Today there are a huge number of various attachments, which are suitable for a conventional drill. Thanks to this, it becomes a universal device that can replace many other expensive tools.

For example, a grinding disc mounted on a drill will help eliminate the need to buy a grinding machine, and an accessory that can tighten a screw will replace a screwdriver.

Using various attachments, you can perform the following drill actions

- polishing;

- cutting;

- mixing;

- twisting;

- drilling various holes;

- milling.

If you choose the right nozzle, the result will be the same as if the work was done using special equipment.

Useful equipment is suitable for construction and various works on a summer cottage. The construction of a chicken coop, pigsty, cages and other outbuildings will not be possible without such equipment.

Types of nozzles

Grinding attachments for drills differ in shape and material, but they all have a common part - this is a cylindrical rod that is clamped into a chuck. An abrasive or grinding material is attached to the rod in one way or another.

The most common grinding attachments for drills are:

- End - in the form of cylinders, cones and other figures of rotation made of hard abrasive.

- Cup brush or soft, cup-shaped material.

- Plates - made of plastic or rubber with a fixed piece of sandpaper.

- Disc - metal or soft.

- Fan-shaped with strips of sandpaper fixed in the shape of a fan.

- Soft in the form of discs for polishing.

- Drums with sandpaper.

Cup attachment

There are other designs of grinding attachments for drills, some are designed specifically for grinding the surface of parts with particularly complex shapes.

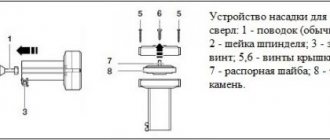

Angular attachments for drills stand apart. They do not have a working element, but serve to change the plane of rotation of the shaft, by 90° or by an arbitrary angle from 0 to 90°. At its end there is another cartridge into which the usual nozzle is clamped. This device allows you to work in hard-to-reach places. When installing an angle attachment on a drill, it is important to carefully check its attachment to avoid personal injury and damage to equipment and materials.

Dimensional characteristics

In terms of size, the nozzles differ in such parameters as length, width and thickness of the slot. Each parameter has its own range:

- In terms of length, bits from 25 to 90 mm are mainly used;

- popular widths from 2 to 9 mm;

- thickness usually varies from 0.3 to 1.6 mm.

Here you need to start from what kind of fastenings you have to work with. The best solution is to buy a set or separately several different bits that can cope with various tasks.

Advantages and weaknesses

The main advantage of the device is to expand the functionality of an already purchased tool. Additional surface finishing capabilities do not require the purchase of expensive specialized equipment.

Advantages of a drill attachment compared to specialized equipment:

- high-quality grinding of hard-to-reach places;

- ease of working with small parts;

- cost savings;

- opportunity to do it yourself.

But there are also disadvantages:

- not as convenient to work as with a special tool;

- for high-quality grinding you need to acquire the skill;

- lower productivity;

- Rotation speed adjustment is often required.

If the amount of work is small, then the advantages far outweigh their disadvantages.

How to use attachments

The main areas of application for drill attachments are as follows:

- cleaning surfaces from rust, old paint residues and other contaminants before painting;

- polishing metal surfaces;

- polishing paint and varnish coatings;

- polishing glass or plastic (for example, car headlights);

- glass edge grinding;

- cleaning of metal parts after welding;

- grinding surfaces in hard-to-reach places.

Polishing the surface using a nozzle

In addition to grinding, special devices are also used for cutting thin sheets of metal and for plucking bird feathers.

Attachment with automatic screw feeding

Another attachment from Drillpro - for automatically feeding self-tapping screws - can turn a regular electric drill into something like a belt screwdriver.

The device is made of metal and literally consists of a couple of parts: a linen holder with screws and the feed mechanism itself. The attachment is attached to the drill using a mounting hole with a diameter of 44 mm and tightened with a clamp.

The nozzle mechanism is equipped with adjustment systems for screws of various sizes and screwing depths.

The screws are fed each time you press the wall of the tape holder.

You can purchase special tapes with self-tapping screws for use with this attachment, or simply insert new screws into the holes of the already used tape.

Price 1500 rub.

