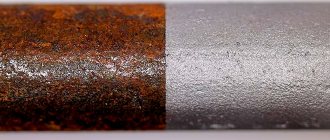

Every man should have such things as a grinder and a drill in his assortment of tools. A grinder can clean metal from old paint and corrosion. In everyday life, a drill can greatly facilitate repair work if you need to stir any mixture or tighten screws.

But each of these tools has a common goal - cleaning the surface from rust and corrosion. For this, metal brushes are used. You can find photos of metal brushes on the Internet so you don’t make a mistake in choosing. In this article we will look at the types of brushes.

Brushes for drills and grinders

Tools such as drills and grinders can clean any surface from rust and corrosion. Let's look at the main types of brushes.

Preparing body parts

When removing rust, you first need to properly treat the affected parts of the body. This process plays an important role in removing rust, since the further result will depend on it.

Algorithm of actions:

- First, you will need to remove parts of the car body so that removing rust from the car is faster and does not cause inconvenience. Only those parts that are affected by body corrosion should be removed;

- Then the removed parts are firmly fixed on the work stand. Failure to follow this advice is fraught with consequences, such as accidental damage to the part;

- The outer surface must be sanded very carefully using an additional tool.

The main thing is to carefully remove the paint that covered parts of the vehicle. It is not necessary to remove the entire painted area; you can get by with a small area near which there are traces of rust. It is important that there is at least 5 cm to the “epicenter”.

These points will save time and money. But to carry out all the above steps, you need to use a special tool.

Cup brush

The brush is capable of cleaning the surface from traces of concrete and corrosion. This kind of metal brush for grinders and drills is often used for processing flat steel products.

If you need to treat a wooden surface, you should use a nylon brush.

Criterias of choice

You can choose the most suitable brush based on the following criteria.

Manufacturer

The quality of the nozzle is identified with the manufacturer. Products made by well-known brands inspire confidence. These include brands:

- STAYER;

- Bosch;

- GROSSSMEISTER;

- Lessmann;

- SKRAB;

- Matrix;

- Anchor;

- Bison

What are there

Metal brushes for angle grinders come in different types.

Cord brush

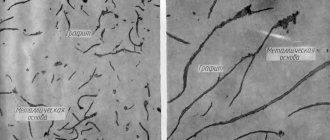

The equipment is characterized by high rigidity and hardness. Therefore, it is not used for processing wood and soft metal alloys. The main purpose is brushing. This is where the tool got its name – a cord brush.

For wood and soft metals, a hard attachment is not suitable due to damage to the structure of the processed materials and loss of aesthetic qualities of the surface.

Petal disc

The nozzle is available in different diameters. The range is 15-500 mm. Grit values are also available to choose from - 40-2500. For the manufacture of equipment, zirconium and electrocorundum are used.

This type is used for processing flat and curved surfaces with a complex structure.

Abrasive cup

The nozzle got its name because of its similarity to a tableware. Its shape is cylindrical. The abrasive is produced in diameters of 100-180 mm. One of the popular models is the 125 mm cup.

Grinding abrasive disc

The design consists of a metal base onto which circles of different grain sizes are fixed. They can be replaced quickly. Circles are consumables. The base of the nozzle does not wear out.

To treat the surface, a type of grinding agent is also used - a grinding brush wheel. It comes in different diameters, grits and heights. Selected taking into account the type of work and type of material.

Type

When choosing a brush for processing a part, you need to consider the type of surface. Is it smooth, or has grooves, corners, internal edges, or hard-to-reach recesses? Based on the characteristics of the workpiece, a suitable nozzle shape is selected.

| Nozzle type | Peculiarity | Purpose |

| Disk | The basis of the design is the disk. Wire flagella are fixed along its edges. | Processing surfaces with corners, grooves, parts with joints. |

| Cup | The base is made in the form of a cup. Its edges are equipped with bristles made of straight/twisted wire. | Removing scale, removing old paint from a large surface area. |

| Conical | The base design resembles a slightly concave disk. The edges are framed with twisted wire. | Processing of parts with plane differences, radius changes, and notches. |

| Radial | The base is almost the same as the disk attachment. Features wire bristles. It is made of a thin flat/twisted shape with dense padding around the circumference. | Cleaning steel parts from scale, rust and other sludge. |

Brush material

The wire acts as an abrasive. To give the nozzle different rigidity, different materials are used:

- brass;

- nylon;

- stainless steel.

The first and third options are suitable for processing metal, concrete, brick, etc. Nylon is chosen for sanding wooden and plastic blanks and applying patterns to wood.

Using wire

The bristles differ not only in the type of material, but also in the shape.

- Harness - is a twisted bundle of metal fibers. This attachment is used primarily for rough work.

- Corrugated - reduces vibration of the angle grinder due to its springy properties.

- Twisted is another type of twist that provides high rigidity.

- Smooth is a standard product for processing wood, metal, and steel.

Using equipment as intended extends the service life of consumables.

Purpose

Angle grinder attachments can be used for processing workpieces and products made from the following materials:

- metal;

- tree;

- concrete;

- tile;

- brick.

