For any work to be successful, you must have good equipment and tools. The same statement applies to amateurs (or professionals) “tinkering” with wood. Craftsmen who make furniture or other wooden products always try to acquire various tools and devices that can help them in their work.

For example, a jointer. This device significantly increases the productivity and quality of woodworking. But not all fans can purchase it, because its price is quite high. How to get out of such a difficult situation? There is a solution, and it’s quite simple - it’s to make a tabletop jointer with your own hands. And the manufacturing process itself will be discussed in the article.

Installation of knives

The blades must be strictly straight.

Special instruments are used to check the details of this parameter. The tested knives are mounted on the shaft sequentially, their edges protrude above the edge of the clearance lining by 1-2 mm. To control the parallelism of the knives, an indicator or a checking parallelepiped is used. The first gives less error when checking parallelism. The knives must not be distorted when fixing them.

Attention! It is strictly forbidden to use any gaskets when installing the blades. Knives that are worn out or mechanically damaged must be replaced as soon as possible.

Working area dimensions

An important criterion for choosing an industrial machine is the width of the table. Depending on the size of the parts that are intended to be processed, modifications of planing units can be divided into the following types:

- Heavy, with a milling width of up to 63 cm.

- Medium, for which this figure is 40 cm.

- Lightweight, with a table width of 25 cm.

The table has a smooth surface. Its receiving part is located at the level of the contour formed during torsion of the knives. The front plate is adjustable; by adjusting it, it is set below the receiving half of the work table to the thickness of the layer that needs to be removed in one pass of the board.

Design and principle of operation

A wood planer is one of the main types of equipment that is equipped not only with industrial, but also with private carpentry companies that professionally process wooden blanks. They are also purchased for home workshops, whose owners are engaged in the manufacture of wood products.

Device

Structurally, the jointing machine consists of the following components and parts:

- bed;

- working surface;

- cutting shaft;

- guide;

- circular fence.

The working surface is assembled from two plates - front and back. In this case, the level of the stationary (rear) plate is at the same level as the top point of the edges of the cutting knives, and the front (moving) plate is lowered down to the thickness of the layer of wood removed during processing. As a rule, the height difference between the surfaces is 1.5 mm, which is enough for high-quality processing of the workpiece in two passes.

Both plates are cast from cast iron, which makes the frame more stable. To better preserve the edges, special steel plates are mounted on the plates, which also serve as chip breakers.

The cutting shaft is the main part of the machine, installed on the frame between two plates. It is on this that the cutters are installed. Most often, identical single-edged knives that can be sharpened are used for work. However, in carpentry workshops they often prefer to use double-edge cutters, for the manufacture of which they use tool high-speed steel. It is impossible to resharpen such cutters, so knives that become very dull during operation are replaced with new ones.

Note: when working with hard wood, carbide-tipped knives are used.

The cutting shaft is covered with a circular guard, which is installed on the front plate. At the same time, it fits tightly to the guide, which is ensured by a special spring.

Planing machines of recent years are distinguished by the presence of a digital indicator of the depth of jointing, the ability to electronically adjust the height of the front table and the tilt of the guide ruler. In addition, almost all of them have an increased table length.

Advantages of jointing machines

Woodworking factories use a wide variety of equipment. One of the most popular units in a carpentry shop is a jointer for processing wooden blanks. This equipment is characterized by the following advantages:

- Ability to perform many different operations.

- For home use, you can purchase an industrial-made jointing machine at an affordable price. The most budget model will cost a home craftsman around 10 thousand rubles. The planing device is capable of processing massive wooden blanks, and small parts are also made on it, for example, furniture legs and more.

Briefly speaking about the purpose of a jointing machine, the main thing will be to prepare a piece of wood for the next precision processing operation. Such units perform curved planing of parts along planes or edges for assembling furniture and wooden structures. Using the machine, you can easily chamfer the workpiece at the desired angle.

The workpiece is fed to the knife shaft manually or using a conveyor attached to the machine. Modern jointers are equipped with chip collectors and dust absorbers.

The jointing device consists of the following elements:

- Massive metal frame.

- A table of two independent planes.

- Guards all moving parts.

- Planks that set the direction of the wooden workpiece.

- Vala with knives.

All parts and elements of the machine are attached to the bed; it is capable of supporting workpieces of significant weight. For its production, rolled metal with high strength values is used.

Before each new start of the unit, you need to check the location of all working parts.

How to choose a jointing machine?

When purchasing woodworking equipment, you need to take into account all the options that may be useful in your work. It is advisable to hire experienced carpenters to help and read the reviews. Here are the main criteria when choosing an electric jointer for your home:

- Small-sized and low-power machines are not suitable for large volumes of work.

- It is better to select the motor power, width and length of the planing surface with a reserve.

- Additional options make the jointer more practical and versatile.

- For large loads, it is better to buy a device with automatic wood feeding.

- When purchasing a planer-jointer, always carry out a test run of the mechanisms, inspect the insulation and main components for visible defects.

Jointer knives

On planing equipment, blades often fail and periodically require sharpening.

- In terms of standard size, standard knives are produced from 200x20 mm to 810x40 mm. Consider the steel the critical tool is made from. For example, P6M5 alloy is suitable for alder or pine, but for hardwood it is better to use HSS 18%.

- In carpentry, curved and straight knives are used. The straight blade ensures an even cut, while the curved edge allows you to obtain original contours.

- Even a professional jointer with dull knives will not be able to properly process the workpiece.

The main signs of poor sharpening of a cutting edge:

- The surface of the planed part is uneven.

- The material after processing has a fleecy appearance.

- Severe engine overheating.

Operating woodworking machines

Woodworking mechanisms require special care and attention when working with them. There are rules that must be strictly followed:

- Preventive repairs, sharpening knives and circular saws, should be carried out regularly.

- Monitoring engine operation, lubrication of bearings, tightening belts, cleaning contacts should be carried out by the operator as often as possible.

- It is not allowed to operate the machine without a protective motor casing.

The work place at the machine must be free of sawdust and shavings, the floor must be anti-slip, and the lighting must be sufficiently powerful.

Republished by Blog Post Promoter

What is a jointer?

At the initial stages of wood processing, carpentry workers need to create a relatively flat base surface, forming a plane on one side of the workpiece. This stage is called planing of the wooden element. The jointer machine replaced hand planes. Such equipment allows you to effectively and quickly cut off excess layers of material from the bottom plane with rotating knives, significantly speeding up an extremely tedious, monotonous and labor-intensive process.

The device of a jointing machine

Each device has a properly selected electric motor and drive. You need to understand that hard wood in carpentry cannot be processed normally on low-power equipment. 1-3 kW motors are installed on household planing devices. A wood planer consists of the following main components:

- Bed.

- A composite work table consisting of a pair of massive slabs.

- Knife shaft.

- Set of planing knives (2-4 pcs.).

- Guide ruler.

- Feeding mechanism (not available on manual jointers).

- Drive device.

Working principle of a jointing machine

The main part of such a device is the knife shaft for attaching the planing knives. Wood planing machines for home use have a work table consisting of two halves. The side stops have their own purpose; they help give the workpieces the desired shape and obtain the desired angle between adjacent planes. The operating principle of planing devices is as follows:

- The back of the table on the machine is always stationary and installed with the circle of the working knives in line.

- The front of the table is set by the carpenter a little lower to the desired height.

- The part is fed towards the rotation of the knives.

- As the block is fed, the jointer uses rotating blades to remove a layer of material.

- When set correctly, its thickness exactly matches the height difference between the front and back halves of the cast iron table.

Knives

Another, no less important selection criterion is the number of knives on the cutting shaft, it can be 3 or 4, when there are one or two knives, it cannot be called professional, it is strictly for domestic use and is only suitable for rough planing of minor parts in a country house.

The cutting shaft is fixed between the feed and receiving planes of the table. The knives must be 100% identical, which makes a simultaneous, uniform cutting contour possible. The gap between the plates is equipped with metal plates located flush with the back surface of the table. The edges of the overlays should not have mechanical damage and be well polished.

When buying a machine, the consumer needs to find out an important parameter - the frequency of rotation of the knife shaft. It can be in the range of 4.7-5.0 thousand revolutions if the machine is equipped with an electric motor of 5-5.5 kW. This parameter is the most popular when assembling woodworking equipment.

Attention! For woodworking units, the electric motor power must be at least 3 kW; no upper power limit is set for this equipment.

Principle of operation

The operating principle of the jointing machine is as follows:

- The back plate always remains stationary during the processing of parts. The location of the front of the work table is adjusted by the operator to the required height.

- After turning on the machine, the electric motor directs revolutions to the knife shaft. As a result, the cutting elements begin to rotate.

- The wooden piece is applied to the guide ruler with both hands and directed towards the knives. When working with inexpensive devices, the workpiece must be fed manually, which can lead to injury. Modern machines are equipped with an automatic workpiece feeding system. It ensures work safety and increases the feed speed of the bars.

- After feeding the workpiece, the rotating blades remove the layer of wood, eliminating unevenness, and creating a flat, finishing base surface. The processing speed depends on the workpiece planing technology. Most tools plan the surfaces of workpieces separately. There are devices that can process 2 sides of a wooden part at the same time.

If during the processing process fibers or small particles of wood appear on the block, then the blades need to be sharpened. If there are irregularities on the planed surface, it is recommended to adjust the distance between the plates and the planing shaft.

Planer or surface planer? How to decide

Among woodworking machines, there are those whose purpose at first glance is the same. And it may be difficult for a non-professional to understand all the nuances, as a result of which the wrong device will be purchased. Such machines with similar functions can be called jointers and surface planers. Both of these devices are designed to level wooden surfaces. However, there are still differences. And if you don’t know what you need – a jointer or a surface planer, then this article is for you.

What is a jointer and jointer

Now, in the age of technology, if you type the word “jointer” into a search, you will see all kinds of jointing machines. However, originally a jointer was a hand tool designed for leveling wooden surfaces.

It is an elongated plane with a double blade. When processing a wooden product with this tool, you should monitor the chips.

When it becomes continuous, then you can understand that the work of leveling is nearing completion.

Such an instrument can still be purchased today. If you have a small amount of work and a lot of time, a simple hand jointer will be enough for you.

A jointing machine is most often a fairly large device with a lower knife shaft to which two or four knives are attached. In other words, the surface to be leveled should be located below. When the shaft rotates, irregularities are carefully cut off with knives.

What is a jointer used for?

The boards and timber that come out of sawmills can be called rough lumber. There are irregularities, knots and resin pockets left on them. During their storage, temperature and humidity change, which is why the board may “lead” a little. If you are building a shed or temporary structure, then this is not so scary. It’s a different matter if the lumber will be used to make parquet, for interior decoration of a house, for furniture or to build a permanent structure. For example, a gazebo or a summer kitchen. In these cases, everything must be neat and beautiful, therefore, the boards and beams must be leveled before starting work.

Models

When choosing equipment, you need to take into account the size of the workpiece and the volume of work performed. If you plan to process small bars, you can purchase a compact model with a power of 4 kW. For large lumber, you will need a larger unit with a high-performance engine.

Joining machines "Kraton"

Model Kraton WMPT-260 (39,300 rubles) performs jointing and thicknessing, has a power of 1500 W, is compact, and is equipped with automatic feeding of workpieces.

Jointer JET

Combined machines JET JPT-10B (34,000 rubles) with a power of 1.5 kW are distinguished by their small dimensions and the ability to extend the working surface.

JET JPT-310 machines (80,000 rubles) have a power of 5 kW and are distinguished by double motor insulation. It is possible to connect a vacuum cleaner.

The JET Jointer 6'' jointing machine (193,000 rubles) with a capacity of 3.5 kW is equipped with a shaft with 48 knives. This is equipment for jointing and thicknessing.

SF-4 machines

The single-sided jointing unit SF-4 (179,000 rubles) has a two-knife round shaft that makes 5000 rpm. The machine is equipped with a three-phase squirrel-cage asynchronous electric motor.

Holzstar ADH 305 machine

A tabletop planer-thicknesser unit with a power of 1.8 kW is equipped with two knives and a rubber-coated output shaft. The average price is 44,900 rubles.

Brand Corvette

Series 106 (29,960 rubles) with a power of 1.5 kW is equipped with special pushers and a shaft with three knives.

The Enkor Corvette-24 sample (18,130 rubles) has a power of 1.25 kW and allows you to quickly switch planing from thicknessing to jointing mode.

Machines MB5026

The single-sided model MB5026 (54,900 rubles) made in China is equipped with a shaft with three cutters and has a power of 3 kW.

Brand Scheppach

Planer-thicknesser machines Scheppach HT-1050 (23,000 rubles) with a power of 1.5 kW and a productivity of 9000 rpm demonstrate reliable operation and clean processing of lumber.

The Scheppach HT-850 sample (17,000 rubles) of combined action with a 1.25 kW motor is compact and allows for a smooth surface of the workpiece.

The HT-650 jointer (18,020 rubles) is equipped with a 1.28 kW engine, has a mobile design, and provides for manual feeding of lumber.

| Manufacturer | Model | Power, W | Average price, rub |

| Kraton | WMPT-260 | 1500 | 39 300 |

| JET | JPT-10B | 1500 | 34 000 |

| JPT-310 | 5000 | 80 000 | |

| Jointer 6'' | 3500 | 193 000 | |

| Kurgan plant of woodworking machines | SF-4 | 2800 | 179 000 |

| Holzstar | ADH 305 | 1800 | 44 900 |

| Corvette | 106 | 1500 | 29 960 |

| Enkor Corvette-24 | 1250 | 18 130 | |

| — | MB5026 | 3000 | 54 900 |

| Scheppach | HT-1050 | 1500 | 23 000 |

| HT-850 | 1250 | 17 000 | |

| HT-650 | 1280 | 18 020 | |

| Makita | 2012NB | 1650 | 41 000 |

| DeWalt | D27300 | 1600 | 78 900 |

The price of Makita and DeWalt machines depends on the type of device and its configuration. The Makita 2012NB planer-thicknesser has a power of 1.65 kW, the price is about 41,000 rubles. The DeWalt D27300 machine with a power of 1600 W costs 78,900 rubles.

Video review of the Enkor Corvette-24 jointer.

What is a jointer

A wood planer is a woodworking machine of a planing type, designed for the initial processing of a workpiece of material. The device allows you to obtain a supporting surface, which will subsequently be the basis of the entire geometry of the product. The most common type of jointer is a single-sided device with an adjustable front worktable plate. The composition of such a machine includes the following elements.

- Bed.

- Drive consisting of an electric motor and a belt drive.

- A jointer consisting of two worktable plates (front and rear) and a working shaft.

- System for adjusting the thickness of removed chips.

- Side support that helps maintain the geometry of the product.

- Movable protection element.

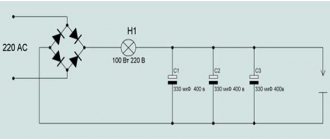

- Electrical part, which includes power wires, start and stop buttons and motor thermal protection system.

Some models of woodworking machines can be equipped with a chip collection system. The movable protection element is designed to prevent contact with the working shaft when there is no workpiece on it. Working knives are installed on the shaft in special slots. Depending on the requirements for the equipment, the manufacturer can install from 2 to 4 knives. The more knives are installed, the higher the quality of planing, but the more difficult it is to adjust them.

The difference between a thickness planer and a jointer

On the jointer, the operator holds the workpiece with his hands, and on the surface planer it is fixed with special rollers. All thicknessing machines are equipped with an automatic feeding system, which allows processing without human intervention. The support table of the jointer is divided into front and rear plates, with the rear plate installed higher than the front one, and the work shaft installed between them. In a thicknesser device, the supporting surface is made as one piece at the bottom, and the planing shaft with support rollers is located at the top. Planing equipment has one side stop; for a surface planer, both sides can serve as side stops.

The difference between an electric stationary jointer and a planer-thicknesser machine

For simple operations on processing short boards, hand tools with an electric drive are used. To trim the surface, a lot of force is required, so an electric motor was added and the design was slightly improved. Because of this innovation, its performance characteristics have improved:

- the mass has become larger, the pressing force has increased;

- processing has become more accurate;

- work has accelerated;

- Replacement nozzles have appeared in the kit sold.

Planer, jointer or planer

- The plane makes the first pass when preparing the surface, removing the top to the thickness of the working blade setting. Planing actively combats bumps, knots, and other irregularities. A plane as a working tool contains a knife and a block. There may be two knives in the design, then they are located one behind the other and the second one removes thinner chips, making the surface even, but the final turning is done with another tool.

- A jointer is essentially a type of planer; it has a more advanced structure. The body of the jointer is longer and heavier, this gives a tighter pressure to the processing area. Blades (2 pcs.) are configured for finishing penetration.

- A jointer is often confused with a surface planer, but the purposes of these tools are different. The jointer levels the wood, and the thicknesser is needed to transfer parallel features to the part. An electrically powered manual thicknesser lays out parallel lines to the specified size.

In the operation of professional machine tools, a distinction is made between the operation of a surface planer and a jointer:

- The jointer removes a certain layer, imparts a flatness to the surface, the end on the jointing equipment is processed in a perpendicular direction to the main plane;

- To make the planes perfectly parallel, a thicknesser is used, but its work is possible only after preliminary alignment.

Proper Use of a Portable Electric Planer

Jointing refers to the processing of wooden elements using any type of jointer. The portable tool can be fixed permanently for ease of processing. Procedure:

- the tool is secured to the workbench; when moving the board, a stop must be provided for it;

- the board is placed on the blade of the device against the stop after turning on the power of the tool;

- To obtain the required surface quality, the board is passed along the blade several times.

To control the thickness of the cut layer, a line is drawn with chalk on the workpiece. The layer above it should disappear smoothly, and the line itself should be removed if an even workpiece is obtained. To work with the edge, the board is turned to the blade with the corresponding side, then all actions are repeated in the same sequence.

Working with a jointer mounted on a work table is not difficult, but requires compliance with safety precautions:

- hands should not be in the blade working area;

- the work is performed using special protective clothing;

- To avoid holding the board with your hands and putting them in danger, use clamp-type holders.

To protect the worker from premature switching on of the tool, it is equipped with a protective tool control system. There are two power buttons on the case; power is supplied only when they are pressed simultaneously.

External structure of the hull

There is a socket on it for connecting the vacuum cleaner pipe and making it easier to remove chips; most often, models are equipped with such an entrance on the right. A handle for support during operation and control buttons are installed on the body. There is a manual screw to adjust the planing depth and layer thickness. To change the width of the processed strip, a stop is provided on the side .

The tool has a protective casing that can be folded down when needed. The lower sole of the unit is made of thick aluminum sheet. On the case there is a connector for connecting a battery or batteries with a voltage of 18 V. The kit includes a working cable 2 meters long with a plug for a household network.

Such stationary units are much more expensive than portable options, but their functionality is much wider. Operations that can be performed on a stationary jointer:

- the beam is planed quite long, the cross section is processed;

- the ends are made at any angle, a selection is made in the body of the board of figured elements or through gutters (such operations are not done with a hand-held electric tool);

- the array is turned with a width of 600 mm, the length is allowed up to 3 m, and the thickness of the incoming part should not be less than 13-15 mm;

- Hard and durable wood is allowed for processing, which cannot be processed with portable tools of low power.

What is important to know about the design of the device

Regardless of the model chosen, the main elements of all machines are the same. The differences are only in their quality and performance. The main design includes:

bed, which is made of durable materials; work table on which the workpiece is placed; shaft with knives (it is important to check the quality of fixation of this element); electric motor; start button and control levers.

To produce the frame, tool steel of special strength is used. This element is the most important, since all the main components, as well as additional equipment, are attached to it. On top there is a desktop, which is divided into 2 parts. The first is the feeder; a wooden blank is placed on it, which is directed to the shaft with cutting elements. The second is the receiving one, where the processed material goes out.

Some manufacturers of planer-thicknesser machines install a vertical plate, which is fixed to the side of the working surface. Thanks to it, the operator can accurately guide the workpiece.

One or knives are installed on the shaft. There are 2 options for this element:

- Single edge.

- Double edge.

When using the first option, you must remember that the cutting part requires constant sharpening, so the number of operations is limited. Machines with double-edge knives are characterized by long service life and efficiency. This is due to the fact that the element is made of durable steel and sharpened on both sides.

The electric motor is selected based on the area of application of the machine, power and shaft speed. For power supply, both a standard network - 220 V, and an industrial network - 380 V can be used. To turn on the device, start buttons are provided. Control is carried out using a special block.

To improve the quality of processing and make work safer, auxiliary equipment is installed in modern models. Each machine is designed to perform a given number of operations, which is calculated based on the rotation speed and the number of installed knives. Processing is performed in both 1 and 2-3 passes.

Machine assembly sequence

For the work to be successful, first working drawings and a brief description of the device are drawn up.

- The assembly of the machine begins by transferring the dimensions from the drawing onto the workpieces, and full-size parts are manufactured. In this case, you need to pay attention to the location of the rotor bearings.

- A rotor with a bearing is installed, the belts are attached to the knife shaft and the engine.

- The serving and receiving tables are installed. The moving parts of the machine are covered with sheets of metal or plywood.

- The starting switch/switch is installed.

- A test start-up of the unit is performed.

Video: jointer instead of thickness planer.

Review of factory models

| Model | W0108 | W0106FL | W0103FL | W0100 |

| Engine | 0.75 kW 220V | 0.75 kW 220 V | 2.2 kW, 220V | 3.7 kW 380V |

| Cutting width | 153 mm | 153 mm | 203 mm | 400 mm |

| Maximum cutting depth | 3 mm | 3.2 mm | 3.2 mm | 3 mm |

| Number of knives of the cutting shaft | 3 | 3 | 4 | 4 |

| Cutting shaft diameter | 61 mm | 61 mm | 78 mm | 98 mm |

| Table length | 1210 mm | 1535 mm | 1800 mm | 2250 mm |

| Feed table length | 700 mm | 760 mm | 880 mm | 1090 mm |

| Reception table length | 590 mm | 755 mm | 880 mm | 1090 mm |

| Table width | 255 mm | 255 mm | 330 mm | 420 mm |

| Table height from floor | 820 mm | 850 mm | 795 mm | 820 mm |

| Stop dimensions | 740 x 98 mm | 889 x 124 mm | 889 x 124 mm | 1195 x 150 mm |

| Packaged sizes | 1245x515x275 mm | 1600x360x250 mm | 1850x450x300 mm | 2300x820x1025 mm |

| Gross weight | 104 kg | 135 kg | 208 kg | 570 kg |

| Price | 52000 rub. | RUB 68,000 | 112000 rub. | RUB 229,000 |

Working principle of a jointer

chipboard guide ruler

One person is enough to operate single-sided jointing equipment at home. He examines the condition of the workpiece and places it with its convex plane up on the front plate. With both hands he presses it against the ruler and points it at the cutters. Next, the already trimmed side is pressed with the left hand to the surface of the back plate. The master inspects the processed workpiece: if it is not planed enough, he sends it to the knives. It is advisable to avoid processing very warped workpieces, since too thick a layer of chips is removed. The remaining workpiece may turn out unacceptably thin.

When processing two perpendicular planes, the larger area is used first. Then it is applied to the guide and the second one is planed. The double-sided machine allows you to process both sides simultaneously.

- If “burns” or “mossiness” appear on the surface during processing, it’s time to sharpen the cutters;

- When working with parts shorter than 40 cm and narrower than 3 cm, they are held only with special pushers, and parts of complex shapes are held with templates;

- If the planed plane is curved or has the shape of an impeller, you should check the level of the tabletop plates and the blade shaft.

Guide bar

Just like the table, it is made of metal, smooth. The bar is located in the grooves available on the table and is fixed with bolts. When changing the width of the workpiece, the bar moves in the grooves across the table.

A fan guard is attached to the table receiving plate, which protects the shaft by means of a fan guard spring to the guide bar.

Setup and operation

The first thing they do when starting to work on a jointing machine is to check and, if necessary, adjust the latter. Only after this is it transferred to operating mode.

