The appearance of rust on metal surfaces and parts is a very common phenomenon that is often encountered not only by motorists. Corrosion is a chemical reaction that causes damage to metal. Cleaning rust from iron at home is one of the frequently asked questions that does not have a definite answer. In this material we will look at all possible ways to combat corrosion, and what tools, preparations and improvised means will be needed for this.

Rust on metal - causes of its occurrence

The first and very important question with which you need to start fighting corrosion involves finding out the cause of its occurrence. Having learned the reasons for the reaction, you can not only choose the optimal method for removing corrosion, but also prevent its reoccurrence.

Why does metal rust? The main reason for the reaction is the composition of the metal. It consists of various compounds such as oxygen, carbon, sulfur and others. It is these components that become the result of the appearance of rust stains on metal parts placed in water or a humid environment.

This is interesting! Pure metals do not rust, and these include gold, silver and platinum.

Metal in contact with air forms oxides, and with moisture - hydroxides. The effect of moisture and oxygen on metal contributes to its destruction, and the thinner the steel, the faster the process of its destruction occurs. This phenomenon is called corrosion, and the result of its occurrence is rust. It is almost impossible to avoid the occurrence of these processes, but various methods and techniques are used to reduce the rate of corrosion development.

Corrosion is a long-term process, so the destruction of metal products requires a long period of time, which directly depends on the thickness of the iron. It follows from this that the main reasons for the appearance of rust on metal are the following factors:

- Exposure of untreated metal to oxygen and moisture. In this case, the part does not necessarily have to be in a damp room. If you store a metal product in a dry and ventilated area, then signs of corrosion will also form after some time.

- Lack of special protective coatings - these include not only varnishes and paints, but also zinc coatings, which provide highly effective protection against the destructive effects of corrosion.

- Type of steel - high-alloy steels are susceptible to rusting with less intensity, which is due to the low percentage of carbon in the composition. However, such steels are quite expensive, so they are used for the manufacture of various high-precision parts or consumables for power tools.

Many people mistakenly believe that a type of steel such as stainless steel does not rust. We will not go into details of the composition of this material, but it is worth noting that even stainless steel is subject to the corrosion process. This is due, first of all, to the fact that the chrome film, which forms upon contact with oxygen, and thereby protects the metal from rust, is damaged, which ultimately leads to the appearance of rust.

To summarize, it should be noted that metal rusting is a normal natural phenomenon, which is a global problem for humans. And we are talking not only about problems with a rusting car body, but also about such global disasters as the sinking of ships, the destruction of bridges, etc., provoked by rusting metal.

Preventing rust

Oxidation stains eat into the surface of the metal quite strongly, and getting rid of rust can be difficult. Next, we will tell you how to protect metal objects and prevent corrosion. Basic tips:

- Since water is one of the biggest causes of oxide stains, make it a habit to thoroughly wipe all metal surfaces after contact with moisture. Do not allow puddles to stagnate near iron structures, remove water in a timely manner.

- Store iron products in a dry, clean place. It is recommended to wrap scissors and other metal tools in oiled rags or paper after use.

- If you want to protect iron items outside your home (such as window grilles and pipes) from corrosion, we recommend that you coat them with a coat of enamel paint. In addition to its decorative function, paint creates a protective coating on the metal surface that will not allow moisture and air to pass through.

- The problem of corrosion can often be encountered on various fastenings. Often, without proper care, bolts or nuts can become tightly “stuck” in their places. To prevent this from happening, lubricate the fasteners with a special paste or Vaseline before tightening. To prevent corrosion, regularly lubricate parts with any fatty oil.

- A rusty padlock not only looks unsightly, but can also lead to big troubles. If rust forms in the keyhole, the key will not be able to turn in it and it will be very difficult to open the lock. To prevent this from happening, regularly treat all moving elements of the lock with grease-containing products. It would also be a good idea to make a protective screen for the lock from a plastic bottle.

Read also: Formulas for serial and parallel connections

Remember that if measures are not taken in time, it will be very difficult to remove deep oxides from the surface of the metal. If you find traces of emerging rust on an iron product, quickly provide assistance. The sooner you eliminate corrosion, the longer your item will last. Next, we’ll tell you how to remove rust from metal at home.

Harm from rust or why you need to fight it

Everyone knows the danger of corrosion. In addition to the fact that the appearance of the metal part deteriorates, it also begins to lose its mechanical properties - strength, elasticity, rigidity, etc. Many people do not pay attention to the appearance of rust spots, which increase in size over time. The main danger of corrosion is that it corrodes the metal inside, making it ultimately unusable. As a result, you have to buy new parts, which causes additional costs.

The reasons for the need to combat rust are known. This must be done not only to protect the part from complete unsuitability, but also for aesthetic purposes. Moreover, the process of combating corrosion must be approached responsibly. An incorrect approach will only accelerate the rusting process, and in a short period of time it will fail.

