from 250 to 350, but often higher depending on the quality of the workpiece

Material strength coefficient:

Steel, kg/mm

| Indicator value | |

| 50,1–60,1 | 1,61 |

| 60,1–70,3 | 1,27 |

| 70,3–80,1 | 1,1 |

| 80,3–90,1 | 0,87 |

| 90,3–100,1 | 0,73 |

| Cast iron, kg/mm | Indicator value |

| 140,1–160,3 | 1,50 |

| 160,1–180,1 | 1,21 |

| 180,1–200,3 | 1,1 |

| 200,3–220,3 | 0,83 |

Cutter life coefficient:

| Duration value, minutes | Index |

| 27–30 | 1,27 |

| 43–46 | 1,11 |

| 57–60 | 1,09 |

| 83–90 | 1,03 |

Cutting modes for turning and turning: formula tables, feed calculation and speed

Let's prepare for one of the most common operations. Let's consider the calculation of feed and cutting modes during turning. Its importance is difficult to overestimate, because if it is carried out correctly, it helps to make the technical process efficient, reduce production costs, and improve the quality of part surfaces. When it is optimally selected, it has the most positive effect on the operating life and integrity of the tools, which is especially important in the long term operation of machine tools while maintaining their dynamic and kinematic characteristics. And vice versa, if you choose it incorrectly and take the wrong initial indicators, you won’t have to talk about any high level of product performance, and you may even be faced with a defect.

Eco-decor: 35 decor ideas from branches for the home

Decorated dry branches for a vase on the balcony will look beautiful

A large number of plants in a vase will harmoniously complement the interior of the room

Branches can be decorated with small flowers and beads

A vase with dry branches can be placed in the bedroom

Flowers can be coated with bright shiny varnish

And an endless number of ideas! Rare branches in the interior are so complex and beautiful that you want to look at them. Each tree has unique branches, but often we pay so little attention to this, focusing on the leaves.

Large thick branches will look very beautiful in the interior of the room

Branches for a floor vase can be painted golden

Any branches are suitable for decorating a vase.

Cutting modes: what are they?

This is a whole complex of characteristics that determine the conditions for carrying out a turning operation. According to the technological routes, the processing of any element (especially complex in shape) is carried out in several transitions, each of which requires its own drawings, dimensions and tolerances, equipment and accessories. Having calculated and/or selected all these parameters once for the first workpiece, in the future you will be able to substitute them by default - when producing the second, fifth, hundredth part - and thus minimize the time for preparing the machine and simplify quality control, that is, optimize the production process .

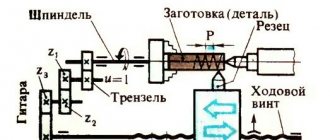

The main indicators include depth, speed, feed, the list of additional ones includes the mass of the object, allowances, the frequency with which the spindle rotates, and, in principle, any characteristic that affects the result of processing. And it is important to choose those that will provide the best final accuracy, roughness and economic feasibility.

There are several ways to calculate cutting conditions when turning:

The first is quite accurate and, before the advent of powerful computer technology, was considered the most convenient. According to it, all calculations were carried out on the basis of the equipment’s passport data: engine power, spindle speed and other indicators were substituted into already verified empirical expressions and the required characteristics were obtained.

With the development of specialized software, the calculation task has been significantly simplified - all operations are performed by a machine, faster than a person and with a much lower probability of making mistakes.

When you don’t have a computer or formulas at hand, but you do have experience, you can determine the appropriate criteria based on normative and reference data from the tables. But for this it is necessary to take into account all changes in values, even the slightest, which is not always convenient in production conditions.

: Polishing

At this point, some people start sanding their ball with increasingly finer sandpaper, up to thousands of grits. I saw no reason to do the same, given that the ball was already quite shiny.

Instead, I polished it in several passes with aluminum polish. You coat it generously with polish and then rub it into the metal until it turns black, then you scrub it off with a few rags.

Features of determining cutting modes during turning

First of all, you need to select the processing depth, then the feed and speed. It is important to follow exactly this sequence - in order of increasing degree of impact on the instrument. First, those characteristics are calculated that can only minimally change the wear of the cutter, and finally those that affect the service life to the maximum.

Parameters should be determined for the maximum capabilities of the equipment, necessarily taking into account the dimensions, metal, and design of the tool.

An important point is to find a suitable roughness. Plus, it’s best to choose a blade for a specific material, because cast iron has one strength and hardness, while aluminum has a completely different one. Do not forget also that during the process the part heats up and the risk of its deformation increases.

