The bolt dimensions are determined by simply measuring all fastener parameters. True, there may be some features that need to be taken into account when choosing a product. It would seem that this does not require special knowledge and experience, it is enough to know the diameter and length of the thread, but this is not entirely true. The choice of fastener must be made taking into account all the parameters and technical characteristics of the product. The bolt dimensions are determined by measuring the main parameters of the fastener. These include diameter, bolt thickness and length. Sometimes such a parameter as height is used. The sizes are designated by letters of the Latin alphabet and mean the following:

- D – diameter (diameter), can be denoted by a capital or small letter d;

- L – bolt length (length);

- S – hardware thickness (stoutness);

- H – bolt height (high), used when it is necessary to indicate the full height of the product.

It is possible to use other parameters that can clarify and expand the use of these products.

TEST METHODS

4.1. Inspection and verification of the dimensions of bolts and nuts is carried out in accordance with GOST 1759-70, and washers - in accordance with GOST 6960-68.

4.2. The straightness of the bolt shaft is checked for inclusion in the control matrix with a hole, the diameter of which must correspond to the diameter of the through hole of the first row according to GOST 11284-65 with a hole length of 100 mm.

4.3. Tensile testing of bolts is carried out with nuts screwed onto them using a tensile testing machine. The rupture must occur in the rod, without tearing off the head, with a temporary tensile strength within the limits specified in the table. 5.

How to measure the diameter of a fitting?

The main tool for measuring threads is a caliper. It is very convenient to use the Columbus electronic boom (also known as Columbia) with a depth gauge - its jaws for internal diameters are made in such a way that the size on the scale does not have to be recalculated taking into account the width of the jaws.

Interesting materials:

How to start a Husqvarna chainsaw correctly? How to start the FS 55 correctly? How to start the Huter trimmer correctly? How to properly tighten the cable? How to properly water the soil with potassium permanganate? How to properly grill shish kebab on ready-made coals? How to properly fry in a tandoor? How to terminate an easement? How is maternity capital divided during a divorce? How did you come up with polyurethane foam?

Measuring with a thread gauge

Accurately identifying the threads on a fastener is critical before selecting and installing the correct fittings.

How to measure thread:

- Use a combination caliper to measure the thread diameter. It is worth taking into account that the threads of the used fitting may wear out and become distorted, so calculations may not be accurate.

- Use a thread gauge to determine the number of threads per inch. For metric connections, the distance between the threads is calculated. To do this, you need to place the device on the thread until it fits snugly, and then compare your measurements with the thread diagram.

- If the port is located at an angle, determine the angle of inclination using a protractor on the sealing surface. The center line of the fitting and gauge should be parallel.

Using a combination of three tools, identifying connectors is easy. The use of a caliper, thread gauge and protractor allows accurate measurements of most connections.

A caliper is used to measure the diameter of an external internal thread. When comparing calibration measurements to thread diagrams, keep in mind that threads on connections that have been in service may be worn and distorted from use. This results in inaccurate comparisons with thread tables.

For English, British and other European threads, the pitch meter has an inch scale. However, for metric parts, the device will determine the distance between threads in millimeters.

The protractor is used by placing it on the sealing surface. The center line of the fitting end and gauge should be parallel. In English, the thread size system and pitch (number of threads per inch) are specified along with the thread type.

When using a thread gauge, you need to align it with the threads and make sure that it fits snugly. Match the measurement to the thread, then calculate the diameter using a caliper.

How to measure a nut

Most nuts have metric threads. Measuring the thread diameter will require a little more steps than in other cases. If possible, it is recommended to check the size of the bolt or screw used for it rather than the nut itself. This way you can achieve a more accurate result.

The value obtained after measuring the internal thread is an indicator of the internal diameter din.

In order to accurately determine the diameter of the metric thread of the hardware, you will need to find out the correspondence between din and the outer diameter of the bolt used. This is done using a special table.

Accuracy is controlled through the use of certain pass-fail gauges. One part should connect well with the nut, the second part, on the contrary, should not.

The nuts differ in appearance, and it is easy to determine upon detailed inspection. To find out the standard of the fastener, you may need to measure the height of the hardware, since there are high, low, extra high and other options.

Turnkey dimensions are also used to classify hex nuts. This is explained by the fact that hardware also differs in its types.

To accurately measure the thread pitch, it is possible to use the method considered in the case of a bolt. You will need a thread gauge or you will have to count the number of turns at the required interval.

Determining the dimensions of inch nuts

To check the thread dimensions of an inch nut, you need to examine the threads of the bolt or other hardware used with it. If you don’t have a suitable one at hand, but have information about the presence of an inch thread, then use the appropriate thread gauge. Do not forget to divide the resulting value by 25.4 mm.

Determining washer dimensions

For washers, a short designation in the form D is used, which stands for the diameter of the metric thread of the hardware used for the fastener.

To accurately measure indicators, a ruler or caliper is suitable. The result is a value that is slightly higher than the figure in the notation. This is explained by the fact that free movement is required during installation, which requires a small gap.

Measuring screws

Screws with metric threads are designated in the documentation similarly to bolts in the MDxPxL , where:

- M - metric thread icon;

- D —screw thread diameter in millimeters;

- P - thread pitch in millimeters (there are large, small and especially small pitches; if the pitch is large for a given thread diameter, then it is not indicated);

- L is the length of the screw in millimeters;

First, by inspection we establish the type of screw being measured, determine its standard in order to determine the features of the measurement.

The thread diameter of the screws is determined similarly to the measurement of bolts.

Depending on the geometric configuration of the screw, the method for measuring its length may differ, and all screws can be divided into 4 groups:

- screws with a protruding head (in Fig. 1, 2, 6);

- screws with a countersunk head (in Fig. 4);

- semi-countersunk screws (in Fig. 3);

- screws without a head (in Fig. 5).

• Screws with cylindrical head and internal hexagon GOST 11738-84 ; • Screws with cylindrical head GOST 1491-80 .

• Round head screws GOST 17473-80 .

• Screws with semi-countersunk head GOST 17474-80 .

• Countersunk head screws GOST 17475-80 .

