Today, sheet metal is used to make products in various industries. Sheet metal is not always in perfect, ready-to-use condition; it may have burrs, stains, rust and other defects that must be eliminated before using the products. Removal of burrs and other imperfections using automated equipment or hand tools. Automatic devices are becoming increasingly popular and are produced in various configurations, taking into account their specifics. This article will help you understand the work process and choose the most appropriate equipment or tool.

With so much choice, it's obvious to think about how to choose the most suitable sheet metal stripping equipment. However, answering such questions can be difficult unless there is an understanding of the type of surface defects and the available sheet metal cleaning techniques.

Methods for removing rust from metal products

There are three ways to clean rust from metal:

- Processing using hand tools.

- Mechanical cleaning.

- Treatment with abrasive substances.

Processing with hand tools

The essence of the method is that the tools used do not require power. Manual cleaning is usually used as a preparatory step before the main surface treatment. It can be used to easily remove rust from metal.

The main tools for such cleaning are wire brushes, chipping hammers, spatulas, coarse sandpaper, abrasive cloths, scrapers, etc.

Hammers are good at chipping away the products of corrosion processes; this helps other processing methods to clean the internal layers of metal structures faster and deeper.

Mechanical restoration

In this type of corrosion removal, mechanical installations and equipment are used, but they are simpler than sandblasting (abrasive blasting).

For mechanical cleaning, the same sandpapers, scrapers, sandpaper, etc. are used. as for manual cleaning, however, they are improved by an electric mechanism that speeds up the work process due to rotating elements. Vivid examples of such devices are: grinding wheels, pneumatic and electric driven hammers, abrasive grinding stones and more.

Mechanical cleaning is not always effective in places where equipment is difficult to access, so some areas are treated manually.

Mechanical cleaning from corrosion

Sandblasting

Cleaning metal surfaces with abrasives is the most effective cleaning method. The essence of the method is that pressure is created in a special installation, abrasive particles are mixed with air in a special compartment, and then supplied through a hose (nozzle) to the surface to be cleaned. Solid abrasive particles hit the top of the product, thereby chipping off dirt and affected areas.

Sandblasting metal

There are several types of such installations:

- Sandblasting rust from metal surfaces using compressed air - everything is simple here: abrasive particles are mixed with air and discharged through nozzles.

- Sandblasting with moisture injection - the principle of operation is the same as when using compressed air, the difference is that a little liquid (for example, water) is added to the abrasive. In this case, too much dust does not form around the treatment area.

- Cleaning using pressurized liquid. In this case, the main thing is liquid (usually plain water), abrasive particles are added to it, and water under pressure with abrasive is sprayed onto the area that needs cleaning. With this method, it is easy to control the pressure and supply of liquid, and it also penetrates deeply and cleans the material.

Sandblasting degreases the surface well, which does not require additional use of degreasers.

Cryo-purification

Cryo-cleaning, or dry ice blasting, essentially uses the same principle as sandblasting: ejecting material with a directed air flow. Dry ice, being frozen with carbon dioxide, does not heat the surface upon contact with the material, so it can be used in areas where the risk of fire or explosion is increased.

Cryo-cleaning is more gentle than sandblasting, since it damages the surface less and, in addition, no static electricity is released during the processing, so this method is safe when processing complex equipment, such as turbines.

Since, unlike sandblasting, the cryo-cleaning process uses low-temperature material, the equipment must have specific characteristics, which are offset by the increased cost of the devices, as well as the need to monitor the availability of dry ice as a consumable.

Cryo-cleaning, for example, is used in cleaning the car body before painting, the food industry, woodworking and paper production.

Chemical methods for removing rust

Each of the above methods has its own advantages and disadvantages. But the modern world has made it possible to obtain special compounds that answer the question of how to easily remove corrosion from metal. They fight destructive reactions in any, even the most inaccessible places, do not require bulky installations and electrical equipment, and also do not require the application of serious physical force.

Chemical corrosion removers, when applied to the surface to be cleaned, penetrate into rusty areas and destroy them from the inside. After destruction, it is only necessary to remove the remnants of the past reaction.

Chemicals do not always cope perfectly with rust the first time; sometimes re-application is required.

Before we consider special compositions for cleaning metal surfaces, we will reproduce the procedure for this cleaning method:

- If sandblasting units clean the material and degreasing occurs during this process itself, then during chemical treatment, first of all, it is necessary to degrease the surface yourself using special compounds.

- Next, the selected substance is applied directly

When applying, it is important to observe safety precautions, since this kind of substance is very aggressive and can harm human health. It is necessary to apply the product while wearing gloves.

- For the effect to appear, it is necessary to let the product “work” for a certain time (this time is different for each solution), usually about 20 minutes. During this time, the rust and the solvent react and, as a result, when the rust disintegrates, it becomes gray in color (the so-called orthophosphate is formed).

- Next, it is necessary to clean the material from reaction products. This is done with a lot of water.

Chemical corrosion treatment

Preparing metal for welding after thermal cutting

As mentioned above, after thermal cutting of parts, it is necessary to remove a layer of 2-3 mm before using the workpieces for welding. Control of the depth of the removed layer is mandatory. Clean the edges to a metallic shine.

Using gas cutting, you cannot cut edges on metal with a thickness of less than 5-6 mm. Gas and plasma cutting of sheets of small thickness and greater length causes warping of the part. Therefore, for such cases, edge cutting can be done using scissor cutting followed by processing.

Preparation of the edges of sheet structures can be carried out using a portable edge processing tool.

