It would seem that there is something complicated in the pipes? Connect and twist... But, if you are not a plumber or an engineer with a specialized education, then questions will definitely arise for answers to which you will have to go wherever you look. And most likely the first thing they look at is the Internet)

We have previously talked about the diameters of metal pipes in this material. Today we will try to clarify the threaded connections of pipes for various purposes. We tried not to clutter the article with definitions. The basic terminology is contained in GOST 11708-82, which everyone can familiarize themselves with.

Pipe cylindrical thread. GOST 6357 - 81

Parameter Unit: Inch

Direction: Left

Accuracy class: Class A (increased), Class B (normal)

Why in inches?

The inch size came to us from our Western colleagues, since the requirements of the GOST are formulated on the basis of BSW (British Standard Whitworth or Whitworth thread). Joseph Whitworth (1803 - 1887), a design engineer and inventor, demonstrated the screw profile of the same name for detachable connections back in 1841 and positioned it as a universal, reliable and convenient standard.

This type of thread is used both in the pipes themselves and in the elements of pipe connections: locknuts, couplings, elbows, tees ( see picture above

). In the profile section we see an isosceles triangle with an angle of 55 degrees and roundings at the tops and bottoms of the contour, which are made for high tightness of the connection.

Threading of threaded connections is carried out on sizes up to 6”. All larger pipes are fixed by welding to ensure a reliable connection and prevent rupture.

Symbol in the international standard

International: G

Japan: PF

UK: BSPP

The letter G and the bore diameter (internal Ø) of the pipe are indicated in inches. The outer diameter of the thread itself is not included in the designation.

Example:

G 1/2 - external cylindrical pipe thread, internal pipe Ø 1/2". The outer diameter of the pipe will be 20.995 mm, the number of steps over a length of 25.4 mm will be 14.

The accuracy class (A, B) and the direction of turns (LH) can also be indicated.

For example:

G 1 ½ - B - cylindrical pipe thread, internal Ø 1 ½ inches, accuracy class B.

G1 ½ LH- B - cylindrical pipe thread, internal Ø 1 ½ inches, accuracy class B, left.

The make-up length is indicated by the latter in mm: G 1 ½ -B-40 .

For internal pipe cylindrical threads, only the Ø of the pipe for which the hole is intended will be indicated.

size table

| Thread size | Thread pitch, mm | Threads per inch | Thread diameters | |||

| Row 1 | Row 2 | d=D | d2=D2 | d1=D1 | ||

| 1/16″ | 0,907 | 28 | 7,723 | 7,142 | 6,561 | |

| 1/8″ | 9,728 | 9,147 | 8,566 | |||

| 1/4″ | 1,337 | 19 | 13,157 | 12,301 | 11,445 | |

| 3/8″ | 16,662 | 15,806 | 14,950 | |||

| 1/2″ | 1,814 | 14 | 20,955 | 19,793 | 18,631 | |

| 5/8″ | 22,911 | 20,749 | 20,587 | |||

| 3/4″ | 26,441 | 25,279 | 24,117 | |||

| 7/8″ | 30,201 | 29.0З9 | 27,877 | |||

| 1″ | 2,309 | 11 | 33,249 | 31,770 | 30,291 | |

| 1⅛» | 37,891 | 36,418 | 34,939 | |||

| 1¼» | 41,910 | 40,431 | 38,952 | |||

| 1⅜» | 44,323 | 42,844 | 41,365 | |||

| 1½» | 47,803 | 46,324 | 44,845 | |||

| 1¾» | 53,746 | 52,267 | 50,788 | |||

| 2″ | 59,614 | 58,135 | 56,656 | |||

| 2¼» | 65,710 | 64,231 | 62,762 | |||

| 2½» | 75,184 | 73,705 | 72,226 | |||

| 2¾» | 81,534 | 80,055 | 78,576 | |||

| 3″ | 87,884 | 86,405 | 84,926 | |||

| 3¼» | 93,980 | 92,501 | 91,022 | |||

| 3½» | 100,330 | 98,851 | 97,372 | |||

| 3¾» | 106,680 | 105,201 | 103,722 | |||

| 4″ | 113,030 | 111,551 | 110,072 | |||

| 4½» | 125,730 | 124,251 | 122,772 | |||

| 5″ | 138,430 | 136,951 | 135,472 | |||

| 5½» | 151,130 | 148,651 | 148,172 | |||

| 6″ | 163,830 | 162,351 | 160,872 | |||

How to determine the pitch of an inch thread

I’ll give you a picture from the English-language Internet that clearly demonstrates the technique. Pipe threads are characterized not by the size between the tops of the profile, but by the number of turns per 1 inch along the thread axis. A regular tape measure or ruler can help. Apply it, measure one inch (25.4 mm) and visually count the number of steps.