How to remove red marks from nickel and chrome surfaces?

For this type of coating, the use of aggressive acids is contraindicated to avoid damage to the appearance. For example, to effectively remove red stains from a sink or nickel- or chrome-plated plumbing, you can use fish or any animal oil.

- Simply apply the melted product to the stains and forget about them for a few days.

- After the specified time has passed, wipe the product with a clean soft cloth soaked in ammonia.

- To clean light rust marks on chrome, prepare a mixture: mix lemon juice and table salt in a 1:1 ratio.

- Apply the mixture to the stain and leave for 10 minutes.

- Finally, simply rinse the treated area with water and wipe dry.

Cleaning metal from rust - special preparations and mechanical methods

To combat metal corrosion, there are three main methods - the use of chemical compounds, mechanical and electrochemical effects (processing). It is simply impossible to answer unequivocally the question of what is the best way to remove rust from metal. To understand why, let's look at the features of each method.

- The chemical method of combating corrosion has its advantages and disadvantages. The products are available in the form of formulations of various consistencies - liquids, gels and even sprays. They contain substances such as acids that come into contact with materials and effectively remove traces of corrosion. However, such preparations can only be used on surfaces of acid-resistant metals. If the metal is not acid-resistant, then substances containing inhibitors should be used to clean it. They remove rust without destroying the structure of the product.

- Mechanical methods - there are a large number of them, as well as drugs to combat corrosion. If in the first case the removal of corrosion stains occurs automatically due to a chemical reaction, then the mechanical method involves physical action. The most common method is to use sandpaper or files.

- Electrochemical - the principle of their operation is based on passing an electric current through a calcium solution. In this case, a reaction begins to occur, through which oxide ions move from the iron to the clean electrode. The method for removing corrosion in this way is called electrolysis, which is used in industry and household activities.

The advantage of the chemical method of combating corrosion is that there is no need to apply physical effort. Anyone who has dealt with rust removal knows how difficult it is to clean the surface to a shine by hand. However, the chemical method has some disadvantages that you should be aware of before choosing and using them:

- when using chemical reagents, you can remove not only rust, but also speed up the process of metal corrosion, which is especially important for steel less than 3-4 mm thick;

- When using reagents, it is important to use protective equipment, since the acids and alkalis contained in the composition can cause a chemical burn if they come into contact with human skin.

Chemicals are very effective, but it is important to use them with extreme caution. This is especially true when removing corrosion from a car body, where the slightest inaccuracy can lead to corrosion of the paintwork.

The mechanical method of removing corrosion, despite its main disadvantage in the form of significant time consumption, is more relevant and in demand. The main reason for its popularity is safety and effectiveness. Next, consider all kinds of ways that will help get rid of corrosion that has arisen on a metal surface.

Chemical methods of removal

Chemical attack is the most effective way to eliminate corrosion. There are several means for this.

Lactic or phosphoric acid

If there is a lot of rust, the product can be cleaned with a solution of 0.1 liters of lactic acid and 0.1 kg of Vaseline or paraffin oil. The acid converts corrosion into salts, which then dissolve in Vaseline. After this, the surface to be treated should be wiped with a soft cloth.

Phosphoric acid turns the rusty layer into a dense material. To do this, the substance must have a concentration of 30% or 15%. The product is applied to problem areas using a spray bottle, after which it is left to dry naturally. To enhance the effectiveness, it is recommended to mix 1000 ml of acid with 15 ml of tartaric acid and 5 ml of butanol.

Sulfuric or hydrochloric acid

It is recommended to combine acids with inhibitors. To remove rust, experts recommend adding methenamine to the acid solution.

For processing, small metal parts can be dipped into a solution of 5% sulfuric or hydrochloric acid mixed with 1 liter of clean water and 500 mg of hexamine. Large objects are treated with a brush. After treatment, the item must be additionally treated with a weakly concentrated solution of ammonia.

Formalin or zinc chloride

A solution for eliminating corrosion is prepared from 0.25 liters of water, 0.25 kg of formaldehyde, 0.05 kg of caustic soda and 50-60 ml of ammonia. The prepared mixture is diluted with 1 liter of clean water.

Before placing rusted parts into the solution, they should be degreased. Removing rust using this method takes about half an hour.

Chemicals and traditional methods for effectively combating rust

Corrosion problems have been known for a very long time, and if now there are many different chemicals that can quickly and effectively remove rust stains, then previously improvised means were used instead. We will consider methods for removing corrosion using chemicals in more detail below.

Acetic acid is a cheap and effective drug

To quickly and cost-effectively remove rust from metal, you need to use 70% acetic acid or essence. You can also use regular vinegar. Fill the container with acid and place the part in it. After 2-3 hours, the workpiece can be removed from the container and the effectiveness of this drug can be verified.