The choice of cutting mode when turning on a lathe continues by establishing the type of processing. What will it be, rough or fine? The first is rough; tools made of hard steel and capable of withstanding the high intensity of the technical process are suitable for it. The second is thin, carried out at low speeds, with the removal of a minimal layer of metal.

The depth is determined by the number of passes during which the allowance is removed. Feed is the distance covered by the edge during rotation of the workpiece, and can be one of three types:

The speed largely depends on what kind of operation is being performed, for example, when facing it should be high.

Characteristics of cutting conditions

Before we consider all the main parameters in detail, let’s say a few more words about calculation methods. More precisely, about how they moved from graphics to analytics and computerization.

As production improved, even the most detailed tables turned out to be less and less convenient: columns, columns, ratios - it took a huge amount of time to study this and find the right value. And this despite the fact that the main indicators are interconnected, and a decrease/increase in one of them provoked changes in the others.

Having established such an obvious dependence, engineers began to use the analytical method, that is, they thought through empirical formulas, and began to substitute spindle speed, power of the power unit and feed into them and find the necessary characteristics. Well, the development of computers and the emergence of computing software seriously simplified the task and protected the final results from human errors.

In what interior style can decor from dry branches be used?

The combination of colors will perfectly complement the interior

Living branches will look very beautiful

Tree branches in the interior, like many free materials lying in any forest, have a very valuable advantage: they are free. You breathe a second life into them, increase the price of a piece of wood with time, effort, materials spent: paints and ribbons. When you get tired of this trash, you can always throw it away. Everything requires change, tastes are revised, children are born, they will have other plans for your living space, beautiful but useless things are covered with a thick layer of dust, it is almost impossible to remove it without damaging the composition. And when the children grow up, you will be with them looking for beautiful twigs in the forest, cutting out dolls from them, hanging them on the wall in beautiful compositions, or making school crafts.

Source

Scheme for calculating the cutting mode on a lathe

The procedure is as follows:

Now we move on to consider specific characteristics that play an important role, and to ways of finding or changing them in practice.

Depth of cut when turning on a machine

A key indicator for ensuring the quality of a part, showing how much material needs to be removed in one pass. The total number of the latter is calculated taking into account the following ratio of allowances:

The shape of the workpiece and what kind of operation is being performed also play a role. For example, when facing, the parameter in question is equated to the double radius of the object, and for cylindrical parts it is found as follows:

If the product is flat, the usual linear length values are used - 2, 1-2 and up to 1 mm, respectively. There is also a dependence on the supported accuracy class: the lower it is, the more approaches you need to make to get the result.

How to determine feed when turning

In fact, it represents the distance that the cutter moves in one revolution made by the workpiece. It is highest during roughing, least during finishing, when you should act carefully, and the quality of roughness also comes into play. In general, it is done as much as possible (for the operation) taking into account limiting factors, including:

When milling, preference is given to the “tooth” option, when cleaning holes - recommended for the current tool, for training purposes - the most common one, that is, 0.05-0.5 rpm.

The formula for calculating feed during turning, connecting all its types, looks like this:

n – cutter rotation frequency,

To simplify the calculations, you can take the data from here:

Diameter, blanks, mm

Feed, mm/rev, with selected cutting depth, mm

Source

Ready-made balls for the tree of happiness

Purchased blanks and improvised bases for topiary:

- Styrofoam ball. For the tree of happiness, it is advisable to use ready-made foam balls with a diameter of 7 to 30 cm.

- Hanging rattan. Ready-made rattan balls are available at decor stores. In addition, you can make them yourself (rattan is wrapped around a balloon).

- Rubber ball. Limited selection of trunks for topiary: only a cable is suitable, which must be attached to the outside of the ball.

- A ball of knitting thread.

- Chipboard is a die-cut made of thick cardboard. Blank for flat topiary on a magnet, thickness 1-3 mm.

- Tennis ball. For miniature trees.

- Ostrich egg. An original base for Easter topiary. Ostrich eggs are very durable and decor sticks well to the surface.

- Foam ball. Multi-colored products are used by magicians to perform tricks, but are also great for our purposes!

- Wooden ball. They are rarely used, but for a certain design a wooden base is optimal.

What it is

Cutting mode most often refers to characteristics that are found by calculation. These are depth, speed and serve. These values are very important. Without them, it is simply impossible to qualitatively turn any part.

When calculating operating modes, other characteristics of the work manipulations performed are also taken into account:

If necessary, many other characteristics of those elements that affect the processing of parts are taken into account.

Characteristics of operating modes

The calculation of the cutting operation is carried out using special reference and regulatory documents, of which there are quite a few at the moment. It is necessary to carefully study the tables presented and select the appropriate values in them. A correctly performed calculation guarantees the high efficiency of the applied part processing mode and ensures the achievement of the best result.