In the picture with an example ( see above

) threads - from English these are literally “threads of thread”. In this case there are 18 of them. by one inch.

It’s even easier if you have a thread gauge for inch threads lying around in your tool box. It is very convenient to take measurements, but it must be remembered that inch threads may differ in the apex angle of 55° and 60°.

| Thread pitch P, mm | Threads per inch |

| 0.907 | 28 |

| 1,337 | 19 |

| 1,814 | 14 |

| 2,309 | 11 |

TOLERANCES

3.1. Axial displacement of the main plane D1 l

2 external and D2

l

2 internal threads (Fig. 4) relative to the nominal location should not exceed the values specified in table. 3.

The displacement of the main plane is total, including deviations of the average diameter, pitch, angle of inclination of the side of the profile and cone angle.

3.2. The maximum deviations of the average diameter of the internal cylindrical thread must correspond to those indicated in the table. 3.

Crap. 4

Note. In the main plane, the average diameter has a nominal value.

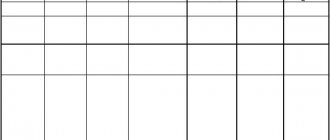

Table 3

Dimensions in mm

| Thread size designation | Offset of the main thread plane | Maximum diameter deviations D 2 internal cylindrical threads | |

| ±D1l 2 | ±D2l 2 | ||

| 1/16 | 0,9 | 1,1 | ±0,071 |

| 1/8 | |||

| 1/4 | 1,3 | 1,7 | ±0,104 |

| 3/8 | |||

| 1/2 | 1,8 | 2,3 | ±0,142 |

| 3/4 | |||

| 1 | 2,3 | 2,9 | ±0,180 |

| 11/4 | |||

| 11/2 | |||

| 2 | |||

| 21/2 | 3,5 | 3,5 | ±0,217 |

| 3 | |||

| 31/2 | |||

| 4 | |||

| 5 | |||

| 6 | |||

Note. Limit deviations ±D1 l

2 and ±D2

l

2 do not apply to threads with lengths shorter than those indicated in table. .

3.3. It is allowed to connect an external conical thread with an internal cylindrical thread of accuracy class A according to GOST 6357-81.

3.4. Recommended maximum deviations of individual thread parameters are given in the reference appendix.

Tapered pipe threads

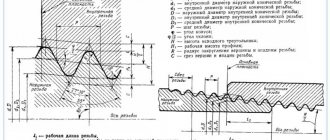

drawing of pipe tapered threads

Tapered pipe thread GOST 6211-81 (1st standard size)

Parameter Unit: Inch

Fits a rounded 55° straight pipe thread profile. See the top part (I) of the 3D image "drawing of pipe tapered threads".

Symbol

International: R

Japan: PT

UK: BSPT

The letter R and the nominal diameter Dy are indicated. The designation R means external thread, Rc internal, Rp internal cylindrical. By analogy with cylindrical pipe threads, LH is used for left-hand threads.

Examples:

R1 ½ - external pipe thread, nominal diameter Dy = 1 ½ inches.

R1 ½ LH - external pipe thread conical, nominal diameter Dy = 1 ½ inches, left.

Conical inch thread GOST 6111 - 52 (2nd standard size)

Parameter Unit: Inch

Produced on surfaces with a taper of 1:16

Has a profile angle of 60°. See the bottom part (II) of the 3D image "drawing of pipe tapered threads". It is used in pipelines (fuel, water, air) of machines and machines with relatively low pressure. The use of this type of connection assumes tightness and locking of the thread without additional special means (linen threads, yarn with red lead).

Symbol

The first letter is K, then GOST.

