Manholes and claws are special devices used by electricians during repair and installation work at heights.

In cases where it is necessary to make repairs or carry out routine maintenance on power lines, these products allow installers to climb the supports without the involvement of expensive equipment.

Inspection and testing: general principles

Claws and manholes used at enterprises must be inspected and tested for static loading every six months.

Before carrying out the next one, a complete visual inspection of the devices is carried out. If necessary, repairs are carried out, which may involve replacing the main parts. The devices are cleaned of dirt and dried at room temperature. Tip No. 2. It is not necessary to subject the straps used to secure the electrician’s foot to a load test. Their compliance with all current requirements is checked visually.

External examination of claws

A visual inspection of manholes and claws is carried out in order to identify damage visible to the naked eye, in the presence of which the devices are rejected. During the inspection of the claws, the technical condition and serviceability of all elements are checked:

- correct sharpening of the spikes;

- safety of the connection between the crescent element and the footrest;

- reliability of buckle seams;

- continuity of stitching of belts;

- the degree of tightening of the locking nut and the presence of a locking ring cotter pin.

Claw load test

Upon completion of the visual examination, identified deficiencies must be eliminated before testing the claws for static loading. The device, located in working condition, is loaded in the weakest section. The test is carried out on a wooden support stand with a diameter suitable for this claw model. The device must bear the load for 5 minutes without damage or rupture of welds, damage to the buckle or rupture of the belt. After release from the load, the presence of residual deformations is not allowed; their absence is checked by measuring the rise and alignment of the device before and after loading.

Visual inspection of manholes

When inspecting manholes, the condition is analyzed:

- bolts and connections;

- main components;

- removable plates;

- the presence of locknuts and cotter pins;

- belts and other fastenings.

The degree of sharpening of the removable plates, the reliability of their attachment, and for models of universal use, the condition of the cable loop nodes and the mechanism that regulates the opening of its solution are checked especially carefully. When checking the cable loop, the level of wear of the wires and branches of the paired spring tape and the quality of its attachment to the cable are revealed. Welding seams are checked for mechanical deformation and cracks. Damaged or sufficiently worn studs must be replaced with new ones.

Testing manholes under load

For testing under load, the manholes are placed on a stand in the working position, with the help of which the outlines of the lower part of the column are simulated. Upon completion of the inspection, the manhole is carefully inspected for residual deformations, tears in the fastening belts, cracks, and malfunction of the mechanism that regulates the opening of the cable loop. If at least one of the listed defects is detected, the hole is rejected and removed from the working stock.

Installer's claws for working on wooden supports

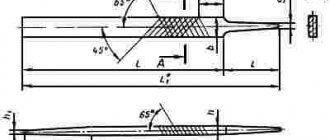

The design capabilities of assembler's claws for wooden supports, commercially produced in accordance with GOST 14331-77, are presented below:

- Type KM-1 – recommended support diameter 140...245 mm, throat 245±10 mm;

- Type KM-2 – recommended support diameter 220...315 mm, throat 315±10 mm;

- Type KM-3 - recommended support diameter 310...415 mm, throat 415±10 mm.

The platform of the KM series claws is stamped, with perforated holes, which makes it possible to increase the reliability of contact of the foot with the surface, while simultaneously reducing the weight of the platform. After stamping, the platform is hardened to a hardness of HRC 38...42. On one of the side surfaces of each platform there are ears for attaching steel arches. Along the remaining edges of the platform there are low sides, the presence of which prevents the electrician’s foot from accidentally slipping. To strengthen it during manufacturing, stiffening ribs are formed on the rear surface of the platform.

The fixing part of the arc rotates freely in the ears, ensuring the fixation of the spikes along the support at the moment of lifting the electric line operator. The permissible play should be no higher than ±15º.

The quick-wearing part of repairman's claws are the spikes, despite the fact that their initial hardness after hardening is 45...50 HRC. For claws on wooden supports, spikes are always made with conical tips. Experiencing significant frictional stress, steel spikes become dull and deformed over time. The durability of carbide studs is much higher, but they are sensitive to impacts and bending loads. Replacing the studs is not difficult, since their fastening part is threaded. The rear part of the platform is also equipped with spikes of a similar design.

The leg of the working person is attached to the arch of the claw using straps. In order to ensure elasticity, their upper part is made of yuft, and the lower part is made of rawhide impregnated with animal fat. The stitching of the belt elements is carried out with nylon threads, and the thickness of the belt and the diameter of the threads are calculated for a load of at least 140...160 kg.

Varieties

Claw models differ in the diameter of the post for which they are designed. Types of claws.

- Type KM-1. Pole diameter 140 - 245 mm. The maximum distance between the spines in the claws is 245 ± 10 mm.