• Set screws with straight slot GOST 1476-93, 1477-93, 1478-93, 1479-93 ; • Set screws with hexagonal socket for wrench GOST 8878-93, 11074-93, 11075-93 .

• Set screws with square head GOST 1482-84, 1485-84 .

Round Head Bolts

Such an extraordinary fastening, like a bolt with a semicircular head, was not invented in vain. There are industries that simply cannot do without this product. Let's learn about the mechanism in more detail, and finally find out the scope of its application and the advisability of using it in repair work. More on all this below!

Let's find out how a bolt with a semicircular head works

In this case, we can say with confidence that the technical name fully corresponds to the appearance of such fasteners: a semicircular head without edges and slots for a screwdriver or an internal multi-faceted key. And this design was made for a reason, but with a certain intent, one might even say, for ease of use. First of all, such fasteners were intended for use in everyday life, where in the future, human contact with the protruding bolt head could lead to injury or undesirable consequences.

The semicircular head reduces the risk of injury to a minimum and is considered absolutely safe. After all, the mounted device fits tightly to the surface of the base, leaving only a smooth surface of the cap. Also, such a bolt has a special fixing device called a “header”. This design is located under the fastener head, usually made in a rectangular shape. This design makes it easier to install the fastener in place; the “head” should fit tightly into the material and not allow the fastener to turn when tightening the nut.

This design is designed for use in soft materials, but it can also be used in hard ones. Well, the main part of this fastener is a stud with a metric thread, onto which, accordingly, a nut of the required diameter is screwed, and the fastener is mounted at the destination. But the question naturally arises: where is it still advisable to use such a bolt? As we have already said, in places where we want to protect ourselves from injury and protect ourselves from protruding parts of fasteners.

For example, in places with high traffic of people, in large enterprises, we can see such fastening on the floor, where communications pass. After all, very often, while walking, the protruding shaped caps of the fastenings can simply cling to the shoes. Various flange connections use such fasteners in order to minimize the possibility of personal injury.

Information: it is worth noting that the fastener itself is just a bolt, and for installation it requires additional elements, such as a nut and washer, which are usually purchased separately at any hardware store.

Specifics of furniture bolts - for chairs, sofas and tables

As for places with high traffic, everything is clear here, but it turns out that you simply cannot do without such fasteners in everyday life. It is fully used as a fastener in furniture production. Almost any chair or sofa cannot do without such a universal fastener. Due to the fact that soft material is used on the chair, the head of such a bolt is simply hidden in the upholstery and is not visible at all.

Look: the side wooden backs of the sofa are held firmly to the base only due to the fact that they are secured using furniture bolts with a semicircular head. At the same time, the hats fit tightly to the varnished wooden surface and in everyday conditions are not capable of causing you any inconvenience, not to mention the fact that you cannot get injured by them. Moreover, this fastening fits organically into the design of such a sofa without disturbing its appearance.

Selection of inch wrenches

The size of an inch wrench is expressed in inches and does not indicate the width of the wrench, but the diameter of the thread of the inch fastener it is designed to work with. The hexagonal working profile of inch bolts and nuts differs in size from the metric standard profile by fractions of millimeters. Therefore, metric wrenches will either not fit tightly onto the edges of inch fasteners, or will not fit at all. To work with it you need inch keys and socket heads.

Table 2. UNC/UNF Threads and Wrench Nut Sizes.

| Thread diameter (key size), inch | Wrench nut size, inch | Wrench nut size, mm |

| 1/4 | 7/16 | 11.11 |

| 5/16 | 1/2 | 12.7 |

| 3/8 | 9/16 | 14.29 |

| 7/16 | 5/8 | 15.88 |

| 1/2 | 3/4 | 19.05 |

| 9/16 | 13/16 | 20.63 |

| 5/8 | 15/16 | 23.81 |

| 3/4 | 1 1/8 | 28.58 |

| 7/8 | 1 5/16 | 33.34 |

| 1 | 1 1/2 | 38.10 |

| 1 1/8 | 1 11/16 | 42.86 |

| 1 1/4 | 1 7/8 | 47.63 |

| 1 3/8 | 2 1/16 | 52.39 |

| 1 1/2 | 2 1/4 | 53.15 |

| 1 3/4 | 2 5/8 | 66.68 |

| 2 | 3 | 76.20 |

| 2 1/4 | 3 3/8 | 85.73 |

| 2 1/2 | 3 3/4 | 95.25 |

| 2 3/4 | 4 1/8 | 104.76 |

| 3 | 4 1/2 | 114.30 |

How to distinguish metric from inch fasteners?

First of all, you need to make sure that your foreign fasteners are inch.

It is difficult to distinguish it from a metric one “by eye” and there is a risk of mistaking, for example, a 5/16″ UNC bolt for M8, which is similar in parameters. A metric thread gauge will help identify inconsistencies - none of its templates will fit an inch thread. In the absence of such an identifier, you can use a more accessible method - try to screw a nut with known parameters onto the rod. If you have to frequently identify threads, we recommend purchasing thread gauges.

In fact, finding the differences between inch and metric fasteners can be even easier. If there are radial lines

– this is “American”, and if there

are numbers on the head

– it is a metric. Lines and numbers are markings of strength. However, it is worth noting that fasteners of strength class from 0 to 2 are not marked at all, so this method is not always acceptable.

Measuring rivets

Rivets with a closing head - solid (hammer type) are indicated in the documentation in DxL , where:

- D is the diameter of the rivet body in millimeters;

- L is the length of the rivet in millimeters;

Depending on the GOST standard and the configuration of a solid rivet, the method for measuring its length may differ, and all rivets can be divided into 3 groups:

- rivets with a protruding head (in Fig. 1, 3);

- rivets with a countersunk head (in Fig. 2);

- rivets with semi-countersunk (in Fig. 4);

• Rivets with a flat (cylindrical) head GOST 10303-80 ;

• Rivets with countersunk head GOST 10300-80 ;

• Rivets with a semicircular head GOST 10299-80 ;

• Rivets with semi-countersunk head GOST 10301-80 ;

Tear rivets installed using a special gun are designated in DxL , where:

- D is the outer diameter of the body of the rivet itself in millimeters;

- L is the length of the rivet body in millimeters, excluding tear-off elements.

