Steel bluing is increasingly used for painting metal products. It provides reliable surface protection from rust and a decorative finish. With the chemical dyeing option, a protective shell appears on the surface. Oils and acids are used during the work process. Depending on the type of material used and the degree of heating, metal compounds acquire a natural shade.

Many people believe that this processing option is used only in factory conditions. But you can organize it yourself if you follow the sequence of actions and use suitable means.

What can be achieved by bluing

As a result of chemical or thermal treatment, a layer of iron oxide with a thickness of 1 to 10 microns appears on the surface of a steel part. The thickness of the layer is determined by the selected processing technology.

Blueing of metal allows you to achieve two main goals:

- Increasing the corrosion resistance of the product. Treated parts do not rust.

- Improved appearance. It is especially important for those parts that, due to operating conditions, cannot be painted.

Temperature conditions for bluing

The treatment does not affect other properties of the steel.

Blueing of steel is possible not only in production conditions, but also at home. There are many methods and compositions, almost all of them involve the use of chemically active substances that can cause serious harm to health. To successfully and safely use these substances at home, you must follow the following safety rules:

- Use a protective mask and gloves.

- Ensure ventilation of the room in which work is carried out.

- Use stainless steel utensils.

- Do not exceed the recommended processing temperature.

Corrosion protection

This is the most important goal. This is especially true when a metal structure is used outdoors, that is, the steel is constantly exposed to oxygen and moisture. With such actively reacting substances, an oxidative process - rusting - is possible. As a result, red rust is formed. It greatly affects the strength, reducing it, and also shortens the service life. In this regard, many car enthusiasts are actively interested in how to make the surface of the metal black, and how to blue the steel elements of the car, since corrosion spoils automobile spare parts.

Methods for bluing metals at home and requirements for their implementation

Popular methods of bluing metal at home are:

- Boiling in self-prepared or purchased chemical compositions.

- Coating the steel with special oil and subsequent heat treatment.

- Coating the surface with the prepared composition at room temperature.

Burnishing steel at home

Chemical bluing of iron also involves preparatory operations of etching and cleaning, as well as grinding and polishing.

When carrying out blueing of steel, it is important to select a container for the solution so that it completely covers the object being treated.

Popular bluing methods

The most common methods of bluing at home are:

- alkaline;

- thermal;

- acidic.

The alkaline method is well suited for self-use at home. It will require

- water;

- precision scales;

- sodium nitrate and hydroxide.

For the coating to become durable, the process must last at least an hour and a half.

Alkaline

The technology for bluing steel using the alkaline method at home is divided into the following operations

- Degrease the surface with a solvent or special degreaser.

- Pour 100 g of water into a stainless steel container with a capacity of at least a liter.

- Add 120 g of caustic soda and 30 g of sodium nitrate, stir thoroughly until completely dissolved.

- Heat the solution to 130-145 °C.

- Place the product in the dish, avoiding touching the walls.

- After 20 minutes, after the part has turned black, rinse it in distilled water.

- After drying, generously lubricate the product with machine oil and wipe thoroughly.

Steel bluing with alkali

Careful adherence to proportions and parameters will allow you to obtain a smooth and abrasion-resistant coating that does not require polishing.

Important! The product must be completely covered with the solution throughout the treatment. Otherwise, coating inhomogeneities, color transitions, etc. are possible.

Acid

This method involves the use of acidic solutions.

Before starting processing, you should carefully remove all rust from the surface of the object. To do this, use ordinary sandpaper, and in hard-to-reach places and with severe rust, use a grinder or a screwdriver with a wire brush.

Means for degreasing steel before processing

Next, chemical cleaning is carried out. It is used for

- sodium triphosphate;

- ethanol mixed with kerosene;

- or pure kerosene.

The product is placed in a container with the solution so that it completely covers it and kept for at least a quarter of an hour. After cleaning, the product is washed with plenty of water and dried.

The composition for acid bluing consists of:

- water: 1 l;

- tannic acid: 2g;

- tartaric acid: 2g.

After thorough mixing and complete dissolution, the composition is heated to 150 ° C and the workpiece is completely immersed in it. Leave for 15 minutes, then rinse with running water and briefly dip in boiling water for complete and high-quality rinsing.

Components of the solution for bluing

The last stage of the process is soaking in machine oil for an hour. After drying, the product is ready for use.

Thermal

Thermal bluing is the oldest and simplest method for home use. The whole process boils down to heating the steel in the open air. It lasts until the upper layers of steel react with oxygen in the air and result in an oxide film. The more a part is heated, the darker it becomes.

