GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. Individuals who are at least 18 years of age, fit for health reasons and have completed: - introductory training are allowed to work independently on a lathe; — introductory training on fire safety; — initial instruction on labor protection in the workplace; — training in safe labor methods and techniques; — testing knowledge of labor protection requirements; — training and testing of knowledge on electrical safety for the appropriate group, as operational and repair personnel when performing work related to the operation of electrical equipment; — training on fire-technical minimum. 1.2. Employees have the right to perform only the work that is assigned to them and that corresponds to their specialty. In necessary cases (unfamiliar work, lack of knowledge of safe work practices, etc.), workers must obtain an explanation and demonstration of safe work practices and methods from the work manager. 1.3. When working together with other workers, you should coordinate your actions and ensure that they do not lead to injury to anyone. 1.4. During work, employees should not be distracted themselves or distract other employees from their work. 1.5. Workers should not turn on or stop (except in emergency cases) machines, machines and mechanisms that they are not assigned to operate. 1.6. Employees are required to comply with the requirements of the Internal Labor Regulations. Drinking alcoholic beverages at the enterprise and appearing at work while intoxicated is prohibited. Smoking should only be done in designated areas. 1.7. It is not allowed to obstruct the approaches to panels with fire-fighting equipment and to fire hydrants. The use of fire-fighting equipment for purposes other than its intended purpose is not permitted. 1.8. The main dangerous and harmful production factors can be: - electric current; — moving and rotating parts of the machine; — small chips, flying pieces of metal and aerosols of cutting fluid; — high surface temperature of processed parts and products; — industrial dust; — production noise; — sharp edges and roughness of materials and tools; — increased vibration; — insufficient illumination of the working area, the presence of direct and reflected glare, increased pulsation of the light flux. 1.9. Based on the approved list of personal protective equipment (hereinafter referred to as PPE) issued at the enterprise, employees are provided with the prescribed PPE free of charge. 1.10. Employees are required to immediately notify their immediate supervisor of any accident or breakdown. 1.11. The requirements of this instruction are mandatory. Failure to comply with these requirements by employees is considered a violation of labor and production discipline. 1.12. Monitoring the implementation of the measures set out in these instructions, as well as compliance with the requirements of labor protection, industrial safety, electrical safety, fire safety and industrial sanitation, is carried out by the employees by their immediate supervisor.

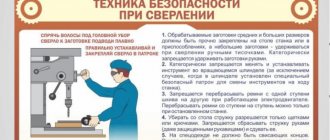

OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

2.1. Wear overalls, safety shoes and other personal protective equipment. Fasten the overalls with all buttons, avoiding hanging ends of the clothing, and tuck hair under the headdress. Check that there are no sharp, piercing or cutting objects in your clothing. 2.2. After receiving the task from the manager, employees are required to check the serviceability and availability of tools and devices, fire extinguishing equipment, general ventilation systems, and workplace lighting. 2.3. Personnel working on a drilling machine must ensure that the machine, all tools and equipment are in good working order, and wear the required protective clothing and safety shoes. Clothes should be tucked in so that there are no loose ends, and cuffs should be fastened. 2.4. Check the operation of the machine at idle speed: - serviceability of controls (mechanisms of the main feed movement, start, stop movement); — serviceability of the lubrication and cooling system; - the locking of the on and off levers is in good working order (make sure that the possibility of spontaneous switching from idle to working is excluded). 2.5. Adjust the local lighting so that the work area is sufficiently illuminated and the light does not blind the eyes. 2.6. Personnel performing work on a lathe are prohibited from: - working without a wooden grid on the floor under their feet along the length of the machine, preventing shoes from getting between the slats and ensuring the free passage of chips; - work on the machine with a broken ground wire, as well as in the absence or malfunction of locking devices; - stand and walk under a raised load; — pass in places not intended for the passage of people; — enter the fences of technological equipment without permission; — remove barriers to hazardous areas of operating equipment; - wash your hands in emulsion, oil, kerosene, coolant and wipe them with wiping ends contaminated with shavings. — touch live parts of electrical equipment, open electrical cabinet doors. 2.7. Employees notify their immediate supervisor of any detected malfunctions. In this case, starting work is allowed after troubleshooting and only after receiving permission from the immediate supervisor.