- Type KM-2. Pole diameter 220 - 315 mm. The maximum distance between the spines in the claws is 315 ± 10 mm.

- Type KM-3. Pole diameter 310 - 415 mm. The maximum distance between the spines in the claws is 415 ± 10 mm.

Fitter's claws for steel poles - KMM. Combined manhole claws for concrete supports - KLM. Universal manholes - LU. Such products are designed for operation in the temperature range from -40 to +50C.

- Type KMM, fitter claws, pole diameter 126 - 150 mm. The maximum distance between the spines in the claws is 136 ± 15 mm.

- LU type, assembly manholes, column diameter 168 - 190 mm. There are models of universal manholes with varying distances between the tenons.

- Type KLM-1, combined claws and manholes. Maximum distance between pins 168 ± 5 mm.

- Type KLM-2, combined claws and manholes. Maximum distance between pins 190 ± 5 mm.

Design

Claws and pole holes have a similar design.

- Leather straps for fixing the fitter’s foot on the support.

- Support or platform for feet.

- Spikes for reliable fixation of the device at height. The spikes are attached to a threaded connection and are replaced as they wear out. Tenons designed for wooden posts differ from tenons for concrete.

- Metal arcs wrapping around a pole. The claws are oval, the holes are rectangular.

The foot platform is stamped, with holes to reduce the weight of the product. On the back side there are stiffening ribs that prevent the platform from bending. Along the perimeter of the platform there are low sides that reduce foot slipping during work.

Spikes wear out the fastest in holes or claws. It is the spikes and fastening straps that must be monitored when using these devices. The spikes are installed on the front (3 spikes) and rear (2 spikes) parts of the arc.

According to GOST, belts must be leather, impregnated with animal fat. Stitched with nylon threads. The mounting structure is designed for 140 - 160 kg.

Features of use

Laps and claws are simple devices, but they are used in dangerous conditions: high altitude, presence of live wires nearby. Therefore, these devices must be operated in compliance with safety regulations.

- Use claws and manholes only for supports made of suitable material.

- Twice a year, claws and holes are checked.

- Before putting on the devices, check the condition of the cleats and straps.

- Climb the pole only with a safety belt.

Prevention and maintenance of claws and manholes for high-altitude work

Claws and manholes do not require complex maintenance. After use, they are cleaned of dirt and stored in a dry place. Requirements for using protective equipment at height.

- Claws and manholes must withstand a static load of 180 kgf without deformation.

- The service life of claws and manholes (without spikes and belts) is set by the manufacturer, but not more than 5 years.

- You cannot use manholes and claws on supports covered with ice, at temperatures below the permissible ones - in this case, the steel becomes brittle and there is a high probability of product breakage.

What other means of protection are needed?

In addition to the claws are used.

- Mounting belt with a wide or narrow sash. A sling made of chain or steel cable is attached to the belt.

- A helmet to protect the head from contact with support elements or wires.

- Protective gloves depending on the work performed. Installation work - leather is suitable, electrical installation - dielectric rubber.

- Signal vests.

Our store sells claws and manholes starting at 4,800 rubles. Electrician's belts with fastening to the belt, belt and shoulders, belt, shoulders and hips. Cost from 500 rubles.

You can increase the safety of installers and electricians by using safety vests. We sell signal vests of protection classes 2 and 3. It is possible to apply a logo.

Find out more about the terms of payment and delivery of mounting manholes and claws1 seven days a week from 9 a.m. to 6 p.m. Moscow time.

" back

Application area

Concrete hooks are designed to quickly lift a worker along a concrete or wooden power line pole to its upper section. Using personal equipment makes it possible to get the job done easier and faster than using a turret truck. It is not always possible to use special equipment. This depends on the terrain and urban density.

In manholes, an electrician is able to carry out installation and cable laying, carry out urgent repair work, and change lamp bulbs on wooden poles. Replacing lamps is often carried out through manholes, since due to the large number of lamp supports it is not financially profitable to use special equipment. It’s easier and faster for an electrician to climb up on his own.

Electrician's manholes, their types and application

Depending on their purpose, concrete power line supports can have different cross-sectional shapes:

- centrifuged (round);

- rectangular;

- trapezoidal;

- polygonal.

Types of electrical supports for power lines

Each type of support (see photo) has its own design of devices for safe and convenient maintenance of lighting elements.

Classification and purpose of the tool

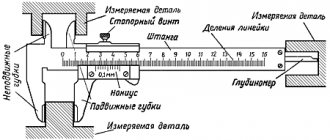

Installation manholes, regardless of the type of work performed, must be equipped as follows:

- sickle (hook);

- thorns;

- step;

- leather straps to firmly secure the fitter's feet.

