The supplier of the combined woodworking machine SD-4 Ant is JSC Algorithm , Rybinsk, founded in 1992.

The production of woodworking machines Ant is organized on a scientific, engineering and production base created in the city of Rybinsk in 1992. This company, in turn, was created on the basis of KB Algorithm, and absorbed the best quality traditions of the military-industrial complex.

Website address: https://www.muravey.ru

Machine tools manufactured at JSC Algorithm, Rybinsk

- SD-3 Ant

- combined woodworking machine - SD-4 Ant

- combined woodworking machine

SD-4 Ant is a combined woodworking machine. Purpose, scope

The SD-4 machine (SD-4-00, SD-4-00) is designed for processing softwood and hardwood lumber.

The machine performs the following operations:

- sawing along and across the grain;

- longitudinal sawing at an angle from 0 to 45°;

- jointing - planing (with a clamping device) along a plane with a processing width along the plane in one pass up to 200/250 mm

- planing at an angle and along the edge;

- milling of grooves with disk and end mills;

- milling with a shaped cutter;

- drilling from 3 to 16 mm;

Design features of the SD-4 machine

The SD-4 machine is available in two modifications with different types of supply voltage: 220 and 380 V.

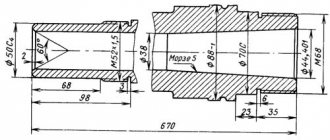

The circular saw, drill chuck, circular and shaped cutters are mounted on the B18 conical shank of the planing spindle.

The machine is designed to operate in the following climatic conditions:

- altitude above sea level - up to 1000 m;

- ambient temperature from +1 °C to +40 °C;

- relative ambient humidity no more than 80% at +20 °C.

Characteristics of the SD-5 model

Model SD-5

The SD-5 woodworking machine can only perform the functions of sawing, jointing and milling with a circular saw. However, along with this, it has a maximum groove size that is formed under the influence of a disk cutter - 70 mm.

The maximum jointing width is 200 mm. In this case, the width of the groove when processing with a disk cutter does not exceed 10 mm. There is no block with a shaped cutter in this model. If installation of other cutting tools is necessary, the diameter of the shank should be taken into account. It is 20 mm.

Other features of the model:

- overall dimensions - 60*50*45 cm;

- equipment weight is 40 kg;

- The drive belt size is 60 cm.

For long-lasting operation of the spindle, rolling bearings 20*47*14 are installed. Thanks to them, high levels of vibration are not observed during equipment operation. Also, this design helps to increase the quality of processed wooden blanks.

To correctly connect the machine to the electrical network, it is necessary to install an RCD. Its characteristics must correspond to the performance of the electrical part of the equipment.

List of components of the combined machine SD-4 Ant

- riving knife;

- guide;

- wall;

- drive belt cover;

- frame;

- electric motor;

- upper saw guard;

- planer table clamp;

- eccentric adjustment mechanism for the front planing table;

- Remote Control;

- side table for sawing, routing and drilling;

- rack and pinion adjustment mechanism for side table;

- lower saw guard;

- chip removal casing;

- spindle housing;

- jointing tables;

Saw blades and their applications

The main characteristics of a circular saw that determine its performance are its power, rotation speed at rated load, and the type of saw blade. Saw blades differ in such indicators as the outer diameter and mounting hole, the material from which the teeth are made, and the number of teeth, which can be from 12 to 110.

For cutting plywood and softwood, it is customary to use saw blades with regular teeth. To increase the service life of discs, some manufacturers apply a special coating to the discs. But, using this type of disc for cutting chipboard or hardwood, you will quickly dull them.

The most practical option seems to be saw blades with carbide teeth. In this case, the number of teeth, as well as their shape, may vary. The teeth of such disks can be soldered with pobedit.

If a craftsman needs to carry out cutting work, including longitudinal sawing of long boards, it will be most convenient to work with discs that have a small number of teeth, up to 24. The quality of the cut will certainly not be high, but the work will be completed quickly.

For clean cutting, discs with a number of teeth from 36 to 48 are recommended. Trapezoidal tipped discs are used for cutting hardwood and wood with a large number of knots. They will also be appropriate when cutting chipboard and boards with nails.

Among the indicators that most influence the cleanliness of the cut are the rotation speed, sharpening and type of blade.

Design of the combined machine SD-4 Ant

The basis of the machines of all models is a woodworking unit, which consists of two load-bearing walls 3 connected to each other by pins. Installed on the walls:

- Ball bearing supports in which the jointing mechanism spindle rotates;

- Planing tables 16 (front adjustable and rear non-adjustable);

- Eccentric mechanism 9 for adjusting the height of the front table 16;

- Height-adjustable table 11 for sawing, milling and drilling;

- The SD-4 machine is additionally equipped with a thicknessing table 18.

The Ant SD-4-00 model machine is made in a floor-standing design on a welded frame 5, on which an electric motor 6 is installed.

Machines of models Ant SD-3-02, SD-3-03 and SD-4-00, SD-4-01 are made in a desktop version on a welded frame 5 on which an electric motor 6 is installed. Machines made in a desktop version can If the consumer wishes to be equipped with a stand for desktop machines (see Appendix B).

