February 18, 2016 Hand-held power tools, electric-pneumatic tools

When the time comes for a major renovation of an apartment with the replacement of outdated electrical wiring in the house with a more powerful one, designed for a larger number of household appliances, then repairmen cannot do without a special attachment for a hammer drill called a “concrete bit”. It is necessary for drilling large round holes in a concrete wall for internal sockets and switches.

The high strength of concrete and its granular structure require the use of a hammer drill or drill with impact drilling mode. However, a crown drill with an impact drill can also be used against a brick wall. A special attachment, compared to a conventional drill or chisel, greatly facilitates and speeds up the process of producing neat holes with smooth walls.

Characteristics

Crowns for concrete are distinguished by height, outer diameter, type of cutting segments, length of SDS shanks, operating mode and the presence of a centering drill. For design bureaus of large diameters, special equipment is required that ensures the exact position of the hammer drill and the progressive advancement of the cutter into the depth of the concrete or reinforced concrete mass.

The working segments of the bits marked “M” have the property of self-cleaning from concrete dust. Crowns are used to cut out cavities in a monolith of low-strength concrete. Design bureaus of the “T” brand are equipped with hard cutters; they perform drilling at low speeds. The heads are equipped with diamond cutters that easily cope with high-strength concrete.

Design blocks of grade “C” are designed to fit in a monolith of concrete M 200 and M 300. Products of this type are in high demand among the population. Crowns with a diameter of 68 mm and 72 mm are used to cut out seats for hidden electrical wiring fittings.

Voting for the best crown for drilling socket boxes

Which crown would you choose or recommend for drilling socket boxes?

PRACTICE 917-293 162 mm

1.89 % ( 1 )

HILTI SPX-L DIAMOND FOR CONCRETE X-CHANGE 82 MM

7.55 % ( 4 )

Dr. Schulze DS-LB Premium 82 mm

11.32 % ( 6 )

Crown Messer 06-20-082 82 mm

5.66 % ( 3 )

Wolverine 500068 68mm

1.89 % ( 1 )

Bison29865-73 73 mm

9.43 % ( 5 )

d28 KURS

0.00 % ( 0 )

HRD150 42x150 mm, M16 Niborit v1007

1.89 % ( 1 )

Diamond bit (102/150 mm M16) KEOS DC102.150

1.89 % ( 1 )

Crown (68/70 mm M16) KEOS DC068.70

13.21 % ( 7 )

New Formula 68 mm TRIO-DIAMOND NF068

11.32 % ( 6 )

Diamond bit for concrete Hilberg Laser (68 mm) TRIO-DIAMOND

7.55 % ( 4 )

Diamond bit for concrete (80 mm) TRIO-DIAMOND GC788

3.77 % ( 2 )

DIAM 311103 M16-SDS+ (82x70 mm)

9.43 % ( 5 )

Diamond bit for concrete (68x70 mm M16/HEX12) Diam 311116

7.55 % ( 4 )

Device

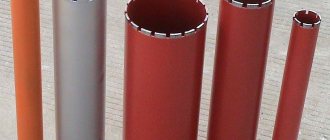

A concrete crown (CB) is a glass made of a high-strength steel alloy, into the bottom hole of which an adapter - a cylindrical rod - is inserted. Its one end is clamped into the hammer drill chuck. On the other side of the shank there is a head into which a centering drill is installed.

Diamond or pobedite segments are soldered along the rim of the sleeve, which simultaneously cut through the concrete in a circle and pierce the mass in depth. The shanks (holders) have grooves for longitudinal movement and rotation of the design unit by the hammer drill chuck. Side holes are made in the glasses to dump crumbled concrete into the sleeve so that debris does not interfere with the sliding of the side surface of the crown in the hole.

Before starting work, the end of the holder entering the chuck must be coated with a special lubricant. If this is not done, the moving metal parts in contact will quickly wear out and become unusable.

Safety precautions at work

When drilling into concrete walls is quite dangerous, it is very important to follow certain safety rules:

- You should not drill into the walls with cutting elements after the plaster has been applied - you can hit a whole bunch of different cables.

- Use an impact drill or a so-called two-handed hammer drill to avoid injury.