Methods for preventing corrosion in industry

In industry, it is extremely important to protect structures and products from corrosion and rust. Constant cleaning of the metal is necessary.

On an industrial scale, the acute question is how to remove corrosion from metal, since it is not always economical to use sandblasting or chemical protection methods, therefore, at the stage of manufacturing the structure, the material is treated with special substances - inhibitors.

Result of corrosion on metal

Most often, products are used that create a protective film on the surface of the metal. This film prevents aggressive environmental influences and substances from penetrating deep into the metal structure and destroying it.

Inhibitors for cleaning metal from corrosion help to significantly increase the service life of structures and products, thereby reducing the cost of new designs and production stoppages.

It is important that the inhibitors are non-toxic substances. Since the contents of metal containers and structures, as well as the person who is constantly nearby, may suffer.

Flame cleaning

This type of cleaning is carried out using burners, as well as acetylene or

propane with oxygen. Flame cleaning can remove almost all mill scale, but not all rust, so this method is not recommended for use where coating requirements are quite high. Flame cleaning is used for metal products whose thickness is at least 6 mm. After the cleaning process is completed, the surface is processed using mechanized brushes and then removed from dust.

How and with what to remove rust from metal - affordable methods

Let's look at the main chemicals that can fight rust.

Rust converters

The converter turns this substance into a red-colored coating. For such a reaction, a spray bottle is needed; a 30% aqueous solution of phosphoric acid is mixed in it and sprayed onto the damaged area. After this, the substance is allowed to dry.

There are several types of converters to eliminate corrosion, but in each of them, the main substance is phosphoric acid.

A solution of hydrochloric acid and inhibitor or sulfuric acid and inhibitor

Hydrochloric and sulfuric solutions are very strong acids that destroy even the metal itself, so to combat rust they are used only in combination with inhibitors. The inhibitor is usually methenamine.

Composition: 5% solution of hydrochloric (sulfuric) acid and 0.5 grams of hexamine per liter.

On large-sized structures, this product is usually applied with a brush, and small parts can be dipped into the solution itself.

Other acids

A mixture of petroleum jelly (you can use liquid paraffin) and lactic acid works well against corrosion. The acid turns the rust into salt, and the salt dissolves in the paraffin.

Treatment with acids

Another proven remedy is a solution of zinc chloride and cream of tartar dissolved in water. Zinc chloride creates an environment with high acidity and reaction products dissolve easily in it.

How to remove rust from metal at home

Rust and other persistent contaminants exist not only within the walls of industrial enterprises or on special structures, but also at home, and the question arises: how to remove corrosion. To clean metal from corrosion at home, they use products that are not too aggressive, but effective.

Lemon juice and vinegar

These two substances are mixed in equal proportions and applied to the damaged area. For the rust to go away, you need to leave the solution for several hours. After the solution is sufficiently absorbed, it is necessary to rub the surface with a brush and clean with water.

Baking soda

Mix soda with water to create a sour cream consistency, apply to the affected area, and leave for an hour. Then clean it with a brush or metal scraper.

Oxalic acid

When using oxalic acid, you must use gloves and a respirator.

Before application, it is necessary to prepare the surface: it is cleaned with a regular detergent. Next, a small amount of acid is mixed with water and applied to the item that requires cleaning. After 30 minutes, rub the desired area with a brush and wash off the residue with water.

Lime and salt

This set will be useful not only for a feast, but it can also get rid of red spots. You just need to sprinkle the damaged area and pour lime juice on top (squeeze). After the product has stood for several hours, you can rinse it with water and enjoy the cleaned surface.

Potato

Using regular potatoes, you can get rid of minor rust stains. To do this, sprinkle the affected area with salt, peel the potatoes and cut them into two parts, then rub the area with salt until the rust disappears.

Original anti-corrosion products

Today there are substances that are firmly established in human everyday life and can be used every day, but even they, in the right dosages, can help get rid of rust if you want to experiment.

Coca Cola

This drink, beloved by many, eats away rust in a few hours (depending on the degree of damage).

Removing Corrosion with Coca-Cola

It's simple: either dip the desired item into a bath of cola, or apply it to the surface using a sponge. Wait a few hours and wash off with water.

The main secret of cola is phosphoric acid. In principle, you can use any drink containing this substance.

Tomato sauces

How to remove metal corrosion in this way? Take spoiled or fresh ketchup (both will work) or tomato paste, apply the product to the surface that needs to be cleaned of rust and leave for half an hour or more, depending on the degree of damage. After this, rinse well with water and the traces of corrosion will be gone.

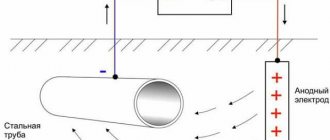

Electrolysis

For adventurers, you can clean metal from corrosion using electrolysis. For this method you need a source of electricity - a battery. The bottom line is that salt or baking soda is added to the water, the battery (for example, from a car) is installed so that a metal plate is attached to one terminal, and the other stamp is attached to the place where it is necessary to get rid of corrosion. The two ends are lowered into a solution obtained from water and salt, and a current is started. It is advisable to apply a current of 5 amperes. After half an hour, you can clean the area with a brush and rinse.

Such a remedy for metal corrosion requires mandatory safety precautions, as an electric shock may occur. Do not remove the product from the solution until the power is turned off.

Based on all the facts, we can conclude that metal cleaning is an integral part of the process of using the product. After the procedure is carried out and a protective coating is applied, it will be able to serve for many more years.