All machines are equipped with removable protective covers for the drive belt 4, spindle 15, upper 7 and lower 13 saw guards, and chip removal guard 14 (Ant SD-4 machines).

All machines include a protective chuck guard.

The set of machines SD-3-00, SD-3-02, SD-3-03 additionally includes a thicknesser housing.

Torque is transmitted from the engine to the spindle via a V-belt. The machine is turned on and off using the “START” and “STOP” buttons on the control panel 10. Electrical diagrams of the machines are given in Appendix A.

Advantages and disadvantages of machines

SD-01 series machine

Before purchasing a specific model, it is recommended to familiarize yourself with its technical characteristics. To do this, you can visit the company’s official website or read the technical data sheet. In the first case, specialist consultation is provided.

One of the defining qualities of equipment from a domestic manufacturer is the optimal price-quality ratio. In addition to this, a long period of operation can be noted. Considering the availability of components, unlike Chinese analogues, repair or modernization of the Ant SD machine can be done independently.

In addition, users note:

- ergonomic arrangement of equipment components. A specific zone is allocated for each operation;

- rigid working frame. Together with its large mass, it reduces the likelihood of vibration during operation;

- regulating mechanisms. With their help, you can set the optimal parameters for processing wooden surfaces;

- security. The machine is supplied with protective covers and the motor has a thermal relay.

Disadvantages include relatively complex pre-setting. In most cases, it is performed on an individual basis, with parameters adjusted to perform a specific type of operation.

After purchasing the Ant 03 machine, you should carefully check not only its equipment, but also the absence of external defects. Some reviews indicate slight deformation of the desktops.

Longitudinal and transverse sawing of lumber on the SD-4 Ant machine

To perform this operation you must:

- Loosen thumbscrews 21 and raise side table 13 to its highest position. Fix screws 21;

- Remove the lower saw casing 15;

- Install nut 11, bushing 9 on the conical shank of spindle 10 and secure with bolt 1 with washers 2 and 3, having previously stopped the rotation of the spindle with a wooden strip inserted into the groove of the spindle;

- Install adjusting washer 8 (if necessary), saw 6 onto sleeve 9 and secure it with sleeve 5 and nut 4;

- Install the lower saw casing 15, connect the chip catcher hose to the casing pipe;

- Install the riving knife 17 with the upper saw guard 16 on the studs 18 between the nuts, adjust the position of the knife so that its plane coincides with the plane of the saw;

- Loosen the screws 21 and, by rotating the handle 22, set the table 13 so that the saw 6 protrudes above the table by an amount greater than the thickness of the sawn timber by 5-10 mm. Fix screws 21;

- Set guide 19 to the desired cutting width and secure it with clamps 20. In this case, the rear end of the guide should be 1 mm further from the plane of the saw than the front to avoid jamming the saw. The scale marked on the edges of the side table serves to pre-install guide 19. To accurately set the cutting width, you should check the distance from the guide to the saw blade;

- Close the saw with casing 16;

- Rotate the spindle (from the saw side) by hand several times to make sure that the saw blade does not touch the edges of the groove of the side table 13, then turn on the machine and check at idle that the saw blade rotates correctly. Feed lumber evenly.

To remove the sleeve 9 from the cone 10, a release nut 11 is provided.

Parameters of equipment of the SD-6 series

Model SD-6

The main difference between the Ant SD-6 machine and the 5th model discussed above is the thicknessing function. If on other equipment the thickness of the material varied from 5 to 75 mm, then for SD-6 this parameter is much larger - from 10 to 100 mm.

It is also worth noting its small dimensions, which are 60*50*60 cm. At the same time, the weight of the entire structure with components does not exceed 50 kg. To install additional cutting tools, take into account the standard shank size, which is 20 mm.

An additional advantage of the equipment is its affordable cost. The machine of this series can perform the following functions:

- sawing;

- jointing;

- processing with a disk cutter;

- thicknessing.

Due to its relatively small dimensions and affordable price, this type of equipment is one of the best options for completing a home workshop.

The main drive shaft rotation speed is the same for all models and is 4200 rpm. To change this parameter, it is necessary to install another power unit.

Milling with disk and shaped cutters on the SD-4 Ant machine

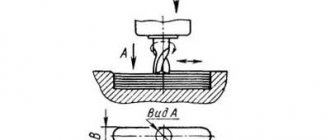

When milling with disk and shaped cutters, it is recommended to use a clamping device (see Appendix B), since it acts as a protective casing.

