There are a large number of synthetic products or folk methods to clean the soldering iron tip. The effectiveness of cleaning depends on which tip is used to solder various surfaces. A distinction is also made between ordinary carbon deposits and chemical oxides. The latter are much more difficult to clean completely. If the soldering is copper, then you can experiment with cleaning. For other alloys (so-called eternal tips), any mechanical stress can lead to damage. You can simply remove the top layer of the alloy; it will no longer be possible to use such a sting.

Electric soldering iron device.

What is the operation of joining heated parts with a molten alloy called?

Soldering is a permanent connection

materials heated below their melting temperature by wetting and filling the gap between them

with molten

solder. ... I use soldering in mechanical engineering, electrical industry and instrument making.

Interesting materials:

What should a designer know and be able to do? What every interior designer should know? What every designer should know? What should be on the festive table on a birthday? What should be on the holiday table? What should be on the table in 2022? What should be on the table on New Year's Eve in the year of the Ox? What should every housewife have in her kitchen? What should be in a fish aquarium? What should be in a dorm room?

Why clean

Regardless of the type and shape of the tool, before starting work, you must clean the soldering iron tip. Over time, deposits accumulate on the working end of the tool, formed during the thermal decomposition of solder and flux. The process is aggravated by the mutual penetration of tin and copper and their thermal diffusion.

A contaminated surface of the tip does not allow soldering to be carried out correctly.

The accumulated combustion products of consumables, which form especially quickly when the soldering iron is left idle in a hot state, interfere with subsequent work. There will be substances in the working area that prevent good adhesion and uniform distribution over the surface. Thorough cleaning avoids problems.

The procedure must also be performed with new soldering irons, because manufacturers, for the purpose of protection, cover the tip with a thin layer of oxides, which is called patina.

A smaller amount of carbon deposits is formed when working with a soldering station that has heating control.

Soldering irons with stainless steel tips do not form deposits at all, but working with them is not familiar or convenient for everyone. It is necessary to choose the right power so that the low thermal conductivity of the tip allows for good soldering.

Tags: soldering

Comments 40

Nowadays, in addition to hair dryers, IR heaters are also common) And hair dryers generally rule)

and there is a way to mount chip parts on a board without a soldering iron or a hair dryer, in a furnace, for example, I experimented and soldered LED rings with 20 or more diodes with 6 legs using a lamp that illuminates display cases, by just plugging this same lamp into a socket and voila factory soldering in 5 minutes and without overheating the LEDs,

I think it’s better to have a soldering iron separate from the hair dryer, I have a KADA 858D station, 550 watts, it’s not economical at all, the soldering iron doesn’t work separately, but the hair dryer can be turned on separately,

I have 3 soldering irons on my desk: - a regular EPSN-40 with a ceramic heater - for massive things; - soldering iron with tip T-2.4D - the most efficient; — turns on as needed with the required tip (several thin cone-needles for small things, “dirty” for working with plastic). Soldering irons 2 and 3 - with stations 852D and 702D. on the first (compressor) the nozzle is thin, the second (fan) is open. I often work second, because with a large heating area, there is less board deformation. There is a bottom heating aoyue 853, I solder boards only on it. even if you need to correct the connector with a soldering iron or transfer the electrolyte to the motherboard, still use 120-150 degrees to heat it up for a few minutes, then solder. All air soldering irons have a calibrated temperature indicator; for each soldering I set the required temperature. flux - EFD FluxPlus in a syringe with a thin nozzle. sometimes for better tinning - active LTI-120 (if I remember correctly what was on the sticker that came off long ago :)). I clean the tip with a scalpel (without fanaticism) and a yellow sponge from the soldering iron kit. If the tip burns out, you can slightly correct it with a needle file. When it burns out badly, I replace it with a new one (now it’s easier to buy a dozen of them on Aliexpress).

Materials used to cover the tip and their features

Before you start looking at how to clean a soldering iron tip, you should say a few words about what they are made of. The main materials used are:

- Copper. Traditional material with good conductivity. The first soldering iron tips were made from copper. This metal is found both in their core and along the edges. It is still widely used today. A negative property of copper tips is their high wear. This material burns out relatively quickly and can dissolve in solder.

- Nickel. The addition of this metal is used to impart increased strength to finished products. It is resistant to chemical attack, so nickel-plated tips can be used for a long time. But they also have a drawback - a low adhesion rate. Because of this, the nickel tip does not hold solder well. And the soldering itself has to be carried out by supplying the consumables to the processing site, which has been preheated using a tip.

