Nickel plating is the most popular electroplating process. Attractive appearance, high corrosion resistance and mechanical properties speak in favor of the wider use of nickel for decorative, protective and functional purposes.

Nickel applied directly to steel is in the nature of a cathodic coating and therefore protects only mechanically. The discontinuity of the coating contributes to the formation of corrosive couples, in which steel is a soluble electrode. This results in corrosion under the plating, which erodes the steel substrate and causes the nickel plating to peel off. In order to prevent this phenomenon, the steel must be coated with a dense, non-porous, thick layer of nickel.

Nickel coatings are the basis of multilayer decorative and protective systems Ni-Cr and Cu-Ni-Cr. The use of baths with shine formers greatly simplifies the technology of applying multilayer coatings.

Due to its high mechanical properties, nickel is used to restore worn machine parts, galvanoplastic production of injection molds, and structural elements that are difficult or even impossible to produce using conventional mechanical methods. In the chemical industry, a thick layer of nickel is used to cover parts exposed to strong alkalis.

Nickel plating baths

Widely used in workshops is a bath consisting of three main components: nickel sulfate, boric acid and chloride, such as nickel.

Nickel sulfate is a source of nickel ions. Nickel chloride significantly affects the performance of nickel anodes. In chloride-free baths, strong passivation of nickel occurs, as a result of which the nickel content in the bath decreases, and the result is a decrease in current efficiency and deterioration in the quality of coatings. In the presence of chlorides, the anodes dissolve to a degree sufficient for normal nickel plating. Chlorides increase the conductivity of the bath and the “operability” of the bath when contaminated with zinc. Boric acid makes it easier to maintain pH at the same level. The effectiveness of this action largely depends on the concentration of boric acid (in practice, predominantly ~30 g/l).

The use of nickel chloride is not considered desirable by everyone. Due to its high price, and often difficulty of acquisition. However, it is necessary to take into account that when introducing nickel chloride into the bath, we also introduce nickel into the bath. NiCl2•6H2O chloride theoretically contains 24.69% nickel and, therefore, by introducing this chloride in an amount of 40 g/l, we increase the nickel content in the bath by approximately 10 g/l, which already has a certain value.

Another frequently debated issue is the use of sodium chloride as a source of chlorides. It is known that many electroplating shops successfully introduce NaCl into bright nickel plating baths.

There are many reasons for poor performance of nickel baths, and the claim that the reason is the use of table salt has little justification. Even the English company Canning, well known among electroplating technicians, introduces sodium chloride in the amount of 28 g/l into the NiSOL bright nickel plating bath. Instead of sodium chloride, another chloride can be used, for example, as in PNR, magnesium chloride. The Watts sulphate bath has been known and widely used for many years. The contents of individual components - the basis of Watts baths for applying matte coatings are, g/l: (200-350) NiS04•7H20, (30-60) NiС12•6H20, (25-40) H3BO3.

Often, additives of so-called electrically conductive salts are added to the Watts bath, which increase the electrical conductivity of the bath and improve the appearance of the coating. Among these salts, the most commonly used is magnesium sulfate (~30 g/l); in baths for mass treatment of small parts, its concentration is much higher.

Nickel sulfate is most often introduced in a concentration of 250-350 g/l. For a long time, an upper concentration limit was considered appropriate, which made it possible to carry out the process at high current densities without fear of burning the coating on the ribs and protruding areas. Recently, there has been a tendency to limit nickel sulfate to less than 200 g/l, which significantly reduces solution losses.

The concentration of chlorides in a nickel bath is not precisely standardized. In so-called chloride baths the concentration of nickel chloride exceeds 200 g/l and therefore there is no need to add nickel sulfate. In a workshop environment this is not justified, even based on the price of nickel chloride.

The concentration of boric acid reaches 25-40 g/l. Below 25 g/l the tendency for the nickel bath to become alkalized rapidly increases. However, exceeding a level of 40 g/l may be unfavorable due to the possibility of boric acid crystallizing in the form of crystals deposited on the walls of the bath and anodes. This phenomenon occurs especially easily in unfavorable or poorly heated baths.

The sulfate bath operates over a wide range of temperatures, current densities and pH. At room temperature, nickel plating is rarely used. For coatings applied in cold baths, nickel peeling off along with the chromium often occurs during decorative chrome plating. Therefore, the bath should be heated to at least 30 °C.

The bath with blackening agents operates at 50-60 °C. The current density must be selected experimentally so that coatings are not burned.

The sulfate bath works reliably over a wide pH range. Previously, baths were usually maintained at a pH value of 5.4–5.8, which was motivated by the less aggressiveness and better hiding power of the bath. However, such a high pH value leads to a significant increase in stress in nickel coatings. Therefore, in most baths used in industry, pH = 3.5–4.5.

Modern baths require mixing, which is necessary from the point of view of intensifying the nickel plating process and reducing the risk of pitting. Stirring the bath entails the need for continuous filtration in order to eliminate mechanical impurities.

Mixing with a moving cathode rod is not as effective as mixing with compressed air, and in addition, it requires a special ingredient that prevents foaming. Accordingly, purified air is currently used in the galvanic workshops of Poland to mix all nickel baths equipped with devices for bright nickel plating, manufactured at the Institute of Precision Mechanics.

General characteristics of bright nickel-plated baths.

Traditional baths for applying matte coatings are currently used indefinitely. They are used, in particular, for pre-nickel plating of steel products before acid copper plating, in the belief that on matte nickel the matte coating deposited in an acid bath has better adhesion than on bright nickel. This assumption is sometimes justified, since decomposition products of organic additives accumulate in baths with brightening agents, leading to passivation of nickel coatings, mainly in galvanic workshops, whose workers neglect the rules for preserving nickel baths that have been used for a long time without regeneration.

However, there is a situation that forces one to abandon nickel plating in baths with shine-forming additives, for the reason that shiny coatings are not flexible enough and are destroyed when nickel-plated objects are bent. Before deciding to use bright nickel plating in series production, the suitability of the process must first be tested on samples.

Types of nickel plating

Nickel plating in simple home conditions is carried out in two ways:

- electrolytic;

- chemical

The choice of method depends on the structure and shape of the material.

Electrolytic nickel plating

The electrolytic method uses substances that partially or completely consist of ions and have ionic conductivity. Nickel coating is applied due to the electrochemical properties of these substances. The most widely used electrolytes are sodium and chromium sulfate.

Depending on the degree of reflection of the coating, nickel plating is distinguished:

Functions of electrolytic nickel plating

- matte;

- shiny.

To apply a matte finish, electrolytes without additives are used. Products with a matte finish do not have a metallic sheen.

Bright nickel plating is obtained by adding special brightening agents based on chloramine, propargyl alcohol, benzosulfamide and other oxidizing agents to the electrolyte.

The best protection of nickel coating is achieved with minimal porosity of the protective layer. For this purpose, it is copper-plated or a multilayer structure of the material is used.

For your information. With the same thickness, multilayer coatings are several times more reliable than single-layer materials.

The most common examples of multilayer materials are copper-nickel-chromium coatings.

The main disadvantages of electrolytic nickel plating are:

- high degree of porosity;

- uneven deposition of nickel;

- difficulty in processing surfaces with complex shapes.