• Rivets with a flat (cylindrical) head DIN 7337, ISO 15977, ISO 15979, ISO 15981, ISO 15983, ISO 16582;

• Tear-off rivets with countersunk head DIN 7337, ISO 15978, ISO 15980, ISO 15984;

How to Determine Screw Size

The instructions, to a greater extent, concern the determination of the sizes of metric bolts, screws and studs (hereinafter simply bolt). The fundamental dimensional characteristics of a bolt are diameter, thread pitch and length.

Bolt diameter

The exact diameter of a bolt, like any other object, is measured with a caliper or micrometer. However, there are situations when special measuring instruments are not at hand. In this case, you can measure the outer diameter of the bolt using a measuring tape.

Wrap the measure around the bolt shaft one turn and mark the connection point on the scale. This is how we found out the circumference of the bolt. We reduce the result by 1-2 mm to eliminate the influence of the thickness of the measure on the calculations.

Knowing the circumference, we can easily calculate the diameter using a simple geometric formula. To do this, divide the circumference by Pi, equal to 3.14. Since most car bolts have standard diameters, even taking into account errors in measurements, the result will be close to standard sizes. Standard diameters of bolts used in cars: 5, 6, 7, 8, 10, 12, 14, 16, etc.

It is fair to note that this method is not suitable for measurements where special accuracy is required. For example, the driven part of a wheel stud, where every tenth of a millimeter is important, is measured only with a caliper or micrometer.

Bolt thread pitch

Another important bolt parameter is the thread pitch. Thread pitch is the distance between two adjacent turns. The thread pitch is measured by a pedometer. However, just like a caliper, there may not be a pedometer. Then calculate the distance between the turns using a ruler

To do this, count 15-20 thread turns (the more turns, the more accurate the result) and measure the distance between the outer turns with a ruler. By dividing the length of the counted turns by the number of turns, we obtain the distance between the turns, i.e. the thread pitch.

The thread pitch of a car bolt is a standardized value and is closely related to the diameter. Knowing the bolt diameter and the calculated thread pitch, we can easily determine the exact thread pitch using the following table.

| Diameter, mm | Thread pitch, mm | Thread type | Tips for car brands | ||

| M6 M7 | 1.00 | standard | |||

| M8 | 1.25 | standard | |||

| 1.00 | small | ||||

| M10 | 1.50 | standard | VW, Audi, Skoda, Seat, Mercedes, BMW, Opel | ||

| 1.25 | small | Lada, Fiat, Alfa Romeo, Peugeot, Citroen, Renault, Toyota, Honda, Nissan, Mazda and other Japanese brands | 1.00 | small | |

| M12 | 1.75 | standard | Ford, Renault, Peugeot, Citroen | ||

| 1.50 | small | VW, Audi, Skoda, Seat, Mercedes, BMW, Opel | 1.25 | small | Lada, Fiat. Alfa Romeo, Peugeot, Citroen, Renault, Toyota, Honda, Nissan, Mazda and other Japanese brands |

| M14 M16 | 2.00 | standard | Ford, Chrisler | ||

| 1.50 | small | Most car brands | |||

| M18 M20 M24 | 2.50 | standard | |||

| 1.50 | small |

Wrench sizes

Today, there are universal wrench options that are great for working with different nut diameters. However, cases are different, and the need to select a tool cannot be ruled out. Several options are offered:

- Thread diameter. There is nothing complicated in this case. You can use special devices and tools that allow you to determine the parameters. Or, as an option, look at the information of interest in the technical documentation. Note that if the fastener has a standard thread diameter, then 2 sizes are offered, namely normal and reduced. However, this option is quite rare.

- Head diameter. Depending on the size, the distance of the edges will change: this is what needs to be determined. A ruler is suitable for this. If everything is done correctly, the bolt head will clearly fit into the selected wrench. Of course, it is not always possible to accurately measure a parameter with a ruler, so it would be better to use a caliper.

- Bolt length. The height of the head is not taken into account, only the shaft is considered. If an M16 bolt is required, the thread diameter dimensions should be 16 mm. The marking may also indicate other information: it shows the nominal height of the head, the thread pitch. If you have a car bolt with a pointed tip, then you need to calculate its length taking into account the guide.

GOST and the need for unification

For a long time, manufacturers performed theoretical calculations of thread pitch using their own methods and manufactured fasteners using their own technologies. With this approach, connectors from different brands often turned out to be incompatible or did not provide suitable joint quality, which often caused problems for users.

Particular difficulties arose during the assembly of machines, apparatus and other component equipment. Literally each element had to be marked separately so that later it could be placed correctly. Banal preventive cleaning of tools or machines, parts of which were supplied by two or more factories, turned into real torture.

Therefore, from the beginning of the 20th century, the issue of standardization became seriously concerned. The matter was approached with the utmost seriousness, taking into account even the experience of the 12th century, or rather the practice-tested formula stating that the distance between adjacent turns should be equal to 20% of the diameter of the rod. Naturally, they took into account that in those distant times the fasteners were made of wood, and only 20 years later they began to tighten the most loaded points with studs and protect them with nuts machined from a single piece of especially strong rock. Today, completely different materials are relevant, which have completely different requirements.

Food for thought

The first path to standardization began to be paved precisely in Russia: at the Tula plant they began to work according to Nikita Demidov’s drawings, and check the results using the calibers he proposed. This made it possible to control the accuracy of casting and execution of individual parts.

Yes, the famous industrialist did not think specifically about the thread pitch (how to measure it or find the optimal one), but sought to unify production as a whole. And he achieved his goal: in 1787, a commission under the tsarist army purchased 500 domestic guns and the same number of English ones. The inspectors disassembled each of them, arranged the elements according to their functional purpose and thoroughly mixed each group, after which they tried to assemble it. In the case of the Russian models, this was possible - even though they required grinding in, they eventually passed the zeroing - but the pride of the British craftsmen remained a pile of useless iron.

This was the impetus for the following events:

Each regiment created a platoon responsible for servicing weapons, and it regularly received consumables marked with notches to replace small items that had failed.