Example:K ½ GOST 6111 - 52

It stands for: inch conical thread with an outer and inner diameter in the main plane approximately equal to the outer and inner Ø of a cylindrical pipe thread G ½

Table of main parameters

| Thread size designation (d, inches) | Number of threads per 1″ n | Thread pitch S, mm | Thread length, mm | Outer thread diameter in the main plane d, mm | |

| Working l1 | From the end of the pipe to the main plane l2 | ||||

| 1/16 | 27 | 0,941 | 6,5 | 4,064 | 7,895 |

| 1/8 | 27 | 0,941 | 7,0 | 4,572 | 10,272 |

| 1/4 | 18 | 1,411 | 9,5 | 5,080 | 13,572 |

| 3/8 | 18 | 1,411 | 10,5 | 6,096 | 17,055 |

| 1/2 | 14 | 1,814 | 13,5 | 8,128 | 21 793 |

| 3/4 | 14 | 1,814 | 14,0 | 8,611 | 26,568 |

| 1 | 11 1/2 | 2,209 | 17,5 | 10,160 | 33,228 |

| 1 1/4 | 11 1/2 | 2,209 | 18,0 | 10,668 | 41,985 |

| 1 1/2 | 11 1/2 | 2,209 | 18,5 | 10,668 | 48,054 |

| 2 | 11 1/2 | 2,209 | 19,0 | 11,074 | 60,092 |

What is carving and its types

A thread is a groove of a special shape and size, applied in a spiral to the inner or outer surface of a pipe or metal rod. Can be applied to cylindrical or conical surfaces. It is characterized and differs from each other by the shape of the groove, the height/depth of the relief and the distance between the turns - the pitch. In order to connect two parts, they must have the same or compatible threads, with one part having an external thread and the other having an internal thread of the same type and size.

In general, threads are divided into fastening and running threads. Chassis are used in machine elements and provide movement. We are more interested in those that are used in everyday life and that we encounter in the process of repair and construction. This is just a mounting thread. In fact, that’s what we’ll talk about.

Types of thread according to the direction of turns and surface

It is also worth knowing that in the direction of application of turns, threads there are right and left, and in the direction of the surface on which they are applied - cylindrical and conical.

Types of threads

Pipe threads have their own profile, which provides a tight seal. It is used for non-welded connections of metal pipes in pipelines, installation of various types of fittings, and connection of devices. Recently, threaded connections have also been used on some types of plastic pipes, but there the approach is different - it is cast, although the essence is the same.

Three types of pipe threads and their differences

There are three main types of carving:

- Metric. You can distinguish them by the sharp tops of the turns and grooves. Shape: triangle with 60° angles. It is called so because its parameters are indicated in millimeters, and these are units of measurement of the metric system. Standardized by GOST 9150-81.

- Inch. It is also based on a triangle, but with an apex of 55°. It is present on imported parts. As you can see, the difference between metric and tapered threads is in the corners.

- Pipe. It differs from metric by a slightly smaller angle - 55°, and has the same angle from inch. The main difference is that the edges are rounded. And this is fundamentally important. It can be applied to a cylinder (pipe), and then the word “cylindrical” is added to the name. Standardized by GOST 6357-81. When threaded on a cone, it is called a pipe taper thread.

What type of carving is there?

These are connecting threads - for connecting parts. The types of threads that can be found on imported fittings and components can also be useful. This is a Whitworth thread, which is designated BSW if it has a coarse pitch and BSF if it has a fine pitch. It was this standard that was taken as the basis for the development of pipe threads in the USSR. So Whitworth threads and standard manufactured pipe threads are compatible.

Types of threads and their areas of application

There are other profiles, but they are common and very specific. Under normal conditions they are not needed. For general development, let's say that there are also rectangular and trapezoidal shapes.

Where is which one used?

Now about where what type of thread is used. Metric is applied to anchors, bolts, studs, nuts and other fasteners. Applied to a cylindrical surface it does not provide a tight seal, so it is not the best choice for pipelines. However, it is used, and for tightness it is “set” on a winding - tow or fum tape. In addition to plumbing, it is used in assembling frames from round pipes with a threaded connection.

What types of threads are there: profiles and standards

The picture changes when a metric thread is applied to a conical surface. This connection has a high degree of tightness. It is the metric conical thread that is applied to caps and is used in industrial pipelines for transporting gas and liquids that emit volatile substances. In everyday life, the use of conical threads is limited, since special equipment is required for its application.

It is not difficult to guess that pipe threads are used in pipelines. Thanks to the smooth profile lines, even without additional sealing, the connection is airtight. It is this type that is applied to elbows, angles, tees, and other devices that are used in the assembly of plumbing, heating and sewage systems.

