When drilling holes for wiring, sockets, socket boxes and switches in concrete walls, ordinary tools cannot withstand such a load, so special crowns for concrete sockets are used.

There are several types of crowns of different designs, used depending on the density of the material and working conditions. Such crowns can be used not only in the case of a concrete wall. They cope well with other hard objects - brick, stone. Therefore, a concrete crown is considered a universal tool and has a wide range of applications.

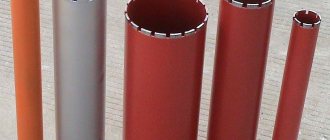

Crown for concrete

Previously, before the advent of diamond or pobedite tools, conventional drilling using a hammer drill or electric drill, as well as an angle grinder equipped with a concrete circle, was used to form holes for sockets and socket boxes. However, with the advent of carbide heads, electrical installation operations have become significantly easier. In terms of efficiency, concrete crowns are significantly superior to outdated tools.

Purpose

- A concrete crown is a universal device that allows you to form cavities and channels with increased surface cleanliness to solve the following problems:

- installation of sockets;

- installation of switches;

- pipe laying.

The performance characteristics of the tool allow you to drill various materials:

- concrete surfaces;

- masonry;

- brick walls;

- different types of blocks.

Device

As you know, concrete has good strength characteristics, which make this material quite popular in the construction of residential buildings. Meanwhile, the high strength of concrete makes working with it very difficult.

If it is necessary to make technological holes for socket boxes, the master is faced with a rather serious problem and the need to use a special tool. If you drill with a hammer drill or a drill with an attachment in the form of an ordinary drill, you can spend a long time and end up doing nothing.

In this case, you simply cannot do without a special concrete crown, which has a diamond coating. In appearance, this cutting tool is a small piece of pipe, the edges of which on one side have cutting segments made exclusively of carbide material. At the moment of drilling the socket boxes, it is these segments that penetrate into the base of the concrete.

At the other end of the bit there is a special flange, which is used to attach the bit to the cylinder of a drill or hammer drill. The tool that is used to drill concrete using a crown must have high power and a sufficiently large diameter of the head itself.

As a rule, to drill socket boxes in concrete, a tool with either a pneumatic or an electric drive is used. In addition, in addition to a concrete crown, a special centering drill can be used, which is fixed in the common tool assembly and allows you to avoid incorrect movement of the main cutting tool.

If the crown additionally has diamond coating along the edges of the edge, then its durability and cutting ability will increase several times. For more efficient and faster work, you should select the correct concrete crown based on its type. Attention should also be paid to the choice of tool, which must have sufficient power and high reliability.

Peculiarities

Diamond cutting edge bits are differentiated by diameter, drive connection design, cylinder length, type of cutting segments, method of use, and mode of operation of the drive mechanism. Working segments with a soft matrix (marked “M”) in the crown are used on particularly strong concrete. They easily self-clean from clogging with drilling products. On ordinary reinforced concrete, diamond bonds of medium hardness (marked “C”) are used.

Segments with solid matrices (type “T”) are used at reduced speeds, including on high-grade concrete. There are products with different frequencies of segment placement and a continuous ring of diamond crystals. All attachments are used for wet and dry drilling. However, the KS crown (matrix “C”) is structurally different in that it has specially shaped cavities on the cylinder that facilitate air cooling.

The concrete bit with a diamond cutting surface is used in a non-impact mode, which makes it easy to pass through reinforcement. Drilling machines have many standards for fixing the bits to the shaft. They differ in size, design, and methods of shank attachment (BSP, SDS, thread).

It is important that the shank (with adapter) matches the drill clamp. According to the outer diameter, the cups are classified into: small (up to 1.2 cm), medium - 3.5 - 8.2 cm (used when forming holes for socket boxes - 70mm), large - with a diameter of 15 to 40 cm and extra large - 40 – 120 cm. The design of the heads, depending on the diameter, can contain a different number of working segments. For example, a cylinder with a diameter of 4.6 cm has 5 cutting elements, and a product with a diameter of 65 cm has 32 segments.

The length of the fixture pipe characterizes the working depth of drilling through holes in structures of various thicknesses. The length of passage of concrete material is up to 500 cm. Such products have a significant resource, for example, a cylinder with a diameter of 20 cm with high-quality diamond cutting segments passes up to 20 m/linear. medium reinforced concrete.

