Every professional who deals with cutting tools, be it a butcher, carpenter, turner or jeweler, always follows the law when sharpening: the sharpening angle depends on the material that will be cut. The material from which the cutter is made has nothing to do with this angle; it’s just that two cutters made of different metals will differ in wear resistance at the same sharpening angle and the same material being processed.

All sharpening angles were determined back in the 19th century. We will shave the hair with a sharpening angle of 8º-12º, regardless of the brand of the razor: “Sollingen” or “Tryd Bacha”. Cutting leather – angle 15º-18º, it doesn’t matter whether our jamb is made from a P9 saw or forged from a spring. A jeweler, for processing steel, will sharpen his gravel to an angle of 85º-90º, be it “Fish” made in Swiss, or homemade from the Dmitrovsky market. I started with this truism, because amateurs who see a knife for the second time in their lives have a completely opposite opinion: everything depends only on the material from which this knife is made. Well, since ignorance of the laws does not relieve responsibility, the result is disappointment and resentment for the rest of your life. I deal with this every day, so I will describe two typical cases of complete ignorance.

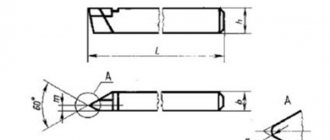

Case one. A short introduction: wood carving chisels have a hardness of 52 units - 59 units. HRC, sharpening angle 23º-30º. The sharpening angle again depends on the type of wood: small for soft species (linden, poplar, aspen), large for hard ones (oak, boxwood, and countless others). Ideally hardened steel with a sharpening angle of less than 18º begins to curl (bend); if the steel crumbles, this is a defect. The chisel must have a “shoulder”, i.e. a chamfer, which determines a certain radius of the thread: entry into and exit from solid wood. If you need to increase this radius, then change the thickness of the chisel, but not the sharpening angle.

This was the preface. And now a typical case. They buy a set of chisels and return them with a complaint: the chisels do not cut and are bent. I look: all the cutters are sharpened, there is no shoulder, the sharpening angle is 5º-8º, i.e. the chisel looks like this:

Fundamentally, it cannot cut, because... has no shoulder, and hence no turning radius - it goes in a straight line. No explanations are accepted because ignorance is aggressive and always believes itself to be right.

Case two. Complaints about a damask knife: it doesn’t cut glass and it doesn’t cut nails. The reason is the same: the knife has been sharpened - the edge is 0.1 mm, the sharpening angle is 20º. Such a knife, no matter what it is made of, can only cut leather. I’ll explain using a chisel as an example. It is made from U7-U8 steel, sharpening angle 45º-60º, shoulder width 10-12 mm, hardness 52-58 HRC units. With these parameters, the chisel cuts iron without becoming dull (until it collides with hardened steel). The main thing here is shoulder width.

It is not necessary to study the strength of materials to understand that the pressure is redistributed evenly over the entire area, the metal experiences a small load per 1 m² and does not deform. Take the same chisel, sharpen it to a thickness of 0.1 mm and try to chop nails - the nail will be dented to its entire diameter, which means that if you want the knife to cut a nail, then sharpen it 45º -60º, and create an edge thickness of 1-2 mm. Then he will chop nails, regardless of what this knife is made of: steel U8, Kh12FM, or damask steel, here I refute the persistent opinion: “and since it is damask steel, then it should...”

Bulat does not owe anyone anything, it is a steel that obeys all the laws of metal science, so how will it cut nails with a small sharpening angle and narrow shoulders?! The advantage of damask steel over steel is that at a sharpening angle of 60º, it shaves. In my practice, I almost cut off the first phalanx on my index finger by running it along the spine at an angle of 90º. They cut carbides sticking out in all directions. Their dimensions are quite noticeable: it is a spindle, 3-5 µ thick and 10-15 µ long. Hence the conclusion: if desired, a damask blade can be easily ruined by sharpening: you need to create narrow shoulders, a small angle, treat it with soft water stones, then stretch the edge along a copper rod or a block of hard wood and tear out all the carbides. A strip of shiny, polished matrix with a hardness of 45 units is formed on the edge. After this, you can safely compete with a knife made from an aluminum spoon - damask steel will lose. Complying with certain laws of sharpening steel and damask steel is no more difficult than pouring gasoline into a gasoline engine, and diesel fuel into a diesel engine. Although you can strike a pose like a stern Siberian man who pushed a rail into a sawmill, and then shook his head reproachfully and said: “Well, what a let down you are - a foreign little thing!”

