The times when wooden huts were built without a single nail have sunk into oblivion. Progress can be seen in everything. New materials appear, technologies change. And only one thing remains unchanged - wood is used everywhere and is an elite material. The wealth of colors and textures allows it to be used for all types of work, and the environmental friendliness and properties of this material make it universal. It is also worth noting that woodworking equipment has changed a little, although its basic principles remain the same. Currently, a plane is also used to process wood, but not a manual one, but an electric one. And also, for convenience, a stand for an electric planer is used.

Homemade machine for a circular saw

Most carpenters and woodworking craftsmen want to have a universal unit on their farm, but many do not know how to make such a device on their own. In this guide, you will learn how to make a universal router table with your own hands. The advantages of a universal woodworking machine are that you do not need to have several units and walk with a workpiece from one to another while working. Unique and universal, it will be located on one table and perform the actions of several units. Of course, there are limitations to such a device, and it is not possible to make an absolutely universal woodworking machine. But making a table for a router with your own hands, which will include an electric planer and a circular saw, is quite possible. To make the idea a reality, you need to take care of the consumables, as well as the tools that will be needed to create an accurate and level table on which the devices will be mounted. Since there will be more than one device on the table, it is necessary to make a wider and longer table. In order not to waste materials in vain, first you need to draw a diagram and location of future devices on a sheet of paper. This is an extremely significant argument, since the efficiency of the machine directly depends on the proper arrangement of all elements. Take care in advance about the position of each node. If the task seems very complicated, you can use ready-made diagrams and drawings. Thus, craftsmen make a table for a circular saw with their own hands, without the help of experts.

What kind of work can an electric planer do?

Let's first figure out why a plane is needed. The tool is used for many types of work. Enter here:

- removing excess wood;

- removal of nicks and burrs;

- chamfer rounding;

- surface leveling;

- giving a pleasant appearance to surfaces;

- selection of grooves.

A stand for an electric planer is needed so that the tool can be mounted on a table and used as a stationary jointer. As for the principle of operation of the equipment, it is as follows: an electric motor powered from the network drives (via a toothed belt) a drum with fixed knives. They process the desired surface. However, it should be noted that over time, the drive belt wears out and requires replacement. Manufacturers took this point into account and placed it under the casing. This way you can replace the belt without any problems.

Pros and cons of a homemade circular saw table

You can make a table for a circular saw yourself, taking into account personal requirements and preferences. It will be as comfortable as possible to use. The table can be made in different sizes and heights.

There are models not only of the manual type, but also with the ability to be fixed on the table.

There are several main advantages:

- cost minimization;

- the ability to equip the structure with pushers and stops;

- ensuring maximum rigidity and stability.

The disadvantages of a homemade table for a circular saw include time costs. The master will need to study diagrams, drawings, prepare materials, and perform high-quality processing.

Do-it-yourself electric planer stand

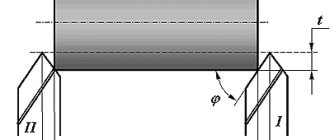

It is recommended to use a metal corner for the frame. You can make such a structure with your own hands from a frame with 3 supports, two spindles, a stepper motor (2 kW) and pipes that are used as holders.

The support bed on the hand tool table acts as a DIY guide. It controls the direction in which the cut is made and fixes the workpiece. If you want to make a homemade electric planer on a bed, then watch the video:

|

Making a manual version of the jointer

If you like to do everything with your own hands, including processing wooden workpieces with a hand jointer, then you can easily make this tool yourself. First prepare a wooden block. Its dimensions must match the future jointer. The block should be taken from hard wood, for example, larch or oak. The stronger the workpiece, the longer your plane will last.

During production, you should take into account some recommendations on the size of the future tool. Experts recommend using the following parameters:

- Most often, the length of the jointer is 60-70 centimeters. Of course, you choose this option yourself, everything will depend on which tool is more convenient for you to use;

- for the workpiece, take a beam with the length you need, with a width of 76 millimeters, and a height of 70 millimeters;

- the size of the knife should be 200 by 65 millimeters;

- To make the handle comfortable, its height is made at least 10 centimeters.

Using a chisel, a through square hole is punched in the block. In this case, its sides should be located at an angle of 45 degrees. The knife will be inserted into this hole. The block itself must have a perfectly flat bottom surface. After all, it is along it that the future workpiece will be leveled.

When choosing a knife for a jointer, you should pay attention to rectangular and durable models. In many specialized stores you can find a large assortment of similar products. The knife is inserted and fixed in the opening made.

Next, a thin wooden plate is installed (which will act as a wedge). Next, the shock plug should be installed. To do this, select a place in the middle between the edge of the hole and the front edge of the jointer itself. At this point, the main working part is ready for use.

How to choose an electric planer in 5 minutes

An electric plane planes wood, smoothing its surface from burrs, chips, splinters and other defects. It is used after primary processing of the material - sawing logs into boards, bars and other building materials.

A good electric planer with a shaped blade allows you to give the workpiece a complex profile—cutting grooves, quarters, chamfers and other recesses. After processing, you can leave protrusions for connecting parts: tenons, ridges and tongues.

Design features of electric planers

An electric planer for woodworking differs from a hand tool in design, but is similar in principle of operation. The working body is a drum or cylinder with fastenings for removable knives. Depending on the model, from 1 to 4 blades are installed. The drum is connected to the electric motor by an elastic belt. Unlike gears, it slips when overloaded, rather than jamming.

