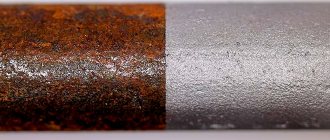

Causes of metal corrosion in the open air

The combined action of water and oxygen occurs according to the scheme where both aggressive substances act on pure iron: 4Fe + 6H₂O + 4O₂ = 4Fe(OH)₃.

As a result, iron hydroxide Fe(OH)₃ is formed; it has a red (orange) color and has a loose structure.

Carbon steel, when periodically heated in the environment, loses carbon, and the iron it contains is more susceptible to corrosion. Decarbonization of steel products occurs through the following chemical reactions:

- Fe₃C + CO₂ = 3Fe + 2CO;

- Fe₃C + H₂O = 3Fe + H₂ + CO;

- Fe₃C + 2H₂ = 3Fe + CH₄,

where Fe₃C is cementite, one of the important components of steel. It is this connection that determines the strength and hardness of steel products.

The surface layer contains more pure iron. It is susceptible to water and surrounding gases. The process is growing. Loose rust quickly spreads inside parts.

To prevent corrosion and decarburization, products are coated with paints or primers. Chemical exposure is reduced hundreds of times. But it is not always possible to use liquid or powder paints. A whole group of steel parts is operated without painting:

- Cold steel and firearms.

- Products obtained as a result of cold forging.

- Claiming couples working with gases and liquids.

For them you need to use a different method of protection.

What does steel blueing do?

Some inexperienced craftsmen often do not know what metal bluing is. This method of processing is used quite rarely, believing that it is a rather complicated procedure. In fact, any manufacturer can achieve positive results with his own hands with minimal costs of materials and labor.

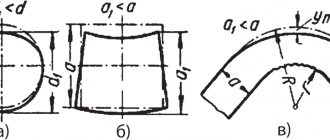

During chemical or thermal bluing, an oxide film with a thickness of 1...3 to 10...15 microns is formed on the surface of the steel. The thickness of the resulting layer largely depends on the technology used. When performing this operation, the main goals are achieved:

- the steel product's corrosion resistance increases;

- parts that have been processed are able to remain resistant to aggressive environmental influences.

If there is action of alkalis, acids and special heat treatment, then the surface is covered with oxide,

2Fe + O₂ = 2FeO.

Oxidation, when iron exhibits diatomic properties, forms black films. Depending on their thickness, the color of the product also changes. If there is a sufficiently thick film (up to 12...15 microns), then the surface is black. To damage such a coating, you need to apply quite a significant amount of force.

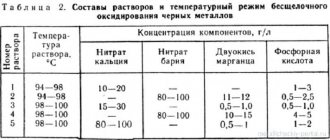

Features of chemical oxidation of metals

Chemical oxidation (also called hot) is most often performed using chromate solutions. Using this method, a uniform oxide film is applied to the surface of the product, which significantly improves the adhesion of paints and varnishes with which it is subsequently coated.

DIY tool Clover for blackening metal.

Hot (or chemical) oxidation is distinguished by the fact that it is a fairly fast process, simple and economical. It does not require the use of expensive and complex equipment, and there is no need to waste electrical energy.

Simple Blueing and Copper Plating of Steel DIY Bluing

Most often, chemical oxidation of metals is used when it is necessary to process products made of copper, aluminum, magnesium and alloys.

Two ways to blue metal in a garage! Turning works

How to oxidize metals at home?

In practice, bluing is performed according to various schemes:

- Heat treatment of parts followed by oil coating.

- Heating to boiling temperatures in chemical solutions.

- Painting with special compounds that penetrate the surface layer. Diffusion of the coating layer with the base occurs.

At home, you can implement any of the methods, you just need to familiarize yourself with the features of the technology, as well as prepare the necessary equipment.

What is the difference between cold blackening?

Cold blackening of products has high productivity, because the complete processing of a part takes a record minimum time - up to 55 seconds. This method is characterized by low energy costs. The baths used in the process of metal blackening do not require heating, and there is also no need to maintain a certain temperature level - work can be performed even at room temperature.

STEEL BLUEING A simple way

When using other types of blackening, a smearing dark-colored coating may appear on the surface of the products, which is easily erased. When cold oxidation of the metal is performed, there is no such deposit at all.

An old tip: cut an onion crosswise and put it in tea.

Selection of technology for bluing parts

To choose the right bluing method, it is advisable to decide on a number of specific parameters and recommendations:

- In the case of restoration of damaged coating, the extent of existing damage should be determined. If you need to revive limited areas where there are scratches or small abrasions, the choice is made on the alkaline method of producing an oxide film on the metal surface.

