materials having metallic properties and consisting of two or more chemical elements, at least one of which is a metal. Many metal alloys have one metal as a base with small additions of other elements. The most common method of producing alloys is to solidify a homogeneous mixture of their molten components. There are other production methods, such as powder metallurgy. In principle, it is difficult to draw a clear boundary between metals and alloys, since even the purest metals contain “trace” impurities of other elements. However, metal alloys are usually understood as materials obtained by purposefully adding other components to the base metal.

Also on topic:

METAL SCIENCE PHYSICAL

Almost all metals of industrial importance are used in the form of alloys ( see

. table 12). For example, all smelted iron is almost entirely used for the production of ordinary and alloy steels, as well as cast irons. The fact is that by alloying with certain components the properties of many metals can be significantly improved. If for pure aluminum the yield strength is only 35 MPa, then for aluminum containing 1.6% copper, 2.5% magnesium and 5.6% zinc, it can exceed 500 MPa. Electrical, magnetic and thermal properties can be similarly improved. These improvements are determined by the alloy's structure—the distribution and structure of its crystals and the type of bonds between atoms in the crystals.

Many metals, say magnesium, are produced in high purity, so that you can accurately know the composition of the alloys made from it. The number of metal alloys used today is very large and is constantly growing. They are usually divided into two large categories: iron-based alloys and non-ferrous alloys. The most important alloys of industrial importance are listed below and their main areas of application are indicated.

Steel.

Also on topic:

CHEMICAL ELEMENTS IN NATURE – CYCLE AND MIGRATION

Alloys of iron and carbon containing up to 2% are called steels. Alloy steels also contain other elements - chromium, vanadium, nickel. There are far more steels produced than any other metals and alloys, and it would be difficult to list all of their possible uses. Low-carbon steel (less than 0.25% carbon) is consumed in large quantities as a structural material, while steel with higher carbon content (more than 0.55%) is used to make low-speed cutting tools such as razor blades and drills. Alloy steels are used in mechanical engineering of all types and in the production of high-speed tools. see also

METAL CUTTING MACHINES.

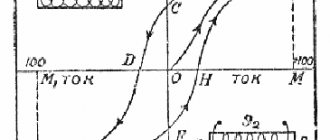

Eutectic

Rice.

137. Fusibility diagram of the Mg-Pb system If two metals form several chemical compounds during fusion, then the same number of maxima are obtained on the fusibility curve, which determine the composition of these compounds.

Thus, thermal analysis makes it possible to judge both the nature of alloys in general and the number and composition of compounds formed by the alloyed metals, on which all the properties of the alloys ultimately depend.

Example.

Using the fusibility diagram of the Bi - Cd system, determine: a) which metal will be released first when cooling a liquid alloy containing 50% bismuth and 50% cadmium;

b) how many grams of this metal will be released from 500 g

of alloy before the formation of eutectic.

1. From Fig. 134 on page 553 it is clear that the point corresponding to the temperature at which solidification of the alloy begins must lie on the BC

above point C. Therefore, when the alloy is cooled, cadmium will be released first until the composition of the remaining liquid part of the alloy reaches the eutectic.

2. Since the eutectic contains 60% bismuth, then, obviously, all the bismuth will have to be included in the eutectic. Then the weight of cadmium entering the eutectic will be determined from the proportion

60:40 = 250:x

where

x = (40 • 250):60 = 166.7 g Cd

Consequently, before the eutectic is formed, it will be released

250 - 166.7 = 83.3 g Cd

Thanks to thermal analysis, the existence of a huge number of compounds of some metals with others, collectively called intermetallic compounds, has been discovered. Most of these compounds, as far as is known, are formed by alkali and alkaline earth metals with metals of odd subgroups, which have relatively weak metallic properties.

Copper-based alloys.

These are mainly brass, i.e. copper alloys containing from 5 to 45% zinc. Brass containing 5 to 20% zinc is called red (tompak), and brass containing 20–36% Zn is called yellow (alpha brass). Brasses are used in the production of various small parts where good machinability and formability are required. Alloys of copper with tin, silicon, aluminum or beryllium are called bronzes. For example, an alloy of copper and silicon is called silicon bronze. Phosphor bronze (copper with 5% tin and trace amounts of phosphorus) has high strength and is used to make springs and membranes.