In France, in 1790, they approved the first pan-European basic system of measures, adopting m and its “derivatives” – cm and mm – as a unit of length, which is still used today; England, by the way, remained with its inches and feet.

In the USSR, the first GOST for the compounds in question was introduced in 1924.

Material of manufacture

The technology for producing bolts characterized by strength class 6.8 is the so-called. volumetric stamping using upsetting presses. High-quality carbon structural steel, mainly grades St.35 and St.45, is used as raw material. The following properties of this material contribute to this choice:

- the value of the HB index (Brinell hardness) ranges from 181 to 238 units;

- the yield strength is 480 MPa;

- ultimate strength – 600 MPa.

The use of steels of other grades is allowed. Instead of

- Article 35 – Article 30, Article 40 and Article 35g;

- Art.45 – Art.50G2, Art.40X.

What is the difference between domestic hardware and other manufacturers?

In European countries, durable fasteners are designated HV. High strength products are used mainly when working with metal structures and bridge areas. The regulations of EN and DIN countries provide for a “set set”. The set is filled with bolts, washers and nuts. Mandatory adherence to important rules: parts from the same brand. Mixing fasteners from different manufacturers is prohibited.

The domestic selection of fasteners is called bolt sets and does not require a set from one manufacturer. Our rules for durable products are based on ISO standards, which were adopted in 1984. All German documentation today was introduced in 2006. There are differences in them compared to modern standards.

When considering the mechanical properties of fasteners, you can find some discrepancies in the characteristics:

1. Relative narrowing.

3. Difference in strength limits.

4. Different hardness.

5. When comparing our rules with European standards, it can be noted that our yield limit is not fixed, but European standards oblige them.

Design and Application

The bolt, characterized by strength class 6.8, manufactured in accordance with the requirements of GOSTs 7805, 7798 and DIN 933, 931 standards, is a cylindrical rod. It consists of a section with a thread and a segment with a smooth one. This may be followed by a small headrest, and the whole structure is completed by a hexagonal head.

The scope of application of bolts with strength class 6.8 are those objects for which the integrity of the formed connection is an important factor, even under significant vibration-type impacts and when the parts being fastened are significantly deformed. In particular, these are shipbuilding and railcar building, the mechanical engineering industry, as well as the nuclear industry.

Bolt materials GOST 7798 70

They are manufactured with average accuracy class B, which has a slight deviation in thread dimensions and tolerances, and is also less expensive to manufacture.

Bolts are made from various materials:

- carbon steel;

- stainless steel;

- non-ferrous alloys;

- polyamide.

For use in aggressive environments, bolts are made of stainless and acid-resistant steels. The difference is that an aggressive environment, unlike moisture, quickly destroys the protective coating, and the metal of the bolt even faster. Hardware made of non-ferrous metals is used in specific operating conditions or devices. They have antimagnetic properties and are not subject to corrosion.

Bolts are available in different strengths from 5.6 to 10.9, which is indicated on the head. High strength is not always the best option for a threaded connection. Specifications require that the strength of the bolt be slightly lower than the strength of the threaded hole or nut with which it is used. For example, if a nut has a strength class of 9, then the bolt must correspond to a strength class of 8.8.

Protective coatings for bolts GOST 7798 70

Coatings are applied for the sole purpose of maintaining the geometry of the bolt for as long as possible and maximizing its service life. The durability and functionality of the bolt will depend on how high-quality the protective coating is.

Factors influencing the formation of rust, which destroys the metal, disrupting the profile of the thread and head, rendering the bolt unusable:

- atmospheric influence;

- high humidity;

- temperature changes.

Hardware, which is made of ordinary carbon steel, is produced with an anti-corrosion coating. The most common coatings are:

- zinc;

- cadmium;

- oxide;

- phosphate;

- tin;

- copper;

- zinc;

- silver;

- Nickel

If a bolt is corroded while in a threaded connection, it will be very difficult to unscrew it during repair or replacement. The threads of the bolt stick to the threads of the nut or hole, and the head loses its hexagonal shape, which makes it difficult to grip with a wrench.

Zinc protective coating is simple and inexpensive to manufacture, and therefore has become the most common for a variety of hardware. Zinc coatings differ slightly in the method and method of application. The most common ones are:

- galvanic galvanization;

- thermal diffusion galvanizing;

- hot galvanizing.

Zinc coating can be of two colors: white and yellow. The color of the coating does not affect the quality and durability in any way and depends on the method of applying zinc.

In the manufacturing industry, bolts with protective coatings are widely used:

- oxide impregnated with oil;

- phosphate impregnated with oil.

They are mainly used for assembling machines, components, assemblies and are easy to distinguish by their appearance, as they are characteristic black in color. Due to this, no additional metal is applied to the bolt; they are cheaper than galvanized ones, but less resistant to moisture.

The standard allows the manufacture of bolts without any coatings (as is). They are significantly cheaper, but can only be installed in areas where there is no exposure to moisture or the parts will eventually be painted.

Buy bolt GOST 7798 70

The online store website has a large selection of GOST 7798 70 bolts

. Here you can choose bolts of any strength, both coated and uncoated. If required, you can purchase bolts of the same size, but in different designs. The company's warehouses have a sufficient number of finished products to instantly satisfy even large wholesale orders.

Choosing the correct wrench size for the bolt

The ideal material for making keys is tool steel, which is based on high-carbon alloys. Products are obtained from blanks by processing on milling machines followed by burnishing. But such an instrument is considered rare and is not cheap. More often on sale you can find simpler keys, made in line production by casting or stamping.

Depending on the size of the gap between the jaws, wrenches are conventionally divided into three groups:

- Small ones are intended for unscrewing and screwing fastening devices with dimensions up to 10-12 mm.

- The middle group includes instruments with sizes ranging from 12 mm to 22 mm.

- Large devices are considered to be devices for bolts and nuts with a diameter of 22 mm and above.