Characteristic

A crown is a special device for drilling holes in concrete. The shape of its end resembles a crown. Since the tool is often used for drilling holes for sockets, it is called a crown for sockets for concrete.

It can be used to drill concrete, masonry, artificial or natural stone, as well as reinforced concrete. The crown can drill to a depth of 1.5 meters. The size of the hole depends on the diameter of the crown itself, which can be in a very wide range.

Socket boxes are used for easy installation of wiring on concrete and brick.

- Their standard sizes are:

- internal diameter – 60 and 68 mm;

- depth – from 25 to 80 mm, traditionally – 40 and 45 mm;

- center distance – 71 mm.

Material and shape

A concrete crown looks like a piece of pipe, the upper edges of which have special cutting sections for drilling holes for sockets and other elements. The cutting surface is made of hard alloy, it is much harder than concrete and can process it without breaking. The other end of the cylinder is equipped with a flange (fastening element) - it is used to attach the device to the cylinder head of the drill.

Additional details

To drill with a crown, use a powerful drill or hammer drill. The drill must have a sufficiently large head and high power.

- The following types of drills are used:

- pneumatic, which are driven by a stream of compressed air;

- electrical;

- special drills.

The set of concrete crowns for socket boxes also includes a centering drill. It is attached in a special unit so that the crown does not “walk around”. This kind of drill needs to be changed frequently - as a rule, it quickly becomes dull. In addition to conventional carbide cutting surfaces, crowns can have a diamond coating, for which industrial diamonds are used. These bits are extremely durable, do not require sharpening and are capable of drilling through the toughest surfaces.

Price

Different dental crowns have different prices, depending on the material being made, the creation method, the professionalism of the doctor, the location and status of the clinic.

Let's look at the approximate prices of different types of crowns (per unit):

- porcelain - 13 thousand rubles;

- from zirconium dioxide - 16 thousand rubles;

- metal-ceramic - 6 thousand rubles;

- plastic - 800-1000 rubles;

- metal - 3 thousand rubles;

- metal-plastic - 4 thousand rubles;

- metal-ceramic for installation on implants - 10-14 thousand rubles;

- zirconium together with an abutment - 25 thousand rubles.

We offer an overview of turnkey prices in Moscow clinics for prosthetics:

| Clinic | Address | Price |

| Dentistry Mendeleev | St. Novoslobodskaya street, 36/1с1 | From 7900 rub. |

| Dentistry ActiveStom | 4th lane Krutitsky, 14 | From 2500 rub. |

| Dental-Studio | Michurinsky Prospekt, 80 | From 6000 rub. |

| Doka-Dent | St. 1st Tverskaya-Yamskaya, 27 | From 2500 rub. |

Types of crowns for concrete

To work correctly with concrete or other material being processed, you need to select the appropriate type of tool.

- When choosing a crown, you need to consider the following conditions:

- properties of the material being drilled;

- drill power;

- working conditions.

- Depending on the material used, they are classified:

- Crowns made of carbide steel with pobedit edges (budget option).

- Diamond coated.

- For stone and concrete made of tungsten carbide alloys.

- Based on the standard of fastenings, the following types are distinguished:

- triangular;

- hexagonal;

- SDS Plus;

- SDS Max.

The most popular shank mount is the SDS Plus standard; this technology corresponds to the connectors of all modern rotary hammers. The diameter of the fastening part is 10 mm, the depth of immersion in the cartridge is 40.

Carbide (pobedite)

Crowns for socket boxes with carbide tips (surfacing) are most often used. They are cheaper than other crowns and are used for drilling under normal conditions, at home for personal use.

Such a crown is created by applying soldering of a durable alloy to the cutting surface of the tool. The peculiarity of such drills is that the soldering tips fly out during drilling when they hit the reinforcement. Therefore, they are not suitable for areas of concrete with reinforcement.

This is the most popular type of crowns, popular in everyday life under normal drilling conditions. On the cutting edge of such a nozzle for socket boxes there are solderings made of pobedit (an alloy of tungsten and cobalt). Their advantage is their low price and large assortment, which includes fairly high-quality products from Russian manufacturers.