But this method of calculation is not always successful, especially in production conditions, when it is inappropriate to spend a lot of time studying tables with a huge number of values. It has been established that all values of cutting modes are interrelated. If you change one value, it is natural that all other processing characteristics will become different.

Therefore, very often specialists prefer to use calculation or analytical methods for determining cutting conditions. Special empirical formulas are used to determine all the necessary standards. In order for the calculations using this method to be absolutely accurate, you need to know the following parameters of the lathe:

In modern industries, special software is used to perform such calculations. The specialist just needs to enter the known data, after which the computer will produce the calculated values. The use of calculation programs greatly facilitates the work of specialists and makes production more efficient.

Calculation scheme

Before performing calculations for a cutting operation, it is necessary to determine what type of cutting tool will be used in this case. When turning or abrasively machining fragile materials, equipment with minimal performance is selected. It should be remembered that during operation the part usually gets quite hot. If the processing speed is very high, it may become deformed, rendering it unusable.

It is necessary to take into account what kind of processing will be carried out - finishing or roughing. In the first case, operating parameters are selected that will ensure maximum accuracy. Experts also pay attention to the thickness of the cut layer. Depending on this characteristic, the number of penetrations is selected to perform trimming using special equipment.

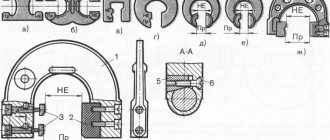

Depth

Depth is one of the most important parameters to ensure the quality of manufactured workpieces. It determines the thickness of the cut layer in one pass. When trimming the end, the diameter of the part is taken as the depth.

The number of passes is taken into account, which is determined by processing allowances:

To determine the cutting depth of cylindrical workpieces, the following formula is used:

k=(Dd)/2 , where k is the cutting depth, D is the initial diameter, d is the resulting diameter.

When determining cutting conditions when working with flat parts, length is used instead of diameters. It is generally accepted that during roughing the depth should be more than 2 mm, semi-finishing - 1-2 mm, finishing - less than 1 mm. This parameter depends on the quality requirements of the parts. The lower the accuracy class, the more passes must be performed to achieve the required properties of the products.

Innings

Feed refers to the amount of movement of the cutter per revolution of the workpiece. When performing roughing, this parameter can have the maximum possible values. At the final stage of work, the feed value is determined taking into account the roughness quality. This characteristic depends on the cutting depth and dimensions of the workpiece. The smaller the size, the lower it is. If the thickness of the cut layer is large, the minimum feed parameters are selected.

To make the work easier for specialists, special tables have been developed. Feed values are indicated there under different cutting conditions. To make accurate calculations, it is sometimes necessary to know the size of the cutter holder.

If cutting is performed with significant impact loads, the values from the table must be multiplied by a factor of 0.85. When working with heat-resistant structural steel, the feed should not exceed 1 mm/rev.

Speed

Cutting speed is one of the most important indicators, which is determined at the calculation stage before performing the main work. Its values depend on the operations performed. Typically, end cutting occurs at the highest possible speed. Drilling or turning have completely different requirements for this operating parameter. Therefore, to perform the assigned tasks efficiently, you need to know the following:

In traditional turning, the speed is determined by multiplying the diameter of the workpiece by its number of revolutions per minute and by π. The resulting value must be divided by 1000. Also, the cutting speed can be determined using standard tables for cutting modes.

Checking selected performance characteristics

Once the depth, feed and speed are determined, they need to be checked. The obtained operating parameters should not exceed the standard values indicated in the passport of the operating lathe.

It is imperative to determine the power of the equipment. To do this, the cutting force is multiplied by its speed and divided by 1000. The resulting value is compared with what is indicated in the machine passport. If the parameters calculated by the formulas are larger, it is necessary to adjust the depth, feed and speed to avoid damage to equipment and tools.

Alternative methods for making a topiary base

Polyurethane foam

We squeeze the polyethylene foam into a plastic bag to get a blank - a figure close to the shape of a sphere, but definitely larger than the required diameter of the ball. We wait until the sealant has completely hardened, remove the bag, and use a utility knife to give the mass the desired shape - not just a ball.

DIY foam ball

Instead of polyurethane foam, you can use a foam blank, for example, packaging from household appliances, or glue several sheets together to obtain the required thickness.

But the foam is non-uniform and crumbles a lot: making a topiary ball of the correct shape is difficult, and a lot of debris remains. You can also cut a base for a flat topiary from a foam sheet.