Electrical installation manholes

The sickle is the working part of the device, made of pipes of the required diameter with fastening elements (spikes) attached to it. The footrest looks like a flat metal structure. The installer's foot is secured using durable leather straps with clamps attached to the body of the footrest.

All parts of the devices are designed for safe operation within temperatures from -40 to +50°C, and with proper use they retain their positive performance characteristics for 36 months.

Depending on the type of work and the shape of the lighting stand, installation manholes for concrete have several varieties:

- KLM (1–2) - claws of Laza montera. They are used for servicing trapezoidal and rectangular lighting poles. Hook opening 160–180 mm. The weight of the sets is respectively 3.7–5.4 kg.

Manholes KLM-1

- LMC - manholes on concrete for climbing and descending round or multifaceted pillars. The opening of the working part is 305 mm. Set weight 4.20 kg. Permissible force 180 kgf/unit.

Device for centrifuged supports

- LU - universal manholes with the ability to adjust the gripper opening. Grip opening 175–190 mm. The structure is adjusted using two bolts located on the device body. Product weight 5.8 kg.

LU-2

Necessary conditions for safe use of devices

The instructions for performing electrical installation work with your own hands provide for the following conditions:

- An electrician performing work at height must undergo training at a specialized center and obtain the necessary certificate allowing independent work.

- Before starting work, you must carefully inspect the device and make sure that all connections are secure, including the condition of the belts for securing the tool.

- The fixing belts must be made of two-layer fat-impregnated leather for installation work in any climatic conditions. The required belt thickness is 3 mm or more. The belt buckle must be made with a protective and decorative coating.

- Metal elements of manholes should not have cracks, dents, breaks or sharp burrs. Welding seams of connections must be smooth without visible defects. Working spikes should not be beveled and have the required geometric shape.

- The spikes of the device must move freely in the horizontal plane, but at the same time, the vertical play should not exceed 1 mm.

Safety belt

The video explains the rules of claw climbing and climbing.

Description KVT 61192

Designed to move along reinforced concrete trapezoidal pillars of power transmission line supports Type of supports: SV 95/105/110 Claw opening: 168 - 190 mm Test and operational load: 180 kgf per 1 manhole Adjustment of the manhole opening is carried out by rearranging the insert Leather fastening straps included Fourth additional belt for rigid fixation of the sling on the claw foot Weight: 5.00 kg

All information on the website instrumentomania.ru is not a public offer. Product photographs on the website are for illustrative purposes only. The name, color, and characteristics of the product may be changed unilaterally by the manufacturer without appropriate notice.

Care, storage, service life

Manholes are a universal device; they can be used in almost any climate zone with a temperature range from minus 40 to 50 degrees above zero. This means that work on power lines can be carried out both in the northern regions and in hot and sultry conditions.

The service life is indicated by the manufacturer. Time is counted from the moment the products are put into operation. No later than a year later, such a tool must be removed and recycled or disposed of. The maximum operating life of manholes is 60 months. Components are changed during operation as needed. The warranty period is usually 1 year from the moment the product is put into operation.

Store the device in a temperature range from minus 20 to 30 degrees above zero. It is unacceptable to store manholes in a room with an open roof; precipitation will leave a sharply negative mark on the quality of the devices.

Monter's manholes do not require special care. After use, they must be cleaned, any remaining dirt must be removed with a rag and stored away. Do not wash under water or wipe with wet material.

In conclusion of our article, we suggest watching a video of how assembly manholes are made and how to correctly lift using them:

Review of brands and manufacturers

The following companies deserve mention and are trusted by consumers:

- CJSC "Potential";

- electrical engineering plant KVT;

- production association "ZMO".

(Nizhny Novgorod)

Installer's claws No. 2, manufactured (Nizhny Novgorod) are used for electrical installation work on wooden vertical supports or wooden poles with reinforced concrete attachments for overhead power lines. The opening of the device is 315 (±10) mm, the lift is 160 (±10) mm.

- The diameter of the supports allowed for use is 220-315 mm.

- The cost of the device is about 2-2.5 thousand rubles.

- The main characteristics of claws No. 2 2 are presented in the table.

Products of the KVT enterprise (KVT electrical plant)

The KVT enterprise produces the popular and sought-after model of KLM claws in two versions - KLM-1 and KLM-2. Both options are used for work on trapezoidal overhead line supports.

- KLM-1 ensure safe operation on columnar supports of types SV110-1a and SV110-2a. The claw length is 168±4 mm, weight is 5.3 kg. The price of KLM-1 claws, depending on the region, is 2.2-2.8 thousand rubles.