Electroless nickel plating

The method is based on the property of nickel ions to be reduced in a liquid medium. For this purpose, sodium hypophosphite or other chemical reagents are used. The chemical method allows you to process products with complex surface shapes.

The disadvantage of this method is the relative high cost of dry reagents used to prepare aqueous chemical solutions.

Consumption of nickel anodes.

Practitioners who deal with nickel plating on a daily basis know that nickel consumption is associated mainly with the consumption of nickel anodes, which also determines the need for frequent replenishment of the anodes; At the same time, the bath works for months without the need to add nickel sulfate.

Wanting to save on nickel, some workshop workers take the line of least resistance and simply apply a thin coating, thereby degrading the quality of the product. The dependence of the mass of deposited nickel on the coating thickness is shown in table. 1.

TABLE 1

THE TIME REQUIRED TO OBTAIN A NICKEL COATING OF A SPECIFIED THICKNESS, S, AND THE MASS OF DEPOSITED NICKEL, mNi, DEPENDING ON THE CURRENT DENSITY. CATHODE CURRENT OUTPUT 92.5%

| Thus, with a nickel coating thickness of 10 microns, often used as a sublayer under decorative chrome for light operating conditions, 0.89 g of nickel is theoretically deposited per 1 dm2 of surface, but in practice it will be more. Even if we accept a nickel consumption of 2 g/dm2 and assume that 1 kg of nickel costs 1000 zł, it turns out that the cost of the required nickel is 2 zł. Consequently, reducing the thickness of the coating does not provide much savings and can damage the company's reputation. |

STATE STANDARD OF THE USSR UNION

| Unified system of protection against corrosion and aging METAL AND NON-METALLIC INORGANIC COATINGS Designations Unified system of corrosion and aging protection. Metal and non-metal inorganic coatings. Symbols | GOST 9.306-85 |

Introduction date for newly developed products is 01/01/87

for products in production - when revising technical documentation

This standard specifies the designations of metallic and non-metallic inorganic coatings in technical documentation.

1. Designations of base metal processing methods are given in table. 1.

Table 1

| Base metal processing method | Designation | Base metal processing method | Designation |

| Kravtsevaniye | KRC | Electrochemical polishing | ep |

| Punching | shtm | "Snow" etching | snzh |

| Hatching | str | Pearl processing | and |

| Vibration rolling | FBR | Drawing arcuate lines | dl |

| Diamond processing | alm | Drawing hair lines | ow |

| Satin finish | stn | Passivation | Chem. Pass |

| Matting | mt | ||

| Mechanical polishing | mp | ||

| Chemical polishing | HP |

2. Designations of methods for obtaining coating are given in table. 2.

table 2

| Coating method | Designation | Coating method | Designation |

| Cathodic reduction | — | Condensation (vacuum) | Con |

| Anodic oxidation* | An | Contact | CT |

| Chemical | Him | Contact-mechanical | Km |

| Hot | Gore | cathode sputtering | Kr |

| Diffusion | Diff | Burning | Vzh |

| Thermal spray | According to GOST 9.304-87 | Enameling | Em |

| Thermal decomposition** | Tr | Cladding | PC |

* The method of producing coatings colored during the anodic oxidation of aluminum and its alloys, magnesium and its alloys, titanium alloys is designated “Anocolor”.

** The method of producing coatings by thermal decomposition of organometallic compounds is designated Mos Tr

Table 2

(Changed edition, Amendment No. 3).

3. The coating material, consisting of metal, is designated by symbols in the form of one or two letters included in the Russian name of the corresponding metal.

The designations of the coating material, consisting of metal, are given in table. 3.

Table 3

| Name of coating metal | Designation | Name of coating metal | Designation |

| Aluminum | A | Palladium | front |

| Bismuth | In and | Platinum | Pl |

| Tungsten | IN | Rhenium | Re |

| Iron | AND | Rhodium | Rd |

| Gold | Evil | Ruthenium | RU |

| Indium | In | Lead | WITH |

| Iridium | Ir | Silver | Wed |

| Cadmium | CD | Antimony | Su |

| Cobalt | Co. | Titanium | Tee |

| Copper | M | Chromium | X |

| Nickel | N | Zinc | C |

| Tin | ABOUT |

4. Designations of nickel and chrome coatings are given in mandatory Appendix 1.

5. The coating material, consisting of an alloy, is designated by the symbols of the components included in the alloy, separated by a hyphen, and the maximum mass fraction of the first or second (in the case of a three-component alloy) components in the alloy is indicated in parentheses, separating them with a semicolon. For example, coating with a copper-zinc alloy with a mass fraction of copper 50-60% and zinc 40-50% is designated M-C (60); coating with a copper-tin-lead alloy with a mass fraction of copper 70-78%, tin 10-18%, lead 4-20% is designated M-O-C (78; 18).

In the designation of the alloy coating material, if necessary, it is allowed to indicate the minimum and maximum mass fractions of the components, for example, coating with a gold-nickel alloy with a mass fraction of gold of 93.0-95.0%, nickel of 5.0-7.0% is designated Zl-N ( 93.0-95.0).

When designating the coating of watch and jewelry parts with alloys based on precious metals, it is allowed to indicate the average mass fraction of the components.

For newly developed alloys, the components are designated in order of decreasing their mass fraction.

(Changed edition, Amendment No. 2).

6. Designations of alloy coatings are given in table. 4.

Table 4

| Name of alloy coating material | Designation | Name of alloy coating material | Designation |

| Aluminum-zinc | A-C | Nickel-phosphorus | N-F |

| Gold Silver | Zl-Sr | Nickel-cobalt-tungsten | N-Ko-V |

| Gold-silver-copper | Zl-Sr-M | Nickel-cobalt-phosphorus | N-Co-F |

| Gold-antimony | Zl-Su | Nickel-chrome-iron | N-H-F |

| Gold-nickel | Zl-N | Tin-bismuth | O-Vee |

| Gold-zinc-nickel | Zl-C-N | Tin-cadmium | O-Kd |

| Gold-copper | Zl-M | Tin-cobalt | Eye |

| Gold-copper-cadmium | Zl-M-Kd | Tin-nickel | HE |

| Gold-cobalt | Zl-Ko | Tin-lead | O-S |

| Gold-nickel-cobalt | Zl-N-Ko | Tin-zinc | O-C |

| Gold-platinum | Zl-Pl | Palladium-nickel | Pd-N |

| Gold-indium | Zl-In | Silver-copper | Sr-M |

| Copper-tin (bronze) | M-O | Silver-antimony | Sr-Su |

| Copper-tin-zinc (brass) | M-O-C | Silver-palladium | Wed-Fd |

| Copper-zinc (brass) | M-C | Cobalt-tungsten | Co-V |

| Copper-lead-tin (bronze) | M-S-O | Cobalt-tungsten-vanadium | Ko-V-Va |

| Nickel boron | N-B | Cobalt-manganese | Co-MC |

| Nickel-tungsten | N-V | Zinc-nickel | C-N |

| Nickel-iron | N-F | Zinc-titanium | C-Ti |

| Nickel-cadmium | N-Kd | Cadmium titanium | CD-Ti |

| Nickel-cobalt | N-Co | Chrome vanadium | H-Va |

| Chrome-carbon | X-Y | Titanium nitride | T-Az |

Table 4

(Changed edition, Amendment No. 3).

