Another way is to make a slot in the middle with a grinder. As a result, we get a screw that you can try to unscrew with a screwdriver. If it works, the problem is solved. But more often the bolt breaks either flush with the part or inside it.

Removing a Broken Bolt

If it is broken at the part level, try unscrewing it with your finger. In fact, when a broken bolt is inside the hole along the thread, it is clean, and the screw simply broke due to metal fatigue or because it was pulled earlier - it can simply come from a finger. Or we pay attention to the chip - when a piece breaks off, a edge always forms on the fracture plane - we substitute a chisel, a screwdriver - we try to unscrew it with light blows.

Such cases often occur when a non-threaded part is attached with a pin or bolt - for example, a manifold to a cylinder block.

Complex option

If you can't unscrew it using these methods, we'll drill it. The main thing is that the broken bolt is not hardened. There are several methods to try before attempting to drill out a broken bolt. The most basic thing is to take a drill with reverse and a drill bit. Sometimes this trick can be done with a regular metal screw with a drill at the end. We press on the broken part, try to unscrew it with small turns, accuracy is needed here - you need to twist it “tightly”. If these methods fail, we move on to serious action. When the diameter of the pin is small, you need to determine how to remove the fragment - there is not enough space for two options.

Method one. Using a small diameter drill, we make two holes in the fragment. Against each other. We drill shallowly - about 5 - 10 mm, preferably away from the center. Then we take a lock ring remover, narrow-nose pliers, or simply insert two nails, clamp them with pliers and try to unscrew them.

Bolt Removal Technology

Method two. You need a special tool - an extractor. It is sold in tool stores. It is something like a cone drill, has a reverse thread, very hard hardened metal. First, we select a drill according to its diameter. Carefully mark the center of the stud with a core; we need it to drill the hole. It is not necessary to go deep - just drill a little deeper than the length of the extractor. Then we wrap the extractor and try to unscrew the broken piece.

When none of the methods help, the most difficult option remains - drilling. To do this you need several sharp drills of different diameters and a strong hand. The most important thing is to catch the center of the fragment. We mark the center as accurately as possible with a core; the accuracy of drilling depends on this. Then, using the smallest drill, we drill through the broken one.

Tool for removing broken bolts Drilling a broken bolt Technology for removing a broken bolt

It is important to drill exactly along the rest, parallel to the wall, so that the alignment of the holes on both sides is maintained. Then we take the next diameter of the drill and so on until we reach the wall of the hole. If you slightly miss the center of the hole, it happens. The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out.

If you find an error, please select a piece of text and press Ctrl+Enter.

Extractor for unscrewing broken bolts

No matter how durable metal is, we all know that even it sometimes fails and fails at the most unnecessary moment. One of these situations may be the breakdown of a fastening element, in particular bolts and studs. There is nothing worse for a person with a wrench to see a broken bolt, part of which remains in the screwed-in element. And then the extractor comes to the rescue, do not be alarmed, its name is much more complicated than its design. Let's talk in more detail about working with it and its features.

Device and types of extractor

There is nothing complicated in the design of this tool. In appearance, it is a steel rod at the end of which a left-hand thread (or wedge) is cut; the shape of this miracle tool resembles a beard or a puncher. There are quite a lot of sizes, the larger the bolt being removed, the larger the extractor. I advise you to always buy this tool as a set, because you never know in advance which bolt or stud will fail. The most commonly used sizes are from M1 to M16.

According to their design features, extractors are divided into:

- Wedge-shaped. They are a cone with edges and work on the wedge principle. The extractor is driven into the pre-drilled part of the stuck bolt and then turned out with a key. Working with it, of course, is simple, but before drilling a hole, be sure to keep in mind that you need to drill strictly in the center, without moving the hole to the side. Otherwise, all of the extractor's rotating force will be displaced and you will not be able to remove the broken bolt. You can also break the extractor itself.

- Rod type. Made in the form of a rod with edges, very similar to a wedge-shaped extractor. It gets hammered into the broken part and is turned out with a wrench. Like the first type, the extractor can be quite difficult to remove from an already unscrewed part.

- Spiral type. The most common and effective extractor for unscrewing broken bolts. The same cone only with a left-hand thread (right if we unscrew the left bolt). The extractor is not clogged, but is screwed into the bolt hole, wedged together with the part and removed.

The operating principle of the extractor for unscrewing broken bolts

If you have read the description of the types of this tool, then you can already imagine the whole simple procedure for removing bolts. But without systematization, this material will be incomplete, and let’s look at everything in more detail.

The first step is to mark the center of the broken bolt. For this we need a center punch and a hammer.

Then we drill a guide hole for the extractor. When drilling, be careful and do not move the axis of the hole to the side. Experienced craftsmen recommend drilling to a depth of three drill diameters.