Papier-mâché technique

We inflate the balloon to the desired size, coat the surface with PVA, glue sheets of paper (you can use toilet paper), fragments of old newspapers or napkins. We continue to increase the mass, generously coating each layer with glue, gaining a thickness of at least 7-10 mm.

After the workpiece has completely dried, carefully deflate and pull out the balloon; the frame remains. The result was a fragile but original ball for topiary using the papier-mâché technique. The method is labor-intensive, the base takes a long time to dry.

Knitting thread

The method exactly imitates the papier-mâché technique, but instead of paper, knitting threads are used: the result is a frame suitable for a light crown. We do not recommend using twine instead of yarn: the material is expensive and strongly absorbs glue.

Which cutting tool to use

The production of parts on such machines is carried out using special turning tools. They must provide the following:

Turning cutters are classified according to different parameters. Depending on the type of work performed, they can be cutting, passing, shaped, scoring, etc. Cutters are made from various materials - diamonds, tungsten, titanium-tungsten and others. Depending on the design, these tools can be one-piece, prefabricated or combined.

The choice of a specific type of tool is carried out taking into account the modes of the work operations being carried out, the hardness of the workpiece, the geometric parameters of the cutting part and other characteristics.

Related video: Metal turning

Source

Turner services

Finding someone who will provide turner services in Moscow is not very easy. There are fewer and fewer good turning specialists left, as young people do not go to study for blue-collar jobs. Turning works photo. We are proud that we have excellent turners in our team. Before answering your question about the cost of turning services, we need to know from you:

- drawing or drawing with exact dimensions (or sample part) (can be sent by email

- type of material processed and type of work required

- required quantity

- material for work, yours or ours

- other recommendations and wishes.

We try to fulfill all orders on time and with high quality. Our prices are quite affordable. Turning works in Moscow.

metal turning works master turning works price

TURNING SERVICES. Turning work photo

Despite the presence of many methods of forming processes (casting, powder metallurgy, etc.), cold metal working is widespread in the engineering industry.

Very often it is simply unprofitable to produce special casting molds and purchase equipment. Or the only way to make a part is from a piece of metal (plate, rod, profile).

What it is

Cutting mode most often refers to characteristics that are found by calculation. These are depth, speed and serve. These values are very important. Without them, it is simply impossible to qualitatively turn any part.

When calculating operating modes, other characteristics of the work manipulations performed are also taken into account:

If necessary, many other characteristics of those elements that affect the processing of parts are taken into account.

Calculation scheme

Before performing calculations for a cutting operation, it is necessary to determine what type of cutting tool will be used in this case. When turning or abrasively machining fragile materials, equipment with minimal performance is selected. It should be remembered that during operation the part usually gets quite hot. If the processing speed is very high, it may become deformed, rendering it unusable.

Metal cutting process

It is necessary to take into account what kind of processing will be carried out - finishing or roughing. In the first case, operating parameters are selected that will ensure maximum accuracy. Experts also pay attention to the thickness of the cut layer. Depending on this characteristic, the number of penetrations is selected to perform trimming using special equipment.

Depth

Depth is one of the most important parameters to ensure the quality of manufactured workpieces. It determines the thickness of the cut layer in one pass. When trimming the end, the diameter of the part is taken as the depth.

The number of passes is taken into account, which is determined by processing allowances:

Changing the processed diameter

To determine the cutting depth of cylindrical workpieces, the following formula is used:

k=(Dd)/2 , where k is the cutting depth, D is the initial diameter, d is the resulting diameter.

When determining cutting conditions when working with flat parts, length is used instead of diameters. It is generally accepted that during roughing the depth should be more than 2 mm, semi-finishing - 1-2 mm, finishing - less than 1 mm. This parameter depends on the quality requirements of the parts. The lower the accuracy class, the more passes must be performed to achieve the required properties of the products.

Metal roughing scheme

Innings

An example of constructing a cutter trajectory

Feed refers to the amount of movement of the cutter per revolution of the workpiece. When performing roughing, this parameter can have the maximum possible values. At the final stage of work, the feed value is determined taking into account the roughness quality. This characteristic depends on the cutting depth and dimensions of the workpiece. The smaller the size, the lower it is. If the thickness of the cut layer is large, the minimum feed parameters are selected.

To make the work easier for specialists, special tables have been developed. Feed values are indicated there under different cutting conditions. To make accurate calculations, it is sometimes necessary to know the size of the cutter holder.

If cutting is performed with significant impact loads, the values from the table must be multiplied by a factor of 0.85. When working with heat-resistant structural steel, the feed should not exceed 1 mm/rev.