7. In the designation of the coating material obtained by burning in, indicate the brand of the starting material (paste) in accordance with the regulatory and technical documentation.

8. In the designation of solder coating obtained by the hot method, indicate the brand of solder in accordance with GOST 21930-76, GOST 21931-76.

9. Designations of non-metallic inorganic coatings are given in table. 5.

Table 5

| Name of non-metallic inorganic coating | Designation |

| Oxide | Oks |

| Phosphate | Phos |

10. If it is necessary to indicate the electrolyte (solution) from which the coating is to be obtained, use the designations given in the mandatory appendices.

Electrolytes (solutions) not listed in the appendices are designated by their full name, for example, Ts9. ammonium chloride. xp, M15. pyrophosphate.

11. Designations of the functional properties of coatings are given in table. 6.

Table 6

| Name of non-metallic inorganic coating | Designation |

| Solid | TV |

| Electrical insulating | eiz |

| Electrically conductive | uh |

12. Designations of decorative properties of coatings are given in table. 7.

Table 7

| Name of decorative property | Decorative coating feature | Designation |

| Shine | Mirror | zk |

| Brilliant | b | |

| Semi-shiny | pb | |

| Matte | m | |

| Roughness | Gladkoe | ch |

| Slightly rough | US | |

| Rough | w | |

| Very rough | Vsh | |

| Picturesqueness | Pictured | calculation |

| Texture | Crystalline | cr |

| Layered | sl | |

| Color* | — | Color name |

* The color of the coating corresponding to the natural color of the deposited metal (zinc, copper, chromium, gold, etc.) does not serve as a basis for classifying the coating as painted.

The color of the coating is indicated by its full name, with the exception of black coating – part.

13. Designations for additional coating processing are given in table. 8.

Table 8

| Name of additional coating treatment | Designation |

| Hydrophobization | gfj |

| Filling in water | nv |

| Filling in chromate solution | NHR |

| Application of paint and varnish coating | paintwork |

| Oxidation | ok |

| Reflow | opl |

| Impregnation (varnish, glue, emulsion, etc.) | prp |

| Oil impregnation | prm |

| Heat treatment | T |

| Toning | tn |

| Phosphating | phos |

| Chemical dyeing, including filling in a dye solution | Color name |

| Chromating* | xp |

| Electrochemical dyeing | email Color name |

* If necessary, indicate the color of the chromate film: khaki - khaki, colorless - btsv; rainbow film color – no designation.

14. The designation of additional treatment of the coating by impregnation, hydrophobization, or application of paint and varnish coating may be replaced by the designation of the brand of material used for additional processing.

The grade of material used for additional coating processing is designated in accordance with the regulatory and technical documentation for the material.

The designation of a specific paint coating used as an additional treatment is carried out in accordance with GOST 9.032-74.

15. Methods of preparation, coating material, designation of electrolyte (solution), properties and color of the coating, additional processing not listed in this standard are indicated according to the technical documentation or written down by the full name.

(Changed edition, Amendment No. 2).

16. The procedure for designating the coating in technical documentation:

designation of the method of processing the base metal (if necessary);

designation of the method of obtaining the coating;

designation of coating material;

minimum coating thickness;

designation of the electrolyte (solution) from which the coating is required (if necessary);

designation of functional or decorative properties of the coating (if necessary);

designation of additional processing (if necessary).

The designation of the coating does not necessarily contain all of the listed components.

If necessary, it is allowed to indicate the minimum and maximum thicknesses separated by a hyphen in the designation of the coating.

It is allowed to indicate the production method, material and thickness of the coating in the designation of the coating, while the remaining components of the designation are indicated in the technical requirements of the drawing.

(Changed edition, Amendment No. 2).

17. Coating thickness equal to or less than 1 micron is not indicated in the designation unless there is a technical need (except for precious metals).

18. Coatings used as technological coatings (for example, zinc during zincate processing of aluminum and its alloys, nickel on corrosion-resistant steel, copper on copper alloys, copper on steel made from cyanide electrolyte before acid copper plating) may not be indicated in the designation.

19. If the coating is subjected to several types of additional processing, they are indicated in technological sequence.

20. The coating designation is recorded on a line. All components of the designation are separated from each other by dots, with the exception of the coating material and thickness, as well as the designation of additional paint coating treatment, which is separated from the designation of a metallic or non-metallic inorganic coating by a fraction line.

The designation of the production method and coating material should be written in capital letters, the remaining components - in lowercase letters.

Examples of recording the designation of coatings are given in Appendix 4.

(Changed edition, Amendment No. 1, 2, 3).

21. The procedure for designating coatings according to international standards is given in Appendix 5.

21. Introduced additionally (Changed edition, Amendment No. 3).

Mandatory

DESIGNATIONS FOR NICKEL AND CHROME COATINGS

| Name of coating | Designation | |

| abbreviated | complete | |

| Nickel, obtained shiny from an electrolyte with brightening additives, containing more than 0.04% sulfur | — | Nb |

| Nickel matte or semi-shiny containing less than 0.05% sulfur; relative elongation during tensile testing of at least 8% | — | Npb |

| Nickel containing 0.12-0.20% sulfur | — | NS |

| Nickel two-layer (duplex) | Nd | Npb. Nb |

| Nickel three-layer (triplex) | Nt | Npb. Ns. Nb |

| Nickel two-layer composite – nickel-sil* | Nsil | Nb. NZ |

| Nickel two-layer composite | Ndz | Npb. NZ |

| Nickel three-layer composite | Ntz | Npb. Ns. NZ |

| Chrome regular | — | X |

| Chrome porous | — | HP |

| Chrome microcracked | — | Hmt |

| Chrome microporous | — | Hmp |

| Chrome "milk" | — | Hmol |

| Chrome double layer | XD | Hmol. H. tv |

* If necessary, the technical requirements of the drawing indicate the symbol of the chemical element or the formula of the chemical compound used as the precipitated substance.

Note. It is allowed to use abbreviations and indicate the total thickness of the coating.

(Changed edition, Amendment No. 2).

Mandatory

DESIGNATIONS OF ELECTROLYTES FOR OBTAINING COATINGS

| Base metal | Name of coating | Main components | Designation |

| Aluminum and its alloys | Oxide | Chromic anhydride | chromium |

| Oxalic acid, titanium salts | emt | ||

| Boric acid, chromic anhydride | emt | ||

| Magnesium and its alloys | Oxide | Ammonium bifluoride or potassium fluoride | fluorine |

| Ammonium bifluoride, potassium dichromate or chromic anhydride | fluorine. chromium | ||

| Ammonium bifluoride, sodium dichromate, orthophosphoric acid | fluorine. chromium. phos |

Mandatory

DESIGNATIONS FOR SOLUTIONS FOR OBTAINING COATINGS

| Base metal | Name of coating | Main components | Designation |

| Magnesium and its alloys | Oxide | Potassium dichromate (sodium) with various activators | chromium |

| Potassium dichromate (sodium) with various activators, hydrofluoric acid and potassium fluoride (sodium) | chromium. fluorine | ||

| Magnesium and its alloys | Oxide | Caustic soda, potassium stannate, sodium acetate, sodium pyrophosphate | mill |

| Steel, cast iron | Oxide | Ammonium molybdate | mdn |

| Steel | Phosphate | Barium nitrate, zinc monophosphate, zinc nitrate | ok |

| Cast iron | Phosphate | Barium nitrate, phosphoric acid, manganese dioxide | ok |

| Magnesium and its alloys | Phosphate | Barium monophosphate, phosphoric acid, sodium fluoride | fluorine |

(Changed edition, Amendment No. 1).