Insert the extractor into the drilled hole and tap it with a hammer to securely fix it. After this, use the tap driver to begin screwing the extractor into the broken bolt. When it goes all the way, it will begin to unscrew the bolt. When working with the extractor, rotate only around its axis, and in no case shift the axis, otherwise you may break the tool.

Once you have unscrewed part of the bolt, you can use pliers or a clamp to continue unscrewing the broken element more quickly.

Some tricky tips

- In order to remove a bolt or stud faster, they should be heated.

- If the screw thread is stripped, you can try to unscrew it with a hex key. There is a high probability that the attempt will end in success.

- When working, use lubricating oil or acetone.

- Using a reverse thread drill bit can easily remove the broken piece.

- You can use a core and a hammer. Holding the core at a 45 degree angle to the part, hit it counterclockwise. Perform the procedure in several places; if the bolt does not budge, you should use another method.

- If all attempts to unscrew the bolt or stud fail, you will have to drill a hole of a larger diameter and re-tap the thread.

Purpose and principle of operation of the extractor

Sometimes it happens that the screw fastening is damaged for various reasons, and without special tools it is not possible to unscrew the fastener.

The fastening rod itself may break or its head may fall off; also, the edges of the head slot are often licked off, so that there is nothing to catch on; in such cases, specially designed extractors are used to dismantle the screw fasteners.

This tool is indispensable for removing broken bolts from the landing site, for example, car mechanics use it to unscrew studs from the cylinder block, fasteners from the cylinder head, from the camshaft bed, from the exhaust manifold, to unscrew damaged or stuck wheel bolts from the hub and others similar cases.

Extractors can also be used to remove self-tapping screws, screws and dowel nails when the slots of their heads are licked.

With the help of small-sized extractors, it is very convenient to disassemble folding knives and other structural devices that use screw fastenings.

The screw connection can be damaged in the most unexpected situation, and then the broken fastener can be quickly and effortlessly removed without damaging the seat only using an extractor.

Each type of this tool has its own specific operating principle, which will be most suitable and effective in certain cases.

Operating principle of a wedge extractor

You need to drill a small hole of sufficient depth in the center of the broken bolt or stud, and then drive a screwdriver wedge into it.

Due to the corners of the tool, a tight engagement occurs, thanks to which it becomes possible to unscrew the broken fastener rod.

Next, using regular open-end wrenches or special tap holders, grab the shank of the screwdriver and unscrew the damaged hardware.

Operating principle of internal thread extractor

Partially similar to the previous version.

Here, too, in the center of the rod of the broken fastener, a hole is drilled into which a screwdriver is screwed, usually with a left-hand thread; accordingly, we turn the tool counterclockwise.

Due to the fact that the unscrew thread is cone-shaped, it fits tightly into the drilled hole and jams in it.

Important!

To prevent idle scrolling, it is necessary to apply sufficient force to press the tool tightly against the hardware being removed for reliable adhesion.

Thus, the extractor firmly engages with the body of the broken fastener, and with further turns it unscrews along its thread.

Such a screw extractor can be useful in the most unpredictable situations where screw fastenings are used.

Operating principle of external extractors

It differs in that it is used only in cases where the damaged fastener is of sufficient diameter and protrudes from the base.

Most often, external screwdrivers are used when there is a bolt head, but its edges are licked and there is nothing to grab onto with a regular wrench.

The process of fixing a bolt with licked head edges takes place from the outside; for this purpose, an extractor of the required size is selected and hammered onto the bolt head.

There are sharp edges inside the outer extractor that dig into the material of the licked bolt head.

Thus, engagement occurs, after which the damaged fastener is turned out.

External extractors are mainly used for unscrewing bolts whose heads have licked off edges and in similar situations.

You can also use an external extractor to unscrew nuts with damaged edges, but only if it is possible to attach a screwdriver to the nut.

Important!

To work with extractors, it is advisable to use a special wrench or a regular open-end wrench, but not pliers.

How to drill out a bolt without damaging the thread? ⋆ Proraboff.rf

When tightening or unscrewing a bolt, you can easily break the head and this is not as difficult as it seems. Subsequently, some craftsmen decide to roughly remove the bolt, which leads to damage to the entire thread.

But, unfortunately, few people know that a bolt without a head can be removed in an easier way and without breaking the thread, with basic tools at home. In this article we will tell you how to drill out a bolt without damaging the thread.

Bolt Drilling Tools

To remove the bolt you will need the following tools:

1. Drill and metal drills.

Read also: Metals with low thermal conductivity

2. Several screwdrivers with different sizes of tips.

3. A gas wrench or, as a last resort, high-quality pliers.

4. Triangular file.

5. Needle files of various sizes and shapes.

6. Tap to create the opposite thread to the broken bolt.

Some tools can be replaced, but the main thing is that you have a drill, drill bits and pliers. You can also buy a WD40 solution, which needs to be poured 15 minutes before the bolt removal process begins. This is done to make it easier to unscrew the bolt.