- Claw-holes KLM-2 weighing 5.4 kg and opening 190±4 mm are widely used for posts SV105-3.6 and SV105-5. The cost of the device is approximately 3.5 thousand rubles.

Comparative characteristics of the KLM-1 and KLM-2 claws are presented in the table.

Production Association "Installation Equipment Plant"

The production association "Installation Equipment Plant" boasts two popular models. KM-1 claws are widely used for work on wooden and wooden with reinforced concrete inserts power transmission line supports, on communication line poles with a circumference of 140-245 mm.

- The forged sickle and spikes are made from reliable 40X steel and are supplied with leather straps. The device's opening is 245±10 mm with a fairly low mass of 3.6 kg. The cost of KM-1 ranges from 2400 to 2900 rubles.

- Universal switchgear manholes are used on supports of trapezoidal cross-section of overhead lines of the SV110-1a, SV95-1(2a), SV105-5 and SV105-3.6 brands. The manhole has an adjustable opening in the range from 168 to 190 mm. Reliable adhesion to the surface of the supports is ensured by carbide spikes. Supplied with leather straps.

- The weight of the product is approximately 5 kg.

- KRU manholes can be purchased for 2900-3700 rubles.

Comparative characteristics of KM-1 claws and KRU manholes are presented in the table.

Design versions

The type of claws depends on the material of the support on which the electrician will climb, the diameter of the support and the mouth of the claws in their open position. All standard sizes are standardized in accordance with GOST 14331-77, TU34-09-10147-88, and TU 34-2412-77.

Installer's claws for lifting onto ordinary wooden supports, or supports with reinforced concrete attachments, include the following elements:

- Steel arches, the configuration of which can be in the form of a semicircle (for round supports) or an oval rectangle (for rectangular supports).

- Removable spikes with tips of various shapes.

- Platforms for the feet of the worker.

- Double-layer leather straps that secure the foot.

Structurally close to these products are the so-called fitter manholes. They are designed for lifting an electrician onto reinforced concrete supports, and therefore have a rectangular arc. Combined claws and manholes are also produced. With their help you can climb wooden, metal and reinforced concrete supports.

The operating principle of lineman's claws is based on the fact that, under the influence of gravity, the platform with the electric lineman's leg begins to slide down while simultaneously rotating around its axis. In this case, the arc enters into an obstacle with the surface of the support, and sticks its spikes into the material (for wood), or rests the end of the spike against reinforced concrete or steel. Since the spikes are made from hardened structural steel of grades not lower than 40X according to GOST 4543-81, self-jamming of the spike on reinforced concrete occurs without damage to the spike, and, therefore, is very reliable. In order to increase safety, the number of spikes is at least three. For the most critical applications, replaceable studs made of hard alloys such as VK 25 or VK 30 are produced.

With increasing load on the spikes, the force of fixing the claws or manholes increases.

Terms of use

There are special instructions for electricians that tell you how to use electrician's claws. First of all, it is necessary to take certain safety measures when performing various works in electrical networks, especially on power lines.

- Before starting work, you need to agree on the procedure, draw up all the necessary documents, prepare the workplace and allow workers to complete the task. These measures are extremely important and necessary in order to protect workers. For example, when an electrician is working, voltage may be applied to live parts (namely wires).

- You need to be able to properly use the protective insulating equipment used during work.

- Installer's claws are used exclusively for those supports that are indicated in the device's passport.

- Before starting work, you need to check the product for damage and check the test date. In this case, yarns and belts, bolted connections, welds, fasteners, and spikes are checked. Electricians who use assembly claws must undergo additional instruction and training. They are also tested on their knowledge and checked whether they have a record of permission to carry out the work independently.

- Twice a year, claws and holes should be sent for inspection. This is necessary in order to detect and correct a defect or malfunction in a timely manner.

- If the integrity of the device is compromised (for example, there is a crack or a hangnail), then they are not allowed to be used.

- In addition to the structure itself, before carrying out work, you need to separately check the safety belt and climb the pole only with it.

- It is prohibited to change anything in the structure of the device or its belts.

- It is strictly forbidden to climb a pole through which fault currents passed to the ground.

- The structure must be stable and integral.

The video below clearly demonstrates how to use lineman's claws when climbing onto a support:

Purpose

The main purpose of the claws is considered to be quick and convenient climbing up the pole in order to perform planned or unforeseen work.

The design of the claws is simple: the main element of the device is two hooks with straps attached to them, with which they are directly attached to the legs (each separately).

The device is made from durable and reliable metal, which guarantees safety when working at heights.

The diameter of the hook is slightly larger than the parameters of the circle post. To conveniently and correctly climb up or down, you need to install the hook perpendicular to the vertical pole. Otherwise, the worker will not be able to move up or down. How difficult is it to climb a pole without claws?

