How to remove rust using electrochemistry

The use of special chemicals allows you to eliminate corrosion without much harm.

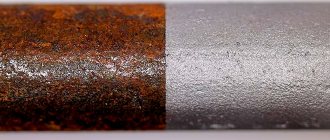

Rust can be removed in different ways:

- The simplest is mechanical, using a special drill attachment, sandpaper, grinder or file. This method is only suitable for flat and smooth surfaces, since carvings or shaped castings can easily be scratched when removing the top layer.

- Chemical method using “folk” recipes: citric or hydrochloric acids, apple cider vinegar, Coca-Cola (which contains phosphoric acid). But it is more effective and safe to use special pastes. Under the influence of acid, iron oxides dissolve and turn into salts. However, acids also negatively affect the iron itself, destroying it, and therefore it is important to observe the specified time and thoroughly rinse the parts and dry them.

- Electrochemical method or electrolysis. The principle of its operation is to pass a weak current through a solution of soda ash, which causes an electrolytic reaction and removal of the affected layer. Iron oxide ions pass from rust into solution and onto a clean electrode - in other words, one chemical element is restored due to the splitting of another upon their contact, the electrolyte acts against rust.

Important! Electrolysis is used in industry and at home.

Is the method effective?

Electrolysis really helps with rust. It is a mixture of iron oxides and hydroxides, which are formed when the metal comes into contact with water and oxygen.

Electrolysis is a chemical reaction that reduces iron from its oxide to its metallic form. Wherever the electrolyte penetrates, the process of rust decomposition begins.

Without delving into complex chemical processes, we can say that the method allows you to reverse the oxidative reaction and restore previously damaged areas .

Correctly, this method of fighting rust is not called electrolysis, but the electrogalvanic method. It is used not only in everyday life, for personal needs, but also for a more serious purpose, for example, in the restoration of archaeological finds.

Advantages and disadvantages

The electrochemical method is effective and simple, it can be used at home.

The advantages of the electrolysis method include:

- Safety for the part: the surface of the item will not be scratched by mechanical brushes and will not be damaged when exposed to chemicals;

- Efficiency: this method removes even long-term and multi-layered rust;

- Cheap: despite the apparent complexity, the things necessary for the procedure are inexpensive (for example, you can use any plastic container, draw water from a tap);

- No effort: just connect the wires, turn on the current and check the part regularly. There is no need to make efforts and clean off corrosion with your hands;

- You can clean items from any brand, without restrictions.

An important drawback is the process itself: since you will have to work with electricity and active chemicals, you must follow safety precautions and be extremely careful during the process.

The essence of the electrochemical method of steel processing

One of the types of processing of seams after welding on non-ferrous metals is the electrochemical method of etching and passivation. This procedure involves exposing the heat-affected zone to electric current and specially developed electrolytes for cleaning, etching, passivation and polishing. When removing tarnish from steel seams, we in no way spoil the surface of the metal itself, this means that if you use “mirror” (polished) steel, then after processing you will not see dull, dull spots in the heat-affected area that may remain when using nitrogen-containing etching pastes. Also, nothing happens to both matte and polished surfaces. Moreover, after processing steel using this technology, the alloying (passive) layer is completely restored, which during further operation protects the steel surface from corrosion. presents to you our own, first in Russia and the CIS, unique equipment for electrochemical processing of steel - weld cleaning installations Steelguard 685 and SteelGuard 425. We also offer to purchase European-made installations from the Nitty-Gritty company.

What you need to remove rust

You can even use a cut plastic bottle for electrolysis.

How to remove rust with electrolyte? To do this you will need to prepare several items:

- Plastic or rubber container;

- A power source with a voltage of 12-24 V, for example, a computer power supply or a car battery is suitable;

- Wires with stripped ends or terminals;

- A substance that will act as an electrolyte. Any powder that contains sodium will do: baking soda or soda ash, salt, sodium hydroxide;

- Positive anode electrode: a piece of stainless steel or galvanized will do. It is recommended to use soda, as it is the most effective and at the same time safe;

- Water.

Important! Any dielectric container will do.

Cleaning procedure

To carry out cleaning you will need soda.

The cleaning procedure is not difficult:

- You need to pour water into a container and dissolve soda in it in the proportion of 1 tbsp. spoon of soda per 1 liter of water;

- Clean a small area from the rusty part using sandpaper and connect the negative wire or terminal to it;

- Lower the part into the water so that the part with the connected wire does not go under water;

- Connect the positive wire or terminal to the stainless steel;

- Turn on the current.

After applying current, the reaction will begin. This can be determined by the active release of air bubbles into the water. If there are few bubbles, it means the reaction is weak and it will take a long time to remove corrosion. You can speed up the process by adding more soda.

Important! To speed up the procedure, you can remove the paint and the top loose layer of rust from the rusty part in advance.

The procedure takes place individually – from a few minutes to 10 hours. At times it is necessary to turn off the electricity, remove the part from the water and wash it. When washed, rust flakes will fly off. If the part is clean, it needs to be dried; if not, you can put it back and continue.

Electrolysis cleaning.