- If the surface of the part is significantly damaged and there is corrosion on it, the existing coating will have to be completely removed.

- Each product has a certain value. Based on this, it is worth estimating how long subsequent operation is expected. If the item will spend most of its time on the wall as an exhibit, simple chemical processing methods are possible.

- For products actively used on hikes or in the open air (knives, utensils or firearms), thermal methods using oil are used.

- When performing work to order, much depends on the price that the customer can pay. Cheap orders are carried out using simple methods, expensive ones involve the use of more expensive bluing techniques. When performing work for third-party customers, the question is: “How much does it cost?” – will be very relevant.

- At the training stage you will have to pay for everything yourself. Any professional training is expensive, but self-learning the basics of the profession has the advantage: knowledge is acquired without additional payment to the mentor.

All that remains is to study the basic methods of applying an oxide film, and then practice the techniques through real experience and gain the necessary skills.

Preparing for bluing at home

When carrying out bluing work using chemicals, you will have to use tools to clean the surface from dirt and various types of grease. You can do the work manually or use a power tool. The work must be done on a desktop (workbench or cover the table in the apartment with a removable tabletop). In the room itself you need to have equipment and certain protective items:

- You need a working container for bluing. It should ensure that the part is completely immersed in the solution.

- Create good exhaust ventilation and fresh air flow. It is advisable to install a probe above the place where processes are carried out, then harmful fumes will not affect humans.

- When working, you need a container made of material that is neutral to alkalis and acids. It should contain water or a solution that can quickly neutralize the drugs used. The container is made of plastic, glass, porcelain or earthenware.

- The work must be done with gloves. Here you will need rubber and other types of gloves to prevent solutions from getting on your hands. They must also protect against possible thermal effects.

- Respiratory protection is achieved by using respirators. When using strong acids, activated carbon filters will be needed.

- Vision protection is achieved by using safety glasses. There are special glasses for working with chemical reagents; they are sold in work clothing stores.

- Aprons and jackets made of tarpaulin will protect the body from drops of solutions.

Alkaline steel bluing

The simplest way to apply an oxide film to products is alkaline bluing. The operating principle is based on the use of caustic soda and sodium nitrate (used as a fertilizer). Both components have a pronounced alkaline reaction.

To process a part weighing about 900...1000 g you need to have:

- 100 g caustic soda (NaOH);

- 30 g of sodium nitrate (sodium nitrate NaNO₃).

Process:

- Dissolve the components in 100 ml of water. If this amount of working solution is not enough, then increase the amount of liquid, as well as caustic soda and nitrate in proportion.

- The solution is heated to 135...145 ⁰С (salt solutions boil at a temperature higher than pure water boils).

- The part is washed with soap or weak alkali to remove possible greasy stains.

- Place in the working solution for 30…35 minutes and maintain a high temperature. In a hot state, the rate of film formation on the surface of a steel object will be high.

- After completing the procedure, it is necessary to wash off the remaining working solution.

- Wipe the product with vegetable or technical oil.

- Then thoroughly wipe the item with a rag; only a thin layer of oil film will remain, which will further protect the finished product.

As a result, the metal surface will receive a black coating with a bluish tint. It is quite durable and can withstand minor mechanical stress.

Other alkaline treatments are possible in NaOH and KOH solutions. Prepare a solution in which 300...400 g of each component is dissolved. The minimum concentration of alkalis is 700 g per 1 liter of solution.

The processing procedure takes place according to the technology described above. In this case, the result is a film with slightly more blue.

Attention! During alkaline processing, the liquid level should be maintained so that the part is always completely in the solution. Then the entire coating will be uniform.

Popular methods

Before we move on to specific techniques that are used in production or at home, we will talk about the stages. They almost always remain the same:

- Preparatory. It is necessary to carefully prepare the part, remove any contamination from the surface and from the holes, before blueing the metal at home. If there are scales or other raised parts, they can be smoothed out using sanding paper. If you use liquid media, be sure to dry the workpiece at the preliminary stage.

- Degreasing. This especially applies to car parts. As a rule, they have a thin oil layer on them, which must first be removed. If there is an oily layer between the steel and the active substance, the chemical solution, the reaction will not occur at all or will be incomplete, with disturbances. Even the slightest traces of oily media should be removed. For example, fingerprints on the handle of a knife, which remain due to the work of the sebaceous glands. Therefore, you should always work with gloves.

- Application of the composition. Below we will tell you more about how you can apply the mass. There are also ways to completely immerse a part.

- Finishing processing. It includes washing the workpiece, drying, and light cleaning if any errors appear.