Instructions for drilling a bolt

1. Put on the thinnest drill bit and start drilling exactly in the center of the bolt. Make sure that the drill does not go to the side, otherwise the drilled hole will not be straight, which will lead to great complications when removing it.

2. Gradually change the drill bits to larger ones until you have drilled the hole to one-third the diameter of the entire bolt.

3. Drive a triangular file into the hole. If the file does not fit tightly in the hole, then you will not be able to remove the bolt.

4. When the file is firmly driven into the hole, you can begin to try to remove the bolt; this is done using pliers or a wrench. To do this, clamp the file with pliers and begin to twist the bolt.

5. If you are unable to unscrew the bolt, you can take a different route. To do this, drill the hole to such a size that you can insert another bolt of a smaller size, diameter and with the opposite thread into it. But before that you will need to make a thread opposite the broken bolt, for this you will need a tap. After that, try to unscrew the bolt using another one as a head.

6. If you still cannot move the bolt, continue drilling the hole in diameter and length. As a result, you will be able to greatly release the bolt and the pressure on it, which will allow you to easily remove it using a suitable sized tap.

Now you know how to drill out a bolt without damaging the thread. If there are no results, check to see if you are turning the bolt in the opposite direction. As a last resort, you can simply break the bolt using a drill and a file. But with this option, you will most likely also break the thread.

Difficulty of choice

It’s worth mentioning right away that the quality of the equipment in question is the determining parameter that should influence the choice. Extractors should not be purchased randomly and without careful analysis of all their operating properties. The characteristics that determine the quality of the extractor include the strength properties of the material used to make it. The steel must be very hard, but not very brittle, otherwise the tool will simply break during operation. Only a few grades of steel from different manufacturers have such characteristics, but in their composition they are more or less very similar to each other. Unfortunately, some manufacturing companies from Asian countries make extractors from almost any type of steel that is somewhat durable. Indeed, such products have a lower cost, but their purchase will not bring much benefit, and the tool itself can only be used a couple of times, then it will break. Therefore, experts advise buying only those sets whose manufacturer does not raise reputational doubts, while at the same time paying attention to the markings of the steel used in the tools.

Modern samples of extractors are sold both separately and as part of various sets. Professionals recommend having a complete set with extractors of different diameters and sizes on hand, and it would also be nice if the kit comes with additional tools. Naturally, the cost of a high-quality and complete set may seem quite high, but all expenses will pay off after the first use.

It's simple: how to drill out a broken bolt?

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt. The main thing is not to panic, but to carefully read this information material to the end.

The most typical failure situations

A bolt can break in different ways. The easiest case is when it breaks flush with the part. In this case, there will be no special problems in how to drill the bolt. But, nevertheless, it will be necessary to carry out some preparatory measures that will allow you to extract the remaining part without much difficulty. And they are as follows:

- The most important thing is to prepare yourself for the fact that you can only drill out a broken bolt without damaging the thread if you apply maximum patience and calm. Haste in this case is the main enemy

- First of all, you need to use a tool to quickly unscrew rusty bolted joints. There are a great many of them in the markets. But the overwhelming majority of such funds are absolutely useless. A self-respecting car enthusiast and mechanic should always have in stock a penetrating agent for loosening nuts and bolts, which contains substances that have the ability to penetrate any joint. Recommendations for choosing can be obtained from any well-known car service center. The most effective lubricants are those based on molybdenum disulfide and graphite.

- Next, you can try one of the simplest options on how to drill out a broken bolt without any problems. To do this, you need to use a thin drill and a low-speed drill to drill a slot for a screwdriver.

- You can purchase a gas torch for loosening bolts at any hardware store. If there is such a burner, then with its help it is necessary to slightly warm up the part itself in such a way that the remaining piece does not heat up. In this case, there should be a fire extinguisher nearby.

- Then try using a screwdriver with a wrench to slowly loosen the rest of the bolt. If the bolted connection is not old, then the piece should come off.

But not many people know how to drill a bolt correctly if it breaks inside the socket. Typically, such breakdowns occur when tightening the cylinder head studs of a car engine. In this case, some skills are needed when using a drill and tap.

Preparatory activities are the same as in the previous version. Then, before drilling out the broken bolt, you need to pour liquid into the hole for quick unscrewing and leave until completely penetrated into the joint for 2-3 hours.