Cast iron

If an iron alloy contains more than 3-4% carbon, then it is called cast iron. In addition, its important element is silicon. A lot of parts and finished products are made from cast iron. For example, engine blocks for cars. In the case of a high-quality casting without cavities or cavities, the product has impressive mechanical strength. In this regard, it is worth recalling at least the guns of the 14th-15th centuries, which often withstood a three to fourfold increase in the powder charge.

Of course, the use of metals and alloys was never limited exclusively to the military industry, but it often turned out that it was this branch of industry that constantly found new methods of metal processing, moving forward the entire civilization.

Lead alloys.

Conventional solder (tertiary) is an alloy of approximately one part lead and two parts tin. It is widely used for connecting (soldering) pipelines and electrical wires. Antimony-lead alloys are used to make shells of telephone cables and battery plates. Alloys of lead with cadmium, tin and bismuth can have a melting point well below the boiling point of water (~70° C); They are used to make fusible plugs for valves in fire-fighting water supply sprinkler systems. Pewter, from which cutlery (forks, knives, plates) were previously cast, contains 85–90% tin (the rest is lead). Lead-based bearing alloys, called babbitts, typically contain tin, antimony and arsenic.

Popular message topics

- Didactic games

Didactics (from ancient Greek “instructing”) is directly related to upbringing and education. Ever since a person consciously began to pass on his knowledge to the younger generation, the need for training arose. - Fire safety

Fire is a combustion process that is completely uncontrollable; a fire causes enormous financial harm, damage to the health and lives of people. During a fire, people around are exposed to dangerous influences, - Tree (Elm)

Elm belongs to the trees of the Elm family. Asia is considered the birthplace of the tree. From where it spread to Siberia and the Volga region, to the Urals and the Caucasus, and to some European countries. Found in mixed forests,

Aluminum alloys.

These include casting alloys (Al – Si), die-casting alloys (Al – Mg) and self-hardening high-strength alloys (Al – Cu). Aluminum alloys are economical, easily accessible, strong at low temperatures and easy to process (they are easily forged, stamped, suitable for deep drawing, drawing, extruding, casting, well welded and machined on metal-cutting machines). Unfortunately, the mechanical properties of all aluminum alloys begin to deteriorate noticeably at temperatures above approximately 175° C. However, due to the formation of a protective oxide film, they exhibit good corrosion resistance in most common aggressive environments. These alloys conduct electricity and heat well, are highly reflective, non-magnetic, harmless in contact with food (since the corrosion products are colorless, tasteless and non-toxic), explosion-proof (since they do not produce sparks) and absorb shock loads well. Thanks to this combination of properties, aluminum alloys serve as good materials for lightweight pistons; they are used in carriage, automobile and aircraft construction, in the food industry, as architectural and finishing materials, in the production of lighting reflectors, technological and household cable ducts, and in the laying of high-voltage power lines.

The iron impurity, which is difficult to get rid of, increases the strength of aluminum at high temperatures, but reduces corrosion resistance and ductility at room temperature. Cobalt, chromium and manganese weaken the embrittling effect of iron and increase corrosion resistance. When lithium is added to aluminum, the elastic modulus and strength increase, making the alloy very attractive to the aerospace industry. Unfortunately, despite their excellent strength-to-weight ratio (specific strength), aluminum-lithium alloys have low ductility.

Basic definitions

In general, metal alloys are materials obtained by smelting, in the production of which two or more metal elements (in the chemical sense) were used, as well as (optionally) special additives.

One of the first materials of this kind was bronze. It is composed of 85% copper and 15% tin (80:20 in the case of bell bronze). Currently, there are several varieties of this compound that do not contain tin at all. But they don't occur very often. It is necessary to clearly understand that metal alloys in most cases are formed without any human involvement at all. The fact is that it is possible to obtain a material that is absolutely pure from a chemical point of view only in the laboratory. Any metal that is used in everyday life probably contains traces of another element. A classic example is gold jewelry. Each of them contains a certain proportion of copper. However, in the classical sense, this definition still means a compound of two or more metals, which was purposefully obtained by man.

The entire history of man is an excellent example of how metal alloys were able to have a huge impact on the development of our entire civilization. It is no coincidence that there is even a long historical period called the “Bronze Age”.

Magnesium alloys.