Acetic acid can also be poured into a spray bottle, and thus treat a large surface. It is important to use safety glasses to prevent the drug from getting into your eyes. There is no need to talk about vinegar being 100% effective, but it all depends on the layer of rust on the part. After using this method, the workpiece should be thoroughly dried, and only then begin to apply additional protective agents.

Baking soda will help remove small pockets of corrosion on the metal surface.

Another product that is available in the kitchen is soda. It helps remove rust stains on metal surfaces. The principle of the procedure is to perform the following actions:

- Prepare a mixture by diluting soda with water and stirring thoroughly to obtain a porridge-like substance.

- Apply the resulting mixture to the area of rust formation and rub thoroughly using an unsuitable toothbrush.

- Wait a few hours, then rinse the surface thoroughly.

The procedure can be repeated several times to achieve an effective result. You can use soda not only to clean rust from kitchen utensils, but also from various parts.

Citric acid - removing rust in hard-to-reach places

Many have faced the need to remove metal corrosion in hard-to-reach places. If the outer surface can be sanded with sandpaper, then it is almost impossible to get into the internal cavities. In this case, a kitchen preparation such as citric acid will help.

In addition to effectively combating corrosion, citric acid is harmless to the skin of the hands, but in any case, it is recommended to use special gloves. The effectiveness of rust removal depends on the concentration of citric acid. It is recommended to dilute the powder with warm water in a proportion of 80 grams of acid per 100 ml of liquid. Next, the part is placed in a container with the solution for several hours, and after that it is removed.

Oxalic acid is a special preparation for fighting rust

Oxalic acid must be handled with care and with the obligatory use of protective equipment. The work algorithm involves performing the following actions:

- Pre-wash the part and dry it.

- Prepare a solution by dissolving six teaspoons of powder in 300 ml of water.

- Immerse the object in acid and remove it after half an hour.

- Remains of rust are removed with a toothbrush.

Acid copes not only with metal corrosion, but also with various surface contaminants.

Hydrochloric acid is a quick way to combat corrosion

To clean the surface of a metal product from rust, it is enough to treat it with a 2 percent solution of hydrochloric acid. When using this product, it is also important to follow safety precautions and use protective equipment.

Rust destroyers

You've probably come across drugs called rust destroyers or rust cleaners in hardware stores. They are liquid consistencies based on various acids that come into contact with metals.

The products are quite effective drugs, but they must be used carefully. They are not only dangerous to humans, but also to the hardware itself. Excessive amounts of acid will not only remove the corrosion, but also damage the metal.

In addition to destroyers, there are drugs such as converters. Their main difference from exterminators is that after treatment with such materials, the surface does not need further treatment with primer compounds. After the converter has dried, you can begin painting the surface.

Hydrogen peroxide - how effective is the drug?

If you need to remove rust from a bathtub, toilet bowl or cutlery, then you can use harmless hydrogen peroxide. The drug itself is not so effective, so it is recommended to use it together with trisodium phosphate. To prepare the product, you must perform the following steps:

- Dilute trisodium phosphate powder in 3 liters of water.

- Add 50 ml of hydrogen peroxide.

- Use the product to wet or wipe surfaces with traces of corrosion.

A popular drink such as Coca-Cola is also used to remove rust. This delicacy has this property due to the fact that it contains phosphoric acid. The process of removing corrosion with Coca-Cola takes a very long time (at least 20 hours), but the result cannot be pleasing to the eye.

This is interesting! In small quantities, the Coca-Cola drink is harmless to the body, but if it is consumed in large doses and constantly, one can imagine its negative impact on human organs.

An alternative to sandpaper is foil, which can be used to clean and remove minor rust on the metal surface. The methods listed above to combat corrosion are considered the best available means. However, to remove rust from important parts, you will need to use more significant methods.

Some unusual means and methods to remove rust from metal

The list of working anti-corrosion compounds is not complete. There is also Coca-Cola, beloved by many, tomatoes and the electrolysis process.

Coca Cola

Glory to the meticulous American housewives who were the first to notice how a tasty drink can corrode iron oxide. And not only the rust is eaten by the cola, but also the nail itself. There is nothing surprising in this; grapefruit acts in much the same way: both Coca-Cola and the fruit contain phosphoric acid.

How to remove rust from a bicycle? Or how to clean a rusty hammer? Buy a cola and give the item a good bath in it!

It is important not to miss the moment when the object has been cleaned and the drink has not begun to corrode the metal itself.

Salvaging metal from the garden or kitchen: tomato paste or ketchup

The chemical composition of tomato allows it to be used not only for food.

Homemade or store-bought tomato paste will do the job; it’s an excellent tool at hand.