In order not to make a mistake when choosing a tool, you can use ready-made data from standard tables. For example, from this one:

| WRENCH SELECTION TABLE | |||||||||

| METRIC PROFILE | UNF/UNC PROFILE | ||||||||

| Thread size | A/F key size | Opening key | Thread size | A/F key size | Opening key | ||||

| (mm) | min (mm) | max (mm) | (inch) | min (inch) | max (inch) | ||||

| M 1.6 | 3.2 | 3.22 | 3.28 | 1/4 | 7/16 | 11.18 | 11.33 | ||

| M 2.0 | 4.0 | 4.02 | 4.12 | 5/16 | 1/2 | 12.80 | 12.95 | ||

| M 2.5 | 5.0 | 5.02 | 5.12 | 3/8 | 9/16 | 14.38 | 14.55 | ||

| M 3.0 | 5.5 | 5.52 | 5.62 | 7/16 | 5/8 | 15.98 | 16.15 | ||

| M 4.0 | 7.0 | 7.03 | 7.15 | 1/2 | 3/4 | 19.18 | 19.38 | ||

| M 5.0 | 8.0 | 8.03 | 8.15 | 9/16 | 13/18 | 20.78 | 20.98 | ||

| M 6.0 | 10.0 | 10.04 | 10.19 | 5/8 | 15/16 | 23.98 | 24.21 | ||

| M 7.0 | 11.0 | 11.04 | 11.19 | 3/4 | 1 1/8 | 28 75 | 29 01 | ||

| M 8.0 | 13.0 | 13.04 | 13.24 | 7/8 | 1 5/16 | 33.53 | 33.81 | ||

| M10.0 | 17.0 | 17.05 | 17.30 | 1 | 1 1/2 | 38.30 | 38.61 | ||

| M 12.0 | 19.0 | 19.06 | 19.36 | 1 1/8 | 1 11/16 | 43.08 | 43.38 | ||

| M 14.0 | 22.0 | 22.06 | 22.36 | 1 1/4 | 1 7/8 | 47.88 | 48.21 | ||

| M 16.0 | 24.0 | 24.06 | 24.36 | 1 3/8 | 2 1/16 | 52.68 | 53.04 | ||

| M 18.0 | 27.0 | 27.08 | 27.48 | 1 1/2 | 2 1/4 | 57.45 | 57.84 | ||

| M 20.0 | 30.0 | 30.08 | 30.48 | 1 3/4 | 2 5/8 | 67.03 | 67.46 | ||

| M 22.0 | 32.0 | 32.08 | 32.48 | 2 | 3 | 76.61 | 77.09 | ||

| M 24.0 | 36.0 | 36.10 | 36.60 | 2 1/4 | 3 3/8 | 86.18 | 86.72 | ||

| M 27.0 | 41.0 | 41.10 | 41.60 | 2 1/2 | 3 3/4 | 95 76 | 96 34 | ||

| M 30.0 | 46 0 | 46 10 | 46 60 | 2 3/4 | 4 1/8 | 105.33 | 105.97 | ||

| M 33.0 | 50.0 | 50.10 | 50.60 | 3 | 4 1/2 | 114.91 | 115.57 | ||

| M 36.0 | 55.0 | 55.12 | 55.72 | BS (Whitworth standard) | |||||

| M 39.0 | 60.0 | 60.12 | 60.72 | BS thread size | A/F key size | The closest correct A/F key size | |||

| M 42.0 | 65.0 | 65.12 | 65.72 | ||||||

| M 45.0 | 70.0 | 70.12 | 70.72 | C | (inch) | (mm) | (inch) | (mm) | |

| M 48.0 | 75.0 | 75.15 | 75.85 | 1/4 | 3/16 W | .445 | 11.30 | 7/16 | 12 |

| M 52.0 | 80.0 | 80.15 | 80.85 | 5/16 | 1/4 W | .525 | 13.33 | 17/32 | 14 |

| M 56.0 | 85.0 | 85.15 | 85.85 | 3/8 | 5/16 W | .600 | 15.24 | 19/32 | 16 |

| M 60.0 | 90.0 | 90.15 | 90.85 | 7/16 | 3/8W | .710 | 18.03 | 23/32 | 18 |

| M 64.0 | 95.0 | 95.15 | 95.85 | 1/2 | 7/16 W | .820 | 20.83 | 13/16 | 21 |

| M 68.0 | 100.0 | 100.15 | 100.85 | 9/16 | 1/2 W | .920 | 23.37 | 15/16 | 24 |

| M 72.0 | 105.0 | 105.20 | 106.00 | 5/8 | 9/16 W | 1.010 | 25.65 | 1 | 26 |

| M 76.0 | 110.0 | 110.20 | 111.00 | 3/4 | 11/16W | 1.200 | 30.48 | 1 1/4 | 31 |

| M 80.0 | 115.0 | 115.20 | 116.00 | 7/8 | 3/4 W | 1.300 | 33.02 | 1 5/16 | 33 |

| M 85.0 | 120.0 | 120.20 | 121.00 | 1 | 7/8 W | 1.480 | 33.02 | 1 1/4 | 38 |

| M 90.0 | 130.0 | 130.20 | 131.00 | 1 1/8 | 1 W | 1.670 | 42.42 | 1 11/16 | 43 |

| M 95.0 | 135.0 | 135.20 | 136.00 | 1 1/4 | 1 1/8 W | 1.860 | 47.24 | 1 7/8 | 48 |

| M 100.0 | 145.0 | 145.20 | 146.00 | 1 3/8 | 1 1/4 W | 2.050 | 52.07 | 2 1/16 | 52 |

| M 105.0 | 150.0 | 150.25 | 151.25 | 1 1/2 | 1 3/8 W | 2 220 | 56 39 | 2 1/4 | 57 |

| M 110.0 | 155.0 | 155.25 | 156.25 | 1 3/4 | 1 5/8 W | 2.580 | 65.53 | 2 9/16 | 66 |

| 2 | 1 3/4 W | 2.760 | 70.10 | 2 3/4 | 70 | ||||

| Note: Whitworth (W) = Old standard; BS = New Standard |

APPENDIX 1 (for reference). Weight of steel bolts (version 1) with coarse thread pitch