Magnesium alloys are lightweight, characterized by high specific strength, as well as good casting properties and excellent cutting properties. Therefore, they are used to make parts for rockets and aircraft engines, car body housings, wheels, gas tanks, portable tables, etc. Some magnesium alloys, which have a high viscous damping coefficient, are used for the manufacture of moving machine parts and structural elements operating under conditions of unwanted vibrations.

Magnesium alloys are quite soft, have poor wear resistance and are not very ductile. They are easily formed at elevated temperatures, are suitable for arc, gas and resistance welding, and can also be joined by soldering (solder), bolts, rivets and adhesives. Such alloys are not particularly corrosion resistant to most acids, fresh and salt water, but are stable in air. They are usually protected from corrosion by surface coating - chrome etching, dichromate treatment, anodizing. Magnesium alloys can also be given a shiny surface or clad with copper, nickel and chromium after being dipped into molten zinc. Anodizing magnesium alloys increases their surface hardness and abrasion resistance. Magnesium is a chemically active metal, and therefore it is necessary to take measures to prevent the ignition of chips and welded parts made of magnesium alloys. see also

WELDING.

Distribution of alloys in modern industry

It should be noted that all metals that are intensively used by modern industry are alloys. Thus, more than 90% of all iron produced in the world is used for the production of cast iron and various steels. This approach to the matter is explained by the fact that metal alloys in most cases demonstrate better properties than their “progenitors”.

Thus, the yield strength of pure aluminum is only 35 MPa. But if you add 1.6% copper, magnesium and zinc to it in a ratio of 2.5% and 5.6%, respectively, then this figure can easily exceed even 500 MPa. Among other things, electrical conductivity, thermal conductivity, or other properties can be significantly improved. There is no mysticism in this: in alloys, the structure of the crystal lattice changes, which allows them to acquire other properties.

Simply put, the amount of this kind of material is large these days, but it is constantly growing.

Titanium alloys.

Titanium alloys are superior to both aluminum and magnesium alloys in terms of tensile strength and elastic modulus. Their density is greater than that of all other light alloys, but in terms of specific strength they are second only to beryllium. With a fairly low content of carbon, oxygen and nitrogen, they are quite plastic. The electrical conductivity and thermal conductivity of titanium alloys are low, they are resistant to wear and abrasion, and their fatigue strength is much higher than that of magnesium alloys. The creep limit of some titanium alloys at moderate stresses (about 90 MPa) remains satisfactory up to about 600 ° C, which is significantly higher than the temperature permissible for both aluminum and magnesium alloys. Titanium alloys are quite resistant to the action of hydroxides, salt solutions, nitric and some other active acids, but not very resistant to the action of hydrohalic, sulfuric and orthophosphoric acids.

Titanium alloys are forged up to temperatures of about 1150° C. They allow electric arc welding in an inert gas atmosphere (argon or helium), spot and roller (seam) welding. They are not very amenable to cutting (seizing of the cutting tool). Melting of titanium alloys must be done in a vacuum or controlled atmosphere to avoid contamination with oxygen or nitrogen impurities that cause embrittlement. Titanium alloys are used in the aviation and space industries for the manufacture of parts operating at elevated temperatures (150–430° C), as well as in some special-purpose chemical apparatus. Light armor for the cockpits of combat aircraft is made from titanium-vanadium alloys. Titanium-aluminum-vanadium alloy is the primary titanium alloy for jet engines and airframes.

In table Table 3 shows the characteristics of special alloys, and table. Figure 4 shows the main elements added to aluminum, magnesium and titanium, indicating the resulting properties.

Production information

In principle, at present, an “alloy” may well be understood as a material based on only one chemical element, but “diluted” with a whole package of additives.

The most common method of obtaining them, melting them to a liquid state, has changed little since ancient times. For example, analysis of metals and alloys shows that the ancient Indians mastered a level of metal processing that was amazing for their time. They even began to create alloys using refractory zinc, which in our time is a rather labor-intensive and complex procedure.

Today, powder metallurgy is also widely used for these purposes. Ferrous metals and alloys based on them are especially often processed by this method, since in this case the maximum cheapness of both the process itself and the manufactured product is often required.

Beryllium alloys.