Properties of hardened metals

Hardening of metals is a procedure for processing a material at high temperatures to a certain limit and further cooling. During the hardening process, a phase transformation occurs from austenite to martensite. After hardening, the mechanical properties of steels change: strength and hardness increase, while brittleness also increases and ductility decreases. To reduce brittleness and improve ductility, I subject the steel to temper annealing.

Hardened steel can be processed using different methods:

- turning;

- milling;

- drilling;

- grinding.

But, for any type of processing, cutting modes should be chosen correctly, since due to thermal effects, the fragility of the metal increases. In addition, it quickly accumulates heat at the cutting site, which leads to material sticking to the turning tool and its rapid wear.

Choosing a tool

Most end mills from the ET family are suitable for milling hardened steels. They are made of hard alloys, have optimal geometry, and are coated with a protective film. And the increased sharpness of the cutting edge makes processing easier and smoother.

For best efficiency, you should use milling on machines with a CPU. Numerical control allows machining precision down to the millimeter and reduces the likelihood of errors and manufacturing defects.

Source of material: detalnaya.ru/

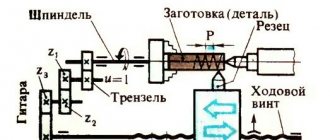

Cutting conditions when turning hardened steel

To obtain a high-quality part, roughing and finishing of hardened steel on lathes must be carried out taking into account the following recommendations:

- Start work at low speed and with the smallest depth of cut. This will allow you to obtain a small angle and achieve correct edge processing, which will have a positive effect on the service life of the tool.

- To achieve high quality surface finish of the part and reliability of the insert, increase the feed gradually. This approach will also improve chip removal and crushing.

- When finishing machining, select a cutting depth greater than the insert nose radius. This will eliminate the risk of deviation and allow you to achieve high precision when working with the internal surfaces of workpieces.

- Do not operate at very low cutting speeds as this will distort the tooling and workpiece.

A significant role when turning hardened steel is played by the use of coolant, which not only increases the reliability of the metal processing process, but also increases the productivity of the equipment and the quality of the finished product. It is important to use coolant correctly:

- for rough and semi-finish turning, it is recommended to opt for the lower coolant supply; in the case of finishing machining, preference should be given to equipment with a high-precision lower coolant supply;

- The level of coolant supply pressure must be adjusted in each specific case, depending on the cutting depth, material supply, nozzle diameter, and grade of steel being processed.

Types of heat treatment of steel

Heat treatment of steel comes down to three stages: heating, holding and rapid cooling. There are several types of this process, but the main stages remain the same.

The following types of heat treatment are distinguished:

- Technical (tempering, hardening, cryogenic treatment, aging).

- Thermo-mechanical, which uses not only high temperature, but also physical impact on the metal.

- Chemical-thermal involves heat treatment of the metal followed by exposure of the surface to nitrogen, chromium or carbon.

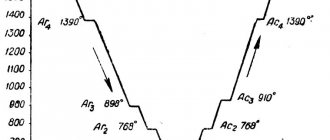

Annealing

This is a manufacturing process of heating metal to a predetermined temperature, and then slowly cooling, which occurs naturally. As a result of this procedure, the heterogeneity of the metal is eliminated, internal stress is reduced, and the hardness of the alloy is reduced, which greatly facilitates its processing. There are two types of annealing: first and second kind.

During first-order annealing, the phase state of the alloy changes slightly. It has varieties:

- Homogenized - the temperature is 1100−1200 °C, the metal is kept for 7−14 hours in such conditions.

- Recrystallization - annealing temperature 100−200 °C, this procedure is used for riveted steel.