Thermal bluing

It should be remembered that heat treatment also changes the physical properties of the steel of the entire product.

Recommendations

Are you wondering how to bury metal objects yourself? To do this, you can use one of the methods that suits you. Using professional advice, you will get the perfect color of the metal, and the process itself will be carried out in a way that is safe for you.

Cold bluing involves the use of a bath or special container. But it cannot be made of any material. A wooden bath or galvanized container is optimal.

It would be good if the container was additionally equipped with hangers-hooks for placing parts in the solution. These elements can be made in the form of curved racks or mounted on a wall. Everything is determined by the height of the sides of the container and the dimensions of the workpiece.

To blue the steel, the container must be properly degreased. The best solution for this is an organic-based solvent. This can be acetone, perchlorethylene or B-70 gasoline. The base remains inert towards these compounds. But for each type of metal it is necessary to select the optimal solution. Only with its help can you obtain the optimal color and maximize the characteristics of the product.

Even if you are doing cold bluing, the work should be done outdoors or in a room with good ventilation. This is due to harmful fumes and a strong chemical odor.

If you cannot clean the surface well with a brush or abrasive, use etching. Each type of metal has its own remedy. If you have a ferrous metal product, the bluing liquid includes 100 grams of nitric, 50 grams of sulfuric and 150 grams of hydrochloric acids per 1 liter of distilled water. The surface is treated for at least 2.5 hours. Chemical polishing is used to give a smooth surface.

Thus, you can do the bluing of a steel object yourself. To do this, it is important to choose the most suitable processing method and adhere to a clear sequence of actions. As a result, you will get a corrosion-resistant surface in a suitable shade.

Do-it-yourself steel blackening (3 videos)

Metal products after bluing (26 photos)

Features of chemical bluing and recipes for some compositions

Before applying a new coating at home, you must remove the old one. This is done by combining mechanical and chemical cleaning methods.

To obtain a durable and beautiful coating, the part must be boiled for 30 to 90 minutes, during which time part of the solution boils away. The workpiece must be completely covered with the composition at all times, so the composition must be prepared with a reserve and periodically topped up during boiling.

At the end of the chemical bluing procedure, the product should be washed in a soapy solution, dried and generously lubricated with oil.

There are many options for chemical bluing. In some, the composition is made by the master himself, while others involve the use of ready-made factory-made products, such as Parisian oxide, Voron3M, Clover and others.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Hot processing: oil and fire

The ancient artisanal method of bluing, in which the part is first oiled and then burned with a blowtorch, has a number of advantages. The process is not accompanied by the release of harmful substances, is cheap and effective. And although oil firing is also not true bluing in the full sense, the resulting coating lasts on the surface much longer than with cold processing. Those wishing to perform thermal bluing should slightly heat the surface of the product and apply a very thin layer of linseed oil to it. It is also fashionable to use olive oil or special weapons grade (for example, Ballistol). The advantage of the latter is its slightly alkaline properties, which do not have a destructive effect on the metal. Lignite and petroleum oils, as well as various paraffins, are suitable for these purposes. When slowly heated to 200-400 C, the light fractions evaporate and a dense oil film forms on the surface. Further gradual heating leads to the formation of first a brown and then a black color, which can no longer be removed. It is fundamentally important with this technology not to use too much oil to avoid stains.

The best results are achieved by using a mixture of twenty parts grease and one part sulfur. The latter contributes to the formation of a very dark layer of iron sulfide. Sulfur balm can be made from sulfur by dissolving it in a small amount of turpentine and then mixing it with linseed oil. The composition is distributed in a thin layer over the surface of the workpiece and subjected to flameless combustion, which leads to uniform bluing.

Sources

- https://accorel.ru/pokraska/voronenie-krasivo-i-prochno

- https://promtu.ru/obrabotka-metallov/sekretyi-voroneniya-metalla

- https://metmastanki.ru/voronenie-metalla-v-domashnih-usloviyah-sposoby

- https://tutmet.ru/holodnoe-chernenie-nerzhaveyushhej-stali-domashnih-usloviyah.html

- https://www.rocta.ru/info/kak-voronit-metall-v-domashnih-usloviyah/

- https://www.umeltsi.ru/slesar/1167-voronenie-v-domashnih-usloviyah.html

Cold bluing at home

“Clover” does not require heat treatment of the part, so this method is considered cold bluing. Cold bluing can be carried out by other means.