The disadvantage is the high risk of edges flying off during concrete drilling, especially with Chinese drill bits. Moreover, it increases when working with reinforced sections. But with proper use, cooling breaks and changing attachments while drilling metal, Pobedit bits for socket boxes will last quite a long time.

Tungsten carbide

Crowns for socket boxes with tungsten carbide coating are used for drilling ceramic tiles except concrete, stone and brick. This type of tool is very convenient for working with different materials at the same time: it does not need to be changed and you can go straight, for example, from drilling concrete to creating holes in ceramic tiles, and then to working with brick or stone.

This tool combines the properties and technical characteristics of several crowns. The tungsten carbide bit has a hex shank and is used for drilling with a conventional drill. Its power must be 800 W or more. The only significant drawback is that this type of crown fails when it comes into contact with reinforcing bars or metal elements.

Suitable not only for drilling concrete, but also other hard surfaces: brick, stone, ceramic tiles. When working with various materials, there is no need to replace nozzles, the only thing is that they fail at the slightest contact with the fittings.

This bit is suitable for drilling concrete with a drill (provided its power is at least 800 W); most often it has a hexagonal shank. In fact, this is a universal product with a very budget price (from 800 rubles). But, unlike diamond-coated crowns, they are subject to wear without the ability to self-heal, and periodically there is a need for sharpening or complete replacement.

Diamond

The strength of such a crown is similar to a diamond wheel - it cuts concrete just as well. This product is most effective for drilling concrete and reinforced concrete. A high-quality tool of this type has a high price, but this is justified by durability, savings in labor costs and time. This crown is ideal for performing large volumes of work.

The cutting surface of this tool is coated with industrial diamonds and is capable of cutting through reinforcement. It is suitable for working in very difficult areas. When working with it, it is still recommended to avoid areas with metal - this will prolong its working capacity.

The cutting edge of this variety is coated with industrial diamonds, which allows it to be used even on reinforced areas. But its main purpose is to work with concrete; in order to extend the life of the tool, it is still better to replace the attachments when drilling metal. They are purchased mainly for rock drills or drilling rigs, most have an SDS Plus shank.

- In comparison with carbide types, a diamond crown for a rosette in concrete has the following advantages:

- Obtaining a neat hole with ideal geometry, without chips and other drilling defects.

- There are no restrictions on penetration depth.

- Versatility and multifunctionality: diamond attachments for socket boxes work well not only with concrete, but also with any other hard materials.

- Minimum level of noise and vibration, which is especially important when carrying out repairs in apartment buildings.

- High drilling speed is the main advantage; even when working with thick slabs of concrete, the process of creating a high-quality hole for a socket box rarely requires more than 5 minutes.

- Low level of dust generated.

Diamond bit for concrete - nuances of use

Before starting the drilling activity, you should select the required size of the bit for the rosette in concrete and assemble it.

- Assembly involves performing the following operations:

- Fixation with a guide drill bolt.

- Attaching the cutting bowl to the shaft thread.

- Checking the strength of the assembly and the absence of backlash.

- When creating a cavity using an assembled crown, follow these steps:

- Make markings and mark the coordinates of the location of the future outlet or switch.

- Drill a hole in the center of the cavity with a regular drill.

- Fix the assembled bit in the power tool chuck and insert the centering drill into the drilled channel.

- Turn on the electric drill or hammer drill and, using little force, drill a hole to install the socket box.

When performing work, it is mandatory to use personal protective equipment - goggles and a respirator. After drilling, remove the drilled part and allow the equipment to cool.

Grouping rules

It is allowed to install several devices in the socket block; their number is almost unlimited, but usually more than 6–8 pieces are not installed . In addition to sockets, the block may contain switches, regulators, television and computer connectors.

Rules for grouping and carrying out work :

- The locations of socket boxes (not switches and regulators, but casings) are marked on the wall.

- To form recesses, crowns for a rosette with a diameter of 70 mm are used to give freedom to adjust the interaxial distances.

- The housings are adjusted by center and aligned vertically and horizontally.

- If you neglect the level, all the sockets in the block will stand askew (the way the boxes are mounted under them).

- Take into account the edge of the casing.

- As a standard, the side should be in the same plane as the wall - then the socket with the lid will fit tightly to the surface.