Ketchup or paste is dripped onto the rusty metal, but not washed off immediately: let the substances interact. After 10-15 minutes, the dirt is removed mechanically, and the surface is wiped with a dry cloth.

Mechanical methods of combating metal corrosion

How to remove rust from metal? The easiest way is to use sandpaper or a metal brush. The disadvantages of this method are known to everyone - the expenditure of effort and time, but even with these disadvantages, the method continues to remain relevant, and moreover, it is very popular.

To remove rust from metal surfaces mechanically, the following tools, consumables and devices are used:

- Hand brush for metal - the tool is a regular brush with a handle, but instead of the usual bristles it uses metal bristles. The wire-shaped bristles have varying stiffness, thereby ensuring their penetration into the smallest pores on the surface of the iron. Brushes are used to remove rust only in cases where there is a large layer of corrosion and dirt on the surface of the part. However, we can’t talk about 100% efficiency, since the brush removes only superficial deposits and is not able to clean out the orange deposits from the pores.

- Mechanical brushes (cord brushes) - the effectiveness of removing rusty deposits on the metal surface depends on the speed and frequency of passage of the bristles through the metal. Especially for such cases, special attachments for power tools have been developed - mechanical brushes for metal. The products are available in different shapes, types and configurations, which allows you to use the best option for cleaning various surfaces. The brushes are suitable for electric drills and angle grinders. Despite the simplicity of the design of the nozzles, it is quite difficult to work with them due to centrifugal force. When the nozzle touches the surface being treated, the tool tends to escape from your hands, so it is very important to hold it with both hands. When working, you need to use protective equipment, which is due to the formation of large amounts of metal dust. In addition, the separation of lint cannot be ruled out, which, at high rotation speeds of the nozzle, can get stuck in the skin. To eliminate such consequences, it is recommended to carry out work in special clothing. The bristles on the brushes can be coated with a layer of brass. This is done so that during the cleaning process a protective brass film is created on the treated area.

- Sandpaper – You can remove rust using sandpaper. This is one of the most effective means, the main advantage of which is the ability to select fractions of suitable size. Sandpaper should be selected depending on the size of the pores present on the workpiece. The disadvantage of using sandpaper is that the process is complicated and time-consuming.

- Power Tools for Sandpaper - To remove corrosion from metal using sandpaper, it is recommended to use power tools. These include drills, grinders and grinders. Special round attachments are designed for fastening in the chuck of a drill (screwdriver) or the spindle of an angle grinder. Sanding sheets are used on sanding machines. The downside to using power tools with sandpaper is that you have limited access to tight spots. And therefore, especially for such cases, a type of tool such as a sandblasting gun was invented.

- Sandblasting gun or sandblasting equipment - the products have a simple design, but their main advantage is the high quality of rust removal. The operating principle of the equipment is based on cleaning the surface using grains of sand. Sand flies out of the nozzle of a special nozzle, called a gun, under the influence of compressed air pressure. Due to the high air pressure, the speed at which grains of sand fly out increases, which, when they hit the surface, clean the rust. Today, sandblasting equipment is the most effective means for high-quality cleaning of metal surfaces from rust.

Knowing what mechanical methods exist to remove corrosion from metal, it will not be difficult to choose the appropriate option or try all methods. It is important to note that when using sandblasting equipment it is important to consider the following:

- The devices have high power, so it is not recommended to use them for processing thin sheet metal.

- Sandblasting machines can easily cope not only with rust, but also with cleaning the surface of dirt and paintwork.

- The efficiency of the equipment depends on the type of sand used - river, quartz, corundum, etc.

Moreover, it is important to understand that the installations effectively remove rust not only in open areas, but also in hard-to-reach places. To reliably and effectively combat rust formed on metal, it is recommended to give preference to sandblasting machines.

Mechanical removal

Since corrosion products have low adhesion, they are easy to remove from the surface of the product by mechanical action. This method is convenient for removing rusty deposits from large, smooth metal surfaces. It is also advisable to use this method for cleaning heavily rusted products as the first stage of completely removing contamination.

The mechanical method includes removing rust using special brushes, grinding wheels, and sandpaper.

To clean large items, you can use a grinding machine, starting with the coarsest grains and finishing with the finest grains. Metal brushes and abrasive attachments for an angle grinder or drill are also suitable. It is more convenient to clean small parts with sandpaper.

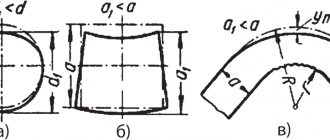

Products with complex geometry are difficult to mechanically influence, so it is more effective to use other methods for them.

Note! The areas of metal treated in this way remain without protection from the environment, and therefore, without special treatment, they will become covered with rust even faster.