The plane rests on a smooth polished aluminum base. The front glides over untreated wood. You can adjust its height using a spring clamping mechanism, choosing the optimal planing depth. The rear part of the sole is fixed and moves along the treated surface.

The choice of an electric planer should also be based on ease of use. Most models have two handles that allow you to smoothly move the device and press it firmly against the surface being treated. Only the most compact tools, 12–15 cm long, have one handle, designed for working in hard-to-reach places - in the attic of a wooden house, inside a cabinet or on a narrow table.

Planes are either manual or stationary. The former are more mobile - they are suitable for processing small parts, for example, photo frames, decorative overlays for furniture and chair legs. A stationary unit has higher productivity - it performs large volumes of the same type of work, including planing boards and making doors. Some hand planes can be turned into stationary machines - for this you will need a special table with a set of fasteners and protective covers.

Main characteristics of electric planers

Power.

Household electric planers for home and garden use a productivity of 400–800 W. This is enough for planing to a depth of up to 3 mm. They work for up to 10–15 minutes without a break, after which they take a half-hour rest. The power of semi-professional models for workshops and small construction is 800-1500 W. They cut up to 5 mm of wood and work for up to 30–45 minutes. The power of industrial planes for manufacturing enterprises is up to 2500 W. Can work up to 8 hours without a break.

Maximum speed

determine the planing speed. If you are wondering which electric planer is worth buying, remember that at 16–17 thousand rpm you will quickly smooth out rough edges, but will leave many small defects. For finishing you will need a lower speed - 8-14 thousand rpm.

Planing depth.

When roughing a part, you can remove chips with a thickness of 3.5 to 25 mm, while finishing - from 0.5 to 3 mm. Find out what range is available in the plane you choose.

Knife width

selected for a specific task. When the question arises of how to choose the right electric planer, take a look at these numbers: for fast planing you will need a blade with a width of 40-150 mm, and for cutting grooves, ridges and quarters - from 5 to 40 mm.

Options for choosing an electric planer

The more information the buyer has about the parameters of the tool, the more suitable the model he will be able to purchase.

Device power

Electric planers are available with motors whose power ranges from 0.5 to 2.2 kW. Power affects performance. The stronger the motor, the faster the device will be able to perform various manipulations.

- If a tool is purchased for periodic use and nothing depends on the daily volume performed, then you can buy a model with a not very high power rating - 0.5-0.7 kW. This way you can save money.

- But in the professional sphere, the amount of processed boards affects the number of products produced and can significantly slow down the process, which affects other production operations. It is for this reason that for large-volume production it is worth purchasing equipment with a power of 1.2-1.5 kW.

Processing width

The work of this tool is that it is carried along the surface being processed. In one approach, the device can process as much width as the parameters of the drum and blades allow. This parameter ranges from 82-312 millimeters.

Models with intermediate values (110 and 170 millimeters) are also common. It follows from this that if the board has a width of 1 thousand millimeters, and the minimum value of the ski is 82 millimeters, then it will be processed in 12 approaches, but with a ski width of 110 millimeters, then in 9. This saves effort and time.

But the presence of an appropriate drum and a wide ski is justified only when working with large boards, but a beam 150 millimeters wide will have to be re-passed with both tools.

- A ski, the width of which is 82 millimeters, is bought for processing and making chairs, stands, beams, and window frames.

- For larger products (cabinets, doors, tables), wider skis 110-170 millimeters are suitable.

Idle speed

This indicator indicates how many revolutions the drum can make in 60 seconds without any load on the surface. There are several blades on each rotating element. The number of revolutions indicates how many times each blade will touch the material. And in the end, how quickly can it be processed?

Tool Specifications

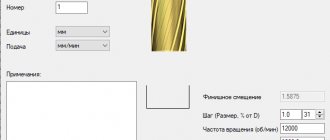

And now a little about the characteristics of the equipment. Having purchased an electric planer with a stand and opened the documentation for the tool, the first thing you will see is the power consumption. It is measured in watts. Power shows how difficult a job the equipment can perform. Also, using this parameter, you can indirectly judge where the device can be used (after all, not every electrical network is capable of delivering the required power).

An equally important parameter for such a power tool as an electric planer with a frame is the speed of rotation of the drum without contact with the surface (idling). It is measured in revolutions per minute. And taking into account the fact that the tool has 2 knives, it turns out that during one revolution of the drum, the knives touch the surface twice.

|

And the larger it is, the faster you can achieve the desired quality and thickness of lumber.

Choosing a combined woodworking machine for your home workshop.

What is better: one universal one or several highly specialized ones for a specific task? There is no clear answer. For a production workshop, naturally, a number of specialized installations are better: a circular saw, a jointer, a surface planer, a milling and grinding device, etc. For home craftsmen, two problems come first: the financial component and free space in the garage. And even if we manage to solve the first one, then a lot of different equipment installed in a small room will resemble a warehouse and you can forget about any comfortable work with wooden blanks (the length is measured in meters).

In addition, professional equipment, the frame of which is made of cast iron, has enormous weight; its setup and maintenance requires the involvement of specialists, and consumables and accessories are expensive.

A combined woodworking machine is the best solution for the owner of a country house; a large garage equipped for a workshop or summer resident. They are not only used in the private sector; Such compact installations are purchased for their needs by educational institutions (schools, colleges, universities) and even industrial enterprises for which wood processing is not a core activity.