- You also need to lean on something when you use special bits; under no circumstances lean on the steps of a wooden ladder, otherwise, due to the inertia force from the hammer drill chuck, it is quite possible to fall and get injured.

- Never press the hammer drills hard against the wall; increase the feed gradually.

- The use of crowns should be preceded by a thorough study of safety regulations.

Remember, the quality of the work performed depends not only on the tools, but also on the professionalism and experience of the workers

It is very important that all work is carried out only by specialists, because there are many nuances in this work

Application

Drilling heads are used to cut out voids in the body of reinforced concrete structures for laying communications (pipes, cables), arranging seats for distribution boxes, switches and sockets.

Crowns are used to drill concrete, brick and stone masonry, both rotary and impact-rotary. During excavation, the walls of the holes do not crumble, and the surface of the concrete fences does not become cracked.

Diamond crowns for concrete do not damage the finishing of walls (ceramic tiles, wood, plastic, etc.). When drilling a hole, a cylinder of monolith remains, which is then knocked out with a hammer drill and chisel in impact mode. This is done carefully, keeping the walls of the recess intact.

Depending on the length of the SDS holders, holes with a depth of 50 mm to 1500 mm are drilled in concrete. To create through passages in adjacent fences, counter-drilling is carried out on both sides.

To prevent overheating of the SDS bit for concrete, the massif is sampled by supplying a stream of water to the drilling zone. At home, the head is periodically moistened with water from a garden spray bottle.

Depending on the diameter, core drills are used for laying communications in reinforced concrete structures of a certain cross-section. Thus, 72 mm concrete drill bits are used to install seats for electrical wiring distribution units. Plastic boxes are inserted into the drilled recesses into which the ends of the wires are brought out.

100 mm concrete crowns are used to create openings into which ventilation pipes are led, diverting air flows from boilers and other heating equipment to the outside. They also have pipelines for air intake from outside.

150 mm crowns are most often suitable for laying sewer pipes. They are used to drill both walls and floor slabs, which is convenient for installing drain lines. Core drills of large diameters (300 mm - 800 mm) are used for wiring special communications in structures and industrial buildings.

Recommendations

When making holes in concrete, remember some subtleties:

- Make sure that the template, structure and tool are tightly secured.

- Start at low speed and gradually increase speed.

- Do not press too hard on the instrument to avoid damaging it.

- When drilling concrete, give preference to a wet cut.

To make a smooth, neat hole, you need high-quality attachments. In the Strong Tools online store you can choose equipment to solve any construction problem. The online store offers a large selection of cutters of various diameters.

To order, call and fill out an application. Consultants will select a quality product for the client and discuss with him the method of payment and delivery.

Features and types of crowns for concrete

Crowns with pobedite incisors

Concrete drill bits ø 68 mm with carbide segments are used for arranging seats for socket boxes, transfer boxes and switches in apartments, private houses, administrative and public buildings.

The disadvantage of Pobedit concrete crowns for sockets is failure upon contact with reinforcement. The cutters cannot withstand the hardness of the reinforcing steel and fly out of their places. CBs with pobedit segments are also manufactured with a diameter from 35 mm to 120 mm.

Diamond bits for concrete

Cutters are not actually natural diamonds. The name refers to the structure of the segments. They are made from a special mixture of diamond dust and metal powder by cold pressing under high pressure.

Diamond bits for concrete ø 50 mm, 68 mm and 120 mm are used for drilling holes in the enclosing structures of buildings for domestic and general civil purposes. In the construction of industrial facilities, holes with a diameter of up to 800 mm are drilled with crowns.

The main advantage of diamond bits is their passage through metal reinforcement, which is important when working with fences saturated with metal.

Crowns with tungsten carbide coating

The serrated end surface with tungsten carbide coating makes the heads universal in application. They cut holes in tiles and ceramics and then pass through the concrete mass. This saves time by not having to change the cutting head.

However, crowns of this type cannot withstand contact with metal reinforcement.

The three most popular types of concrete crowns

Among the wide range of design bureaus, three types of the most popular hammer drill accessories should be highlighted. These are concrete crowns: Distar, SDS and Zubr.

KB Distar

Distar produces high quality diamond tools. The company is the largest European manufacturer of crowns with diamond cutters. Diamond-coated heads occupy leading positions in various ratings.