Electrochemical method of rust removal using the example of a car body

Particular attention should be paid to such a method of combating corrosion as the electrochemical method. It is immediately worth noting that this method is suitable for combating corrosion on any type of metal surfaces, including car bodies.

The essence of this method is based on provoking electrochemical corrosion. Metal conducts electric current, and depending on its magnitude and voltage potential, atoms are aligned in a certain chemical series.

The electrochemical corrosion removal method is also called cathodic protection. Why protection? This method allows not only to remove corrosion, but also to apply a protective zinc film to the metal. All this can be done at home. And if the method of removing corrosion using sandblasting equipment does not suit you, then we will consider in detail how you can eliminate corrosion on a car body using the electrolytic method.

Initially, you need to prepare the necessary tools and materials. For this you will need:

- DC source. You can use a car battery, but it is recommended to use a charger with current and voltage indicators, as well as a step regulator.

- A container made of material that does not conduct current. This is in case you plan to process the removed part.

- Aqueous solution - it is recommended to use baking soda or soda ash as the medium in which the reaction will occur. An alternative is a pipe cleaner called "Mole". It contains sodium.

- The positive electrode acts as an anode. It is recommended to use stainless steel material as an electrode. The metal used must be a conductor of current, but only with less conductivity than the metal being processed.

- To ensure the procedure is carried out correctly, you will need one more important detail - a fabric insert on the anode. It not only eliminates the occurrence of a short circuit, but also allows you to apply an aqueous solution to the area that needs to remove corrosion.

As you can see, every home craftsman has all the necessary materials and tools in his arsenal. After preparing the necessary tools, we move on to creating a tool for electrolytic cleaning of metal from corrosion.

- Initially, it is necessary to attach an electrode to the positive contact (terminal) from the charger or car battery. As an alternative, we use a stainless steel spoon.

- Next, a woven material must be wound around the electrode attached to the positive terminal. You can use a sponge or any cloth. The reaction speed depends on the thickness of the fabric, and the thicker it is, the slower the anodizing process.

- The tool for removing rust from a car body is almost ready for use. All that remains is to secure the negative terminal from the charger to the car body. If a battery is used, then the “ground” is already on the car, and you can begin to manipulate it.

- Prepare an aqueous solution using the “Mole” product. To speed up the process, you can add soda ash or sodium to the solution. If you use regular soda, then 1 tablespoon per 1 liter of water is enough.

- By wetting the anode sponge, we treat the area on the car body with signs of corrosion. It is very important to pre-clean this area of contamination. The saffron caps should also be cleaned of paintwork to ensure that corrosion in these areas is removed.

- Before starting the procedure, connect the charger to the network and set the current. The current strength depends on the size of the part, so we proceed as follows. If saffron milk caps are removed, as shown in the photo above, then we set the current to 6-8 Amperes. It will be quite enough. If you need to clean a large part from corrosion, for example, a car wheel, then you will need a larger current, 10-15A. However, it is important not to overdo it here, since this way you can burn the memory.

- Let's get down to business - wet the woven part of the anode in the solution, and clean the area on the car with signs of corrosion. In just a few minutes you can see how the rust begins to dissolve.

- After thorough treatment, it is necessary to rinse the treated area with distilled water. Using plain water with a salt solution will worsen the situation.

- After cleaning the rust on the car body, you can proceed to the next stage - protecting it with galvanizing and painting.

To galvanize a car body at home, a similar tool is used. The only difference is that instead of a stainless electrode it is necessary to use a zinc plate. In order for zinc ions to transfer to the metal and create a protective film, it is necessary to treat the fabric in which the anode is wrapped with soldering acid.

Naturally, the method of electrochemical removal of corrosion from metal is suitable for untreated cases (for example, a car body). The thickness of a car body is 2-3 mm, and if the metal is completely rotten, then there is no point in trying to clean it or save it in any way. In this case, you will need to replace the failed body part. In order not to have to change part of the car body, it is recommended that when the first saffron milk caps are detected, resort to rust removal.

This is interesting! It is important to understand that although saffron milk caps appear on cars on the outside, the reason for their occurrence is hidden inside. In this case, after removing the saffron cap on the outer part, do not forget to check the inside of the part. There is a high probability that the corrosion stain will be more significant on the inside than on the outside.

You don't have to be a chemist to clean rust from metal using the electrochemical method. The procedure is extremely simple and understandable, however, when implementing it, it is important to follow safety precautions and use personal protective equipment (PPE). Below is a video that describes in detail the process of how to remove rust on a car body quickly, efficiently and efficiently.

Rules to follow when cleaning products

- Rust stains, in most cases, are removed with acids, so be sure to wear gloves and protect your eyes and clothing. During the procedure, children and pets must be removed from the premises. Be sure to ventilate the apartment afterwards.