Structure

Monter's manholes (claws) are a design of two main parts:

- metal hook;

- belt.

The hook has the shape of a trapezoid or rectangle. For strong adhesion to the support, it is equipped with teeth and self-adjusting spikes. The belts are made of genuine leather, sewn in two layers. The total weight of the structure is from three to five kilograms.

The laz works using momentum: different levels of spikes allow the hooks to be more firmly fixed under the influence of a person’s weight. The more weight, the better the grip. The gravity of the body, whatever it may be, will create the necessary moment of momentum, allowing you to maintain the required mass.

Care, storage, service life

from - 40 to + 50 degrees

Each product has a certain service life, which must be indicated in the labeling. Its starting point is the moment when the device was first used for its intended purpose. However, after a year of active use of the tool, operation is stopped, and the tool is sent for recycling or disposal. All manholes have a service life limit of 60 months. To safely perform work on power lines, it is necessary to regularly change components. If all requirements for production technology are met, such a device can work effectively for a year from the moment it is put into operation.

Manhole storage

It is unacceptable to leave claws for storage in the open sun or in rooms where a humid environment is maintained. In order for the manholes to retain their quality characteristics even after the inactive period of operation, they must be kept in a warehouse where an average temperature regime is maintained and ventilation is provided.

If any part is faulty, then a specialist should not repair them if he does not have the necessary experience and knowledge. If any element of the tool is faulty, then it is unacceptable to use it.

In order for assembly manholes to perform their task equally effectively, they do not need to provide special care. To do this, it is enough to clean them from dirt after each use, using any rags, after which they are placed in a storage place. It is unacceptable to use wet material to clean claws.

Which ones are better?

It is impossible to say for sure which claws are better and which are worse. Today there is a wide range of this device for working at height on the market. All claws are different. Therefore, in order to purchase the best option for yourself, you need to know the criteria by which to make a choice, namely:

on what basis will the lifting be carried out;

technical characteristics of the product - carefully study the document on the claws, in which pay attention to information such as load capacity, thickness and material of the belts; it is also very important to look at the production date and expiration date (almost all repair claws can be used for no more than 5 years);

integrity of the structure and all its elements;

compliance with TU, SNiP and GOST; the availability of quality certificates, which confirm that the product has passed all laboratory tests required by law, will help ensure this;

cost, it is best to choose expensive, high-quality products; you should not save, much less go for dubious promotions and discounts. Perhaps the low price is due to the fact that the permissible shelf life is coming to an end or the integrity of the structure is compromised;

manufacturer - this is another important aspect of the correct choice and purchase of a reliable product; give preference to a well-known brand.

Be sure to visually inspect the purchase, check for markings. A bona fide manufacturer must have all the documents for such equipment. If they are not there, it is better not to buy such a product.

Be sure to visually inspect your purchase and check for markings. A bona fide manufacturer must have all the documents for such equipment. If they are not there, it is better not to buy such a product.

Design and principle of operation

The simplest manholes for concrete supports consist of 2 elements for attaching to shoes, each of which consists of the following main components:

- Oval foot support with transverse reinforcements;

- 2 straps holding the foot on the platform;

- “Sickle” is a rectangular grip with 4 conical spikes attached at an angle of approximately 600 to the supporting platform.

Climbing onto a reinforced concrete pole using a similar device occurs as follows:

- The electrician securely fixes the manholes on his shoes using belts;

- Approaching the pillar, he grabs it with the grips of each of the elements of the claws;

- The electrician climbs the pole, thanks to the fact that the claw grips, which he alternately rearranges in the vertical plane, located at an angle to the supporting platforms, bite into the concrete with their spikes and prevent slipping.

Using a similar principle, electrical claws designed for this type of support help you climb onto a wooden pole. Their only differences from the crampons used for concrete pillars are the semicircular shape of the grips and softer spikes.

CATS

CATS

Information about types of concrete pillars at www.ebb.rs |

CATS

| Wood and Concrete Post Crampons are used as safety equipment on wood and concrete posts. Safe and convenient work of electric and PTT installers is guaranteed by the proprietary design of all types of cats, with a 30-year tradition in the production of the specified equipment. |