7

Types of materials for making nozzles

Materials for the working body vary greatly in softness, elasticity and abrasive grain size. The main ones are:

- Sandpaper. They vary greatly in hardness, graininess and water resistance.

- Soft materials. Serve for polishing and fine finishing.

- Grinding stones. For rough surface treatment and correction of defects.

Grinding stone

The variety of materials and shapes of devices allows you to choose the most suitable one for each specific operation. Thus, a drill attachment coated with diamond powder will allow you to polish surfaces made of the hardest materials, and miniature attachments are suitable for finishing jewelry.

Cutting attachments

Special drill attachments for cutting thin sheet metal, unlike the widely used grinder, make a more accurate cut and practically do not deform the sheet coating. This is especially important when cutting profile sheets for a fence or metal tiles for a roof. In addition, the device allows you to rotate the cutting line at large angles and along a minimum radius, which is simply irreplaceable when constructing a roof of complex shape.

The device is installed on a drill chuck and is driven by the working shaft. To ensure reliable operation of such a device, the rotation speed of the chuck should be from 2800 rpm, power - from 400 watts.

Drill attachments for cutting

Special attachments for cutting metal have the following advantages:

- smooth cutting line, without burrs and notches;

- any configuration of the cut out piece of sheet;

- does not damage the anti-corrosion coating of the sheet;

- ease of use.

Cutting devices can handle ferrous metal up to 1.5 mm thick, non-ferrous metals and plastic up to 2 mm thick.

Material and coating

Soft and hard alloys can be used in production. If you take a soft alloy bit, it will quickly fail. Especially when working with fasteners made of harder materials.

Therefore, if you don’t know how to choose the right bit for your screwdriver, designed for tightening screws and other types of fasteners, start from the following alloys. They are considered the most durable and high quality:

- chromium-molybdenum;

- chrome vanadium;

- vanadium-molybdenum;

- silicon-fire.

If we take ordinary steel bats, then they also have every right to exist. Although the steel itself is less durable than the presented alloys, manufacturers correct this through special coatings.

The following can be used as coatings that increase strength parameters:

- titanium;

- diamond sputtering;

- nickel;

- tungsten-nickel alloy.

If the use of tungsten allows to increase the safety margin, then nickel serves solely for protection against corrosion.

But even when working with soft materials, there is little point in spending money on expensive bits. Such costs are unlikely to be justified. Although the cheapest attachments should also be avoided.

Sanding and polishing attachments

Drill attachments for grinding and polishing allow you to perform a wide range of jobs. The main ones are:

- cleaning parts before painting or welding;

- grinding and leveling surfaces;

- final finishing and polishing of surfaces made of metal, wood, plastic or glass, as well as paint and varnish coatings;

- processing the glass edge after cutting.

They allow you to avoid purchasing expensive specialized equipment. It is worth remembering that with a large volume of work, the drill will not be able to provide the required level of performance and will wear out quickly, since it is not designed for constant loads perpendicular to the axis of the working shaft.

Drill attachments for grinding and polishing

Devices for grinding and polishing differ not only in the shape of the working body, but also in the degree of rigidity of its material by:

- hard;

- soft;

- super soft;

- embossed.

It is impossible to complete the grinding and polishing operation from start to finish with just one device. Your home workshop should have a set of such devices.

Bit classification

Bits are usually classified according to several criteria:

- functional features;

- material of manufacture;

- coating;

- dimensions;

- form.

Depending on the functional features, the bits are divided into 3 groups.

- Basic. Here, only one working side is structurally provided. The most common nozzle option.

- Combined. There are 2 working sides at once. Simply flip the nozzle over to use a different tip. The unused side acts as a shank.

- Special. This is the rarest option. Such bits are aimed at highly specialized types of work. They are sold individually.

As for highly specialized ones, this category usually includes the following varieties:

- for bolts and nuts;

- for drywall;

- anti-vandal;

- professional;

- forks;

- spring and magnetic.

Before moving on to the remaining classification criteria, it is worth separately considering the highly specialized bits presented.

Cup

In a cup nozzle, the working body has the shape of a bowl, on which more or less rigid bristles made of wire or plastic are attached. It is used for cleaning surfaces from rust, solid contaminants, welding slag and remnants of old paintwork.