Mandatory

EXAMPLES OF RECORDING COATING DESIGNATIONS

| Coating | Designation |

| Zinc 6 microns thick with colorless chromating | Ts6. hr. bcv |

| Zinc 15 microns thick with khaki chromate | Ts15. hr. khaki |

| Zinc 9 microns thick with iridescent chromating followed by paint coating | Ts9. hr/paint |

| Zinc 6 microns thick, oxidized black | Ts6. ok. h |

| Zinc 6 microns thick, phosphated in a solution containing barium nitrate, zinc monophosphate, zinc nitrate, impregnated with oil | Ts6. Phos. ok. prm |

| Zinc 15 microns thick, phosphated, hydrophobized | Ts15. Phos. gfj |

| Zinc 6 microns thick, obtained from an electrolyte that does not contain cyanide salts | Ts6. non-cyanide |

| Cadmium 3 microns thick, with a nickel sublayer 9 microns thick, followed by heat treatment, chromated | H9. Kd3. t.hr |

| Nickel 12 microns thick, shiny, obtained on a vibro-rolled surface followed by polishing | fbr. H12. b |

| Nickel 15 microns thick, shiny, obtained from an electrolyte with a brightener | Nb. 15 |

| Chrome 0.5-1 microns thick, shiny, with a sublayer of nickel 9 microns thick | Nsil9. H. b |

| Chrome 0.5-1 microns thick, with a sublayer of semi-shiny nickel 12 microns thick, obtained on a satin surface | stn. Npb12.X |

| Chrome 0.5-1 microns thick, shiny with an underlayer of copper 24 mm thick and two-layer nickel 15 microns thick | M24. Nd15. H. b |

| Chrome 0.5-1 microns thick, shiny, with an underlayer of copper 30 microns thick and three-layer nickel 15 microns thick | M30.Nt15. H. b |

| Chrome 0.5-1 microns thick, shiny with an underlayer of a two-layer nickel composite coating 18 microns thick | Ndz 18. H. b |

| Chrome two-layer 36 microns thick: “milky” 24 mm thick, hard 12 microns thick | Xd36; Hmol24. X12. TV |

| Coating with a tin-lead alloy with a tin mass fraction of 55-60%, 3 microns thick, fused | O-S (60)3. opl. |

| Coating with a tin-lead alloy with a mass fraction of tin 35-40%, 6 microns thick, with a nickel sublayer 6 microns thick | H6. O-S(40) 6 |

| Tin coating 3 microns thick, crystalline, followed by paint coating | 03. kr/lkp |

| Copper 6 microns thick, shiny, tinted blue, followed by paint coating | M6. b. tn. blue/paint |

| Gold-nickel alloy coating 3 microns thick, with a nickel sublayer 3 microns thick | H3. 3l-N(98.5-99.5)3 |

| Gold 1 micron thick, obtained on the surface after diamond processing | Alm. 3l1 |

| Chemical nickel 9 microns thick, hydrophobized | Chem. H9. gfj; Chem. H9. gfzh 139-41 |

| Chemical phosphate, oil impregnated | Chem. Phos. prm |

| Chemical phosphate, obtained in a solution containing barium nitrate, zinc monophosphate, zinc nitrate | Chem. Phos. ok |

| Chemical oxide conductive | Chem. Oks. uh |

| Chemical oxide, obtained in a solution containing sodium hydroxide, potassium stannate, sodium acetate, sodium pyrophosphate, followed by application of a paint coating | Chem. Oks. stan/paint |

| Chemical oxide, obtained in a solution of potassium dichromate (sodium) with various activators | Chem. Oks. chromium |

| Chemical oxide, obtained in a solution containing ammonium molybdate, impregnated with oil | Chem. Oks. mdn. prm |

| Anodic-oxide solid, filled in chromate solution | An. Oks. TV NHR |

| Anodic-oxide electrical insulation with subsequent application of paint and varnish coating | An. Oks. eiz/paint |

| Anodic oxide solid, oil impregnated | An. Oks. TV prm; An. Oks. TV oil 137-02 |

| Anodic-oxide, obtained on a hatched surface | line An. Oks |

| Anodic-oxide, obtained colored green in the process of anodic oxidation | Anotsvet. green |

| Anodic oxide, electrochemically painted dark gray | An. Oks. email dark grey |

| Anodic-oxide, obtained on a chemically polished surface, chemically painted red | HP An. Oks. red |

| Anodic oxide, obtained in an electrolyte containing chromic anhydride | An. Oks. chromium |

| Anodic oxide, obtained in an electrolyte containing chromic anhydride | An. Oks. chromium |

| Anodic oxide, obtained in an electrolyte containing oxalic acid and titanium salts, solid | An. Oks. emt. TV |

| Anodic oxide, obtained on a matted surface in an electrolyte containing boric acid, chromic anhydride | mt. An. Oks. emt |

| Hot coating obtained from POS 61 solder | Gor. Pos 61 |

| Silver 9 microns thick, with a sublayer of chemical nickel coating 3 microns thick | Chem. H3. Wed9 |

| Coating obtained by chemical passivation, hydrophobized | Chem. Pass. gfj |

Information

DESIGNATION OF COATINGS ACCORDING TO INTERNATIONAL STANDARDS

1. The base metal and coating material is designated by the chemical symbol of the element.

The base metal material, which consists of an alloy, is designated by the chemical symbol of the element with the highest mass fraction. The main non-metallic material is designated NM, plastic – PL.

The coating material, consisting of an alloy, is designated by the chemical symbols of the components included in the alloy, separating them with a hyphen. The maximum mass fraction of the first component is indicated after the chemical symbol of the first component before the hyphen.

2. The designation of methods for obtaining the coating is given in table. 9.

Table 9

| Coating method | Designation |

| Cathodic reduction | — |

| Anodic oxidation | An |

| Chemical | — |

| Hot | — |

| Thermal spray | met |

3. Designations for additional coating processing are given in table. 10.

Table 10

| Name of additional coating treatment | Designation |

| Reflow | f |

| Filling | u |

| Chromating* | c |

* The color of the chromate film is indicated by:

A – colorless with a bluish tint; B – colorless with a rainbow tint; C – yellow, rainbow; D – olive (khaki).

Coatings A and B belong to the 1st class of chromate coatings, coatings C and D, which have higher corrosion resistance, belong to the 2nd class.