APPENDIX 1 Reference

| Bolt length, mm | Theoretical weight 1000 pcs. bolts, kg, with nominal thread diameter , mm | ||||||||||||||

| 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 | |

| 8 | 4,306 | 8,668 | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 10 | 4,712 | 9,394 | 16,68 | – | – | – | – | – | – | – | – | – | – | – | – |

| 12 | 5,118 | 10,120 | 17,82 | – | – | – | – | – | – | – | – | – | – | – | – |

| 14 | 5,524 | 10,850 | 18,96 | 27,89 | – | – | – | – | – | – | – | – | – | – | – |

| 16 | 5,930 | 11,570 | 20,10 | 29,48 | 43,98 | – | – | – | – | – | – | – | – | – | – |

| 18 | 6,336 | 12,300 | 21,23 | 31,12 | 46,21 | 65,54 | – | – | – | – | – | – | – | – | – |

| 20 | 6,742 | 13,020 | 22,37 | 32,76 | 48,45 | 68,49 | 95,81 | – | – | – | – | – | – | – | – |

| 22 | 7,204 | 13,520 | 23,51 | 34,40 | 50,69 | 71,44 | 99,52 | – | – | – | – | – | – | – | – |

| 25 | 7,871 | 14,840 | 25,22 | 36,86 | 54,05 | 75,87 | 105,10 | 133,3 | – | – | – | – | – | – | – |

| 28 | 8,537 | 16,330 | 26,92 | 39,32 | 57,40 | 80,29 | 110,60 | 140,2 | – | – | – | – | – | – | – |

| 30 | 8,981 | 17,120 | 28,52 | 40,96 | 59,64 | 83,24 | 114,30 | 144,8 | 193,0 | – | – | – | – | – | – |

| 32 | 9,426 | 17,910 | 29,43 | 42,59 | 61,87 | 86,19 | 118,00 | 149,4 | 198,6 | 237,0 | – | – | – | – | – |

| 35 | 10,090 | 19,090 | 31,28 | 45,34 | 65,24 | 90,62 | 123,60 | 156,3 | 207,0 | 246,9 | 340,6 | – | – | – | – |

| 38 | 10,760 | 20,280 | 33,18 | 48,00 | 68,59 | 95,04 | 129,20 | 163,2 | 215,4 | 256,9 | 353,3 | – | – | – | – |

| 40 | 11,200 | 21,070 | 34,36 | 49,78 | 71,25 | 97,99 | 132,90 | 167,8 | 221,0 | 263,5 | 361,8 | 474,8 | – | – | – |

| 45 | 12,310 | 23,040 | 37,45 | 54,22 | 77,30 | 105,70 | 142,10 | 179,4 | 235,0 | 280,1 | 373,0 | 500,9 | – | – | – |

| 50 | 13,420 | 25,020 | 40,53 | 58,67 | 83,35 | 113,60 | 152,40 | 190,9 | 249,0 | 296,7 | 404,1 | 526,9 | 834,5 | – | – |

| 55 | 14,530 | 26,990 | 43,62 | 63,11 | 89,39 | 121,50 | 162,40 | 203,7 | 263,1 | 313,3 | 425,3 | 553,0 | 872,1 | 1304 | – |

| 60 | 15,640 | 28,970 | 46,70 | 67,55 | 95,44 | 129,40 | 172,40 | 216,0 | 278,9 | 329,9 | 446,5 | 579,0 | 909,8 | 1356 | – |

| 65 | 16,760 | 30,940 | 49,79 | 71,99 | 101,50 | 137,30 | 182,40 | 228,4 | 293,8 | 348,8 | 467,7 | 605,1 | 947,4 | 1407 | 2009 |

| 70 | 17,870 | 32,910 | 52,87 | 76,44 | 107,50 | 145,20 | 192,40 | 240,7 | 308,8 | 366,5 | 491,1 | 631,1 | 985,0 | 1458 | 2076 |

| 75 | 18,980 | 34,890 | 55,96 | 80,88 | 113,60 | 153,10 | 202,40 | 253,0 | 323,7 | 384,3 | 513,6 | 659,7 | 1023,0 | 1509 | 2143 |

| 80 | 20,090 | 36,860 | 59,04 | 85,33 | 119,60 | 161,00 | 212,40 | 265,0 | 338,6 | 402,1 | 536,1 | 687,5 | 1061,0 | 1561 | 2211 |

| 85 | 21,200 | 38,840 | 62,13 | 89,77 | 125,70 | 168,90 | 222,40 | 277,7 | 353,6 | 419,8 | 558,6 | 715,2 | 1098,0 | 1612 | 2278 |

| 90 | 22,310 | 40,810 | 65,21 | 94,20 | 131,70 | 176,80 | 232,40 | 290,1 | 368,5 | 437,6 | 581,0 | 743,0 | 1141,0 | 1663 | 2345 |

| 95 | – | 42,790 | 68,30 | 98,64 | 137,80 | 184,70 | 242,40 | 302,4 | 383,4 | 455,4 | 603,5 | 770,8 | 1181,0 | 1715 | 2412 |

| 100 | – | 44,760 | 71,38 | 103,10 | 143,80 | 192,60 | 252,40 | 314,7 | 398,3 | 473,2 | 626,0 | 798,5 | 1221,0 | 1766 | 2479 |

| 105 | – | – | 74,47 | 107,50 | 149,90 | 200,50 | 262,40 | 327,1 | 413,3 | 490,9 | 648,5 | 826,3 | 1261,0 | 1826 | 2546 |

| 110 | – | – | 77,55 | 112,00 | 155,90 | 208,40 | 272,30 | 339,4 | 428,2 | 508,7 | 671,0 | 854,1 | 1301,0 | 1880 | 2614 |

| 115 | – | – | 80,63 | 116,40 | 162,00 | 216,30 | 282,30 | 351,8 | 443,1 | 526,5 | 693,5 | 881,8 | 1341,0 | 1934 | 2690 |

| 120 | – | – | 83,72 | 120,90 | 168,00 | 224,20 | 292,30 | 364,1 | 458,1 | 544,2 | 716,0 | 909,6 | 1381,0 | 1989 | 2760 |

| 125 | – | – | 86,80 | 125,30 | 174,00 | 232,10 | 302,30 | 376,4 | 473,0 | 562,0 | 738,5 | 937,4 | 1421,0 | 2043 | 2831 |