Cup attachments for drill

There are also soft cup attachments with a working body covered with felt or foam rubber. They are used for polishing painted surfaces.

Using it requires developing a certain skill - when the axis of rotation deviates from the vertical or when the drill is held weakly, the cup has a tendency to move to the side, which can lead to damage to the polished surface or grinding of areas not intended for processing.

General information

The interesting thing is that there are several types of this tool, and each of them brings certain benefits:

- Small Screwdriver – Use together with a miniature electric screwdriver to repair phones, watches and small household appliances.

- Folding devices - such models are used for working in confined spaces that cannot be reached with a regular full-size device. If the handle begins to interfere during the process, you can simply unscrew it.

- A drill-driver is a hybrid design. It is able to combine the best properties for each tool.

The connection strength with a cordless screwdriver is much better than using even the most expensive and high-quality screwdrivers. In addition, now you don’t need to look for hundreds of other tools with the serif you need, since there are many screwdriver attachments. This article will discuss the best of them.

Disc and plate

Disc grinding attachments are similar in design to cup ones, but the wire or plastic bristles in them are directed not forward, but to the sides, in a plane perpendicular to the direction of rotation of the shaft. They must be used with caution, as they can damage the sanded coating.

Disc attachment

The plates consist of an elastic plate, to which it is attached with glue, double-sided tape, Velcro (Velcro), or a circle of sandpaper is clamped in the center. The edge of the plate can be curved, which allows you to bring the sandpaper to the surface at different angles and process hard-to-reach places.

Disc ones allow, among other things, the use of abrasive and cutting discs from angle grinders (grinders). They are attached to the shaft through a centering adapter.

In order not to damage small parts, it is better to secure the drill in the machine and bring the part to the disk, holding it with your hands or clamping pliers.

Fan, petal, drum and end

Fans resemble a lady's fan in shape, have a small disk in the middle, and the sandpaper is attached to it not in a solid piece, but in overlapping petals. This design is capable of significant changes in shape, which makes it possible to process the most inaccessible places, especially cavities and internal surfaces.

Fan nozzle

Drum ones resemble the paddle wheel of a pedal boat and the direction of the petals differs from the fan ones - they are perpendicular to the plane of rotation of the disk. They are used for processing hard materials, most often for grinding the edge of glass after cutting.

In the end type, an abrasive in the form of a cylinder, disk, cone, bowl or other body of rotation is attached to the end of the rod. They work similar to a grinding wheel. The devices are made small in size to make them easier to balance and to be able to get to hard-to-reach places.

Other types of attachments

In addition to the most common grinding and polishing attachments, there are other types of attachments. This is the already mentioned angular one, as well as:

- Sharpening for drills. It has a drill feed mechanism and a sharpening stone inside, and holes for drills of various diameters are provided on the outside.

- Mixer for mortars.

- Feather remover for poultry or wild birds. It is a disk with radial rubber fingers from 5 to 10 cm long. Removes the feather without damaging the skin and meat. Particularly convenient for hunting, fishing and hiking.

- Wood cutters. They allow you to decorate products made of solid wood or MDF with relief patterns, grind grooves, drill holes, including large diameters, and eliminate some defects.

Difficulty of choice

Considering that the devices in question are add-ons for the main equipment, it is better for each tool to purchase an adapter made by the same brand. Although there are universal adapters on the market, professionals advise once again not to expose your screwdriver or drill to the unnecessary risk of working with third-party components. Thus, when purchasing a nozzle, you should pay attention to the following points:

- The adapter must confidently withstand at least 300 rpm;

- The presence of a magnet to capture the bit is mandatory;

- The shank and chuck must be adapted to a minimum bat size of 6 millimeters;

- The chosen adapter brand must have a good reputation (and preferably be the manufacturer of the main tool);

- The accompanying documents (instructions) must accurately and completely describe all technical parameters;

- It is desirable to have a quality certificate confirmed by Russian certifying organizations;

- It is desirable to have various options for fixing the bit/drill;

- Possibility of height adjustment;

- Adjustable screwing or drilling depth.

IMPORTANT! If the angle adapter is selected specifically for a drill, then it will be important to be able to secure it using adapter magnetic rings, which will greatly facilitate fixation in the chuck. This feature will help securely fix the bit, and it will be possible to remove it only by pressing the adapter protrusion.

