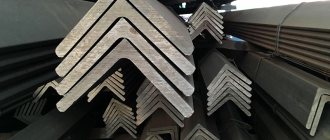

An equal-flange corner is a shaped L-shaped metal product with equal sides (the same length of shelves). It is the most popular and leading type of profile rolled metal products used in various fields of industry and production.

The method of application depends on the type, hardness, width of the sides. The corner can be used during repairs to strengthen concrete structures, in construction as the basis of metal structures, as reinforcement in construction projects, or as a decorative element for decoration.

Corners come in different types, are distinguished by their versatility, low cost, ease of installation, and are manufactured in accordance with state quality standards.

| Table of main characteristics of steel equal angle angle | |||

| Drawing | Shelf size, mm | Weight, kg | Standard |

| from 20 to 250 | from 0.89 to 128.51 | GOST 8509-93 GOST 19771-93 | |

Types of equal angle corner

Equal angles are classified according to the following criteria:

- mode of production;

- precision manufacturing;

- length.

Mode of production

There are two main types of equal angle angles, determined by the production method. These are the corners

- obtained by hot rolling;

- representing bent products.

Hot rolled products

Thus, an equal-flange angle GOST 8509-93 is made from rolled sections of suitable size using the hot rolling method. In this case, certain rolled products of square shape are used.

As a rule, low-alloy or structural steel is used. Its use complies with the current GOST 19281−89. It applies to rolled products made of high-strength steels. Such products can be used without additional heat treatment.

Bent corners

The corner GOST 19771-93 is a bent equal-flange corner. It is considered as a separate type of this product. It is produced using special machines by bending a strip of cold-rolled or hot-rolled sheets. The production uses carbon steel of ordinary quality, high-quality structural steel, and low-alloy steel.

Bent corners are characterized by lower strength and smaller tolerances for deviations specified in GOST, assortment, and other technical documentation. Although in reference books such products have the same names as rolling angles.

Manufacturing accuracy and length

Only equal angles from 4 to 12 meters can be classified by length. These are measured products. Moreover, each type of measured products has certain tolerances for the volume of unmeasured length (no more than 5% of the lot). The unmeasured length has a size of 3-12 meters and an error tolerance of up to 70 cm.

The manufacturing accuracy of the shelf width determines the production of corners of the following types:

- type A (maximum accuracy);

- type B (increased accuracy);

- type B (normal accuracy).

In addition, the shelves of the corners must be located strictly perpendicular to each other within the permissible values according to GOST. The thickness of the shelves is also indicated in GOST and may have permissible deviations. The type of corner determines its main parameters and characteristics.

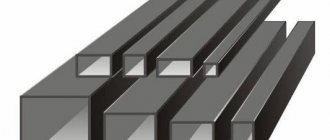

Product characteristics and features

The main characteristics of the corners include the weight of one linear meter and the cross-sectional area. A feature of this type of rolled product is considered to be high strength and rigidity of the product with a low weight of the profile. An equally important indicator is high manufacturing precision. This feature is taken into account to obtain an ideal even angle.

Beam calculator - calculation for different types of structures

Beams in a house usually belong to the rafter system or floor, and in order to get a reliable structure that can be operated without any fear, you need to use a beam calculator.

What is the beam calculator based on?

When the walls have already been brought under the second floor or under the roof, it is necessary to make a ceiling, in the second case smoothly turning into rafters. In this case, the materials must be selected so that the load on the brick or log walls does not exceed the permissible value, and the strength of the structure is at the proper level. Therefore, if you are going to use wood, you need to choose the right beams from it and make calculations to determine the required thickness and sufficient length.

Beam calculator

The subsidence or partial destruction of the ceiling can be due to various reasons, for example, too large a step between the lags, deflection of the cross members, too small their cross-sectional area or defects in the structure. To eliminate possible excesses, you should find out the expected load on the floor, be it basement or interfloor, and then use a beam calculator, taking into account their own weight. The latter can change in concrete lintels, the weight of which depends on the density of the reinforcement; for wood and metal, with a certain geometry, the weight is constant. The exception is damp wood, which is not used in construction work without first drying it.