CATCHES FOR WOODEN POSTS PDS

| The crampons meet the requirements of SRPS Z.B1.055- Cranes for wooden poles for wires. The quality testing and issuance of the certificate were carried out by the Institute IMS Belgrade, which guarantees the quality of the products and the quality of the materials used in production. |

| Type | PDS-220 | PDS-240 | PDS-260 | PDS-280 | PDS-300 |

| Pole diameter (mm) | 120-220 | 140-240 | 160-260 | 180-280 | 210-280 |

| Weight, kg) | 3.10 | 3.20 | 3.30 | 3.40 | 3.50 |

CATS FOR

PU CONCRETE PILLARS

| The design of these crampons is based on a hinged gear mechanism that allows easy adjustment of the desired distance of the crampon's flight. By installing selected materials and heat treatment, a cat is obtained whose quality is guaranteed, in addition to the factory, by the Institute IMS Belgrade. Instructions for use: By pressing the handle, the free branch of the hook is released and the desired flight distance of the cat is opened, corresponding to the shape and size of the post. By lowering the handle, the selected, desired position of the hook branch is fixed. The branch of the cat is closed; for small diameters of the post, we simply support the branch of the hook to the post. |

| Type | Pu-310 | Pu-400 | Pu-650 |

| Pole diameter(mm) | 140-280 | 220-380 | 280-650 |

| Pole type | high voltage carrier 10 kV | low and high voltage angled 40° | high voltage angled 60° |

| Weight, kg) | 6.50 | 7 | 8 |

CAPTIVES FOR CONCRETE PILLARS Pm, Pv, Pn

| The design solution of this cat is based on a hook as an adjusting element, which can be easily and well adjusted using screws in accordance with the diameter of the post. The quality test is carried out by the Institute IMC Belgrade, which guarantees the functionality and quality of our cats. |

| Type | PM-310 | Pv-400 | Pn-500 |

| Pole diameter (mm) | 140-280 | 220-380 | 280-500 |

| Type pillar | high voltage carrier 10 kV | low and high voltage angled 40° | high voltage angled 60° |

| Weight, kg) | 6.80 | 7.30 | 7.60 |

CAPTIVES FOR CONCRETE PILLARS PB

| The new design of fixed crampons for concrete posts has proven to be practical and suitable for working in colder and wetter geographical areas. The cylindrical spiral shape of the steel hook with the help of a metal pusher allows for an almost perfect fit of the cat to the post, thereby minimizing slippage under the most unfavorable conditions. Quality testing and issuance of a certificate were carried out by the Institute IMS Belgrade, which guarantees the quality of products and materials used in production. |

| Type | PB-310 | PB-400 | PB-500 |

| Pole diameter (mm) | 140-280 | 220-380 | 280-480 |

| Type pillar | high voltage carrier 10 kV | low and high voltage angled 40° | high voltage angled 60° |

| Weight, kg) | 4.60 | 4.80 | 6.50 |

HISTORY OF THE ENTERPRISE

The enterprise was founded in 1978 as an independent working organization – Metal Products Factory “BE-VE”...

further

LOCATION

We are located in the western part of Serbia in the town of Bajina Basta, on the border with the Republika Srpska. Bajina Basta is located on …

further

Safety Precautions - Inspection and Testing

When using this device, specialists working at height must have additional equipment in their arsenal in the form of a protective helmet, which will protect against an accidental blow, as well as a safety lanyard, which will help to avoid serious consequences.

Straps for fastenings should also be available. The design of the belts must guarantee convenience and reliability in use, therefore their thickness must be at least 3 mm. These devices are made of two-layer leather, which is impregnated with fat. Each access hole must be marked with the date of the next inspection.

Before climbing to a height, you should thoroughly inspect the claws and check the test date. In addition, it is necessary to ensure the reliability of the welds, the integrity of the spikes, and the serviceability of the worm mechanism.

The metal elements of the device must not contain dents, breaks, sharp edges, cracks, or burrs. The spikes must not be damaged, beveled or knocked down. It is prohibited to use claws whose spines are blunt or absent altogether.

The device must be loaded for five minutes, with the load passing through the center point of the footrest. Before testing, a visual inspection is carried out to ensure that all parts are fastened and that there is no damage to the belt firmware. The fixing nut must be tightened with a locking ring.

In addition, the correct sharpening of the spikes is checked. The tests are carried out on a wooden support, the diameter of which corresponds to the numbering of the claw. After testing on the claws and manholes, there should be no deformation of the elements, damage to the welds, or breakage of the belts. Then measurements are taken, which are compared with previous values and recorded in a special journal.

If, after loading, defects are revealed, then such devices must be repaired; spikes and other damaged components are replaced. After troubleshooting, the device is again subjected to load.