Technical aspects of choosing screwdriver attachments

First, you need to clearly define consumer needs, that is, what screw-in depth is required, what is the minimum height needed, what is the range of fastener diameters. To determine the last parameter, it is possible to use the following relationships (the data is oriented for working on medium-density metal substrates):

- With the largest fastener diameter of 8 millimeters, the torque should be at least 12 Newtons per meter;

- With the largest fastener diameter of 12 millimeters, the torque should be at least 20 Newtons per meter;

- With the largest fastener diameter of 16 millimeters, the torque should be at least 30 Newtons per meter;

- With the largest fastener diameter of 21 millimeters, the torque must be at least 60 Newtons per meter;

- With a maximum fastener diameter of 50 millimeters, the torque should be at least 180 Newtons per meter.

Also, you need to pay close attention to the way the bit is attached to the nozzle. As a rule, brands known for their quality supply an adapter for these purposes with special magnetic rings installed in the screwdriver chuck. This makes the secure fixation of non-magnetized bits and heads of the screws themselves. The ring is removed by pressing the cross-shaped protrusion located on the adapter body. However, it is better to immediately check the quality of fixation on site before purchasing the product. The thing is that sometimes the fastening may not be very reliable due to the small size of the ring, which is a “payment” for the overall compactness of the adapter.

Homemade drill attachments

In addition to the natural desire to spend less, home craftsmen are often driven by a desire for knowledge and self-expression. A couple of such projects for making devices from scrap materials are given below.

Homemade nozzle based on a car valve

Based on Automotive Valve

A good set can be made based on valves from a car engine. These parts are distinguished by high strength, precision manufacturing and excellent balancing.

The flat surface of the valve should be thoroughly degreased, and the head of the required shape should be secured with glue. Heads can be made from wood, thick rubber or hard foam. On a round sheet of sandpaper, draw a circle with a diameter equal to the diameter of the head, and make cuts from the edge to the intended circle. The central part is glued to the base, and the petals are wrapped on the back side of the head and glued to it or secured with construction brackets.

Simple screw device

If you may not have a car valve at hand, then a long screw, a couple of washers and a nut can be found in any home workshop.

Simple screw device

Sandpaper should be cut into squares and a hole should be made in the center, 4-5 of these squares should be put on the screw and clamped with a nut between the washers.

You will get the simplest attachment for a fan-type drill. The screw is clamped in the chuck, and you can clean hard-to-reach places.

The thread will soon be jammed by the drill chuck, in which case the master takes the next screw from the box.

Polishing device

The previous design is taken as a basis, but a circle cut from felt is clamped between the washers. To ensure better polishing, the felt is rubbed with GOI paste.

Homemade devices cope well with relatively flat surfaces; for surfaces with complex terrain, you will have to use store-bought ones.

DIY polishing device

Criterias of choice

You can turn a drill into a universal tool by purchasing attachments for different purposes. Choosing suitable devices from a huge range is not easy. Therefore, it is recommended to take the following criteria into account.

Manufacturer

Various alloys and polymer materials are used to make nozzles. The material does not always have sufficient strength and wear resistance. High-quality equipment can be purchased, giving preference to well-known brands:

- TUNDRA;

- Dremel

- SKRAB;

- Kolner;

- Sibrtech;

- Caliber;

- Matrix;

- BISON

By purpose including drill and screwdriver

Drill accessories are available in different types. One of the classification features is the purpose of the nozzles.

Drill brush attachments

For grinding . The device is used to make the working surface smooth and presentable. It is made from highly efficient abrasive materials (aluminum oxide, silicon carbide, synthetic diamond). The abrasive is fixed to the base of the equipment by gluing or applying it to a base, which can be either fabric or paper.

For milling . The range of problems solved by this type of device is wide. It includes: work with end edges. High-quality alignment of grooves, etc. By supplementing the tool with equipment with auxiliary supports and attachments, it is possible to obtain from a drill equipment that fully performs the functions of a milling machine.

For polishing . Externally, the device resembles a grinding device. The difference lies in the material used to make the working part of the equipment. These are usually soft fabrics, felt or foam rubber.