A ductile beryllium alloy can be produced, for example, by embedding brittle grains of beryllium into a soft ductile matrix such as silver. The alloy of this composition was brought to a thickness of 17% of the original by cold rolling. Beryllium surpasses all known metals in specific strength. Combined with its low density, this makes beryllium suitable for missile guidance systems. The elastic modulus of beryllium is greater than that of steel, and beryllium bronzes are used to make springs and electrical contacts. Pure beryllium is used as a neutron moderator and reflector in nuclear reactors. Due to the formation of protective oxide layers, it is stable in air at high temperatures. The main difficulty with beryllium is its toxicity. It can cause serious respiratory problems and dermatitis. See also CORROSION OF METALS and articles on individual metals.

Table 1. Some important alloys (composition and mechanical properties)

| Table 1. SOME IMPORTANT ALLOYS (composition and mechanical properties) | |||||

| Typical mechanical properties | |||||

| Alloys | Composition (main elements, %) | State | Yield strength (strain 0.2%), MPa | Tensile strength, MPa | Elongation (at a length of 5 cm), % |

| Aluminum | |||||

| 3003 | 1.2 Mn, 98.8 Al | Annealed | 40 | 110 | 30 |

| Cold rolled1 | 186 | 200 | 4 | ||

| 2017 | 4.0 Cu, 0.5 Mn, 0.5 Mg, 95 Al | Annealed | 69 | 179 | 22 |

| Heat treated2 | 275 | 427 | 22 | ||

| 5052 | 2.5 Mg, 0.25 Cr, 97.25 Al | Annealed | 90 | 193 | 25 |

| Cold rolled1 | 255 | 290 | 7 | ||

| 6053 | 1.3 Mg, 0.7 Si, 0.25 Cr, 97.75 Al | Annealed | 55 | 110 | 35 |

| Heat treated3 | 220 | 255 | 15 | ||

| Alkled 2024 | Core: 2024 (4.5 Cu, 0.60 Mn, 1.5 Mg, 94.4 Al). Coating: 99.75 Al | Annealed | 76 | 179 | 20 |

| Heat treated3 | 310 | 448 | 18 | ||

| Heat treated4 | 365 | 462 | 11 | ||

| 7075 | 5.6 Zn, 2.1 Cu, 3.0 Mg, 0.3 Cr, 89.0 Al | Annealed | 100 | 228 | 17 |

| Heat treated3 | 517 | 572 | 11 | ||

| 13 | 12–13 Si, 87–88 Al | Die cast | 145 | 296 | 2,5 |

| 43 | 5.3 Si, 94.7 Al | Cast in sand. form | 55 | 130 | 8 |

| Die cast | 110 | 228 | 9 | ||

| 214 | 4 Mg, 96 Al | Cast in sand. form | 82 | 170 | 9 |

| Copper | |||||

| Red brass | 85 Cu, 15 Zn | Annealed | 100 | 310 | 43 |

| Cold rolled1 | 450 | 550 | 4 | ||

| Cartridge brass | 69 Cu, 31 Zn | Annealed | 100 | 317 | 58 |

| Cold rolled1 | 450 | 586 | 10 | ||

| Yellow brass (high) | 65 Cu, 35 Zn | Annealed | 100 | 310 | 60 |

| Cold rolled1 | 480 | 620 | 5 | ||

| Admiralty brass | 70 Cu, 29 Zn, 1 Sn | Annealed | 124 | 365 | 60 |

| Cold rolled1 | 676 | 689 | 3 | ||

| Shipbuilding brass | 60 Cu, 39 Zn, 0.75 Sn, 0.25 Pb | Annealed | 100 | 372 | 40 |

| Cold rolled1 | 270 | 427 | 30 | ||

| Munza metal | 60 Cu, 40 Zn | Annealed | 100 | 393 | 48 |

| Cold rolled1 | 410 | 552 | 9 | ||

| Aluminum bronze | 92 Cu, 8 Al | Annealed | 206 | 524 | 55 |

| Cold rolled1 | 689 | 924 | 13 | ||

| Manganese bronze | 68 Cu, 29 Zn, 1 Fe, 1 Mn, 1 Al | Annealed | 172 | 414 | 45 |

| Cold rolled1 | 344 | 586 | 20 | ||

| Phosphor bronze | 95 Cu, 5 Sn, traces P | Annealed | 124 | 310 | 50 |

| Cold rolled1 | 517 | 620 | 4 | ||

| Silicon bronze | 96 Cu, 3 Si, rest Mn, Sn, Ni or Zn | Annealed | 150 | 379 | 35 |