| 130 | – | – | 89,89 | 129,70 | 180,10 | 240,00 | 312,30 | 388,8 | 487,9 | 579,8 | 761,0 | 965,2 | 1461,0 | 2098 | 2903 |

| 140 | – | – | 96,06 | 138,60 | 192,20 | 255,80 | 332,30 | 413,5 | 517,8 | 615,3 | 806,0 | 1021,0 | 1541,0 | 2207 | 3045 |

| 150 | – | – | 102,18 | 147,50 | 204,30 | 271,60 | 352,30 | 438,1 | 547,6 | 650,8 | 850,1 | 1076,0 | 1621,0 | 2315 | 3187 |

| 160 | – | – | 108,38 | 156,40 | 216,40 | 287,40 | 372,30 | 462,8 | 577,5 | 686,4 | 895,9 | 1132,0 | 1701,0 | 2424 | 3329 |

| 170 | – | – | 114,58 | 165,30 | 228,50 | 303,20 | 392,30 | 487,5 | 607,4 | 721,9 | 940,9 | 1188,0 | 1780,0 | 2533 | 3471 |

| 180 | – | – | 120,68 | 174,20 | 240,60 | 319,00 | 412,30 | 512,2 | 637,2 | 757,5 | 985,9 | 1243,0 | 1860,0 | 2642 | 3614 |

| 190 | – | – | 126,88 | 183,10 | 252,70 | 333,80 | 432,30 | 536,9 | 667,1 | 793,0 | 1031,0 | 1299,0 | 1940,0 | 2751 | 3756 |

| 200 | – | – | 133,08 | 191,90 | 264,70 | 350,60 | 452,20 | 561,5 | 697,0 | 828,6 | 1076,0 | 1354,0 | 2020,0 | 2860 | 3898 |

| 220 | – | – | – | 209,70 | 228,90 | 382,20 | 492,20 | 610,9 | 756,7 | 899,6 | 1166,0 | 1465,0 | 2180,0 | 3077 | 4182 |

| 240 | – | – | – | 227,50 | 313,10 | 413,80 | 532,20 | 660,3 | 816,4 | 970,8 | 1256,0 | 1576,0 | 2340,0 | 3295 | 4466 |

| 260 | – | – | – | 245,20 | 337,60 | 445,40 | 572,20 | 709,6 | 876,1 | 1042,0 | 1346,0 | 1687,0 | 2500,0 | 3513 | 4751 |

| 280 | – | – | – | – | 361,50 | 476,90 | 612,20 | 759,0 | 935,9 | 1113,0 | 1436,0 | 1798,0 | 2660,0 | 3730 | 5035 |

| 300 | – | – | – | – | 385,70 | 508,50 | 652,20 | 808,3 | 995,6 | 1184,0 | 1526,0 | 1910,0 | 2820,0 | 3948 | 5319 |

(Changed edition, Amendment No. 5).

Calculation of bolt length and selection of connection parts

The length of the bolt (length of the rod to the head) is determined by the formula:

l > H1 + H2 +S + m + D ,

where H1 and H2 are the thicknesses of the parts to be connected, mm (according to the specification option);

S – washer thickness, mm (Table 5); m – nut height, mm (Table 10);

D – free end of the bolt protruding from the nut, mm (see Figure 16)

D = (2.3 ) ∙ P , where P is the coarse thread pitch, mm (according to Table 8).

The resulting number is compared with a number of bolt lengths (Table 9) and the closest standard length is adopted. From the same table, select the thread length b on the rod. All other bolt sizes are selected from table 8, washers and nuts from tables 10 and 11.

An example of calculating the length of a bolt with a nominal thread diameter d = 27 mm and the thickness of the connected parts H1 = H2 = 22 mm.

The given diameter of the metric thread (M27) corresponds to: large pitch P = 3 mm (Table 2); nut height m = 22 mm (Table 4); washer thickness S = 4 mm (Table 5); free end length D = (2…3) ∙ 3 = 6…9 mm.

We substitute these values into the formula for calculating the length of the bolt:

l >22+22+4+22+6…22+22+4+22+9 = 76…79 mm

From Table 3, the closest standard bolt length l = 80 mm and thread length b = 60 mm are selected.

Images of fasteners in a connection

According to GOST 2.315-68, a distinction is made between constructive (Figure 15), simplified (Figure 16) and conventional (Figure 17) images of a bolted connection.

A simplified image is used in assembly drawings; it does not show chamfers, the gap between the bolt shaft and the hole, the thread is applied along the entire length of the rod, and the internal diameter of the thread is not indicated in the top view.

A simplified image is drawn according to conventionally accepted ratios depending on the nominal thread diameter d ; the necessary ratios are shown in Figure 16.

On the drawing of a simplified image, it is necessary to put the dimensions (see Figure 9) : Ø nominal diameter with the letter designation of the metric thread - M , Ø standard bolt length l - size to the bolt head, Ø thickness of the connected parts H1 and H2 .

A conventional image is used if the diameter of the fastener rod is less than or equal to 2 mm. Figure 17 shows a conventional cross-section of a bolted connection in accordance with GOST 2.315-68.

Table 8 - Hex head bolts, accuracy class B

according to GOST 7798-70 *

In millimeters

| Nominal thread diameter d | Thread pitch P | Rod diameter d1 | Turnkey size S | Head height K | Diameter of circumscribed circle e (not less) | Radius under the head R (not less) | dP |

| large | small | ||||||

| (22) (27) | 2,5 2,5 3,0 3,0 | 1,5 1,5 2,0 2,0 | 12,5 14,0 15,0 17,0 | 33,0 35,0 39,6 45,2 | 0,8 0,8 0,8 1,0 | ||

| Notes: 1 Bolt sizes enclosed in brackets are not recommended. 2 Radius under the head R according to GOST 24670-81. 3 dP – according to GOST 12414-94. |