Valera

The voice of the construction guru

Ask a Question

After drilling the holes, a block is installed in them to check all parameters. The deviation of the sides of the block from the axis by 1.5 - 2 mm is allowed. Coordinate the possibility of entering all wires into the socket boxes so that they do not interfere with each other. Low-current and power connectors are separated from each other by a gap equal to another diameter of the socket. This way, electromagnetic waves will not interfere with the operation of devices.

Features when working with reinforced concrete and tiles

Reinforced concrete drills provide drilling of the strongest materials with maximum diameter and depth, which other similar products cannot cope with. It is thanks to this ability that this model received first place in the rating of tools.

Such a part, unlike Pobedit products, is reliable and durable, and if you purchase it for regular construction and repair work, its high price will pay off in a short period of time. Even the presence of reinforcement cast in concrete will not prevent you from equipping a special place for the socket box using a similar attachment.

Ceramic tiles are a rather difficult material to cut and, especially, drill into a certain surface. Until recently, it was almost impossible to drill into tiles without compromising its integrity; however, the advent of diamond parts has simplified this process. Now ceramics can be used for pipe routing, installation of various fasteners for decorative elements, it can be grooved for laying wires, installing sockets and switches in specially equipped socket boxes.

Video

Organic Shop Kitchen Restoring Night Cream for the face “Bayu-Bai”, 100 ml

130 ₽ More details

ARAVIA Professional Intensive Moisture Face Cream with urea (10%), 150 ml

405 ₽ More details

Diploma folders

Diameter of crown for socket

Before you go to the store for a crown for socket boxes, you need to accurately determine their size and diameter. If the crown is purchased incorrectly, the technical hole made in the concrete wall may turn out to be either too large or, conversely, too small.

The most common size, which is considered standard, has a diameter of sixty-eight millimeters. This is what most switches and sockets are manufactured for. However, you can find sockets and switches with other diameters on sale, and therefore, even at the preliminary stage of repair, you should accurately determine what materials will be used and, based on this, purchase everything you need.

You should also pay special attention to preparing the cutting tool for work. The crown must be assembled in accordance with the instructions, otherwise you may cause serious injury during operation. Before starting work, it is recommended to carefully study the instructions that come with the crown. Assembly of the crown begins with the preparation of a pobedit drill.

It must be inserted into the cartridge and securely secured using the appropriate bolts. Next, you should strengthen the bowl under the drill itself along the thread. All elements of the crown should fit tightly in place and not dangle. If the assembly is not complete or of poor quality, then during the work you can break individual elements of the crown or cause serious injury to yourself.

Drilling process

When the drill bit is completely assembled and checked, you can proceed to the concrete work itself. It is best to do the main work using a hammer drill, and if you don’t have one, you can use a powerful impact drill. It is not recommended to use an ordinary drill, as in this case the work will be ineffective and will take a huge amount of time.

To begin with, certain marks should be made on the concrete base in given places, along which the centering drill will subsequently be positioned. After this, you can start drilling the base of the concrete wall with a crown. To do this, place the drill on a pre-made mark and start drilling.

The tool should be held as tightly and level as possible. Work must be carried out in a respirator and special construction glasses, since when drilling a lot of harmful dust is generated in the space. Upon completion of work with concrete, the cutting tool should be correctly returned to its original state.

To begin with, the nozzle should be given time to cool completely, otherwise, when dismantling it, its cutting tip may simply fall off. To do this, the cutting attachment is removed from the hammer drill, and all cement dust and dirt are removed from it. You should also pull out its middle part and this can be done most easily using an ordinary metal chisel or hammer.

This way the cutting attachment will be prepared for further use. When choosing a cutting attachment for working with concrete, you should not purchase cheap options, for example, those made in China. Despite their affordable cost, in most cases they fail after drilling the first technological holes in the wall.

Also, when working with cutting tools, it is imperative to adhere to safety requirements. Despite the fact that concrete is a fairly durable material, it is possible to make the necessary technological holes in it with a properly selected special cutting tool without much effort in the shortest possible time.

Which ones are better?

When preparing for prosthetics, every person wants to choose the best option for themselves. You should make a choice together with the dentist, since after studying the clinical picture and listening to the patient’s preferences, he can suggest which option will be preferable for this particular case.

For this reason, different crowns may be best for each patient. And if we talk about the advantages of materials, the leader can be called crowns made of solid ceramics, obtained by pressing. For teeth in the front part of the dentition, they are simply ideal.