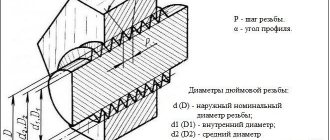

Metric tapered thread. GOST 25229 - 82

Parameter unit: mm

Produced on surfaces with a taper of 1:16

Used when connecting pipelines. The angle at the top of the turn is 60°. The main plane is shifted relative to the end ( see figure above

).

Symbol

The letters MK are followed by an indication of the diameter in the main plane and the thread pitch in mm: MK 30x2

size table

| Thread diameter d for row | Step P | Thread diameter in the main plane | ||||||

| 1 | 2 | d = D | d2=D2 | d1=D1 | l | l1 | l2 | |

| 6 | — | 1 | 6,000 | 5,350 | 4,917 | 8 | 2,5 | 3 |

| 8 | — | 8,000 | 7,350 | 6,917 | ||||

| 10 | — | 10,000 | 9,350 | 8,917 | ||||

| 12 | — | 1,5 | 12,000 | 11,026 | 10,376 | 11 | 3,5 | 4 |

| — | 14 | 14,000 | 13,026 | 12,376 | ||||

| 16 | — | 16,000 | 15,026 | 14,376 | ||||

| — | 18 | 18,000 | 17,026 | 16,376 | ||||

| 20 | — | 20,000 | 19,026 | 18,376 | ||||

| — | 22 | 22,000 | 21,026 | 20,376 | ||||

| 24 | — | 24,000 | 23,026 | 22,376 | ||||

| — | 27 | 2 | 27,000 | 25,701 | 24,835 | 16 | 5 | 6 |

| 30 | — | 30,000 | 28,701 | 27,835 | ||||

| — | 33 | 33,000 | 31,701 | 30,835 | ||||

| 36 | — | 36,000 | 34,701 | 33,835 | ||||

Profile and dimensions of a tapered inch thread with a profile angle of 60 degrees

This table shows what deviations there may be in slope and profile pitch.

Video: cutting tapered pipe threads.

As for additional fastenings, cotter pins are often used as connecting parts, since pipelines can be subject to vibration, both constant and periodic.

The thing is that this type of connection tends to unwind, so to avoid this, cotter pins are used for such connections. This is especially true for places where pipelines are laid under highways, where there is constant traffic movement, which creates vibrations.

What are the main differences

The main differences between the types of pipe threads

Upon initial examination, it seems that it is difficult to distinguish one type of thread from another. This is not so; the main differences lie in the dimensions, profile angles, method of applying notches and the scope of application of such a connection.

Between pipe and inch

The main difference is the rounded cutting edges at the same profile angle.

Between pipe and metric

The main difference is the relief and size of the threaded ridge and depressions. In metric, an equilateral triangle (60 degrees) is used - all dimensions are the same. In a pipe one, the angle is smaller (55), and the dimensions may vary.

Another obvious difference is the units of measurement. Millimeters and inches are used accordingly.

In addition, when cutting pipes, the wall thickness of the product must be taken into account. The latter may vary depending on the operating pressure that the product can withstand and the scope of its application.

Between metric and cylindrical

The difference lies in the reduced profile angle (55 for cylindrical versus 60 for metric). In addition, dimensions are indicated in different units - millimeters and inches. The latter in a pair is applied to a cylindrical surface.

4. NOTATION

4.1. The thread symbol must include: letters ( R

- for tapered external thread,

Rc

- for tapered internal thread,

Rp

- for cylindrical internal thread) and thread size designation.

The symbol for left-hand threads is supplemented with the letters L H.

Examples of thread designations:

external pipe tapered thread 11/2: R

11/2

internal pipe tapered thread 11/2: Rc

11/2

internal pipe cylindrical thread 11/2: RP

11/2

left hand thread:

R

11/2

L.H.

;

Rc

11/2

L.H.

;

R.P.

11/2

LH.

4.2. A threaded connection is designated by a fraction, for example, or Rc

/

R

, the numerator of which indicates the letter designation of the internal thread, and the denominator - the external thread, and the thread size.

Examples of threaded connection designations:

pipe conical thread (internal and external);

; ;

internal pipe cylindrical thread (with tolerances according to this standard) and external pipe tapered thread:

; ;

internal pipe cylindrical thread of accuracy class A according to GOST 6357-81 and external pipe conical thread:

; .