Table 9 Lengths of hex head bolts of accuracy class B according to GOST 7798-70 *

| Bolt length ℓ | Nominal thread diameter d | ||

| (22) | (27) | ||

| V | V | V | V |

| X | X | X | |

| X | X | ||

| X | |||

| (85) | |||

| Notes: 1 Bolts with length dimensions enclosed in brackets are not recommended for use. 2 “X” marks bolts with threads along the entire length of the rod. |

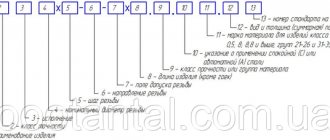

Example of a symbol

a bolt with a hex head of normal accuracy, version 1 (not specified), with a thread diameter d=20mm with a coarse pitch P=2.5mm , bolt length l=

60mm, from material of subgroup 00, without coating, according to GOST 7798-70*

Bolt M20x60 GOST 7798-70

Table 10 Hex nuts, accuracy class B according to GOST 5915-70*

| Nominal thread diameter d | (22) | (27) | |||

| Thread pitch P | Large | 2,5 | 2,5 | 3,0 | 3,0 |

| Small | 1,5 | 1,5 | 2,0 | 2,0 | |

| Turnkey size S | 30,0 | 32,0 | 36,0 | 41,0 | |

| Diameter of circumscribed circle e , not less | 33,3 | 35,0 | 39,6 | 45,2 | |

| Height m | 16,0 | 18,0 | 19,0 | 22,0 | |

| da | no less | 20,0 | 22,0 | 24,0 | 27,0 |

| no more | 21,6 | 23,8 | 25,9 | 29,2 | |

| dw, no less | 27,7 | 29,5 | 33,2 | 38,0 | |

| Note: Nut sizes enclosed in brackets are not recommended. |

Example of a symbol

hex nut version 1 (not specified), normal accuracy with thread diameter d=16mm , with a large pitch P=2.0mm , with a tolerance range of 7H (not specified), without coating, according to GOST 5915-70* : Nut M16 GOST 5915 -70 The same, version 2, fine pitch P = 1.5 mm, with a tolerance range of 6H, strength class 12, made of steel grade 40X, with coating 01 6 µm thick : Nut 2M16xl,5-6H.12.40X.016 GOST 5915- 70

Table 11 Washers of accuracy class A according to GOST 11371-78*

Version 1 In millimeters

| Fastener Thread Diameter | d1 | d2 | S |

Example of a symbol

Washers of execution 1 accuracy class A for a fastener with a thread diameter d = 16 mm, without coating: Washer A.16 GOST 11371-78 Article rating:

Save to:

How to find out the size of a bolt by diameter Link to main publication

Related publications

- How to connect a switch with a backlight indicator

Determining the key number by the diameter of the fastener thread

The “wrench” size of a hex bolt or nut is the distance between two parallel faces. You can quickly and accurately find out it, without resorting to a ruler or caliper, by the diameter of the threaded part, which is indicated in the technical information for the fastener. The fact is that each standard thread diameter corresponds to a certain size of the working profile of the fastener - main (normal), reduced and enlarged. Bolts with reduced and increased head sizes are much less common.

Using the table, you can easily determine which wrench size is suitable for a particular bolt from M1 to M110.

Table 1. Wrench sizes for metric bolts and nuts.

| Thread diameter, M | Key size | ||

| main S , mm | reduced S , mm | increased S , mm | |

| M1 | 3.2 | — | — |

| M1.2 | 3.2 | — | — |

| M1.4 | 3.2 | — | — |

| M1.6 | 3.2 | — | — |

| M2 | 4 | — | — |

| M2.5 | 5 | — | — |

| M3 | 5.5 | — | — |

| M4 | 7 | — | — |

| M5 | 8 | — | — |

| M6 | 10 | — | — |

| M7 | 11 | — | — |

| M8 | 13 | 12 | — |

| M10 | 17 (16) | 14 | — |

| M12 | 19 (18) | 17 | 21 (22) |

| M14 | 22 (21) | 19 | 24 |

| M16 | 24 | 22 | 27 |

| M18 | 27 | 24 | 30 |

| M20 | 30 | 27 | 32 (34) |

| M22 | 32 (34) | 30 | 36 |

| M24 | 36 | 32 | 41 |

| M27 | 41 | 36 | 46 |

| M30 | 46 | 41 | 50 |

| M33 | 50 | — | 55 |

| M36 | 55 | 50 | 60 |

| M39 | 60 | 55 | 65 |

| M42 | 65 | 60 | 70 |

| M48 | 75 | — | 75 |

| M52 | 80 | — | 80 |

| M56 | 85 | — | — |

| M60 | 90 | — | — |

| M64 | 95 | — | — |

| M68 | 100 | — | — |

| M72 | 105 | — | — |

| M76 | 110 | — | — |

| M80 | 115 | — | — |

| M85 | 120 | — | — |

| M90 | 130 | — | — |

| M95 | 135 | — | — |

| M100 | 145 | — | — |

| M105 | 150 | — | — |

| M110 | 155 | — | — |

Some modern ISO standards specify other hex head sizes; they are listed in parentheses in the table.

The dimensions of the wrench mouth are defined in the GOST 6424-73 standard. With proper selection, the gap between the working jaws of the tool and the edges of the fastener does not exceed 0.1 - 0.3 mm.

Determining the length of fasteners: bolts, screws, studs

24/01/2019

How is the length of fasteners determined?

Often the length of the hardware is indicated in the standard according to which these fasteners are produced. However, not everyone always has the required standard at hand, so if you urgently need to measure the length, in this article you will learn how to do it correctly.

So, to determine the length, special tools are needed, such as a centimeter, tape measure or ruler. The most popular element for these purposes is a caliper, since with its help maximum measurement accuracy is achieved. But tools alone are not enough; you also need to be able to do it correctly. In fact, it is not difficult and it was logical to think that the length of bolts and screws is measured from the base of the head to the end of the threaded rod, and studs - from one edge to the other. However, there are some nuances that need to be taken into account and which we will tell you about further.

3) Threaded socket, threaded socket, stud and stud assembly

Table with task by options

GOST 22034-76. “Screw-in studs 1.25d long.”

We draw an M18 pin with a length of 55 mm GOST 22034-76 according to the instructions.

Hairpin M18-6gx120.58 GOST 22034-76