- Silver. The adhesion of this material is beyond praise. But such a coating has low thermal conductivity. Additionally, silver is highly valuable and can be dissolved in solder. Very quickly the coating comes off and exposes the copper base.

- Ceramics. Durable and non-corrosion option. But in terms of heat capacity, a ceramic soldering iron is significantly inferior to a similar copper product.

- Brass. The product is wear-resistant, does not burn, has good thermal conductivity and is little susceptible to oxidation. But it is characterized by reduced resistance to mechanical damage.

For each option, the answer to the question of how to clean a soldering iron will be different. The differences will not always be strong, but they still cannot be ignored.

Which sponge is best for cleaning?

When choosing, you should decide what the product will be used for. There are many types of contamination, which depend on the composition of the solder, the materials being soldered, and other things. Accordingly, pollution control methods will also differ. There cannot be a single correct solution here, but you can choose the most universal scheme.

"Note!

For dry cleaning, you should choose only copper metal sponges with a holder.”

This applies mainly to professionals, since for those who solder once a month, such things will not pay off. If you want to maintain the soldering iron tip in satisfactory condition, then only this option, regardless of the manufacturer, will be the most effective.

If you need to additionally remove oxides, then after dry cleaning you should use a viscose sponge moistened with an appropriate solution. There are many options for how to saturate a soldering iron sponge, and it all depends on the type of contamination. The main principle of choice is that the material of the product should be as wear-resistant as possible and absorb moisture well.

How to use a sponge correctly?

There are several rules for using a soldering iron sponge. Indeed, in some cases, dry cleaning of metal copper models is prohibited when it comes to ceramic tips. This is due to the fact that these types of sponges can damage the top layer of the surface, removing it along with dirt. In this case, a delicate approach with a soft, non-metallic model will be required.

Special products for copper tips

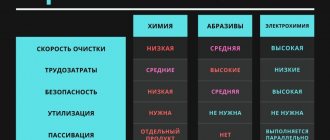

To remove carbon deposits, the industry produces a variety of products; extensive practical experience has been accumulated, which is used in modern tip preparation technologies. Approaches to cleaning differ, although, in principle, they come down to two main options for influencing fumes: mechanical and chemical.

Mechanical types of cleaning

Depending on the type of work to be done, you can choose one or another abrasive material. If there is a need to make the tip strictly even and flat, you should take a file. In other cases you can use:

- sandpaper;

- sharpening stones;

- abrasive sponges.

To remove the patina from a new soldering iron, use fine-grit sandpaper. This will be enough to remove a thin production layer. After mechanical cleaning is completed, the tip is treated with rosin or other suitable resin. The rosin composition does a good job of removing plaque consisting of oxides and other impurities.

If desired and possible, you can buy a ready-made device wts-599b. This metal sponge in a special housing is very convenient to use.

Chemical methods

There are possibilities for cleaning the tip with chemical means.

You need to choose flux cleaners carefully, after first familiarizing yourself with the metal composition of the tip. To clean the copper working surfaces of the soldering iron, you can use oxide. Its composition is dominated by ammonium chloride. The sting is heated, placed in a chemical agent and cleansing is observed, which occurs very quickly.

At the end of the procedure, wipe the heater on a sponge or cloth, which should be pre-moistened with water.

Instead of oxide, many craftsmen use a powder with similar properties called ammonia. This is the same ammonium chloride, which removes oxide products well. When heated, it produces caustic gases such as ammonia and hydrogen chloride.

Cleaning the tip with chemicals must be done with good ventilation because caustic fumes of acid and ammonia are released.

The flux-off flux cleaner gives very good results. It is sold in aerosol form and easily removes dense decomposition products of consumables. Any flux layers and remnants of tin-lead solder quickly dissolve. The aerosol must not come into contact with plastics. Other material, for example, a ceramic fixative, will not be damaged by hydrocarbons or esters.

To improve the condition of a contaminated sting, you can buy paste-like activators from the goot series. The function of the active reagent in them is performed by ammonium phosphate mixed with tin powder. The head heated to 300 ℃ must be immersed in the paste and rotated in it. Usually, one dose is enough. If necessary, the procedure can be repeated.

Traditional methods

Inventive craftsmen and amateurs find a way out of the situation in cases where there are no special means nearby. You can take ordinary food grade citric acid, stored in any kitchen, and dip the heated tip into it. The result will not be long in coming - the cleaning is quick and successful.

Some craftsmen try soda, alcohol, aspirin, pharmaceutical glycerin, and other home remedies. The impressions accumulated were different. There are many compounds with a known effect, so it makes no sense to enthusiastically compete in ingenuity.