Tree climbing devices

Tree climbing device

Selecting and installing a supply valve on a plastic window

For those who have never tried lasagna, it is some kind of overseas, incomprehensible dish. And those who have tried lasagna at least once fall head over heels in love with it. And it’s not surprising, because lasagna is the most favorite dish in Italy and is very popular all over the world. There are as many recipes for lasagna as there are Italian chefs, because the ingredients of this dish are very diverse. This variety depends on the filling and type of cheese that is chosen for making lasagna. The filling of lasagna can be very diverse, including sausage products, various seafood, and all kinds of vegetables. Device for climbing trees There are even options for sweet fillings for lasagna made from fruits and berries. Essentially, lasagna is a matter of layering a base pasta with various fillings, cheeses and sauces. In this section you will find a recipe for making delicious lasagna at home.

We recommend reading: Cat Vomits White Foam With Pieces of Food With Bile

Pasta (or base) for lasagna is not in short supply today and can be bought in any supermarket. But, of course, you will get the most delicious pasta if you prepare it yourself in a Tree Climbing Device at home. The peculiarity of its preparation is the choice of flour. First and second grade flour. You can find out what type of flour you have by reading the manufacturer's information on the packaging. So, you will need:

Knead the dough and leave it in the refrigerator for 20-30 minutes. After this, roll the dough into a sausage with your hands and cut into even pieces. The size of the pieces will determine the size of your lasagna. Roll each piece of dough into thin layers, and the thickness should not exceed 1.5-2.5 millimeters. The rolled out dough is cut into long and wide strips. That's all, the pasta, or base for lasagna, is ready. Next, you should arrange the pasta with various fillings layer by layer, pour the grated ingredients on top

Source

Care, storage, service life

The effectiveness of the claws is that they can be used at any temperature from -40 to +50 degrees. This device can be used in work both in hot areas and in the far north.

The invention is used only for a limited period. With constant use, the claws are used for no more than a year. The maximum service life is 5 years. In addition, it is recommended to periodically replace components. When using this method of lifting onto air supports, you must strictly follow the operating rules specified in the instructions.

The best storage temperature for the device is considered to be from -20 to +30 degrees. This will not interfere with its effectiveness in use. In order not to spoil the functional properties, repair claws are stored in a dry, well-ventilated area. Also during storage it is necessary to avoid sunlight.

In addition, to preserve the manholes, it is necessary to clean them from dirt and wipe them dry after each use. If the claws are wet, they must be dried and taken to a warehouse or other room that maintains the required temperature for storage and ventilation.

If one of the device components breaks down, its further operation is strictly prohibited. Repairs should only be carried out by a specialist in the field.

Changing the heater

Here is one of the methods that allows you to change the heating element on an Ariston automatic washing machine with your own hands. Heater malfunction can manifest itself in two ways: an open circuit or current leakage into the housing. In both cases, it is necessary to replace the faulty module with a new, working one.

To change the heating element, you need to have free access to the rear wall of the case. In the base of the washing machine you can see a small plug. Unscrew the mounting screws and remove the wall covering the hole in the housing. Through the window that opens, you will have access to the heating element, which is located on the top, on the right.

Using your smartphone camera, record how all the wiring should be connected correctly. On the side you can see the power contacts - zero and phase, colored red and blue, respectively. There is a housing contact in the center; this cable has a yellow-green tint

Please note that next to the housing contact and the power wire there is a temperature sensor, which is a plastic connector equipped with a special latch. All wiring going to the heater must be carefully disconnected

The nut located in the center of the heating element must be loosened. She pulls on an elastic band designed to completely seal the connection. There is no need to completely tighten the nut, just loosen it and press it inward along with the tension bolt. These actions will weaken the seal and make it possible to remove the heater from the washer.

When you take out the heating element, you will probably see a white limescale deposit on it. It is this layer that disrupts heat transfer, resulting in overheating of the part and breaking the circuit. When replacing the heater, the temperature measurement sensor is removed from the non-working element and attached to a new one.

To make the installation of the new heating element easy and smooth, lubricate its gasket with liquid laundry detergent. When further installing a working part, be sure to check that the edge of the element is connected to the fastener located in the tank. To do this, insert the heating element into the tank and press it firmly until it completely enters the hole in the tank. Then secure the structure by tightening the tension nut. Connect all existing wires and contacts according to the previous diagram.

Before installing the plug cover, check the heater for leaks - fill the tank with water without starting the wash. If it turns out that the connection is leaking liquid or air, tighten the tension nut more tightly. Once the functionality of the washing machine has been confirmed, assemble the Ariston machine completely.

Operating rules

Work at height has an increased danger, which is why there are a number of rules for its implementation and operation of equipment. Every worker - a high-altitude worker, an electrician - must know and apply the following rules for using assembly claws.

- The equipment may only be used for its intended purpose. This means that when climbing up a concrete base, you need to use claws that are designed for that material.

- You must adhere to safety rules.

- It is worth considering the technical characteristics of the claws, because each model has a certain maximum load capacity.