4. The designation of types of nickel and chromium coatings is given in table. eleven.

Table 11

| Name of coating | Designation |

| 1. Chrome regular | Crr |

| 2. Chrome without cracks | Crf |

| 3. Chrome microcrack | Crmc |

| 4. Chrome microporous | Crmp |

| 5. Nickel polished | Nib |

| 6. Nickel matte or semi-shiny, requiring polishing | Nip |

| 7. Nickel finish is matte or semi-gloss and should not be mechanically polished. | Nis |

| 8. Nickel two-layer or three-layer | Nid |

5. The designation is written on the line in the following order:

the chemical symbol for the base metal or the symbol for the nonmetal followed by a slash;

method of coating, in which the chemical symbol of the metal of the sublayer is indicated;

chemical symbol of the coating metal (if necessary, the purity of the metal in percentage is indicated in parentheses);

a figure expressing the minimum thickness of the coating on the working surface in microns;

designation of the type of coating (if necessary);

designation of additional processing and class (if necessary).

Examples of designations are given in table. 12.

Table 12

| Coating | Designation | International standard designation |

| 1. Zinc coating on iron or steel 5 microns thick | Fe/Zn5 | ISO 2081 |

| 2. Zinc coating on iron or steel 25 microns thick with colorless chromate coating of the 1st class | Fe/Zn25c1A | ISO 4520 |

| 3. Tin fused coating 5 microns thick, applied to iron or steel over a nickel sublayer 2.5 microns thick | Fe/Ni2.5Sn5F | ISO 2093 |

| 4. Silver coating on brass 20 microns thick | Cu/Ag20 | ISO 4521 |

| 5. Gold plating with 99.5% gold content on copper alloy with a thickness of 0.5 microns | Cu/Au(99.5) 0.5 | ISO 4523 |

| 6. Microcracked chrome coating up to 1 micron thick, on shiny nickel 25 microns thick, on plastic | Pl/Ni25bCrmc | ISO 4525 |

| 7. Coating with a tin-lead alloy, with a tin content of 60%, 10 microns thick, fused, over iron or steel with a nickel sublayer 5 microns thick | Fe/Ni5Sn60-Pb10f | ISO 7587 |

Appendix 5 Added additionally (Change No. 3).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Academy of the Lithuanian SSR

DEVELOPERS

E.B. Davidavichus

, Ph.D.

chem. sciences; G.V.

Kozlova , Ph.D.

tech. sciences (topic leaders); E.B.

Romashkene , Ph.D.

chem. sciences; T.I.

Berezhnyak ;

A.I.

Volkov , Ph.D.

tech. sciences; T.A.

Karmanova 2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated January 24, 1985 No. 164

3. The date of the first inspection is 1992; inspection frequency – 5 years

4. Instead of GOST 9.037-77; GOST 21484-76

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 9.032-74 | 14 |

| GOST 9.304-87 | 2 |

| GOST 21930-76 | 8 |

| GOST 21931-76 | 8 |

6. REISSUE with Amendments No. 1, 2, approved in October 1985, February 1987 (IUS 1-86, 5-87)

Change No. 3 was made, approved by Resolution of the State Standard of Russia dated May 22, 1992 No. 498 (IUS 8-92)

Preparation of nickel plating baths.

To prepare nickel plating baths, it is recommended to use demineralized water or, in extreme cases, tap water. Ground water should not be used. Working and spare baths made of steel sheet are lined from the inside with hard rubber or polyvinyl chloride. Both baths are thoroughly washed and filled with water, adding sulfuric acid ~5 g/l.

The next day, the baths are thoroughly rinsed and the spare bath is filled halfway with water. The water is heated to 60 °C and with constant stirring, first boric acid is dissolved, then nickel sulfate and nickel chloride.

Since technical chemicals contaminated with foreign metals and organic compounds are usually used to prepare a bath, preliminary cleaning of the bath is necessary. For this purpose, the pH of the bath is increased to 5.0 by introducing freshly precipitated nickel carbonate obtained from nickel sulfate.

In a separate vessel, half filled with warm water, dissolve nickel sulfate and fill it with an aqueous solution of sodium carbonate until the green precipitate of nickel carbonate completely disappears. Carefully drain the water, and add the remaining sediment to the bath in small portions with constant stirring until pH = 5.0. Commercially available basic nickel carbonate is not as good as freshly prepared nickel carbonate because it is less soluble.

Some simplify the process of increasing pH by adding 20% NaOH in small portions to the bath instead of nickel carbonate. The solution must be vigorously stirred for an hour until the green suspension of nickel carbonate is completely dissolved.

After increasing the pH to 5.0, add an aqueous solution of potassium permanganate in small portions with constant stirring until a stable pale pink color appears. Then add activated carbon “Carborol S-extga” (1 g/l) and stir for 2 hours. The bath is left alone until the next day. In this state, the bath should have the natural color of nickel sulfate, but if it does not have this color, then add sulfuric acid to pH = 3.8-4.0; onto the cathode rod until the purple color disappears.

Further cleaning consists of running the baths at low current densities. The solution, previously purified in the spare bath, is pumped into the working bath, adjusted with demineralized water to the specified level, and sulfuric acid is added to pH = 3.8–4.0; the maximum possible number of corrugated steel plates is hung on the cathode rod and a current with a density of initially ~0.5 A/dm2 is turned on, and after several tens of minutes it is reduced to 0.2–0.3 A/dm2. Electrolysis lasts 6 hours with constant stirring and temperature ~ 60 °C. Once the pH is adjusted to normal, the cleaned bath is ready for use. Test loads are nickel-plated in it in order to select optimal processing conditions. For bright nickel plating, appropriate substances are added.

Operation and regeneration of nickel baths. Stabilization of nickel plating baths consists of maintaining specified concentrations of individual components and regulatory removal of contaminants.

It is easiest to adjust the composition based on chemical analysis, but an experienced electroplater can solve these problems independently.

Particular attention should be paid to monitoring and adjusting the pH - a daily responsibility of the personnel responsible for the reliable operation of the nickel bath. Note that this is not very difficult, since the bath gradually becomes alkalized, and, therefore, there is a need to add pure sulfuric acid. Prepare a solution containing 25% (vol/vol) concentrated acid and 75% (vol/vol) distilled water, and add it in small portions to the bath with constant stirring. To control pH, it is enough to have a limited set of indicator paper, for example, three to five ranges produced by PNR.

The color scale on this paper is not as expressive as on Merck papers, but after a certain time the operating personnel will gain experience and will be able to read pH values with sufficient accuracy. Failure to comply with the required pH value will result in a noticeable deterioration in the quality of coatings.

At a very high pH value, i.e. with insufficient acidity, coatings become brittle and prone to peeling, and also acquire a yellow tint; Burning of the coating also easily occurs in places of high current densities. At a pH less than 4, the gloss of the coating is weakened. A nickel bath is easily contaminated with metal impurities, especially when processing brass and zinc products: most often - copper, zinc, iron and lead. Copper gives nickel plating its dark color.

A low concentration of zinc leads to the appearance of black dots on the nickel coating, a high concentration of zinc manifests itself in the form of blackening of the coating in places of low current densities; Heavy zinc contamination can cause black streaks to spread over the entire surface.