At home, you can carry out cold and hot bluing of metal: how to blued steel at home, we will present videos that show the three most common options.

Alkaline

The process will produce gas. It has an unpleasant odor and is also dangerous if inhaled in excess. Therefore, it is very important to provide yourself with a suitable workplace - an open space with good ventilation. A garage will do if the doors and windows are open and you are wearing a construction respirator that will protect you from inhaling toxic fumes.

Once you've prepared the area, it's time to find the container. It must be spacious so that the object prepared for the procedure fits completely inside and does not touch the walls of the vessel. Manufacturing material – stainless steel. Let's say it's a large saucepan or metal bucket.

After preliminary degreasing of the surface, we recommend hanging the workpiece by thin threads or wire so that you can move it without touching it with your hands.

Now we apply the solution for bluing. We suggest a small experiment with 100 ml of water (suddenly you need to blacken, say, a nail), but for larger products you should prepare a similar composition, only adhering to the proportions. So, pour 0.1 liter of liquid (bottled, without impurities), dissolve caustic soda in it (caustic soda, sodium hydroxide, NaOH - there are many names, you can buy it at any hardware store) in the amount of 120 grams. Plus we add literally 30 g of sodium nitrate. It is very important to mix well so that when mixing the consistency is homogeneous and without sediment.

When the liquid is ready, place the container on the stove. We heat it to 130–150 degrees. We note right away that you will also need a thermometer adapted to such high temperatures. The mixture will begin to boil, and it will be possible to place an object into it in a pre-specified manner (so that it is completely immersed and does not touch the walls). Wait 20 minutes.

During this period of time, a black oxide film is formed. Now you can rinse the product removed from the solution in ordinary water for quick cooling.

After drying, we recommend taking machine oil and a clean piece of cloth. They should wipe the surface and make it dry. Because of this, you get a top layer that has increased wear resistance and smoothness. If everything was done correctly, polishing will not be required.

Let us note once again the important rules:

- the workpiece must be completely immersed in the vessel;

- When working, use gloves and a respirator.

In case of uneven immersion, you may not get the result you expect: the color will not be the same, but with transitions from lighter to darker.

Acid oxidation of metal at home

The use of acids is a dangerous process that can cause chemical burns on the skin and mucous membranes, so you need to protect yourself reliably. Be sure to wear safety glasses. The second important rule when using this blackening technology is careful adherence to the preparatory stage. Any traces of corrosion should be removed. Rust can be easily cleaned with sandpaper (first coarse-grained, then fine-grained). If the corrosion damage or contamination is very deep and has a large area, then it would be appropriate to use an angle grinder with an attachment (metal brush).

Then cleaners, for example, based on sodium triphosphate and ethyl alcohol, help well. Kerosene is also a good way to deal with greasy stains. You can soak it in it for about 10–15 minutes, then rinse it with running water and dry it at room temperature in a room where dust will not actively settle. While drying, prepare a solution for blackening the metal. For one liter of water you will need only 2 grams of tannic and tartaric acid.

Mix the ingredients thoroughly, place the container on the heating element and wait until the temperature reaches 150 degrees. Now you can place the workpiece into the boiling liquid. The rest of the rules are the same - complete immersion, should not touch the walls, do not touch with your hands. 15 minutes of boiling is enough.

Unlike alkaline, acidic is not easily washed off with cold water. It is best to first place the part in a container with ordinary cool liquid, rinse, and then pour over boiling water - this will wash off all the remaining substances. To consolidate the result, place the product in machine oil for 1 hour. After the time has passed, remove and dry the metal with a clean cloth, which was blued using a chemical method at home. Now you can use the tool.

Thermal

It is also called hot bluing. This is an older and more reliable, proven method. The advantages are that the top coating lasts much longer, and less harmful fumes are produced during the process. But precautions are still necessary.

The technology is simple, it consists in the fact that when heated, the steel acquires a tarnished color. An interesting point - this way you can achieve not only black, but also interesting tints, it all depends on the temperature and the duration of hardening.

First you need to carry out classic cleaning. Then preheat the workpiece a little so that the oil composition can better adhere to the warm material. Now cover the entire surface with oil, linseed or olive works well. How exactly to completely lubricate the part is up to you. It seems to us that it is best to immerse it in a container with liquid.

It is very important to wait a while after immersion so that no oil traces remain; otherwise, unsightly stains, stains, and drips will remain. After this, you can take it outside and heat it evenly. Most often, a blowtorch is used for this. At the same time, watch for changes in shade. Stop firing when it turns black.

Sometimes an oil product is not used at all. That is, they simply heat and process iron in the open air. Due to interaction with oxygen, steel changes its color.