- Before putting on the device, it must be checked, namely the spikes and belts for deformations. Every bolt, tenon, strap and fastener must be free of damage. If defects are found on at least one of the parts, it is strictly not recommended to use the equipment.

- Carefully study the product data sheet. The document must indicate the expiration date and dates of mandatory inspections.

- You need to have your claws checked at least twice a year.

Also, experts do not recommend using claws from dubious and little-known manufacturers in high-altitude work.

There is a certain permissible operating temperature, which is also indicated in the product passport.

Watch the video about monter's claws below.

Selection rules

When considering the models offered by manufacturers, you need to evaluate the following details:

For quality products, the seller must have an appropriate certificate.

- Price segment. It is dangerous to skimp on installation equipment. A low price may be a sign of poor quality materials from which the equipment is made. It is recommended to consider models from the middle and highest price categories.

- Company manufacturer. You should not choose a model from an unknown manufacturer. It is better to give preference to a trusted company.

- Qualitative indicators. A product of any type must have a certificate of compliance with TU and GOST. Metal parts must not be damaged. It is important to check that the seams are even and the thickness of the belts is at least 3 mm. The stitching on leather elements must be securely fastened.

The finished equipment indicates the release date of the product, trademark and batch number. Every six months, devices are checked for wear. A corresponding marking with the result is left on the hole. If the tools are used without errors, then they are allowed to work for at least a year. The more damage to the hooks, the lower the level of safety.

Types and their characteristics

You can purchase the required type of manholes by deciding on their purpose. If you plan to work on wooden poles, then you should buy one type of device. When working on concrete supports, a different type is chosen.

Manholes are divided into several types:

- lineman's claws (for round metal and wooden poles), now they are practically not used;

- assembly manholes for concrete (for round or trapezoidal concrete pillars), very common;

- Installer's manhole claws (for supports made of reinforced concrete in the shape of a trapezoid) are quite popular, the opening of the manholes is adjustable, which allows them to be used on any support.

Where and how to use a safety lanyard, read in this publication.

A safety harness is used to cover the worker’s body to prevent him from being caught in the future. What are the requirements for a harness, read here.

What it is?

Claws or claws are special devices for lifting a worker onto a power line pole. They are fixed on a person’s legs and make it possible to gain a foothold on a support and stay in one position for the required amount of time. The structure of the manholes will be improved to increase the reliability of the equipment and the speed of climbing to the top. There are three groups of such devices:

It is convenient to climb the round pillars using universal equipment.

- Lazy. Designed for lifting reinforced concrete structures of round and trapezoidal shape in section.

- Universal hooks. The installation tools are suitable for round pillars made of concrete or wood. The latter have lost their relevance.

- Claw-holes. They differ in structure. Equipped with a specific control solution, especially effective in relation to trapezoidal reinforced concrete supports.

The latter devices are used more often than other types, because their specificity allows this device to be used to work with all types of standard supports. The use of manholes is permitted if this possibility is confirmed by accompanying documents. Each company specializing in electrical installation has its own set of tools for servicing power lines.

Operating rules

Each enterprise involved in the operation and maintenance of power lines must develop its own instructions for the use of manholes. However, the main sections of the rules do not differ significantly. The main message of the instructions is that personnel must be able to operate tools and devices, which include claws. Among the basic rules are:

- The devices should only be used on the types of poles specified in the instructions.

- Before starting work, you need to make sure that the claws are in good condition.

- During the inspection, all connections, tenons and fasteners should be inspected.

- Personnel performing work at height using manholes must undergo training and then pass an exam. After this, a permit is issued to carry out the work independently.

- Devices must undergo mandatory inspection once every six months.

- If a design malfunction is detected, the claws and manholes must be removed from the working stock.

- Before starting work, the employee must check not only the device itself, but also the safety belt.

Electrician's claws in the online store "Cheap Electrics"

In our online store in the “Fitter Claws” section you can find products in stock at low prices. The assortment is updated regularly. Product cards contain information about the name of the product, its manufacturer, properties and characteristics, as well as an image.

Using catalog filters it is very easy to find exactly what you need.

How to buy repairman's claws at "Electrics Cheap"?

It’s easy to place an order in the Electrics Cheap online store: add the product you like to the “Cart”, indicate your full name, e-mail and contact phone number. For legal entities, it is also necessary to indicate the name of the company, TIN and KPP. After this, wait for confirmation of the order from our manager.

If you don’t find what you need in the “Fitter Claws” section, you can always call us at the contact numbers listed in the header of the site, and we will help you select an analogue from stock.

Online store "Cheap Electrical" is:

- Quality products

- Low prices

- Delivery and pickup options

- Manufacturer's Warranties

We value our customers!