To perform this operation you must:

- Remove the side table 13 from the slats 14 by unscrewing the four screws;

- Remove the lower saw casing 15;

- Remove the riving knife 17 with the upper saw casing 16 (Fig. 2);

- Install nut 11, bushing 9 on the conical shank of spindle 10 and secure with bolt 1 with washers 2 and 3, having previously stopped the rotation of the spindle with a wooden plank, inserting it into the groove of the spindle;

- Install adjusting washer 8 (if necessary), cutter 7 onto sleeve 9 and secure it with sleeve 5 and nut 4. If the cutter is 40 mm thick, do not install sleeve 5;

- Install the lower saw casing 15, connect the chip catcher hose to the casing pipe;

- Install the side table 13 on the slats 14 so that the cutter is under the special groove (rotate the table 180°);

- Install guide 19 in accordance with Fig. 4 and secure it with clamps 20;

- Loosen screws 21 and, by rotating handle 22, set table 13 to the required milling depth. Fix screws 21;

- Rotate the spindle (from the cutter side) manually several times to make sure that the cutter does not touch the edges of the groove of the side table 13 and the guide 19;

- Install the clamping device;

- Turn on the machine, at idle speed, check the correct rotation of the cutter and feed the lumber evenly.

To remove the sleeve 9 from the cone 10, a release nut 11 is provided.

Additional components for machines

Pressing device

One of the benefits of purchasing specialized equipment is the wide range of additional accessories. With their help, you can significantly increase the productivity of work performed and improve their quality.

Before choosing additional components, you should check the availability of these components in the standard configuration of the Ant machine. Once this is done, you can begin to analyze the company’s product range.

The most popular additions to equipment:

- clamping device. Necessary for firmly pressing the material being processed to the table surface. It has a smooth adjustment of the degree of mechanical impact, the design dimensions are designed for installation on equipment from this manufacturer;

- universal guide. It is a bar with the function of adjusting the angle of inclination relative to the table surface. The maximum angle is 45°;

- a device for sawing boards across the grain. It consists of a square with a scale and a support bar connected to it. The advantage over similar models lies in steel components, which have a much longer service life than polymer ones;

- sets of cutters – disk and finger;

- desktop with height adjustment function.

A milling head with replaceable knives will reduce operating costs when operating the equipment. However, according to reviews, then it will be necessary to purchase knives with shanks of a certain shape.

Drilling on the SD-4 Ant machine

This operation is carried out using a conical key chuck (cone designation - B18) (see Appendix B).

To perform the operation you must:

- Remove the lower saw casing 15 (Fig. 2);

- Remove the pads from the side table 7;

- Remove the riving knife 17 with the upper saw casing 16 (Fig. 2);

- Install table 7 below the spindle axis;

- Install nut 8 and drill chuck 2 on the spindle shank 3;

- Attach drill bit 1 to the drill chuck;

- Install the chuck casing 4 (included in the machine kit) using M5 screws – 2 pcs. with A5 washers – 2 pcs.;

- Adjust side table 7 in height relative to the tool using handle 5. Fix with screws 6;

- Turn on the machine, at idle speed, check the correct rotation of the drill and feed the lumber evenly.

To remove chuck 2 from the spindle shank 3, a release nut 8 is provided.

Features and device

Woodworking machines "Ant" are universal combined devices that allow you to perform a number of operations. One unit can easily replace several analogues of the same type, not to mention electric hand tools.

A wide range of models allows any consumer to choose a copy according to their needs, depending on the power supply, required work and cost. The machines are characterized by high productivity, efficiency, ease of operation and maintenance. Let's look at the modifications that Ant woodworking machines have, their characteristics and capabilities.

Jointing (planing) of lumber on the SD-4 Ant machine

To perform the jointing (planing) operation on the SD-4 machine, you must:

- Check the installation of knives 8 and, if necessary, align them in accordance with Fig. 6. To do this, press ruler 4 to the plane of the fixed back table 1, loosen bolts 2, adjust knives 8 with screws 7 so that the edges of the knives lightly touch the bottom plane of the ruler. Securely secure the knives in the grooves of the shaft using wedges 3 and bolts 2;

- Set the cutting depth (thickness of the layer being removed) by raising or lowering the movable table 5 using the handle of the eccentric mechanism 9, fixing it with screw 8 (Fig. 1);

- Set casing 15 (Fig. 1) to the desired jointing width;

- Turn on the machine and feed the lumber evenly.

ATTENTION! When jointing workpieces less than 400 mm long, it is necessary to use pushers (Fig. 3). To facilitate the operation, it is recommended to use a clamping device (see Appendix B).

Consumer Reviews

To obtain objective information about the actual performance of the equipment, you should read real consumer reviews. But it is necessary to take into account their subjectivity.

- After a long analysis of offers on the market, I chose the Ant SD-03 machine. There was an alternative to buy a Chinese analogue, but after analyzing the components I realized that it’s better to be a little more expensive, but more reliable. The equipment performed well. Sawing and jointing occur cleanly. The only thing is that I didn’t think about a reliable foundation. I had to make a more stable desktop.

- Working on the Ant-03 machine requires some skill. As I understand it, when designing the structure, the manufacturer expected that it would be used by people with experience. First of all, I noticed a slight difference in the level of the table. I had to level it myself. Also among the shortcomings I can note the inconvenient adjustment knobs. But after solving these problems, no new ones arose in 1.5 years of work.

- I purchased an Ant machine for building a summer house. In general, I am satisfied with the equipment; the technical characteristics fully correspond to the passport specifications. I'm having trouble adjusting the level. The bolts on the legs are inconvenient; it takes a lot of time to set the level.

In the video you can familiarize yourself with the operating features and configuration of the described equipment: