A grinder is an extremely necessary tool that is widely used in any construction work. But even the highest quality tool sometimes breaks down at the most inopportune moment.

One of the most common problems is disk . It arises due to the large volume of the consumable itself and is most often found not in all types, but only in angle grinders. At the moment when cutting begins, a small impact occurs - force pressure is applied directly to the consumable itself.

With a disc size of up to 12 cm, the impact is insignificant, and with a component of 12 or more, the nut that holds the disc is tightened even more. This process occurs due to the influence of inertia. Because of this, it is not always possible to dismantle the consumable using conventional methods.

In order for a tool to last for an extremely long time, it must be used correctly. Also, timely maintenance will avoid problems with the tool in the future.

Therefore, in this article we will tell you in detail how to remove a disc from an angle grinder using standard and unusual methods.

Specifics of using an angle grinder

The tool has increased functionality. It can be used to clean surfaces. To do this, it is necessary to equip the grinder with special steel rods and sandpaper petals - such a circle will act as a cleaner.

How else can you use an angle grinder:

- for grinding - a concentric attachment with Velcro is screwed onto the tool. The abrasive is attached to the latter. Immediately before starting work, the functionality of the connection is checked;

- for grinding with abrasive wheels - the last component must be used extremely carefully. Overexposure may cause the abrasive to break.

By installing special cutting discs, the grinder can also be used for cutting concrete. Due to its versatility, the tool is in wide demand for any type of work.

How to remove the cleaning disc on an angle grinder

First of all, it is necessary to carry out preparatory measures, namely:

- disconnect the grinder from the network - otherwise you will get an electric shock or there will be a short circuit;

- press the spindle rotation button;

- While holding the stop button, you need to unscrew the flange nut.

It would also be useful to carefully inspect the body of the angle grinder. Perhaps some component has failed due to jamming. This will allow you to find out as accurately as possible what the problem with the grinder is.

Why do you need to change the disc on an angle grinder?

As practice shows, the problem rarely occurs at idle. This is also true when working with light wheels and grinders that have a soft start.

The problem immediately begins to appear at the moment of increasing speed and upon contact with an object that needs to be cut:

- material resistance provokes a sharp decrease in revolutions and rotation speed;

- by inertia, the angle grinder motor still rotates, engaging the gearbox and spindle;

- Often, the problem is aggravated by the high power of the grinder .

Due to the above-mentioned problems, it is not always possible to remove the disk using the usual methods. Therefore, we will consider all methods of dismantling the consumable.

Safety regulations

When working with an angle grinder, it is important to remember that this tool has an increased risk of injury. Accordingly, you should not lose vigilance under any circumstances, even when disconnected from the power supply. When using auxiliary tools and materials to replace the disk, pay close attention to them. Plumber tools can also cause significant injury.

An angle grinder (angle grinder) or grinder has proven itself to be a very effective tool with which you can perform a wide range of work. However, during its operation, you should adhere to safety precautions, since the disk speeds are very high and you can get injured. Judging by numerous reviews, many home craftsmen have problems with the discs; they often split, and the nuts with which they are clamped become jammed. The reason for this may be the human factor or simply marriage. As a result, such a nozzle cannot be used for its intended purpose.

It would seem that there is nothing difficult about replacing the disk with a new one. However, at this stage the master is faced with a problem - the nozzle is tightly clamped by a fixing nut that does not want to unscrew. How to remove a jammed disc from an angle grinder? What methods are used for this? What means can be used if the standard key is lost? You will learn how to remove a jammed disc from an angle grinder from this article.

Read also: Switching power supply is clicking

How to unscrew a disc on an angle grinder when clamped with a nut

During intense cutting, the disc breaks and is clamped by the clamping nut. When such a situation arises, you can use the standard wrench that comes with the kit or a gas tool. But the mentioned means do not always provide the desired result.

The dismantling itself can be done much faster and easier. To do this, you need to perform the following operations:

- use pliers;

- use the above-mentioned tool to break the disk so that it completely disintegrates;

- You must first take care of personal protective equipment, namely a helmet or goggles.

Using protective equipment is a mandatory step. This will avoid injury due to fragments.

Next, using a metal plate (MP), grind off the remains that remain in the grinder. In this case, the metal plastic should be less than the disk in thickness.

How does stitching happen:

- The grinder turns on;

- the metal plate is clamped with pliers;

- then, the disc is carefully ground down using MP.

After completing the above steps, the nut on the angle grinder can be unscrewed without a special key.

Heating the retaining flange

This is one of the simplest and most effective ways to replace a cutting disc on an angle grinder when there is no special key nearby. The locking nut must be heated using a hair dryer, a gas cutter, or by pressing it firmly against a wooden block. Once the flange is hot enough, it can be easily pressed out with a hand protected by a welding glove. However, there is one drawback to this method: there is a risk of damaging the plastic body of the angle grinder.

PHOTO: Heating the nut by pressing a working grinder against a wooden log

How to avoid replacing a disc on an angle grinder

Want to avoid costly repairs? Then you must initially take care of the safe and problem-free operation of the device:

- Place a cardboard or plastic washer between the disc, flange nut and spindle head. Due to this, you will provide protection against jamming;

- correctly install the abrasive wheel - the front side of the component is mounted on the support flange. In this case, it is necessary to avoid contact of the element with the nut. This method involves using a standard metal ring as a fuse;

- Weld a nut onto the clamping flange. The latter will provide the ability to press the consumable without the use of special tools. Using a standard wrench will suffice.

In addition to the above recommendations, tightening must be carefully monitored. When installing the disc on the angle grinder, you do not need to apply too much force. Otherwise, in 100% of cases this will cause jamming of the consumables and breakdown of the expensive grinder.

What solution to the problem is offered by specialists and amateurs + (Video)

- Install a newspaper gasket under the nut;

- Place a gasket from a plastic bottle under the nut;

- Replace the nut with a nut of a different design.

What is a newspaper gasket? This is a paper washer the size of a nut. It is put on the installed disk, and a nut is screwed on top. This piece of paper was a stumbling point, because the safety inspection always spoke about the harmfulness of such a decision.

Representatives of safety authorities treat the installation of gaskets made of any other materials in the same way:

- Cardboard;

- Paronitis;

- Gaskets made of various plastics;

- Rubber gaskets of various thicknesses.

But there is a solution that does not contradict safety requirements and allows you to install and remove the disk normally. This is a special nut that consists of two elements - a nut and a pressure washer. The use of such a nut does not require any shims, because with it the disk does not jam.

Method 2 – How to remove a disc from an angle grinder with a key

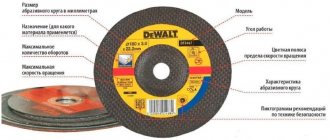

Pretty standard way. It involves the use of a special key that comes with the grinder. Initially, you need to fix the spindle. The disk is installed on the latter, and the clamping occurs due to the flange nut (FN).

Dismantling of the FG is carried out with an open-end wrench; for this purpose, the flanges are equipped with holes. The key pins enter into the latter and removal is carried out.

How to dismantle:

- to clamp the spindle, press the button;

The latter is located on the reverse side. Then, using an open-end wrench (RK), the latch is clamped - you cannot release it, because the disk will rotate.

Does the disk rotate clockwise? Then the open-end wrench must be rotated counterclockwise and vice versa if the disc goes counterclockwise. It is important to understand here that the flange must give in and move.

If this happens, then the component can be safely unscrewed. After this, the old disk is easily removed and a new one is installed.

- use of a gas key (GK);

When using such a tool, you need to take into account the fact that the tool has increased shoulder strength. Therefore, in the process of activation, it has a powerful effect on the parts of the angle grinder.

This should be understood as a gas wrench can easily damage, tear off parts or even “kill” the gearbox. Therefore, it is necessary to use HA with extreme caution.

Important: Any manipulations with the grinder should be done only after the tool is completely disconnected from the network. If you do not take into account the high speed of the grinder, then injuries cannot be avoided.

There is also a large amount of waste to consider. Working with an angle grinder involves the presence of a significant amount of metal shavings and dust.

Therefore, as mentioned above, first of all you need to take care of personal protective equipment (PPE) - goggles or a helmet. Otherwise, emergencies cannot be avoided.

PPE provides more than just safety. With glasses or a helmet, you can pay much more attention to working with the angle grinder. This will certainly increase the quality of the result.

Also, optimized application will increase the efficiency of the grinder. This will allow you to use materials such as abrasive wheels more efficiently.

It is worth remembering that the disc in the grinder is installed in several ways. Self-assembly is notable for the fact that during the biting process the disc jumps forward. Therefore, this type of installation is safer in contrast to the “hands-on” installation method.

Tip : To work without clamps, long metal workpieces should not be cut to the end. It is enough to leave only 2 mm of metal. You can easily break it off and at the same time protect yourself from jamming of the angle grinder.

It is more efficient to process small workpieces directly if they are pressed with a vice or clamp to the workbench. The pressure density directly affects the quality of the cut and safety.

Method 3 - How to change a disc on an angle grinder without using a key

A special tool may not always be at hand. Therefore, in some cases, maintenance of an angle grinder associated with replacing an old disk with a new one may become somewhat more complicated.

But other means come to the rescue, such as a gas key. We have already talked about it above, so we will analyze in more detail the specifics of its operation. To work with a tubular or gas wrench, it is necessary to open it as far as possible to fit around the flange.

When turning the key, the spindle must be held with a metal plate - this was also discussed above. In most cases, a gas wrench helps. But there are situations when even he is not able to help.

In addition to the gas key, it is worth trying the “tapping” method. To do this you need:

- take a metal rod or thin chisel;

- fix the angle grinder spindle as tightly and securely as possible;

- Gently tap the edge of the flange to displace the nut.

In this case, the blows must be performed in the right direction. The latter is equivalent to the direction of rotation of the disk in the angle grinder . Regarding safety, this technique is characterized by an increased danger associated with damage to the flange mechanism. Therefore, this method should be used only if other methods do not help.

What is the cause of the problem?

Before asking how to remove a disc from an angle grinder, experts recommend understanding why the nut on an angle grinder bites. It has been noticed that this problem is mainly observed in angle grinders that have a significant disc size. A disc is considered large . During operation, torque is generated. Next, when the master begins cutting, a small impact occurs. In other words, a force is exerted on the disk. If the size of the nozzle is no more than 12 cm, then this impact will be insignificant. If the disk is large, then the nut is tightened more by inertia. As a result, it is not possible to dismantle it in the usual way. Read more about how to remove a disc from an angle grinder below.

Sources:

https://stroy-podskazka.ru/instrumenty/bolgarka/kak-stavit-disk/ https://vahatehnika.com/bolgarka/kak-snyat-disk-s-bolgarki-bez-klyucha.html

Method 4 - How to unscrew a disc on an angle grinder without a key using a nail

It is worth noting that a damaged disk can be removed with a simple key made from an ordinary nail. Such a tool must have a size of 100 mm or more.

How to make a nail wrench with your own hands:

- the workpiece must be bent into a U-shape. In this case, the distance between the legs should be equal to the holes in the flange itself;

- Use a hacksaw to cut off the head of the nail and its tip.

Just two operations and the homemade key is ready for use. To unscrew a disc on an angle grinder using this tool you need:

- fix the spindle;

- gradually unscrew the fastener.

It happens that due to inertia the nut is tightened very tightly. This problem is also easily solved. You need to use a larger lever - insert another “hundredth”. And then the disc can be easily removed.

Method 5 – How to replace a disc on an angle grinder using a torch

Situations arise when none of the above methods can help. Then you need to use a gas burner.

The essence of the principle is to heat the nut. The latter will expand under the influence of high temperatures due to certain properties of the metal. And then it can be cranked out.

There is another method, but it is very crude. To remove the nut, you can cut it with a hacksaw. But this method is very sloppy and will require additional costs to purchase a new component.

You can also use penetrating lubricant. It will lubricate the nut and make it much easier to unscrew.

Rotary hammer or impact drill

To be honest, it is not the best or easiest option to unscrew a jammed nut on an angle grinder, but it is used if other methods do not work. As an attachment for a drill or hammer drill, you need a drill of a suitable diameter, most often 6 mm. If you are using a drill, you need to set it to jackhammer mode in advance. It is better to fix the grinder in a vice, clamp the spindle stopper, insert the drill into one of the holes of the clamping nut with emphasis in the direction of unscrewing, and briefly press the “Start” button. This method allows you to move even a tightly clamped flange. The disadvantage is that this can break the mounting holes for a standard key.

PHOTO: i.ytimg.com Insert the drill into one of the holes in the nut and turn on the drill in impact mode