During second-order annealing, a phase change in the metal occurs. The process has several types:

- Full annealing - the metal is heated 25−40 °C above the critical value for this material and cooled at a special speed.

- Incomplete - the alloy heats up to a critical point and takes a long time to cool down.

- Diffusion - annealing is carried out at a temperature of 1100−1200 °C.

- Isothermal - heating of the metal occurs as during complete annealing, but cooling below the critical temperature, cooling in the open air.

- Normalized - the metal is completely annealed and cooled in air.

Hardening

This is the process of manipulating metal to achieve martensitic transformation, which provides increased strength and reduced ductility of the product. During quenching, the alloy is heated to a critical value, as during annealing, but the cooling process is much faster, and a liquid bath is used for this. There are several types of hardening:

- Quenching in one liquid, oil is used for small parts, and water for large parts.

- Intermittent hardening - lowering the temperature occurs in two stages: sharp cooling to a temperature of 300 ° C using water, and then the product is placed in oil or in open air.

- Stepped - when the metal reaches the required temperature, it is cooled in molten salts and then in the open air.

- Isothermal - similar to stepwise, differs in exposure time.

- Quenching with self-tempering, the alloy is not completely cooled, leaving a warm area in the middle. As a result, the metal gains increased strength and high toughness. This combination is great for percussion instruments.

Incorrectly done hardening can lead to the following defects:

- decarbonization;

- cracks;

- warping or leashes.

The main cause of leashes and cracks is an uneven change in the size of the part during cooling or heating. They can also occur with a sharp increase in strength in certain places. The best way to avoid these problems is to slowly cool the metal to the martensitic transformation point.

Leash and warping occurs when curved parts are cooled unevenly. These defects are quite minor and can be corrected by sanding. Preliminary annealing of parts and their gradual and uniform heating will help avoid warping.

Decarburization of metal occurs as a result of carbon burning out during prolonged heating. The intensity of the process depends on the heating temperature; the higher it is, the faster the process. To correct the part, it is heated in a neutral environment (muffle furnace).

Scales on the metal surface lead to waste and deformation of the product. This reduces the heating rate and makes machining more difficult. Scales are removed chemically or mechanically. In order to avoid their appearance, you need to use a special paste (100 g of liquid glass, 25 g of graphite, 75 g of refractory clay, 14 g of borax, 100 g of water, 30 g of carborundum). The composition is applied to the products and left until completely dry, and then heated as usual.

Vacation

It softens the effects of hardening, relieves stress, reduces fragility, and increases toughness. Tempering is carried out by heating a part hardened to a critical temperature. Depending on the temperature value, the states of trostite, martensite, and sorbitol can be obtained. They differ from similar hardened states in properties and structure, which is more point-specific. This increases the ductility and strength of the alloy. Metal with a dot structure has higher impact strength.

Depending on the temperature, the following types of holiday are distinguished: low, medium, high.

To accurately determine the temperature, use a color table. The film of iron oxides gives the metal different colors. It appears if the product is cleaned of scale and heated to 210 °C; with increasing temperature, the film thickness increases.

During low tempering (temperatures up to 300 °C), martensite remains in the alloy, which changes the structure of the material. In addition, iron carbide is released. This increases the toughness of the steel and reduces its hardness. During low tempering, the metal is cooled in salt and oil baths.

High tempering significantly improves the mechanical properties of steel, increases toughness, ductility, and strength. It is widely used for the manufacture of springs, engine connecting rods, forging dies, and car axles. For fine-grained alloy steel, tempering is carried out immediately after normalization.

To increase the workability of the metal, it is normalized at a high temperature (970 °C), which increases its hardness. To reduce this parameter, make a high tempering.

Cryogenic treatment

Changes in the structure of the metal can be achieved not only by high temperature, but also by low temperature. Alloy processing at temperatures below 0 °C is widely used in various industries. The process occurs at a temperature of 195 °C.

Advantages of cryogenic processing:

- Reduces the amount of austenite, which gives stability to the dimensions of parts.