We all worry about how to clean iron. And we all do it in our own way. For example, I settled on electrolysis and I think that there is simply no better way. I am sharing with you my method for cleaning iron. Maybe it will be useful to someone. Making a cleaning device takes just a few minutes and is very affordable! I bought myself a universal power supply. I attached two wires to one of the adapters, inserted one inside and, to ensure reliable contact and fall out, inserted a simple match there. I simply wound a wire around the external contact and insulated it. It would be ideal, of course, to solder it, but I’m afraid that the plastic that insulates + and – might melt inside. I put crocodiles on the ends of the wires, it’s up to you to decide which ones you like. The result is a ready-to-use device. Next I give an example of cleaning that I found on the Internet. Of course, I could write it myself, but I’m afraid I won’t be able to write it more clearly than here. How to use it? Elementary! One of the simplest and most accessible methods in a home workshop is described below.

What are the advantages of this method? The advantage over mechanical methods is one, but important! This method does not affect living metal. When you clean with wire brushes, abrasives or acids, some metal is inevitably lost

The electrolytic method removes only rust. What about rusty bolts and studs? Sometimes the method helps in these cases. Wherever the electrolyte penetrates, the process of rust decomposition begins. It is safe? Absolutely! The solution is not toxic (although you should not drink it), the voltages are low, and no toxic or flammable gases are released. The process is self-stopping; overexposure of the workpiece does not pose any danger. What do you need to get started? Plastic bucket, stainless steel or steel electrode (plate), water, washing (soda ash). A teaspoon of soda dissolves in 3 liters of water. How long can the solution be used? A teaspoon for 3 liters? It's easier to pour it out and make a new one. But if you really need it, just add water to 3 liters and continue. What can you say about the electrode? Ideally, the electrode should completely surround the object being cleaned, then the process is very active. It all depends on your capacity. A flat plate will also work. The steel electrode will become thinner over time and will have to be replaced with a new one. A stainless steel electrode lasts much longer. How to connect the charger? Polarity is critical. The electrode must be connected to the positive conductor, indicated by the + symbol. The object being cleaned is a minus. Try to ensure the best possible contact with the object being cleaned. How will I understand that everything worked? Place the electrode in the vessel with the solution. Position the part to be cleaned so that it does not touch or touch the electrode. Turn on the power. If there is an ammeter on the charger, you will see that current is flowing through the system. After some time, bubbles will appear from the surface of the workpiece. How long does the process take? The time depends on the size of the part, the size of the electrode and the amount of corrosion. Remove the part from the solution and inspect it. I take a metal brush and clean the surface under running water. If you are not cleared, continue. Typically, the cleaning process for medium-rusty parts takes 5-6 hours. Very rusty parts can be left overnight. What then to do with the cleaned part? Rinse under running water. Dry the part with a heat gun or place it in the sun. Cover with a thin layer of lubricant. The part is very healthy, can it be cleaned in parts? Yes. What does the part look like after processing? The surface that was corroded will be black; the pitting will not disappear. Pure metal will remain pure. What to do with electrolyte after work? Pour it down the drain. This is not dangerous. Can I use metal containers? Dangerous. Either it will shorten or holes will appear. Better than plastic. What containers can be used? Any you find. Long pieces of iron can be put into a plastic pipe, wide and flat ones - into a trough (but put a film on the bottom so that there is no short circuit. Good luck

Safety precautions

During cleaning, pieces of rust will fly off the metal.

When using electrolysis, safety precautions must be observed:

- Carry out the procedure in a well-ventilated area, preferably outside;

- It is important to ensure that the entire apparatus is grounded: the utensils must be rubber or plastic, and your hands must be wearing thick rubber gloves;

- The wires should not have random contacts, so as not to disrupt the connection; it is also important not to mix up the terminals;

- If a rusty object has any value, it is better not to use the electrochemical method for cleaning; you should stop at cleaning with a chemical agent, since there is a high probability of not keeping track and ruining it.

Also, we must not forget about safety precautions when working with electricity.

Important! Ready-made Zinkor-Auto rust removal kits are sold, which contain everything necessary to carry out a reaction for 1 square meter. meter of rusty surface.

Neutralization

Neutralization is a necessary stage of the work, since it cancels the effect of the agent that was used to pickle the welds

It is important to neutralize this effect to avoid the possible appearance of efflorescence (salt deposits). This procedure is performed using a unique Inox Fit product, which was developed by Nitty-Gritty

It is applied directly after pickling and polishing of welds, affecting the entire treated surface, while guaranteeing a perfect surface cleanliness. This was made possible due to the higher surface tension compared to water.

Common mistakes and how to avoid them

The best way to avoid mistakes is to strictly follow the instructions and do not forget about protection.

The diagram will help you better understand the procedure for cleansing.

Common mistakes include:

- Incorrectly secured terminals. It is extremely important to connect the wires correctly (positive - to the stainless steel, negative - to the part), it is better to double-check this before turning on the current;

- Using salt instead of soda. Nothing bad will happen, but many note that with salt the reaction is less active and cleanses worse;

- Using too little or too much current. In the first case, the reaction will be weak and of little use; in the second, the current source may fail and “burn out”;

- Too long exposure. In the worst case, the part will turn black and cannot be washed off. Since the exposure time cannot be determined even approximately, it is worth checking how the process is going often. Even seemingly identical parts can behave differently.

Removing rust using the electrochemical method is the safest and most effective. The essence of electrochemistry is to pass a weak current through a solution of soda, causing an electrolytic reaction to occur. Cleaning can be done in this way at home, subject to safety precautions.