Acid bluing of steel blanks

Before starting acid coating, the workpiece is cleaned and washed. You can get by with pure alcohol or a 40% strength solution (regular vodka). Some people use white spirit. Using a swab, clean the surface from greasy stains.

Recipe No. 1

Working solution for bluing:

- 2 g citric acid;

- 2 g oxalic acid;

- 1 liter of water.

Process:

- The solution is heated to a temperature of 120…125 ⁰С.

- Place the product in it for 20 minutes.

- Once completed, the part is removed and washed with a slightly alkaline solution. You can use a sponge soaked in shampoo.

- The treatment is completed by rubbing with machine oil.

The product takes on a black color with some brown tint.

Recipe No. 2

Vegetable tannins (tannins) are used. They are obtained from oak or willow branches.

Preparation of concentrate:

- willow or oak branches (about 3 kg) are boiled in a 10 liter container;

- 3 hours after cooking, a black solution forms;

- the branches are removed from the solution;

- evaporate the solution to 3 liters. The result is concentrated tannic acid. Only part of the solution is used for bluing. The remaining concentrate is poured into a glass container and covered with a tight lid (can be stored for up to 3...4 years).

Blued parts:

- Use 20...30 g of tanning concentrate per 1 liter of working solution.

- To activate the process, bluing is carried out with citric acid, which is added to the composition of the working solution (2...3 g per 1 liter of water).

- The part that needs to be blued is placed in the prepared solution.

- The duration of the process is 24..30 hours.

- After processing, the part is removed and washed.

- The finished part is wiped with machine oil.

- Remove any remaining oil from the part using a rag.

Metal Blackening Technology

Blackening of metal is carried out in a certain sequence of actions:

How not to blue metal (and how to do it)

- First, chemical degreasing is carried out, which is necessary to remove residual grease and other contaminants from the surface of the product.

- Then washing is carried out, as a result of which the remaining alkaline solution is removed.

- Next, the part is etched by immersing it in an HCl solution. And again the washing is done.

- The next stage is activation, when the product is immersed in a solution with special additives for several minutes.

- Afterwards the part is washed again.

- Then a black mixture is applied to the engraved metal surface and fired. This composition, in molten form, evenly fills the design, giving a subtle contrast with the rest of the surface of the product.

- Next, the part is immersed in a bath of cold water for half an hour or an hour.

- At the very end, the product is sealed with a special inhibited water-repellent compound to protect the metal from rust.

Using "Rusty Varnish"

“Rusty varnish” is on sale. It is used for surface coating of parts:

- the part is wiped clean from residual grease;

- varnished;

- use an acetone-based solvent, for example, No. 646, to wash off excess varnish from the surface;

- This is one of the fastest bluing methods using ready-made solutions.

Video: bluing at home.

Thermal bluing of parts

In industrial conditions, they prefer to perform bluing using a thermal method. Usually this operation is combined with low tempering, which relieves internal stresses inside steel products:

- The part is heated in a muffle furnace for 20...30 minutes to a temperature of 180...220 ⁰C.

- The removed part is wiped with machine oil using a swab. It is advisable to treat all surfaces.

- If necessary, the treatments are repeated.

- Usually, a double heat treatment is sufficient to obtain a high-quality blued surface.

Information: weapons factories producing firearms and bladed weapons use thermal bluing. The coating on many products lasts more than 100 years. Example, Mosin rifles manufactured in 1891 and Nagan revolvers released at the end of 1888.

Republished by Blog Post Promoter

Secrets of bluing

There are many recipes for bluing. Each master prefers his own , some may have tricks. In ancient times, blued steel recipes were often kept secret. Today you can find various recipes for every taste.

Cold bluing

The following example of cold bluing of a house can be given:

- Take a liter of water (distilled), two types of acid: 30% hydrochloric (4 g), 69% nitric (13.5 g). Ferric chloride (170 g) and divalent copper sulfate (4 g) are also added.

- The mixture is treated with the surface and left for some time. The longer the better.

- Rust is removed using water steam and a brush.

- Everything is repeated until the result is the desired one. Some do this up to 10-20 times.

Recipe with oxidizing agent

For example, the following recipe for an alkaline solution can be given:

- You will need caustic soda (400 g), sodium nitrate (10 g), water (600 ml).

- The mixture should act for 30 minutes or longer.

- Then the surface is washed well, dried, and slightly oiled. If the alkali is not completely washed off, plaque will form.

Care should be taken during operation. Hot substances and chemicals can cause damage to health or damage property. It is important not to forget about the correct selection of containers, suitable clothing and basic safety precautions.