Diameter

The indicator is measured in millimeters. In stores there are models with a diameter of 115-200 mm. To perform non-standard work, equipment from 5 to 900 mm is used.

The smaller the diameter, the lower the load on the power tool motor.

Landing diameter

This parameter determines the size of the hole in the nozzle. It corresponds to the diameter of the grinder spindle on which the equipment is installed. Options for metal brush diameters:

- 22 mm;

- 22.2 mm;

- M

Disc thickness

The unit of measurement for the indicator is millimeters. Discs are available in thicknesses of 1.7-55 mm.

Diamond layer thickness

The diamond layer is applied to a nozzle with a thickness of 2.4-6 mm.

Grain

Abrasive consumables have varying degrees of hardness. On the nozzle, the grain size indicator is indicated by the symbol P. For metal brushes, the following values are used: 40; 60;80. These are coarse grain options. The lower the number, the smaller the grain.

Amount in a package

The nozzles are sold in packaging. The quantity varies from 1 to 230 pcs.

Disc brush

If you need to clean a large area of the surface, then use a disc brush. It has high rigidity and strength, so you can use it for a long time.

The brush for stripping metal is manufactured using the latest technologies. This brush is usually called a brush brush and is used in industry.

Safety precautions when working

Using accessories for an angle grinder requires compliance with safety measures.

- It is prohibited to use accessories for angle grinders with inappropriate technical parameters.

- When processing any surface, small solid particles fly off. They can damage the eyes, skin, and respiratory system. At high speeds, the brush itself may fly apart. To avoid a traumatic situation, it is recommended to wear personal protective equipment before connecting the power tool. These are: glasses, a respirator, gloves, workwear made of thick fabric.

- Contact of the brush with metal at high speed is accompanied by a loud sound. Construction headphones or earplugs will help to avoid irritability and strain on the hearing organs.

- Before installing the attachment on the grinder, you need to inspect it for damage and defects. If they are present, they must be replaced.

The importance of safety lies in taking care not only of your health, but also of those around you.

Corbrush

Brushes are used to clean parts from rust and flux deposits. Also, if it is necessary to give the product a marketable appearance, this type of brush is used.

In industry, a good and correct brush is used in the production of aluminum radiators for various brands of cars.

Cleaning up minor defects

To remove small defects on the paintwork, an eccentric rotary-vibrating machine with an eccentric stroke of 5-8 mm, a rigid plate (for example, with a diameter of 115 mm) and grinding wheels of P80 and P150 gradation are suitable (the first are used in the main defect area, the second - in peripheral areas ). Operating speed - up to 10,000 rpm.

Examples include a Rodcraft 7665 two-handed pneumatic machine or an electric Festool WTS 150/7, a Sia 7-hole sanding pad and siadrive siafast sanding paper (see table at the end of the article).

Professional eccentric sander Festool WTS 150/7 (eccentric stroke 7 mm)

Special SCM circles also cope effectively with this task. And not only when removing standard layers of paintwork with minor defects, but also when removing thick layers of repair coatings.

Types of hardness

The work performed depends on the pile. The following wires are distinguished:

- Corrugated. This brush reduces machine vibration and applies gentle pressure to the surface. This happens due to the fact that the brush has springing properties;

- Twisted. The bristles curl and give a harsh action on the plane. The brush has great strength;

- Smooth. The brush quickly loses its shape and over time is unable to do its job.

All brushes differ in their cup diameter.

Main characteristics of brushes

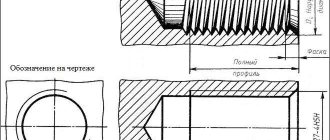

The base of the brush is a circle with a hole in the center (diameter 22.2 mm). Outwardly, it resembles a cutting disc. The equipment is installed on the angle grinder in the same way. To do this, the attachment is put on the spindle of the angle grinder, and then tightened with a lock nut.

Brushes are produced in different diameters (from 115 to 200 mm). The degree of stiffness of the bristles depends on the thickness of the wire. The nozzle option is selected taking into account these parameters so as not to damage the appearance of the working surface.

Tooling with fine wire is suitable for processing workpieces of complex shapes or soft structures. It is advisable to use thick bristles for cleaning weld seams or burrs.

The stiffness of the brush head also depends on the type of material used to make the brush and the shape of the bristles. Each variety is designed to perform specific jobs.

When choosing a nozzle you need to consider:

- cup diameter;

- spindle rotation speed;

- number of rows of bristles on the base;

- pile material.

Angle grinding attachment for angle grinders

This multifunctional adapter turns your grinder into a mini grinder. Its presence allows you to process various wooden, metal, and ceramic parts. It is indispensable if you need to sharpen a tool - a knife, chisel, scissors.

The gadget is designed to connect to a machine with a disc standard - 100mm, 115mm, 125mm. For its operation, you need a sanding belt, specially glued sandpaper, with a width of 30mm.

An angle grinder will be useful in any private household. It is small and can be installed permanently, connecting to an angle grinder if necessary.