Risks during processing

Safety precautions when working on a metal lathe include:

- worker eye protection;

- protection from flying parts;

- exclusion of external negative factors.

When processing metals, the chips are hot and they are fused into plastic objects, so special requirements are placed on protective clothing and protective equipment. An external dangerous factor is uneven lighting. The work area should not have weak or excessive lighting. When moving away from a bright area of the machine, the operator or adjuster may trip or fall due to the fact that vision has not yet had time to adjust to the darker area of the room.

Indoor climatic conditions can also pose a danger to workers if they deviate from the recommended ones: 25 degrees, humidity about 70%. These conditions are taken into account in safety precautions when working on a wood lathe. Wood shavings are no less dangerous, although their flight speed is definitely lower than that of metal.

Woodworking carries similar risks to working with metal. But clothing being grabbed by a rotating wooden workpiece occurs more often. Many turners sand the rotating surface with sandpaper, holding its ends with their hands. This is unacceptable from the point of view of safe work.

OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

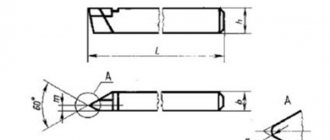

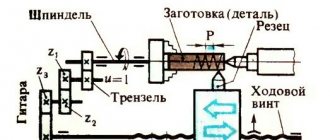

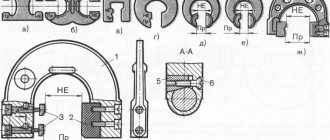

3.1. Check that the product is installed correctly before starting the machine. 3.2. The workpiece must be securely secured in the chuck or centers. 3.3. It is prohibited to brake the chuck or faceplate with your hand or other objects to speed up the machine stop. 3.4. When processing parts in centers, you need to carefully monitor the condition of the centers and lubricate them in a timely manner; if this is not done, the centers will quickly wear out and will fall out of them. 3.5. Fastening devices (chuck, faceplate, etc.) must be installed on the mill so as to exclude the possibility of self-unscrewing or tearing them off the spindle during operation and during reverse rotation of the spindle. 3.6. Clamping devices (rear center, chuck, etc.) of lathes must also ensure reliable fastening of the part. 3.7. The cartridge and faceplate should not have protruding parts or unsealed open recesses on the outer forming surfaces. In exceptional cases, the cartridge and faceplate with protruding parts must be protected. 3.8. For turning long products, steady rests should be used. 3.9. When processing metals that produce twisted chips, tools and devices for crushing chips (chip breakers) must be used during the cutting process, and for metals that produce chipping chips during processing, chip removers must be used. 3.10. When polishing and filing products on machines, methods and devices must be used to ensure the safe performance of these operations. 3.11. It is necessary to clean workpieces on machines with an emery cloth only with the help of appropriate devices. 3.12. Installing and removing a chuck or faceplate is permitted only after the machine has completely stopped. 3.13. To install the cutter, it is allowed to use only special pads with an area equal to the entire supporting part of the cutter. 3.14. The clamp for securing the workpiece in the centers must have a hidden clamping bolt that cannot catch the worker’s sleeve or injure his hand. 3.15. It is necessary to periodically check that the tailstock is securely fastened and prevent it from moving or vibrating. If the product rotates in the direction of screwing the chuck, you need to carefully monitor the position of the chuck and secure it in a timely manner. 3.16. When securing the product in the chuck, the set screw must be in a vertical position, and not inclined, in which the chuck can turn and use a key to press the worker’s limbs to the machine bed. 3.17. When manually processing parts with a file on a lathe, the cutouts or slots on the surface of the part must be sealed with inserts. 3.18. When sanding parts with sandpaper, you need to use special pressure pads, and when cleaning internal surfaces, you need to use a round mandrel. 3.19. When processing bar metal, the end of the bar protruding from the spindle must be protected. 3.20. You cannot turn on the self-propelled gun until the cutter comes into contact with the part. To avoid breaking the cutter, it should be brought to the workpiece slowly and carefully. 3.21. Before you begin manual processing of the part (scraping, cleaning and grinding) on a lathe, you should move the support to the side at a safe distance. 3.22. Before stopping the machine, the cutter must be moved away from the workpiece. 3.23. Cleaning, lubricating, wiping down the machine, changing components or cutting tools, removing chips from under the machine should be done only after the machine has completely stopped; moving away from the machine is also allowed after it has completely stopped. 