Feeds for rough external turning

Speed

Cutting speed is one of the most important indicators, which is determined at the calculation stage before performing the main work. Its values depend on the operations performed. Typically, end cutting occurs at the highest possible speed. Drilling or turning have completely different requirements for this operating parameter. Therefore, to perform the assigned tasks efficiently, you need to know the following:

Table for calculating cutting conditions

In traditional turning, the speed is determined by multiplying the diameter of the workpiece by its number of revolutions per minute and by π. The resulting value must be divided by 1000. Also, the cutting speed can be determined using standard tables for cutting modes.

Checking selected performance characteristics

Once the depth, feed and speed are determined, they need to be checked. The obtained operating parameters should not exceed the standard values indicated in the passport of the operating lathe.

It is imperative to determine the power of the equipment. To do this, the cutting force is multiplied by its speed and divided by 1000. The resulting value is compared with what is indicated in the machine passport. If the parameters calculated by the formulas are larger, it is necessary to adjust the depth, feed and speed to avoid damage to equipment and tools.

Selecting cutter material for turning

Sheet material bending technology

Let's look at the process using the example of making a lid for a smokehouse. The sheet thickness in our case is 2 mm.

Read also: DIY pig pen

Make markings on the sheet. For each bend, 35 mm is provided; for bending, it is recommended to subtract 4 mm from this size. Accordingly, you need to draw a rectangle 508×308 mm on the sheet, the bends will be 31 mm long. Draw lines under the ruler.

So that the sheet can be easily bent, it is necessary to cut small grooves. Put on safety glasses or a mask and use a grinder to smoothly walk along the lines, cutting depth is approximately one millimeter, but no more. Disc thickness 1 mm.

Change the disk to 2.5 mm and go over the lines again. There are two reasons to use two disks.

- A thin disk is much easier to work with, it gives an even cut, and it’s easier to control the depth.

- The wide disc increases the kerf, which allows you to bend metal without resting on the edges.

Cut through one side of the corner; they are completely cut off after bending.

Cutting speed and its calculation

One of the most important indicators is speed. Its value directly depends on the work performed. At maximum speed, the ends of the workpieces are trimmed. Turning or drilling have different requirements for this parameter.

To select the optimal speed value and perform high-quality processing of the part, you should consider:

The cutting speed for traditional methods of influencing parts can be determined using the corresponding tables from reference books. But in production conditions it is not always advisable to resort to this option. It is much faster to calculate the value of this parameter using a simple formula:

V – desired speed, m/min;

D – maximum diameter of the workpiece used, mm;

n – the number of revolutions of the part in one minute, corresponding to the machine spindle speed;

π is a constant equal to 3.141526.

This shows that the processing speed is directly proportional to the diameter of the original workpiece. And the smaller it is, the higher the rotation speed should be.

When choosing and assigning one or another mode of operation of a lathe, it is necessary to take into account the hardness of the cutters and the material of the part. For example, when machining with carbide cutters, the recommended value should be in the range of 100–200 m/min.

With a known value, the required cutting frequency can be easily calculated from the above formula.

The processing depth is selected taking into account the drive power and cutting tool material. If parasitic vibrations appear during operation, the cutter feed speed should be reduced.

Example No. 4 of programming a CNC machine G-code G02

Example No. 4 of programming a CNC machine G-code G02

N10 T0101 N20 G92 S1000 M42 N30 G96 S200 M03 N40 G00 X0 Z5 N50 G01 Z0 F0.5 N60 G01 X80 F0.2 N70 G02 X100 Z-30 I50 K0 N80 G01 Z-120 N90 G00 X200 Z200 M30

G-code explanation

- G92: Spindle speed limit.

- G96: constant surface speed.

- G02: Clockwise circular interpolation.

G02 Explanation

G02 has some meanings in the CNC programming block, such as x, z, I, K.

- X: The end point of the arc along the x axis.

- Z: The end point of the arc along the z axis.

- I: distance from the starting point of the arc to the center of the arc along the x-axis.

- K: distance from the arc starting point to the arc center along the z axis.

Which cutting tool to use

The production of parts on such machines is carried out using special turning tools. They must provide the following:

Types and purposes of turning tools

Turning cutters are classified according to different parameters. Depending on the type of work performed, they can be cutting, passing, shaped, scoring, etc. Cutters are made from various materials - diamonds, tungsten, titanium-tungsten and others. Depending on the design, these tools can be one-piece, prefabricated or combined.

The choice of a specific type of tool is carried out taking into account the modes of the work operations being carried out, the hardness of the workpiece, the geometric parameters of the cutting part and other characteristics.