Iron contamination leads to an increase in internal stresses in the coating, resulting in the brittleness of nickel. A colloidal suspension of iron compounds appearing in a nickel bath can cause severe pitting.

Lead contamination appears as a brown or silver-brown layer in areas of low current density. Lead can enter the bath from lead pipes used for heating or from immersion heaters placed in a lead casing. This is extremely harmful for baths with shiners.

Impurity metals are removed electrolytically at low current density using the method described when preparing the bath. Cleaning time depends on the degree of contamination of the bath and can last from several hours to several dozen. After a certain time, the steel sheets should be removed from the bath, cleaned with a steel brush and placed back into the bath. You should not leave de-energized sheets in the bath, as this leads to at least partial dissolution of contaminants in it.

Modern nickel plating baths are mixed with air and, therefore, mechanical impurities settling at the bottom are distributed throughout the entire volume of the bath and some of them enter the coating, giving it roughness. Thus, there is a need for continuous filtration of the bath, although most workshops avoid this, limiting themselves to periodic filtration, and do not complain about the roughness of the coatings. This indicates the ability to maintain the bath in proper cleanliness, first of all, the impossibility of getting anode sludge into the bath due to its good retention by the anode bag.

There are different opinions regarding the filtration of bright nickel plating baths using activated carbon. Theoretically, during each bath filtration, carbon should be used to remove harmful organic contaminants, which include, among other things, decomposition products of shine-forming additives. In fact, coal also absorbs some organic additives necessary for normal operation, as a result of which the consumption of rather expensive drugs, for example, “DF-bis” increases.

Despite this unfavorable situation for the consumer, it is necessary to choose a middle ground here, which is that filtration through fresh activated carbon occurs once a week and, finally, the frequency of carbon replacement can be set based on your own observations. Complete abandonment of coal is a technical mistake, since over time the bath becomes so contaminated with organic compounds that the coatings become brittle and passivated, making their decorative chrome plating difficult.

However, it is necessary to pay attention to the type of activated carbon. In Poland, Carbonol S-extga coal is used in dusty form. Random varieties can do more harm than good as they are contaminated with impurity metals such as zinc.

Despite great care of the nickel bath, it can become so contaminated with organic substances that a major regeneration using potassium permanganate becomes necessary.

The contents of the bath, heated to 60 °C, are pumped into a spare bath and the pH is adjusted to 5.5-5.8 using nickel carbonate. Permanganate dissolved in water is added in small portions until a pale pink color is obtained. Thorough mixing is required during the administration of permanganate.

For each liter of bath thus treated, add 3 g of activated carbon and stir vigorously for several hours. Then leave the bath for 10-12 hours, after which the clear solution is carefully filtered into the working bath, without touching the sediment at the bottom. If the pink color remains, then add perhydrol, diluted in distilled water in a ratio of 1:5 until the normal green color of the bath is obtained. To prevent excess perhydrol, it is added in small portions. After adjusting the pH, test products are nickel-plated, remembering that the shine will be worse, since part of the shine-forming solution has been destroyed and only after adding shine-forming agents will the desired decorative appearance be obtained.

Iron contaminating the nickel bath is mainly removed during the low current density treatment described above, however, to more completely remove this metal proceed as follows:

the electrolyte is poured into a spare bath, heated to a temperature of 60 C and alkalized to pH = 6 with nickel carbonate or caustic soda, and stirring is necessary. Then add perhydrol in an amount of 1 cm3/l, stir for 3 hours and leave until the next day. The light solution is carefully filtered into the working bath, making sure that the sediment at the bottom of the bath does not fall into the clean bath.

After bringing the pH to normal, test nickel plating is carried out and glitter-forming additives are added until the desired gloss is obtained.

The correct dosage of brightening agents is the main requirement for success in bright nickel plating. Manufacturers of brighteners give approximate consumption of the substance depending on the amount of electricity passed in ampere hours, but few workshops have electric meters, and recording the load of the bath in the form of detailed records is not as simple as it seems.

During long-term operation of the bath, various situations arise, which are accompanied by a significant loss of brightening agents, for example, during the regeneration of the baths described above. This happens outside of electricity.

The content of the brightener in the bath can be determined analytically, but for this you need to have the appropriate equipment and a thorough knowledge of laboratory techniques. You can use the services of special laboratories, but this is not always possible. Consequently, it remains the own initiative of the galvanizer servicing the bath, or another more competent person.

If we get a semi-shiny coating, this means that there is very little shine-forming agent in the bath. For 100 liters of bath, you can add 25 cm3 of the “DF-bis” additive. If this does not lead to an improvement in shine, then the reason lies in the bath itself. The pH and temperature of the bath should be determined and, if after adjusting these parameters there is still no improvement, then it is necessary to begin cleaning the bath using activated carbon and electrolysis at low current density, which is described in detail when considering baths.

A very difficult situation arises in the case of excessive introduction of brightening agents. In this case, the coatings become brittle in areas of very low current density; for example, in places where the product comes into contact with the pendants, visible black spots form and there may even be final defects in the coatings. Therefore, it is necessary to get rid of excess brightening agent by working the bath under normal conditions, hanging waste steel sheet on the cathode rod, degreasing them accordingly and etching them.

One of the common defects of nickel coatings is porosity - the so-called pitting - small depressions in the coating, reminiscent of pinholes, that occur during nickel plating as a result of the adhesion of hydrogen bubbles to the cathode surface. This is due to the high surface tension, especially in nickel plating baths. A coating does not form at the location of the bubble; a crater appears.

In addition to hydrogen, air bubbles contained in the bath can also settle on the surface of the cathode. The idle bath cools and absorbs a certain amount of air. When the bath is heated, air is released in the form of bubbles, some of which settle on the surface of the cathode, leading to pitting. Before starting nickel plating, the bath should be heated to a temperature several degrees higher than usually used, turn off the heat and wait until the temperature drops to normal. In addition, air may enter the bath due to a leak in the filter pump. Pump leaks should definitely be eliminated.

The condition of the substrate also has a great influence on the formation of pitting, the porosity of which, non-metallic inclusions and all kinds of surface contamination contribute to the formation of pitting. Contamination of the bathtub with suspension or decay products of organic substances also affects the bathtub in the same way.

To prevent the formation of pitting, oxidizing or wetting agents are added to the bath. The first includes hydrogen peroxide, added to ordinary baths in the form of perhydrol in quantities of 0.2-0.5 cm3/l.

Perhydrol is not added to baths with shine formers, as it has a destructive effect on organic substances. In such cases, wetting agents, for example, sodium lauryl sulfate, are added in an amount of 0.1-0.2 g/l.

Hydrogen peroxide and wetting agent are not radical anti-pitting agents. Mechanical shaking of products on suspensions in the bath helps eliminate gas bubbles. A movable cathode rod, or even better, mixing the bath with compressed air, makes the fight against pitting much easier. For persistent pitting, bath cleaning with activated carbon should be used.

Nickel anodes

Nickel anodes are manufactured in accordance with the PN-82/N-92914 standard with dimensions of 25x25x(3-8) mm and sheets 100-300 mm wide, 600-1000 mm long and 6-12 mm thick.