- Does not require subsequent tempering, which shortens the production cycle.

- After this treatment, the parts are better suited for grinding and polishing.

Chemical-thermal treatment

Chemical-thermal treatment includes not only high temperature exposure, but also chemical exposure. The result of this procedure is increased strength and wear resistance of the metal, as well as making it fire and acid resistant.

There are the following types of processing:

- Cementation.

- Nitriding.

- Nitrocarburization.

- Borating.

Steel carburization is a process of additional processing of metal with carbon before hardening and tempering. After the procedure, the product’s endurance during torsion and bending increases.

Before cementation begins, the surface is thoroughly cleaned, after which it is coated with special compounds. The procedure is carried out after the surface has completely dried.

There are several types of cementation: liquid, solid, gas. In the first type, a special bath oven is used, into which 75% soda, 10% silicon carbide, 15% sodium chloride are poured. After which the product is immersed in a container. The process takes place for 2 hours at a temperature of 850 °C.

Hard cementation can be conveniently performed in a home workshop. For it, a special paste is used based on soda ash, soot, sodium oxalate and water. The resulting composition is applied to the surface and waits to dry. After this, the product is placed in an oven for 2 hours at a temperature of 900 °C.

Gas cementation uses mixtures of gases containing methane. The procedure takes place in a special chamber at a temperature of 900 °C.

Nitriding of steel is the process of saturating the metal surface with nitrogen by heating to 650 °C in an ammonia atmosphere. After processing, the alloy increases its hardness and also becomes resistant to corrosion. Nitriding, unlike carburization, allows you to maintain high strength at high temperatures. And also the products do not warp when cooled. Metal nitriding is widely used in industry to impart wear resistance to the product, increase hardness and protect against corrosion.

Nitrocarburization of steel involves treating the surface with carbon and nitrogen at high temperatures, followed by hardening and tempering. The procedure can be carried out at a temperature of 850 °C in a gas environment. Nitrocarburization is used for tool steels.

When boriding steel, a layer of boron is applied to the surface of the metal. The procedure takes place at a temperature of 910 °C. This treatment is used to increase the durability of die and drilling tools.

Thermo-mechanical treatment

This method involves high temperature and plastic deformation. There are the following types of thermomechanical treatment:

- High temperature.

- Low temperature.

- Preliminary.

During high-temperature processing, metal deformation occurs after heating. The alloy is heated above the recrystallization temperature. After which hardening and tempering are carried out.

High temperature metal processing:

- Increases viscosity.

- Eliminates temper brittleness.

Structural, tool, carbon, spring, and alloy steels are subjected to this treatment.

In low-temperature processing, the workpiece after cooling is kept at a temperature below the recrystallization value and above the martensitic transformation. At this stage, plastic deformation is performed. Such processing does not provide stability to the metal during tempering, and its implementation requires powerful equipment.

To carry out thermomechanical processing, it is necessary to use special devices for pressure, heating and cooling of the workpiece.

Selecting a cutting tool for turning hardened steel

Turning hardened steel is one of the most difficult tasks in metalworking, which is best solved using the following types of cutting equipment:

- Carbide inserts are a versatile and economical option that is resistant to abrasive wear. This tool is best suited for working with steel with a hardness of no more than 55 HRC. At higher specifications, the tool life will be significantly reduced.

- Ceramic plates – equipment made of mixed ceramics or reinforced with special crystals. It can last a long time even when working with very hard steel, but the surface processed by such a plate will not be of very high quality. Therefore, they are recommended for rough and semi-finish turning.

- Cubic Boron Nitride (CBN) inserts are a high-strength cutter that can handle hardened steel up to 65 HRC and allows for perfect metal finishing results with up to 70% time savings in the production process.

Features of heat treatment

To impart the desired properties to a metal part, it is subjected to heat treatment. During this process, a structural change occurs in the material .

Metal products used in the household must be resistant to external influences. To achieve this, the metal must be strengthened by exposure to high temperature. This treatment changes the shape of the crystal lattice, minimizes internal stress and improves its properties.