- The methods described in this article for enamel surfaces can be applied once every 1-2 months. They are not suitable for everyday cleaning, as the substances used can damage the enamel. Of course, at first glance, you won't notice it. But acids, interacting with the glaze, thin it, and microcracks form on the smooth surface, which in the future will even more attract various pollutants.

- Before applying the product, rinse and clean the product from other contaminants.

- Rinse the surface with water and dry it with a clean cloth.

- Then follow the instructions.

Laser cleaning of metal from corrosion

In addition to the methods described above, there is another method of combating metal corrosion. It involves the use of laser equipment. This is a modern technology that is characterized by high speed, quality and efficiency. It has only one drawback - its high cost, so not everyone can afford to use it. Due to the high cost of the method, it is used to clean precious metals from corrosion and plaque.

The advantages of this method include the following factors:

- no release of harmful substances;

- automatic shutdown of the laser beam;

- ability to work with combined materials;

- high speed and quality;

- no need to replace consumables.

The cleaning procedure involves applying laser radiation to areas that need to be cleaned from corrosion. The laser beam acts exclusively on contaminated surfaces. The beam is reflected from clean areas, and damaged areas are heated, thereby removing plaque from them.

During laser exposure, heating causes a transformation of the structure, which ultimately causes plaque exfoliation. As the power of the equipment increases, the process of plaque evaporation occurs. The equipment is capable of heating workpieces to a temperature of 16.5 thousand degrees Celsius. The cleaning process is performed automatically. Initially, the working surface is scanned, and then the focused beam processes the part.

This is interesting! The use of such equipment for home use is irrational due to its high cost.

Video

We invite you to watch videos on the topic of cleaning metal objects from rust:

Graduated from the economics department of the Aviation University. Married, has a daughter. Loves to play musical instruments and spend time in pleasant communication. She always strives to learn something interesting and master a new craft. Loves to cook for the whole family. Life motto: “Never give up!”

Found a mistake? Select the text with the mouse and click:

There are special traps to combat moths. The sticky layer with which they are covered contains female pheromones that attract males. By sticking to the trap, they are eliminated from the reproduction process, which leads to a decrease in the moth population.

Fresh lemon is not only suitable for tea: clean dirt from the surface of an acrylic bath by rubbing with half a cut citrus, or quickly wash the microwave by placing a container of water and lemon slices in it for 8-10 minutes at maximum power. The softened dirt can simply be wiped off with a sponge.

The habit of using an automatic washing machine “sparingly” can lead to the appearance of an unpleasant odor in it. Washing at temperatures below 60℃ and short rinses allow fungi and bacteria from dirty clothes to remain on internal surfaces and actively multiply.

The easiest way to remove scale and carbon deposits from the soleplate of the iron is with table salt. Pour a thick layer of salt onto the paper, heat the iron to maximum and run the iron over the salt bed several times, applying light pressure.

Before removing various stains from clothing, you need to find out how safe the selected solvent is for the fabric itself. It is applied in a small amount to an inconspicuous area of the item from the inside out for 5-10 minutes. If the material retains its structure and color, you can move on to stains.

Stretch ceilings made of PVC film can withstand from 70 to 120 liters of water per 1 m2 of their area (depending on the size of the ceiling, the degree of its tension and the quality of the film). So you don’t have to worry about leaks from neighbors above.

If your favorite things show the first signs of gestation in the form of untidy pellets, you can get rid of them using a special machine - a shaver. It quickly and effectively shaves off clumps of fabric fibers and returns things to their proper appearance.

Threads made of gold and silver, which were used to embroider clothes in the old days, are called gimp. To obtain them, the metal wire was pulled for a long time with pliers to the required fineness. This is where the expression “to drag out the rigmarole” came from - “to do long, monotonous work” or “to delay the completion of a task.”

The dishwasher cleans more than just plates and cups. You can load it with plastic toys, glass lamp shades and even dirty vegetables, such as potatoes, but only without using detergents.

Reading time: 5 minutes No time?

Any unprotected metal will become rusty over time. The more severe the operating conditions, the faster this happens. Home plumbing, car body parts, tools, dishes - all of this is subject to corrosion. If you notice red spots in time, you can quite easily deal with them with home remedies, without resorting to serious chemicals. This material from Housechief.ru will tell you how to remove rust from a metal surface.

Read in the article

Preventive actions

To protect iron from rust, various alloys are used. These include chromium, molybdenum, nickel, sulfur, etc. The disadvantage of these methods is their high cost. A cheaper and more practical means of protecting steel is to coat it with various materials that create a barrier between the surface of the product and the environment. As such coatings, not only varnishes and paints are used, but also coatings made of zinc, chromium, tin, copper and nickel.