The chemical composition of the anodes must comply with the PN-79/N-8181 standard, and the sheets - with the PN-79/82180 standard. Anodes in the form of sheets have grades No. 2, No. 3 and No. 6A. For bright nickel plating, anodes No. 2 are used. An example of anode designation when placing an order: nickel anode No. 2 8Х300Х600 in accordance with standard RN-82/N-92914. The cubes are placed in titanium baskets.

Removing Nickel Platings

Nickel coatings on steel and copper alloys are typically removed in a dilute sulfuric acid bath. To 20 liters of cold water, add 30 liters of concentrated sulfuric acid in portions with constant stirring, making sure that the temperature does not exceed 60 ° C. After cooling the bath to room temperature, its density should be ~1.63.

In order to reduce the risk of seeding of the substrate material, 50 g/l glycerol is added to the bath. Bathtubs are made of vinyl plastic. The products are hung on the middle rod connected to the positive pole of the current source. The side rods, on which lead sheets are hung, are connected to the negative pole of the current source. The bath temperature should not exceed 30 °C, since the hot solution acts aggressively on the substrate. The current density reaches 4 A/dm2, but the voltage can be varied within 5-6 V. After a certain time, concentrated sulfuric acid should be added to maintain a density of 1.63. In order to prevent dilution of the bath, it is necessary to immerse the products in the bath after pre-drying them. In the case of brass products, controlling the process is not difficult, since at the moment of complete removal of nickel, the current density drops sharply.

How to increase the service life of the coating?

The resulting coating has a porous structure. Therefore, the metal of the product is susceptible to corrosion. To reduce the risk of its occurrence, the nickel layer is coated with lubricants. After applying them, the item is immersed in a container with fish oil. After 24 hours, its excess is removed using a solvent.

If the product is large in size and it is impossible to immerse it in a container, then its surface is simply rubbed with fish oil. This procedure will need to be carried out twice, with a time interval of about 12 hours. 48 hours after treatment, remaining fat must be removed.

Nickel plating protects metal from corrosion

There are two ways to carry out nickel plating of steel at home. This process is simple, but requires careful preparation and extreme care when performing. It is necessary to purchase high-quality components for preparing the solution, prepare the work area, containers, tools and devices in advance.

During work, it is important to observe safety measures: protect your eyes and skin from chemicals, ensure adequate ventilation of the room, and prevent the possibility of ignition of the mixture and the electrical installation.

Video on the topic: Chemical metallization - nickel plating

Useful articles

The process of chrome plating metal products at home

Pickling stainless steel at home

Technology for galvanizing at home

Black Nickel Platings

Black nickel coatings are used for decorative and special purposes. Their protective properties are very low, so they are applied to an underlayer of zinc, cadmium or ordinary nickel. Steel products are pre-galvanized, and brass and copper are nickel-plated.

Black nickel plating is hard and brittle, especially when thick. In practice, a thickness of 2 microns is usually satisfied. The bath for applying such coatings contains a significant amount of zinc and thiocyanate. The coating contains ~50% nickel, with the rest being zinc, sulfur, nitrogen and carbon. Below are typical compositions of black nickel plating baths, g/l:

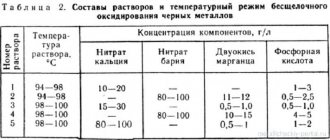

| Bath 1 operates at room or slightly elevated temperature, J = 0.1–0.5 A/dm2, pH = 5.6–5.9. Bath 2 is chloride and, therefore, more aggressive than sulfate. It operates at room temperature, pH = 5.0 and J = 0.2 A/dm2. Bath 3 contains molybdates and is therefore more expensive than the first and second baths. Its advantage is high covering power and stability, as it contains boric acid. The disadvantage is the higher operating temperature, usually above 50 °C. The current density is 0.2–0.5 A/dm2, pH = 4.3–4.7. Black nickel plating baths are prepared by dissolving all components in warm water and filtering through filter paper. If difficulties arise in dissolving boric acid in bath 3, then it is dissolved separately in water heated to 70 °C. The stability of the baths lies mainly in the control and regulation of pH using H2SO4 or NaOH. Achieving deep black color depends mainly on the correct choice of current density. Nickel-plated products are lubricated with hot oil. |

Nickel plating methods

Nickel plating of a product at home can be done in two ways: chemical and electrolytic.

Electrolytic method

Plating using an electrolyte is called electroplating. First you need to prepare an aqueous solution (electrolyte). The following components are required for this:

- nickel sulfate – 70 g;

- magnesium sulfate – 15 g;

- table salt – 2.5 g;

- sodium sulfate – 25 g;

- boric acid – 10g;

- water – 500g.

Each component must be separately dissolved in water and filtered. The resulting solutions are mixed and poured into a glass container. For galvanic nickel plating, nickel electrodes are placed in a vessel with an electrolyte. To ensure uniform coating on the workpiece, at least two electrodes are installed on all sides.

The prepared workpiece is placed in a vessel between the electrodes so that it does not touch the walls and bottom of the container. The electrodes are connected to each other by copper conductors and connected to the positive contact of a direct current source. The conductive wire is connected to the negative terminal.

Installation diagram for electrolytic nickel plating

During the process of nickel plating steel, the supply voltage should not exceed 6 Volts. The current density should be controlled; it should not exceed 1.2 A. The process takes about 30–40 minutes. Upon completion, the item must be rinsed with running water and dried thoroughly. The applied coating should be matte and smooth. In order for the surface of the product to acquire shine, it will need to be polished.

Chemical method

Chemical nickel plating of steel and other metals differs from galvanic plating in the durability of the coating. Using chemical nickel plating, you can easily apply the substance to even the most inaccessible places.

To complete the process you will need:

- sodium succinate – 7.5 g;

- nickel chloride – 12.5 g;

- sodium hypophosphite – 15 g;

- water – 500 ml.

Water is poured into an enamel bowl and sodium succinic acid and nickel chloride are dissolved in it. Then the solution is heated to a temperature of 90 degrees. Once the required temperature is reached, sodium hypophosphite is added. The product is carefully suspended above the container with the solution. The amount of liquid is calculated based on the fact that 1 liter of solution can cover a surface area of 2 dm2.

Nickel plating is controlled visually: when the part is evenly covered with a film, the process is completed. When finished, the part must be washed in a solution made from water and a small amount of chalk. After this, the part is dried and polished.

Electroless nickel plating

This process was at one time one of the main ones in the technical literature, and it seemed that it created strong competition for traditional electrolytic nickel plating. Currently, it is assessed more calmly and used when there is technical and material support for this.

The main advantage of electrochemically applied nickel coatings is the uniform thickness regardless of the shape of the product. This is typical for all metal deposition processes without the use of current.

A feature of chemical nickel plating is the continuous deposition of a layer, which creates the possibility of forming coatings of any thickness.

Baths for chemical nickel plating consist of nickel salt, sodium hypophosphite and additives. The basis is nickel salts and sodium hypophosphite.

There are two types of baths for chemical nickel plating - acidic and alkaline. Nickel sulfate or chloride of relatively low (~5 g/l) concentration is mainly used as nickel salts. The content of hypophosphite reaches 10-30 g/l. Additives are introduced in the form of complexing compounds that accelerate the deposition of nickel, and stabilizers that prevent the decomposition of the electrolyte.