Such products have sufficient strength, wear resistance and are as similar as possible to living teeth, repeating all their properties.

Dimensions of crowns for concrete

To correctly select the appropriate size crown, you should know the diameter of the hole being made for a socket or other element - for example, for the cross-section of pipes or the size of the wire route when laying communications. When purchasing a crown in a store, you should check with your consultant for its technical characteristics, which are indicated in the attached documentation or labeling.

Crowns can be sold either as individual instruments or as special sets of several pieces of various sizes. Most socket boxes or switches have a standard outer diameter of 68 mm (with an internal diameter of 60 mm), so 68 mm socket box crowns for concrete are the most popular in use. Nozzles of 70 and 75 mm are used less frequently.

For laying communication routes, the most common option is a concrete crown with a diameter of 300 mm. The choice of tools is also influenced by its length and the number of segments of the cutting part: 5, 6 or 8 - the larger this indicator, the higher the productivity of the crown. The kit for concrete crowns for socket boxes also includes a centering drill, the role of which is to fix the crown in the center of the hole being made, preventing it from “walking” in the working material.

The centering drill must be changed frequently as it quickly becomes dull. The concrete bit is designed to penetrate into the depth of the material up to 1.5 meters. If you need to go from the opposite direction - the socket has already been purchased, but the size of the hole is unknown - you should measure the outer circumference of the socket with a caliper.

The resulting indicator will determine the diameter required to make the hole. Among the models from branded manufacturers, we can note Bosch, REMS, DeWalt, acceptable quality and a budget price are offered by the South Korean Arix and the Chinese SuperHARD. Among domestic manufacturers, DISTAR and Adele should be highlighted.

What it is?

Drilling bits are attachments for a drill in the form of a cylinder. On the one hand, these drills have devices for fastening in a hammer drill or drill. On the other hand, there are teeth, on top of which spraying of various compositions is often applied. Such cutters are used for cutting ceramic, porcelain stoneware, tile or mosaic tiles.

Cutting with a crown on tiles is only possible in conjunction with a special drill or a special hammer drill. The first should have the option of low speed, and the second should have the function of turning off the “impact mechanism”. Thanks to this, drilling holes, for example, for a switch or socket, will be easier and more efficient. By the way, the most popular crown diameters are 40, 68, 100 and 110 mm. This is enough to carry out all the work in the bathroom.

Recommendations for selection

First of all, you should clarify the dimensions of the socket box: as a rule, they are standard, but there are exceptions. In particular, if you need a hole of a larger diameter, you need to buy a 70 or 75 mm crown. The cost of non-standard options practically does not differ from the usual 68 mm, it mainly depends on the quality of the material and thread used.

But it’s better to make a big mistake and seal the cracks with concrete mortar than to try to insert a socket box into a narrow and unsuitable niche. For one-time work, it is allowed to use inexpensive crowns with pobedit edges. In this case, it is better to choose products from a domestic manufacturer rather than a Chinese one; the low cost does not justify the abrasion or knocking down of elements during the first drilling.

Products from Zubr or Praktika have good recommendations. They can last longer provided that they are periodically cooled while drilling into concrete and that the type of attachment matches the material being processed. This type of crown should not be used to create holes in walls with metal reinforcement.

For professional needs, it is better to choose high-quality standard SDS Plus diamond-coated tools. In addition to higher efficiency, they are characterized by the ability to self-heal and are practically not subject to wear.

Products from European manufacturers have good reviews: Makita, Bosh, Hilti. But the price of such crowns for making socket boxes is appropriate: up to 10 times higher than Russian ones. The number of segments for drilling also matters: the more there are, the more efficient and faster the concrete is drilled.

What to pay attention to

- Only a specialist can choose a crown correctly, but if the following rules are taken into account, a beginner can cope with this task:

- Decide on the base in which the hole for the socket box will be drilled. Thus, for reinforced concrete, the nozzle for ordinary concrete, plasterboard or other materials is not suitable.

- Specify the maximum drilling depth, as well as the diameter of future socket boxes, switches and other devices. Otherwise, it may turn out that the diameter of the hole does not fit the dimensions of the devices.

- An important criterion when choosing a bit is the operating speed, as well as the maximum value of revolutions per minute of rotation.