Using zinc as a protective layer is not only the most common, but also an effective method. The corrosion process of zinc occurs very slowly, and if applied correctly, the metal part will last at least 20-30 years. If a part has become rusty, its service life can be extended with timely treatment.

To summarize the above, it should be noted that metal corrosion is a normal phenomenon for nature, but abnormal for humans. A person cannot exclude the development of such processes, but it is quite possible to stop them if they choose the right method for removing rust.

How does corrosion affect the performance of equipment and tools?

What is metal corrosion? As people of the older generation would say, this is such a hellish foreign group that destroys our brain with its music. But let’s not argue about tastes and leave the “Metal Corrosion” group alone, but the essence of the statement is true: this is a chemical process that destroys a metal surface.

Equipment and tools made of metal and subjected to a corrosive process begin to change in appearance. At first it is almost invisible to the naked eye. Then rusty pitting and roughness appear on the surface

The process is started, and if it is not stopped, the damage penetrates deep into the material. All metal devices damaged by rust begin the countdown until they are written off. Therefore, to prevent this from happening, you need to remove corrosion in a timely manner.

Why even a little rust can become a big problem

As soon as man learned to mine and use iron ore, he began to look for ways to preserve the metal from corrosion. Herodotus, in his works, described in detail the technique of coating iron with a layer of protective tin, and archaeological excavations of more ancient cultural layers indicate the practice of protecting metal products using lubricant.

Only high-quality lubricant can prevent corrosion.

So what happens to such a hard and durable metal, why does it become loose and brittle over time? It's all about oxygen. It is he who causes a chemical oxidation reaction, gradually capturing deeper and deeper layers. There is only one way to stop this reaction: to cover the object with a protective layer that will prevent direct contact of the metal with air. If this is not done, the rust will grow from a small speck into a huge ulcer, and then completely turn into a hole. Objects made of thin sheet metal especially suffer from this process: plumbing fixtures, dishes, various household containers.

Read also: Torque booster wrench with heads

Is it possible to prevent this process? Careful care, protective coating and timely lubrication are all simple preventative measures. What to do if corrosion does appear?

Chrome plating: concept and applications

Chrome plating is a special technology of applying a thin layer of chromium to metal products. Today, galvanic chrome plating is most often used. The process involves the deposition of chromium using an electrolytic solution onto a metal surface directly under the pressure of electrical charges.

The popularity of this operation is due to the fact that the chrome-plated part acquires improved technical and operational characteristics: strength, resistance to negative environmental factors. All this allows the metal to be used not only for finishing, but also for decorative purposes.

The disadvantages of this type of surface undoubtedly include low resistance to mechanical stress - small scratches, holes and chips appear on the coating quite quickly. If the material is used for external finishing work, then under the influence of oxygen (oxidation reaction) rust may also appear.

Recommendations for surface treatment

To ensure that rust removal has maximum effect and does not cause harm, it is recommended to use the following expert advice:

When using caustic acids and their solutions, it is necessary to use personal protective equipment, including a respirator.- It is advisable to carry out work outdoors. Or in a room with very good ventilation.

- If there is significant corrosion, it is recommended to clean the metal with a stiff brush before treating with acid.

- After washing off the acid, the metal surface must be dried.

- Several acids should not be mixed together unless specified in the recipe.

Using purchased products to remove rust is more convenient than making your own solutions.

You will find a lot of useful information about rust removal in this section of the site.

Methods for preventing corrosion in industry

In industry, it is extremely important to protect structures and products from corrosion and rust. Constant cleaning of the metal is necessary. On an industrial scale, the acute question is how to remove corrosion from metal, since it is not always economical to use sandblasting or chemical protection methods, therefore, at the stage of manufacturing the structure, the material is treated with special substances - inhibitors.

On an industrial scale, the acute question is how to remove corrosion from metal, since it is not always economical to use sandblasting or chemical protection methods, therefore, at the stage of manufacturing the structure, the material is treated with special substances - inhibitors.

Result of corrosion on metal

Most often, products are used that create a protective film on the surface of the metal. This film prevents aggressive environmental influences and substances from penetrating deep into the metal structure and destroying it.

Inhibitors for cleaning metal from corrosion help to significantly increase the service life of structures and products, thereby reducing the cost of new designs and production stoppages.