Then, using a low-speed drill and a drill with a diameter half as big as the bolt, carefully drill a hole in the center, without tilting and at low speeds, to a depth of one-third of the total length of the fragment. Using a left-hand thread tap, cut a thread to the full depth of the hole. Then a high-strength bolt with the same thread is screwed in. Using a spanner wrench, lightly tapping and rotating the bolt, remove the remaining part of the bolt.

Replace the old fasteners with new ones: https://avselectro.ru/catalog/4976-bolty - excellent quality bolts from global manufacturers in a large assortment.

How to drill out a high strength bolt?

The sequence of actions is the same until the thread is cut in the drilled hole. In this case, before drilling the hardened bolt, it is necessary to make the following part: a bolt with a wrench head is machined from carbon steel. The end of the bolt is given a tetrahedral conical shape using a forging hammer.

Next, the bolt is driven into the drilled hole to the full depth where it should jam. Using a spanner wrench, loosen and gradually unscrew the broken piece of the bolt.

But how to drill out a broken bolt if no other method helps? In this case, the only drastic way is to completely drill out the rest of the part. This is the most difficult and responsible way to drill a bolt without damaging the threads in the mechanism parts.

To begin with, a hole is drilled in the fragment using a thin drill. Then thicker. And so on until most of the remaining piece is drilled out. This is one of the most effective ways to drill a bolt from a car hub.

Other “folk” methods

Craftsmen in various videos offer other more radical ways of how to properly drill out a broken bolt. One of the popular methods is when, using an electric welding machine, they weld a piece of metal in the form of a handle to a fragment and try to unscrew it.

Sometimes this works, but this usually damages the threads and fades the paint on the mechanism. And if the handle breaks off, then drilling a hole will be very difficult. Therefore, if you don’t have a basic idea of how to drill a bolt without damaging the thread, it’s better not to try it, as the consequences can be very sad.

How to drill out a broken bolt from an aluminum block?

It happens quite often that a small diameter bolt in an aluminum car engine block breaks. It is not easy to drill out such a remaining bolt. The Internet offers a lot of options on how to drill out a broken M6 bolt from aluminum without much difficulty.

In fact, the most reliable method is classic drilling followed by tapping. In this case, all the preparatory operations discussed above must be carried out very carefully.

All sorts of Chinese extractors are advertised, but they very often break inside the hole, which greatly aggravates the situation. In addition, this tool, with its conical shape, creates additional friction between the walls of the bolt and the block, which makes extraction difficult.

Rating of designs up to 500 rubles

Forcekraft 37826218

A set of thread extractors from a Chinese manufacturer includes 5 elements (M3 – M18). Allows you to quickly remove fasteners with broken heads. Manipulations do not require much effort and free time. In this case, the master’s actions do not lead to damage to the main item. It is supplied to stores in regular packaging, the parameters of which are 0.06 * 0.02 * 0.1 cm. For storage, it is advisable to purchase a special case.

Purchase price – 498 rubles.

Forcekraft extractor set

Advantages:

- significant work resource;

- reliability;

- strength of the materials used;

- wear resistance;

- practicality.

Flaws:

- none.

Partner 37826211

The kit from the Chinese manufacturer has 6 components (M3 – M25). Allows you to quickly and efficiently remove broken fasteners from an object. The tools are made from durable steel alloy, therefore they have high wear resistance and a long service life during active use. It is in high demand among both beginners and professional craftsmen due to the price-quality ratio. There are no problems with the purchase. The product can be found in specialized retail outlets or ordered online in an online store.

The average cost is 471 rubles.

extractor set Partner

Advantages:

- ease of use;

- product strength;

- durability;

- reliability.

Flaws:

- not identified.

Patron 37826213

A convenient and practical set is not produced in the Celestial Empire. There are no complaints about the product. User reviews are positive. Includes five items (M3 – M18). The devices make it easy and simple to remove broken bolts from objects. It is supplied for sale in standard packaging with parameters 0.1*0.02*0.17 cm.

The average price is 440 rubles.

Patron extractor set

Advantages:

- affordable price;

- practicality;

- quality of the material used;

- durability.

Flaws:

- not installed.

Forcekraft 40791699

Chinese-made products are in high demand among domestic consumers due to their reasonable cost and good characteristics. The set includes 5 elements for removing broken fasteners. Working with devices is easy and simple. Supplied to stores in durable plastic cases.

The purchase price is 314 rubles.

Forcekraft extractor set

Advantages:

- value for money;

- practicality;

- wear resistance;

- long service life.

Flaws:

- not identified.

Sparta 38114916

Products are produced in the Middle Kingdom. Steel and plastic are used in production. Suitable for removing broken studs and right-hand threaded bolts. The set contains 5 elements made of durable steel alloys. The product is in high demand among domestic consumers.

The average cost is 256 rubles.

Sparta extractor set

Advantages:

- versatility;

- reliability;

- durability;

- practicality.

Flaws:

- none.