| Cold rolled1 | 620 | 758 | 5 | ||

| Beryllium bronze | 97.6 Cu, 2.05 Be, 0.35 Ni or 0.25 Co | Annealed | 210 | 483 | 42 |

| Cold rolled5 | 1100 | 1310 | 2 | ||

| Nickel silver | 60 Cu, 20 Zn, 20 Ni | Annealed | 138 | 310 | 35 |

| Cold rolled1 | 517 | 620 | 3 | ||

| Cupronickel | 70 Cu, 30 Ni | Annealed | 228 | 440 | 35 |

| Cold rolled | 503 | 552 | 5 | ||

| Magnesium | |||||

| AZ 92 (daumetal C) | 9 Al, 2 Zn, 0.1 Mn, 88.9 Mg | Cast in sand. form3 | 150 | 275 | 3 |

| AZ 90 (daumetal R) | 9 Al, 0.6 Zn, 0.2 Mn, 90.2 Mg | Die cast | 150 | 228 | 3 |

| AZ 80X (daumetal 01) | 8.5 Al, 0.5 Zn, 0.2 Mn, 90.8 Mg | Extruded | 228 | 338 | 11 |

| Nickel | |||||

| Monel metal | 67 Ni, 30 Cu, 1.4 Fe, 1 Mn | Annealed | 240 | 517 | 40 |

| Cold rolled1 | 689 | 758 | 5 | ||

| Inconel | 77.1 Ni, 15 Cr, 7 Fe | Annealed | 241 | 586 | 45 |

| Cold rolled1 | 758 | 930 | 5 | ||

| Iron | |||||

| Wrought iron | 2.5 slag, the rest is basic. Fe | Hot rolled | 206 | 330 | 30 |

| Technically pure iron | 99.9 Fe | Annealed | 130 | 260 | 45 |

| Carbon steel SAE 1020 | 0.2 C, 0.25 Si, 0.45 Mn, 99.1 Fe | Annealed | 276 | 414 | 35 |

| Cast carbon steel | 0.3 C, 0.4 Si, 0.7 Mn, 98.6 Fe | Cast6 | 276 | 496 | 26 |

| Cast7 | 414 | 620 | 25 | ||

| Type 302 stainless steel | 18 Cr, 8 Ni, 0.1 C, 73.9 Fe | Annealed | 207 | 620 | 55 |

| Type 420 stainless steel | 13 Cr, 0.35 C, 86.65 Fe | Annealed | 414 | 676 | 28 |

| Heat treated | 1380 | 1724 | 8 | ||

| Cast iron | 3.4 C, 1.8 Si, 0.5 Mn, 94.3 Fe | Cast | — | 174 | 0,5 |

| Nitensil | 2.7 C, 1.8 Si, 0.8 Mn, 2.3 Ni, 0.3 Cr, 92.1 Fe | Cast8 | 278 | 552 | — |

| Niresist type 2 | 2.8 C, 1.8 Si, 1.3 Mn, 20 Ni, 2.5 Cr, 71.6 Fe | Cast | — | 207 | 2 |

| Nihard | 2.7 C, 0.6 Si, 0.5 Mn, 4.5 Ni, 1.5 Cr, 90.2 Fe | Cast in sand. form | — | 379 | — |

| Chill cast | — | 517 | — | ||

| 1Vacation at max. hardness. 2 Heat treatment for solid solution. 3 Heat treatment for solid solution and aging. 4Heat treatment for solid solution, aging and hardening. 5Vacation at max. hardness and aging. 6Casting and annealing. 7Casting, water quenching, tempering at 677° C. 8Casting and heat treatment. | |||||

Table 2. Some important alloys (physical properties, characteristics and applications)

| Table 2. SOME IMPORTANT ALLOYS (physical properties, characteristics and applications) | |||||||||||

| Physical properties | |||||||||||

| Alloys | Density | Melting point (range), °C | Coeff. thermal expansion (0–100° C), 10–6/K | Thermal conductivity (0–100° C), 106 W/(mCHK) | Electrical resistivity (0°C), 10–9 OhmHm | Tensile modulus of elasticity, 103 MPa | Characteristics and Application | ||||

| Aluminum | |||||||||||

| 3003 | 2,73 | 645–655 | 22,9 | 8,32 6,70 | 98,9 125 | 68,9 | Plastic and lightweight material. Tanks, pipes, rivets, etc. | ||||