- Attention should also be paid to the need to cool the mechanism, as well as the possibility of doing without it.

- You can analyze crowns from different companies.

When choosing a crown, you should not save, because a cheap product will not cope with the task at the same level as expensive analogues, and the socket may not work out at all. There are many fakes on the construction tools market, which can also be bought at a low cost.

Remember that sprayed crowns are very expensive, so purchasing one will be justified in case of a large volume of concrete work. It is irrational to take high-quality products if you have a weak and cheap hammer drill. This combination is extremely unprofitable, since drilling a socket box requires high power and high speed of the tool itself.

Author: Sergey Vladimirovich, electrical engineer. More about the author.

Installing socket boxes in drywall: tips for a novice master

The socket box for gypsum boards is an important element when installing electrical equipment into hollow walls, which is securely attached to the sheet and allows you to mount any electrical structures - switches, sockets, sensors or switchers. Important! When installing several socket boxes in one line, it is necessary to maintain a distance between their centers of 71 mm. When planning to mount a socket box in plasterboard, it is important to be able to choose it correctly. Of course, in any hardware store, consultants can help with the choice, but it is better if you yourself know what the differences are between socket boxes and how not to make a mistake with the purchase.” A glass for drywall differs from the rest in the presence of special fasteners installed on screws. These fasteners secure the socket box to the inside of the wall.

This is the only way “the glass can be securely fixed – neither with putty solution nor with cement. There are times when it is necessary to install 2 or 3 socket boxes in a row. In this case, you need to select “glasses with connecting tunnels through which the wire will be laid. If you only need to install one socket box, these connections can be cut, as they may interfere with installation in the recess in the drywall. There is a second option - you can purchase special connecting elements.

These partitions are installed in the glasses immediately before they are installed in the wall.

Features of pricing in dentistry –

How much it costs to install a crown (even of one type) can vary significantly in different clinics, and depends on:

Pricing policy - each dental clinic can be targeted at a specific segment of consumers (taking into account their income). That is why the cost of crowns of the same type, for example, zirconium, in different clinics can range from 30,000 to 40,000 rubles per unit.

- From the qualifications of the staff - → an orthopedic doctor, whose task is to grind the teeth for crowns, take impressions, select the color of future crowns, and fix the finished crowns on the teeth.

On average, the salary of an orthopedic doctor will be about 20% of the cost of the crown (maximum 25%, if a very highly qualified doctor). → a dental technician whose task is to make crowns based on dental impressions. On average, the cost of making a crown in a dental laboratory is about 25% of the final cost of the crown. Those. the clinic retains about 50%, from which it is necessary to deduct administrative expenses, rent of premises, depreciation of equipment, the cost of some consumables, utility bills, salaries of nurses, orderlies, chief physician... taxes. - Depending on the cost of the materials used - for example, you can use high-quality German ceramic mass in the manufacture of metal ceramics, or you can use our Russian or Belarusian one. The price of the latter is an order of magnitude lower, which allows you to slightly reduce the final cost of the work. The same applies to metal alloys necessary for the manufacture of both solid-cast crowns and a metal frame for metal-ceramic ones.

From having our own dental laboratory, the technical stage of making crowns takes place in a dental laboratory. Dental technicians sit there and make crowns. Not all dental clinics have their own laboratories. If it does not have its own laboratory, then in this case the clinic must have an agreement with one of the third-party dental laboratories. Accordingly, the cost that will be included in the services of a third-party dental laboratory will include not only the cost, but also the profit margin like any commercial enterprise. Having its own laboratory allows the clinic to be more flexible in setting the final price for the consumer.

How clinics save on patients:

Low qualification of personnel means lower salary costs, because good doctors, when hired, require a higher percentage of remuneration, which affects the cost of services. Therefore, clinics often hire bad and inexperienced doctors who are willing to work for a small percentage of revenue (this is somewhere around 12-15%). Therefore, when you are offered 1 unit of metal ceramics for 6,000 or 8,000 rubles, you need to think carefully.