3.24. If the electrical voltage fails, remove the workpiece and turn off the machine. 3.25. When leaving the workplace (even if for a short time), the personnel performing work on the lathe must disconnect the machine from the power source. 3.26. During operation, personnel performing work on a lathe are prohibited from: - working on the machine in mittens or gloves, as well as with bandaged fingers without rubber fingertips; - remove chips directly with your hands and tools; - blow compressed air from a hose onto the workpiece; — use local lighting with voltage above 42 V; - take and feed any objects through a working machine, tighten nuts, bolts and other connecting parts of the machine; - slow down the rotation of the spindle by pressing your hand on the rotating parts of the machine or part; — while the machine is running, take measurements, check by hand the cleanliness of the surface of the workpiece, grind with sandpaper or abrasive; - be between the part and the machine when installing the part with a lifting crane; — while the machine is operating, open and remove guards and safety devices; — work with worn out or clogged centers; — sharpen short cutters without an appropriate mandrel; — use clamping chucks if the working surfaces of the cams are worn out; - when cutting off heavy parts of a part or workpiece, hold the cut end with your hands; - use a center with worn or clogged cones. The dimensions of turning centers must correspond to the center holes of the parts being processed; - leave keys, fixtures and other tools on a working machine.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. In the event of smoke or fire, immediately stop work, turn off electrical equipment, call the fire department, inform the immediate supervisor and administration of the organization, and take measures to evacuate the premises. When extinguishing a fire, it is necessary to use primary fire extinguishing means and take part in the evacuation of people. When electrical equipment catches fire, use only carbon dioxide or powder fire extinguishers. 4.2. In case of injury, the employee is obliged to stop work, notify his immediate supervisor and call emergency medical care or go to a medical facility. 4.3. If voltage (feeling of current) is detected on the metal parts of the equipment, if the equipment hums, if vibrations or increased noise levels occur, if the case suddenly heats up and melts, electrical equipment sparks, or the power cable breaks, it is necessary to stop the operation of the equipment and report the incident to your immediate supervisor. It is prohibited to start work without instructions from the supervisor. 4.4. In case of electric shock, it is necessary to free the victim from the action of the current by immediately turning off the electrical installation with a switch or circuit breaker. If it is impossible to turn off the electrical installation quickly enough, it is necessary to free the victim using dielectric gloves or a dry wooden object, and you must also ensure that you do not become energized yourself. After releasing the victim from the action of the current, it is necessary to assess his condition, call an ambulance and provide first aid until the doctor arrives.

Non-standard situations

If, during turning work on wood or metal, electrical voltage appears on metal parts, vibration is felt, one phase has disappeared, the smell of smoke is felt, or some other dangerous or unusual situation has arisen that threatens the failure of equipment or threatens the health of people, it is necessary to turn off the machine and inform to the master.

If a fire occurs, you must stop work and begin extinguishing it using special equipment.

If the lighting goes out, you must remain at your workplace until the power supply is restored.

Only strict adherence to safety rules during turning operations will not endanger the life and health of people.

OCCUPATIONAL SAFETY REQUIREMENTS AFTER WORK COMPLETION

5.1. Upon completion of work on lathes, personnel are obliged to: - turn off the power to the equipment, tidy up the workplace, clear passages and emergency exits; — tidy up the workplace, assemble the tools and put them in the designated storage areas; — make sure there are no fires, if there are any, cover with sand; - report all violations of safety requirements that occurred during the performance of work to the immediate supervisor - leave the territory.

Lathe safety precautions

The workplace at a lathe is a high-risk place. Workpieces and machine parts rotating at enormous speed, flying chips, and a voltage of 380 Volts pose a threat to human life and health. Therefore, safety rules when working on wood and metal are the first thing a worker should know.

Download safety instructions when working on lathes