Drill glasses with diamond segments 450 – 500 mm long are especially valued. SDS adapters allow you to adapt the tool to almost all types of rotary hammers.

SDS crowns for concrete

Design bureaus are associated with holder designs. These are models SDS, SDS-plus and SDS-max. A standard adapter with a diameter of 10 mm has two longitudinal grooves. Plus shanks have 4 grooves. Two grooves fix the device in the hammer drill chuck, and the other two perform a guiding function. The length of the shank can reach 1 meter.

Max adapters with a diameter of 18 mm are equipped with 5 grooves. 3 grooves guide the drilling head, and the remaining 2 longitudinal grooves act as clamps. Recently, SDS top and quick shanks have appeared on the power tool market. This is a new product from Bosch, which is compatible only with rotary hammers of the same name.

Concrete crown Bison

Zubr concrete crowns have gained a strong leading position in the Russian market. Domestic design bureaus largely owe their popularity to affordable prices for this type of product. The leading Russian manufacturer of power tools, the Zubr company, has established itself as a manufacturer of high-quality concrete drill bits.

Drilling tools on the Russian market are represented by a wide range. These are SDS plus and max holders, drill glasses with carbide cutters of the VK8S brand, bimetallic products with a progressive arrangement of teeth and much more.

KB Zubr with a diameter from 50 mm to 150 mm and a length from 70 mm to 120 mm are equipped with shanks with centering drills. SDS plus and max adapters with a length of 600 – 800 mm are suitable for all products.

TOP 16 best diamond crowns for socket boxes

| Photo | Name | Rating | Price | |||

| The best diamond crowns for premium socket boxes | ||||||

| #1 | PRACTICE 917-293 162 mm | ⭐ 5 / 5 1 - voice | Find out the price | |||

| #2 | HILTI SPX-L DIAMOND FOR CONCRETE X-CHANGE 82 MM | ⭐ 4.95 / 5 4 - votes | Find out the price | |||

| #3 | Dr. Schulze DS-LB Premium 82 mm | ⭐ 4.9 / 5 6 — votes | Find out the price | |||

| #4 | Crown Messer 06-20-082 82 mm | ⭐ 4.85 / 5 3 - votes | Find out the price | |||

| The best budget diamond drill bits for socket boxes | ||||||

| #1 | Wolverine 500068 68mm | ⭐ 5 / 5 1 - voice | Find out the price | |||

| #2 | Bison29865-73 73 mm | ⭐ 4.95 / 5 5 — votes | Find out the price | |||

| #3 | d28 KURS | ⭐ 4.9 / 5 | Find out the price | |||

| #4 | HRD150 42x150 mm, M16 Niborit v1007 | ⭐ 4.85 / 5 1 - voice | Find out the price | |||

| The best diamond bits for socket boxes in terms of performance | ||||||

| #1 | Diamond bit (102/150 mm M16) KEOS DC102.150 | ⭐ 5 / 5 1 - voice | Find out the price | |||

| #2 | Crown (68/70 mm M16) KEOS DC068.70 | ⭐ 4.95 / 5 7 — votes | Find out the price | |||

| #3 | New Formula 68 mm TRIO-DIAMOND NF068 | ⭐ 4.9 / 5 6 — votes | Find out the price | |||

| #4 | Diamond bit for concrete Hilberg Laser (68 mm) TRIO-DIAMOND | ⭐ 4.85 / 5 4 - votes | Find out the price | |||

| #5 | Diamond bit for concrete (80 mm) TRIO-DIAMOND GC788 | ⭐ 4.8 / 5 2 - votes | Find out the price | |||

| #6 | DIAM 311103 M16-SDS+ (82x70 mm) | ⭐ 4.75 / 5 5 — votes | Find out the price | |||

| #7 | Diamond bit for concrete (68x70 mm M16/HEX12) Diam 311116 | ⭐ 4.7 / 5 4 - votes | Find out the price | |||

| #8 | Diamond bit (68 mm SDSplus/M16) Enkor 48280 | ⭐ 4.65 / 5 3 - votes | Find out the price | |||

Which crown would you choose or recommend for drilling socket boxes?

Take the survey