- "Voron-3M". The drug forms a dense film of deep black color on the surface.

- "Paris Oxide" An imported selenium-based preparation is supplied in three containers: 1- for surface preparation, 2- the main composition and 3- a fixative that gives the coating additional protection.

Liquid for cold bluing is applied to the parts with a brush, and after painting it is washed off with warm soapy water. The method is popular for processing barrels and other parts of firearms that do not require boiling.

Burnishing steel at home

If you are bluing steel at home, you need to wisely choose the components of the boiling solution. Heating hardened parts can lead to them losing their strength properties.

Alkaline solutions have a less harmful effect on steel, and experienced craftsmen advise choosing them. Treatment with acidic solutions is preferably carried out at low temperatures

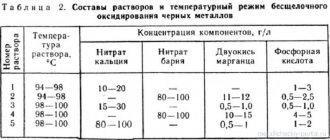

So, for example, when using an acid composition for bluing steel from:

- calcium nitrate – 94%;

- orthophosphoric acid – 3%;

- manganese dioxide – 3%.

processing is carried out from half an hour to 45 minutes at 100 ° C

Metal blackening

Depending on the acidity of the environment in which the workpiece is processed, the color of the resulting coating changes, from yellow to black. Therefore, bluing and blackening of metal are not the same thing. The required shade is selected by varying the intensity and duration of heat treatment and the percentage of solution components.

Metal blackening

If you take a mixture of 7 parts copper nitrate and 3 parts alcohol denatured alcohol, apply it to the product and heat it over a fire, then as it heats up the coating begins to change its color. When the desired shade is achieved, stop heating.

It is also possible to blacken steel by coating it with oil and calcining it in an open flame. The result is a durable film of deep black color. There are other compositions for blackening.

Give the product a presentable look

A dark matte shade can give a stylish design to an ordinary knife. The blade, coated with an oxide film, looks very unusual and attractive. The same can be said for a number of other items. This need is especially relevant when the item is already old.

The technology is also used for artistic purposes, when a creative approach is taken to decorative elements of the interior.

Application of rust varnish

The method using the so-called “rusty varnish” is distinguished by its cost-effectiveness against the backdrop of quite acceptable quality of the coating.

The product is immersed in a chemically active corrosive liquid based on hydrochloric acid, which forms red and black oxides on its surface.

To remove rusty deposits, you will have to use a stiff wire brush. A black oxide film will remain on the product.

Ready rusty varnish

The method is long and labor intensive, but provides excellent results at home.

Before starting processing, as with all other methods, you should thoroughly clean the object with sandpaper and degrease it with a solvent.

The active liquid is prepared in special porcelain vessels; the use of protective gloves, an apron, acid-resistant shoes and thick work clothes is mandatory. A respirator and clear face shield should also be used.

A small amount of hydrochloric acid is poured into the vessel, adding rust scraped off the iron, sawdust and nitric acid. The mixture should be stirred carefully with a porcelain stirrer until bubbles stop appearing.

Next, carefully add water and vodka in equal parts. The solution is allowed to settle and drained from the sediment.

The result of using rusty varnish

The part is placed in the solution for a time sufficient to acquire a deep black color. At the end of the process, the part should be rinsed with plenty of water.

Attention! The solution used in this method is one of the strongest solvents. Beware of even the smallest splashes - they can cause very serious injury and property damage.

If splashes get on clothes, they should be removed immediately. If, despite all precautions, drops get on the skin, the affected area should be washed generously with a soda solution and immediately seek medical help.

How to make steel blue

The technology for blueing metal is more complex and requires not only more effort, but also the presence of some equipment. We'll need a forge. It is very good if it has automatic blowing. It is clear that not everyone has a forge, so if you don’t have one, you can use an ordinary metal barrel, half filling it with chopped brushwood.

So, we have a part, now we need a metal box to fit its size.

- It needs to be filled with fine birch charcoal and placed in a thoroughly heated forge (or in a barrel).

- The part to be treated must be wiped with vinegar and left to dry.

- You should wait until the coal in the container begins to smolder.

- The workpiece is placed in the smoldering coals and left there until a slight blue color appears.

- As soon as the part begins to turn blue, it needs to be pulled out and cleaned with soft charcoal.

- The part is again placed in its place in the drawer and, after changing the color of blue, it is again pulled out and cleaned.

- The work is repeated until the part acquires the desired color.

It is important to monitor the heating process and remove the part in time, otherwise its color will change to gray.