Use of cheaper materials – the use of low-quality materials of Russian and Belarusian origin has its consequences. For example, the use of cheap ceramic mass can lead to inaccurate fit of the crowns to the teeth, because such a mass can give uncontrolled shrinkage during firing

Cheap ceramics may have transparency indicators that differ significantly from natural tooth enamel, which will lead to poor aesthetics of the finished crown. Cheap ceramic mass may also have poor adhesion to metals (which is important in the manufacture of metal-ceramics), which will lead to a high risk of ceramic chips. The use of cheap metal alloys can lead to cracks in the metal frame of the crowns and the need to replace them

We hope that our article on the topic: Types of crowns for teeth and which ones are better was useful to you!

Varieties

In order to find out how to choose a set of crowns, it is worth understanding their variety.

In the photo of a set of bits you can see a section on the surface of a steel pipe. The fastening process takes place using a hammer drill chuck with grooves - clamps. They comply with the SDS standard.

There are different options for nozzles. It all depends on the purpose of use, in particular, on the material used. Criteria such as the type of fastening are also important. The diameter of the holes is important;

The following main types of crowns are made for concrete:

Tooth type crowns

The most suitable option for impact drilling will be gear-type drill bits. The material they are made of is quite durable, made of hard alloys. Shanks are suitable for attaching tool chucks.

Note! This type of crown is best used in spaces between bricks or slabs.

Diamond crowns

It is worth using diamond core bits for socket boxes for impactless drilling. This option is considered a more advanced, modern model. Therefore, nozzles are used for hammerless drilling.

In terms of external characteristics, they are smooth and have small cutouts. They are formed by the accumulation of a small dusting of diamond sand and corundum particles.

Comparing this method with the drum method, we can highlight a number of undoubted advantages:

- low dust content;

- high quality characteristics. Holes in solid material are made precisely to suit your needs;

- The tool is quite easy to work with due to low recoil;

- the material being processed is not additionally loaded with impact loads. In the latter version, cracks often appeared because of this;

- low noise level.

Even with metal reinforcement of concrete slabs, crowns cope.

Their diameter is 12-650 mm, which allows you to make a hole approximately 1.5 m deep.

Crowns standard KS

Another option is to use KS standard crowns, which have a diamond coating.

Their peculiarity is that on the cutting edge there are elements that protrude beyond the surface area. Such features are replacing gear bits made of hard alloys.

Their scope of application is huge. Here are a few of them:

- use in rocky soil;

- in slabs;

- use in monoliths.

Among the main advantages of use, a long service life is noted; repairs are not required during the process.

Socket boxes and their classification

Before proceeding to the immediate topic of our article, it is necessary to clearly understand what a socket box is, an object for the installation of which a core drill is used. Everyone has a lot of sockets in their home, but they are not just the decorative overlay that we see on the wall. Underneath it lies a terminal block for connections with electrical wiring hidden in the wall (when installing wiring in a wooden house, it is recommended to use surface wiring rather than hidden wiring). It has certain overall dimensions in diametrical terms and in depth. They are the ones who determine the parameters of the socket box, which affect the characteristics of the crown.

Each manufacturer of socket boxes offers its own solutions, but all of them, as a rule, have a round cross-section and are adjusted to the current standard. The wall material (concrete, plasterboard, wood, etc.) determines some of the characteristic design features of socket boxes, as well as their classification.

All socket boxes can be divided into three groups:

- Mounting blocks for concrete. This is a round plastic glass that does not have any elements for fixation (it sits on the gypsum solution in the recess).

- Mounting blocks for plasterboard, plastic. These are almost the same glasses made of plastic, only with additional pressure plates for fixation on the back side of the sheet.

- Mounting blocks for wood. They are a round metal glass (defined by fire safety standards). Used when installing hidden wiring in wood. Adapted for installation in old panel structures.

Drilling tool

Crowns with a diameter of up to 100 mm are installed on hand tools.

When using larger crowns, the drilling tool is fixed with anchors, which ensures precise direction of the drill and prevents it from jamming due to misalignment. To use a diamond tubular drill with a diameter of up to 250 mm, a drill with a power of 1000 W is required.

Adapters should be used with caution: a low-power drill equipped with an overly large bit may break. To use large and especially large bits (diameter from 150 mm), a special drilling rig is required

Tags: beat, sconce, view, harm, choice, switch, house, , sign, how, design, , installation, power, skew, transfer, potential, manufacturer, , work, size, regulator, repair, socket, row, garden, means, term, ten, type, current, installation, shield, power tool, effect