Glycolic, lactic, citric and aminoacetic acids are mentioned as complexing compounds in the specialized literature. Accelerators are succinic, malonic, propionic, butyric, valeric and other acids. Lead compounds, thiosulfate, thiourea, etc. are mainly used for stabilization.

Below are examples of two baths for electroless nickel plating, g/l:

| Bath 1 is acidic, works best at pH = 4.3-4.8. The operating bath temperature of 85–90 °C must be maintained during the entire nickel plating process. To regulate the pH, use a diluted (for example, 5%) solution of sodium hydroxide. Prepare bath 1 as follows: in distilled water heated to a temperature of 60 ° C, first dissolve sodium acetate, then nickel sulfate and add lactic acid, previously neutralized with sodium hydroxide to pH = 3.5-4.0. After heating the bath to 85 °C, add sodium hypophosphite. After this, you can begin nickel plating. The concentration of thiourea is very small and in a workshop there is no possibility of weighing with an accuracy of fractions of a gram. Since excess thiourea can completely delay the nickel plating process, it is better to avoid this stabilizer completely and use a thiourea-free bath. Bath 2 is alkaline. Sodium citrate, ammonium and nickel chlorides are dissolved in distilled water heated to 60 °C, and an ammonia solution is added in portions with constant stirring to achieve pH = 8-9. In this case, a noticeable change in the color of the solution occurs from greenish to blue. After heating to 80 °C, hypophosphite is added and the bath is ready for use. The information provided is very general and does not reflect much of the practical side of nickel plating. Below 80°C the bath efficiency is very low. At 90 °C, a nickel layer 10–20 μm thick is obtained within 1 hour. With a further increase in temperature, for example to 95°C, thicker layers are obtained, but the stability of the bath decreases. At a certain point, sudden decomposition of the bath may occur, which is accompanied by the appearance of black powder on the bottom and walls of the bath. This bath is unsuitable for further use. A major problem is the selection of appropriate working containers. In industrial settings, complex installations made of corrosion-resistant steel are used, while for small-scale nickel plating, glass, porcelain or enamel containers are mainly used. The best way to heat small and medium-sized containers is with a water jacket. Let's lower a 5 liter glass vessel into an enameled 10 liter tank of water, we can get a water jacket suitable for gas or electric heating to boiling point. In a glass vessel, you can reach a temperature of 83-85 ° C, sufficient to carry out the process. High temperature and strong gas evolution on the surface of the products are detected by the service personnel by a strong unpleasant odor. Obviously, the entire installation must be under a hood. As you can see, the whole procedure is not simple, as a result of which the use of chemical nickel plating is limited to those cases where electrolytic methods are not applicable. For example, metal bellows in the form of a cylindrical accordion, used to measure pressure during pneumatic adjustment, cannot be electrolytically plated with nickel due to their complex geometric shape. Electroless nickel plating is an excellent solution to this problem. Steel products can be chemically nickel-plated without difficulty. On copper and brass, nickel deposition begins after brief contact with a less noble metal, such as iron or aluminum. For nickel plating of aluminum alloys, alkaline baths are usually used (for example, bath 2). Small particles of nickel may settle on the walls and bottom of a vessel used for chemical nickel plating, especially if the surface of the vessel is not very smooth or has scratches. Before further use of such a vessel, it is necessary to remove deposited nickel particles by dissolving them in nitric acid. |

Electrolytic nickel plating

The essence of the technology of electrolytic nickel plating of metal parts, which also has another name - “galvanic nickel plating”, can be considered using the example of how copper plating of the surface of a metal product is carried out. This procedure can be carried out both with and without the use of an electrolytic solution.

The part that will be further processed in an electrolytic solution is subjected to careful processing, for which the oxide film is removed from its surface using sandpaper. Then the product to be treated is washed in warm water and treated with a soda solution, after which it is washed again with water.

Large parts are best cleaned with a sandblaster.

The nickel plating process itself is carried out in a glass container into which an aqueous solution (electrolyte) is poured. This solution contains 20% copper sulfate and 2% sulfuric acid. The workpiece, on the surface of which it is necessary to apply a thin layer of copper, is placed in an electrolyte solution between two copper anodes. To start the copper plating process, an electric current must be applied to the copper anodes and the workpiece, the value of which is calculated based on the indicator 10–15 mA per square centimeter of the part area. A thin layer of copper on the surface of the product appears after half an hour of its presence in the electrolyte solution, and such a layer will become thicker the longer the process takes place.

Installation diagram for electrolytic nickel plating

You can apply a copper layer to the surface of the product using another technology. To do this, you need to make a copper brush (you can use a stranded wire, having first removed the insulating layer from it). Such a hand-made brush must be fixed on a wooden stick, which will serve as a handle.

The product, the surface of which has been previously cleaned and degreased, is placed in a container made of dielectric material and filled with an electrolyte, which can be a saturated aqueous solution of copper sulfate. A homemade brush is connected to the positive contact of the electric current source, and the workpiece is connected to its minus. After this, the copper plating procedure begins. It consists in passing a brush, which is previously dipped in electrolyte, over the surface of the product without touching it. Using this technique, the coating can be applied in several layers, which will allow the formation of a copper layer on the surface of the product, on which there are practically no pores.

Diagram of a simple coating device

Electrolytic nickel plating is performed using a similar technology: it also uses an electrolyte solution. Just as in the case of copper plating, the workpiece is placed between two anodes, only in this case they are made of nickel. The anodes placed in the nickel plating solution are connected to the positive contact of the current source, and the product suspended between them on a metal wire is connected to the negative one.

To carry out nickel plating, including do-it-yourself, electrolytic solutions of two main types are used:

- an aqueous solution containing nickel sulfate, sodium and magnesium (14:5:3), 2% boric acid, 0.5% table salt;

- a solution based on neutral water containing 30% nickel sulfate, 4% nickel chloride, 3% boric acid.

Bright nickel plating electrolyte with the addition of organic brightening agents (sodium salts)

Bright nickel plated equalizing electrolyte. Suitable for surfaces with low cleaning class

To prepare an electrolytic solution, add one liter of neutral water to the dry mixture of the above elements and mix thoroughly. If a precipitate has formed in the resulting solution, get rid of it. Only after this the solution can be used to perform nickel plating.

Treatment with this technology usually lasts half an hour, using a current source with a voltage of 5.8–6 V. The result is a surface covered with an uneven matte gray color. To make it beautiful and shiny, you need to clean it and polish it. It should be borne in mind that this technology cannot be used for parts with high surface roughness or with narrow and deep holes. In such cases, coating the surface of a metal product with a layer of nickel should be done using chemical technology, which is also called blackening.

Electrolyte for black nickel deposition

The essence of the technological operation of blackening is that an intermediate coating is first applied to the surface of the product, the base of which can be zinc or nickel, and on the top of such a coating a layer of black nickel no more than 2 microns thick is formed. Nickel plating, made using blackening technology, looks very beautiful and provides reliable protection of the metal from the negative effects of various environmental factors.

In some cases, a metal product is simultaneously subjected to two technological operations, such as nickel plating and chrome plating.