Settings

A properly configured machine is the key to trouble-free operation and high-quality wood processing. During the setup process:

- control of parallelism, and, if necessary, sharpening of the cutting edge of knives;

- complex adjustment of tables and guide ruler to the size of the thickness of the layer of wood being removed;

- setting the workpiece feed speed and adjusting the feeding mechanism.

Each of the cutting knives has a 40° sharpened angle and a chamfer. In this case, the rounding of the cutting edge of the knife should not be more than 8 microns. Sharpening knives on a knife sharpener

When installing knives, it is equally important to ensure their parallelism - the deviation over a length of 100 cm should not exceed 0.1 mm. Such accuracy can be achieved using special indicators.

The knives are installed in the cutting shaft after both plates have been lowered. In this case, both the shaft and blades should not protrude beyond the edge of the chip breaker by more than 2 mm.

The work surface plates are raised until the gap between their jaws and the edges of the blades reaches 2.5 mm. If the size of the gap is large (> 3 mm), then the wood will begin to be pulled out in pieces, and if it is less than 2 mm, then the cutting edge of the knives will be deformed. The gap is controlled with special calibrated plates.

As for the guide, the gap between it and the left edge of the cutting shaft should be slightly larger than the width of the workpiece.

The automatic feeder is configured to feed workpieces with low pressure.

ATTENTION! The working mechanisms of the jointing machine are adjusted taking into account the following tolerances:

- perpendicular - no more than 0.1 mm for every 10 cm;

- along the plane - no more than 0.15 mm/m.

Having set up the machine, they do a test run, during which several workpieces are processed. In the event that it was not possible to achieve the required result, the adjustment is repeated.

Operating principle

When starting work, the workpiece is inspected and placed on the front plate with the convex plane down. When the shaft with knives begins to rotate, a workpiece is fed towards it, which is pressed against the guide. The processed part of the workpiece is pressed against the surface of the back plate.

If upon inspection of the processed workpiece it turns out that it is not planed enough, then the process is repeated.

If there are two perpendicular planes, the one with the larger area is processed first. Then the workpiece is pressed with the processed side against the guide and the process is repeated.

Setting up the jointer

Before using a new machine, or during its operation, sharpening of the knives is required at certain intervals (depending on the workload, they may vary in duration). The blades are removed from the shaft, sharpened, and after that they must be correctly (strictly parallel) installed in the working shaft.

The sharpening angle of knives for a jointer should be 400. To sharpen such a knife, you need a special device. The radius of curvature of the knife edge should not exceed 8 microns, and its straightness per 10 cm of length should not be more than 0.0025 mm.

To install sharpened knives into the shaft, the front table, along which the workpiece is fed to the shaft, and the rear table, on which the “finished product” arrives, must be lowered. For installed blades, it is possible for them to protrude beyond the edge of the chip breaker by 1-2 mm; the same tolerance is possible for the shaft itself.

A responsible action when installing sharpened knives is to control their parallelism. To implement this, a special indicator device is used.

The next step in setting up the planer is to fix the height of the front and rear tables, the guide bar, and the devices for feeding the workpiece. After performing these manipulations, the machine is tested in idle mode. If necessary, deviations from the required parameters are identified, additional adjustments are made.

Design Features

Planing and thicknessing machines are designed for beautiful and high-quality processing of the front part of wood. All defects and irregularities are removed, giving the product a beautiful appearance. The devices are used both in home workshops and in large-scale production, where these operations must be performed daily.

After processing, the result is a smooth and clean workpiece that preserves the texture of the wood. Some models are capable of not only performing this process, but also chamfering

It should be remembered that it is important to completely dry the wood before starting work. This is the only way the operation will be completed without problems.

Planing-thicknessing units

Designed for simultaneous thicknessing and jointing functions. The thicknesser makes it possible to make a chamfer to the desired depth. The working shaft is located between the feeding part of the table and the receiving, rear part.

Planer-thicknesser devices are especially in demand at large woodworking enterprises and construction sites. Such popularity of these units is explained by the ability to make workpieces of the required thickness.