HELL DEVICES!!! 35 ATTACHMENTS for DRILL, SCREWDRIVERS and GRINDERS with ALIEXPRESS

For cleaning . Another name for devices is brushes. They are made from wire or other rigid materials. The purpose of the attachment is to remove old coating or rough wood processing. The scope of application is limited to rough work, which is carried out before grinding and polishing.

For cutting . The distinctive qualities of this type are the high price and complexity of the design. The functions of a tool equipped with such an attachment are equivalent to the purpose of a jigsaw. With the help of such a device, it becomes possible to cut wood blanks whose thickness reaches 20 mm. The products are also suitable for cutting some alloys and polymer materials.

For working with self-tapping screws . The simplest type of nozzles. It is used in combination with a tool that can operate at low speeds. Manufacturers produce kits containing equipment with different diameters. This expands the range of applications.

Flexible shaft . The drill device includes a gearbox and an electric motor. They are enclosed in a voluminous housing, which reduces the maneuverability of the instrument. This drawback can be eliminated by installing a flexible shaft. Thanks to this solution, it is possible to penetrate small cavities and other hard-to-reach places. Range of tasks performed using the attachment: grinding, engraving, removing burrs and old coating, milling, drilling, polishing.

Riveter attachment for drill/screwdriver

Rivet nozzle . Special equipment is produced for installing rivets. Purchasing it to perform a small amount of work is considered an unreasonable waste of money. You can beat the situation by equipping the drill with a special riveter attachment. Most often, the equipment is equipped with rivets of different parameters.

Eccentric . This is a practical device that allows you to perform a number of tasks in close proximity to the edge of the workpiece. Processing wood or making holes in hard-to-reach places will become commonplace with minimal labor costs.

Angle attachment for drill

Corner . The purpose of the device is to make holes in areas where a conventional drill cannot penetrate. The design is a body consisting of two parts. They are located at right angles. The drive spindle is located inside. There is also a unit that holds the drill and ensures its rotation.

Design features

Drill attachment for sharpening drills, D 3, 5-10 mm SPARTA

The modern range of attachments is diverse. The products have characteristic design features:

- a certain form;

- options;

- lines and curves.

Plate . The equipment is available in several versions. The constant element is the abrasive surface. The grinding product is made of rubber and plastic. The polishing attachment has a fine-grit sandpaper surface. There are also designs on sale that can adjust the angle of the abrasive fixation rod.

Cupped . Devices of this type are used for removing old paint and other operations involving rough processing of wood. Cup-shaped structures have a characteristic shape, a tightly fixed brush, which is made of abrasive nylon or wire material. The choice of equipment is carried out taking into account the degree of alignment of the working plane.

Drums . They are used primarily for processing the end parts of parts and making holes. Externally, the design resembles a barrel. Its shape is regular cylindrical. The working area of the equipment is covered with sanding tape. Drum products do an excellent job of sanding wood parts. During their rotation, a high-quality passage is carried out along the roundness and holes of the processed material.

End . The designs of this type of nozzles are characterized by external differences and the materials from which they are made. The scope of application of end tooling includes the processing of the internal surface of the part and holes at the initial and final stages of grinding.

Disk . This is a type of cup design. A distinctive quality is the location of the hairs. They are directed in different directions (opposite). This solution allows processing wood blanks in places where it is impossible to penetrate due to the volume of the drill body.

Flap circle for drill, P 80, 80x30x6 mm

Petalaceae . Another name for products of this type is fan. The nozzles have a rod to which a large number of sheets of sandpaper are fixed. Externally, the equipment for going to a flower. The scope of application of the flap design is grinding and polishing with a radius pass of the tool along the working surface. It is advisable to use the tool for accurate processing of parts with complex terrain.

Soft . The products are characterized by minimal abrasion resistance. Used for polishing work. Nozzles are made from foam rubber, leather, felt. The design is characterized by a rounded shape and reliable fixation on the axis.

Number of elements in the set, pcs.

The set may contain a different number of attachments. Each manufacturer completes the equipment at its own discretion, but running positions must be taken into account. The package contains from 2 to 349 devices. Depending on the number of items in the organizer, the price of the set changes.