Original cleaning solutions

You can get rid of rust not only with potatoes or flour. Sometimes very unexpected products or things are suitable for cleaning. Among them:

- Coca-Cola - this drink contains phosphoric acid, which helps remove rust. The drink must be poured into plastic or glass, then rusty products are immersed in it. You need to take them out after 5-8 hours and wipe them with a toothbrush. The drink is applied to the machine or pipes using a sponge or spray bottle. First you need to wait until the rust softens, then the coating is removed with a brush or foil;

- ketchup or tomato juice - do not rush to throw away ketchup or juice if the expiration date has expired. They can also be used to remove rust. To do this, treat the rusty stains with juice or sauce and leave the item for 20 minutes. Remove the remaining product along with the deposits with a rag, then rinse the surface in warm water;

- hangover cure - another original cleansing remedy is drugs like Alka-Seltzer. To prepare the solution, you need to dissolve 5 tablets of this drug in a jar of water. Place rusty objects into the resulting liquid and remove them after 15 minutes. Brush them with a toothbrush and rinse under running water;

- tooth powder - a mixture based on tooth powder, liquid glycerin and white chalk is perfect for cleaning tools, accessories and metal rivets. Chalk and powder are mixed in equal proportions, then glycerin is added. You should get a creamy paste. Apply it to the rusty areas and leave it there for a day. Its residues and plaque are removed with a toothbrush, then the item is rinsed under the tap and wiped dry with a soft cloth;

- fish oil - this product is well suited for cleaning car parts, fittings or water pipes. Apply it to the entire object in a thick layer and leave for 3=5 hours so that the rust becomes pliable and soft. After which it is removed with a sponge or brush. In addition, fish oil will create a special protective film for the future, which will protect the item from repeated corrosion and increase its service life.

Naturally, this is not a complete list of available means with which you can clean metal objects from rusty areas. If one option doesn't help, you should try another.

Special anti-corrosion agents

You can also often find special anti-corrosion solvents or converters on sale.

Solvents tend to react with plaque and change its structure. After treatment, it can be easily removed with a dry cloth. The most famous solvent is “Rust Neutralizer VSN-1”, which, moreover, is cheap. Its key component is oxalic (orthophosphoric) acid.

And converters not only remove rust, but also form a protective film on the surface, thereby preventing the reappearance of corrosion. They are based on phosphoric acid or tannin. Converters are in the form of emulsions, suspensions or solutions.

Thermal cleaning of steel surfaces

To implement this method, you will need an industrial steam generator or, in extreme cases, a construction hair dryer. In this case, cleaning is based on the fact that the combination of scale of any chemical composition with the base metal is relatively small. Therefore, exposure to temperature, moisture, and changes in air flow speed will help remove surface rust.

The most effective cleaning using this method occurs if the surface to be treated is placed at some distance from the unit and the heated steam supply is turned on. A jet of steam-air mixture supplied under pressure first softens the scale and then crushes it into separate fragments, which are subsequently easily removed by an air stream.

In this way, you can remove rust from the surface of a steel door, ventilation duct, and other metal objects, the dismantling of which is either difficult or completely impossible.

We suggest you read: How to remove glue from rhinestones from clothes?

Processing at home

To clean rust from metal, you do not need to use industrial equipment. You can carry out the work at home. To do this, you need to prepare tools and consumables. We must not forget about compliance with safety regulations.

Tools

To treat metal with orthophosphoric acid, you need to prepare:

- deep stainless steel container;

- roller, wide brush or spray (if there is no suitable utensil to completely immerse the metal part);

- reagent;

- ammonia and medical alcohol, water;

- plastic stick;

- detergent.

Additionally, you may need a metal brush.

Metal brush (Photo: Instagram / hoz.magazin)

Preparation of the solution

Before starting to process a metal part, you need to prepare a working solution:

- Pour 1 liter of water into a metal container.

- Add 150 ml of acid.

- Mix the ingredients with a plastic stick.

You also need to make a composition to wash away the remaining caustic substance. Cooking method:

- Pour 500 ml of water into a glass jar.

- Add 50 ml of medical alcohol, 450 ml of ammonia.

- Mix the ingredients.

After preparing the acid solution, you can begin processing.

Treatment

Cleaning metal from rust:

- Prepare your work surface. Clean off coarse dirt with a metal brush.

- Cover parts of the part that do not need to be treated with plastic wrap. This way they can be protected from the caustic effects of the reagent.

- Degrease the work surface from any grease film using a detergent. Remove any remaining moisture with a dry cloth.

- Cover the prepared part of the workpiece with the cleaning composition using a roller, brush or spray. Leave for 1 hour.

All that remains is to wash off any remaining rust, dirt, or acid using a cleaning solution.

It is important to remember that it is impossible to remove a thick layer of rust with a chemical reagent. To do this you need to use a grinder with a grinding disc or a grinder.

Processing results (Photo: Instagram / sk.elvis)

Safety precautions

Safety regulations:

- Work must be carried out in protective equipment. It is necessary to wear a respirator, rubber gloves, long sleeves, and safety glasses.

- The room should be well ventilated.

- Flammable substances, heating equipment, and open flame sources should be removed from the workbench.

- After working with some powder reagents, you need to brush your teeth and rinse your mouth.

- After using chemicals, wash your hands thoroughly.