| 2017 | 2,79 | 535–640 | 23,2 | 7,41 5,23 | 111 169 | 71,7 | Aircraft manufacturing and other branches of technology where high specific strength is required | ||||

| 5052 | 2,67 | 590–650 | 23,6 | 6,00 | 144 | 70,3 | Good strength, lightweight, corrosion resistant material | ||||

| 6053 | 2,69 | 580–650 | 23,2 | 7,41 6,70 | 111 125 | 69,0 | Same | ||||

| 2024 | — | 500–640 | 23,0 | — | — | — | Durability exceeds 2017 | ||||

| 7075 | 2,80 | 480–640 | 23,2 | 5,23 | 169 | 71,7 | Strength exceeds 2024. Aircraft manufacturing | ||||

| 13 | 2,66 | 576–620 | 19,8 | 6,14 | 140 | 71,0 | Good casting properties. Excellent material for complex castings | ||||

| 43 | 2,66 | 576–630 | 22,0 | 6,32 6,32 | 136 122 | 71,0 71,0 | Good casting properties, gas-tight material. General purpose casting alloy | ||||

| 214 | 2,63 | 580–640 | 23,8 | 5,98 | 144 | 71,0 | Good mechanical properties. Excellent corrosion resistance. Kitchen and dairy utensils | ||||

| Copper | |||||||||||

| Red brass | 8,75 | 1023 | 17,6 | 6,85 | 143 | 103 | Corrosion resistant. Water pipes, fittings | ||||

| Cartridge brass | 8,50 | 938 | 20,0 | 5,17 | 204 | 97 | Cartridge cases and other deep-drawn products | ||||

| Yellow brass (high) | 8,47 | 932 | 18,9 | 5,17 | 204 | 97 | General purpose brass. Good mechanical characteristics. | ||||

| Admiralty brass | 8,54 | 934 | 18,4 | 4,73 | 214 | 103 | Corrosion resistant. Condenser pipes | ||||

| Shipbuilding brass | 8,42 | 885 | 20,1 | 5,00 | 214 | 103 | Resistant to salt water. Shipbuilding | ||||

| Munza metal | 8,40 | 904 | 19,4 | 5,42 | 184 | 90 | Good high temperature properties and corrosion resistance | ||||

| Aluminum bronze | 7,78 | 1040 | 16,6 | 3,00 | 357 | 103 | High strength alloy, corrosion resistant. Propellers, gears | ||||

| Manganese bronze | 8,36 | 896 | 20,1 | 4,36 | 214 | 103 | Increased strength. Pipeline fittings | ||||

| Phosphor bronze | 8,86 | 1050 | 16,9 | 3,52 | 290 | 103 | High fatigue strength. Springs, membranes | ||||

| Silicon bronze | 8,54 | 1018 | 17,1 | 1,40 | 816 | 103 | High strength and fatigue resistance, corrosion resistance | ||||

| Beryllium bronze | 8,23 | 954 | 16,6 | 4,00 | — | — | Exceptionally high fatigue strength. Springs, membranes | ||||

| Nickel silver | 8,75 | 1110 | 16,2 | 1,45 | 893 | 128 | Corrosion resistant white metal. Basic material for silver plated utensils | ||||

| Cupronickel | 8,94 | 1227 | 15,3 | 1,25 | 1122 | 139 | Corrosion resistance. Condenser pipes, salt water pipes | ||||

| Magnesium | |||||||||||

| AZ 92 (daumetal C) | 1,82 | 599 | 25,2 | 2,89 | 490 | 44,8 | Light alloy for sand casting and multiple molds | ||||

| AZ 90 (daumetal R) | 1,81 | 604 | 25,2 | 2,98 | 520 | 44,8 | Lightweight die casting alloy | ||||

| AZ 80X (daumetal 01) | 1,80 | 610 | 25,2 | 3,30 | 444 | 44,8 | Light alloy for extrusion | ||||

| Nickel | |||||||||||

| Monel metal | 8,84 | 1299–1349 | 14,0 | 1,12 | 1480 | 179 | Corrosion resistant. Kitchen and hospital equipment | ||||

| Inconel | 8,51 | 1393–1427 | 11,5 | 0,64 | 3000 | 214 | Heat and corrosion resistant alloy | ||||

| Iron | |||||||||||