Beam systems in floors and rafter structures are loaded by forces acting on section bending, torsion, and lengthwise deflection. For rafters, it is also necessary to provide for snow and wind loads, which also create certain forces applied to the beams. You also need to accurately determine the required step between the jumpers, since too many crossbars will lead to excess weight of the floor (or roof), and too little, as mentioned above, will weaken the structure.

How to calculate the load on a floor beam

The distance between the walls is called a span, and there are two of them in the room, and one span will necessarily be smaller than the other if the shape of the room is not square. Interfloor or attic floor lintels should be laid along a shorter span, the optimal length of which is from 3 to 4 meters. Larger spacing may require non-standard sized beams, which will result in some unsteadiness of the deck. The best solution in this case would be to use metal crossbars.

Regarding the cross-section of a wooden beam, there is a certain standard that requires that the sides of the beam have a ratio of 7:5, that is, the height is divided into 7 parts, and 5 of them must make up the width of the profile. In this case, deformation of the section is excluded, but if you deviate from the above indicators, then if the width exceeds the height, you will get a deflection, or, if the opposite discrepancy occurs, a bend to the side. To prevent this from happening due to the excessive length of the beam, you need to know how to calculate the load on the beam. In particular, the permissible deflection is calculated from the ratio to the length of the lintel as 1:200, that is, it should be 2 centimeters per 4 meters.

To prevent the beam from sagging under the weight of logs and flooring, as well as interior items, you can grind it from below a few centimeters, giving it the shape of an arch; in this case, its height should have an appropriate margin.

Now let's turn to the formulas. The same deflection mentioned earlier is calculated as follows: fnor = L/200, where L is the span length, and 200 is the permissible distance in centimeters for each unit of beam subsidence. For a reinforced concrete beam, the distributed load q on which is usually equal to 400 kg/m 2, the calculation of the maximum bending moment is performed using the formula Mmax = (q · L 2)/8. In this case, the amount of reinforcement and its weight is determined according to the following table:

Cross-sectional areas and mass of reinforcing bars

Beam calculator - calculation for different types of structures

Security in the house is not only video surveillance, but also strong walls and ceilings, which means that during construction it’s a good idea to use a beam calculator

Weight of equal angles

The weight and other characteristics of the corners depend on indicators such as width, wall thickness, and manufacturing accuracy. The shelf width can be from 20 to 250 mm. Products are marked according to the shelf dimensions. The labeling indicates the name of the product and the size of the shelf. For example, “Equal angle 50”.

The weight of a linear meter of products is determined by quality characteristics, including the following indicators:

- type of metal;

- steel grade;

- corner size;

- product thickness.

For each product there are calculation tables indicating the mass and number of meters per ton of the batch. For example, it is calculated that the weight of a linear meter of a 50x50x5 mm corner is 3.74 kg. And the number of meters in a ton is 267.48 m.

All the necessary parameters of the corners of interest can be found in the table:

| Weight table for equal flange hot-rolled angles | ||

| Size | Weight of 1 meter, kg | Meters in 1 ton |

| 20x20x3 | 0,89 | 1123,6 |

| 20x20x4 | 1,15 | 869,57 |

| 25x25x3 | 1,12 | 892,86 |

| 25x25x4 | 1,46 | 684,93 |

| 28x28x3 | 1,27 | 787,4 |

| 30x30x3 | 1,36 | 735,29 |

| 30x30x4 | 1,78 | 561,8 |

| 32x32x3 | 1,46 | 684,93 |

| 32x32x4 | 1,91 | 523,56 |

| 35x35x3 | 1,6 | 625 |

| 35x35x4 | 2,1 | 476,19 |

| 35x35x5 | 2,58 | 387,6 |

| 40x40x3 | 1,85 | 540,54 |

| 40x40x4 | 2,42 | 413,22 |

| 40x40x5 | 2,98 | 335,57 |

| 45x45x3 | 2,08 | 480,77 |

| 45x45x4 | 2,73 | 366,3 |

| 45x45x5 | 3,37 | 296,74 |

| 50x50x3 | 2,32 | 431,03 |

| 50x50x4 | 3,05 | 327,87 |

| 50x50x5 | 3,77 | 265,25 |

| 50x50x6 | 4,47 | 223,71 |

| 56x56x4 | 3,44 | 290,7 |

| 56x56x5 | 4,25 | 235,29 |

| 63x63x4 | 3,9 | 256,41 |

| 63x63x5 | 4,81 | 207,9 |

| 63x63x6 | 5,72 | 174,83 |

| 70x70x4.5 | 4,87 | 205,34 |

| 70x70x5 | 5,38 | 185,87 |

| 70x70x6 | 6,39 | 156,49 |

| 70x70x7 | 7,39 | 135,32 |

| 70x70x8 | 8,37 | 119,47 |

| 75x75x5 | 5,8 | 172,41 |

| 75x75x6 | 6,89 | 145,14 |

| 75x75x7 | 7,96 | 125,63 |

| 75x75x8 | 9,02 | 110,86 |

| 75x75x9 | 10,07 | 99,3 |

| 80x80x5.5 | 6,78 | 147,9 |

| 80x80x6 | 7,36 | 135,87 |

| 80x80x7 | 8,51 | 117,51 |

| 80x80x8 | 9,65 | 103,63 |

| 90x90x6 | 8,33 | 120,05 |

| 90x90x7 | 9,64 | 103,73 |

| 90x90x8 | 10,93 | 91,49 |

| 90x90x9 | 12,2 | 81,97 |

| 100x100x6.5 | 10,06 | 99,4 |

| 100x100x7 | 10,79 | 92,68 |

| 100x100x8 | 12,25 | 81,63 |

| 100x100x10 | 15,1 | 66,23 |

| 100x100x12 | 17,9 | 55,87 |

| 100x100x14 | 20,63 | 48,47 |

| 100x100x16 | 23,3 | 42,92 |

| 110x110x7 | 11,89 | 84,1 |

| 110x110x8 | 13,5 | 74,07 |

| 125x125x8 | 15,46 | 64,68 |

| 125x125x9 | 17,3 | 57,8 |

| 125x125x10 | 19,1 | 52,36 |

| 125x125x12 | 22,68 | 44,09 |

| 125x125x14 | 26,2 | 38,17 |

| 125x125x16 | 29.65 | 33,73 |

| 140x140x9 | 19,41 | 51,52 |

| 140x140x10 | 21,45 | 46,62 |

| 140x140x12 | 25,5 | 39,22 |

| 160x160x10 | 24,67 | 40,54 |

| 160x160x11 | 27,02 | 37,01 |

| 160x160x12 | 29,35 | 34,07 |

| 160x160x14 | 34,2 | 29,24 |

| 160x160x16 | 38,52 | 25,96 |

| 160x160x18 | 43,01 | 23,25 |

| 160x160x20 | 47,41 | 21,09 |

| 180x180x11 | 30,47 | 32,82 |

| 180x180x12 | 33,12 | 30,19 |

| 200x200x12 | 36,96 | 27,06 |

| 200x200x13 | 39,92 | 25,05 |

| 200x200x14 | 42,8 | 23,36 |

| 200x200x16 | 48,65 | 20,55 |

| 200x200x20 | 60,08 | 16,64 |

| 200x200x25 | 74,02 | 13,51 |

| 200x200x30 | 87,56 | 11,42 |

| 220x220x14 | 47,4 | 21,1 |

| 220x220x16 | 53,83 | 18,58 |

| 250x250x16 | 61,55 | 16,25 |

| 250x250x18 | 68,86 | 14,52 |

| 250x250x20 | 76,11 | 13,14 |

| 250x250x22 | 83,31 | 12 |

| 250x250x25 | 93,97 | 10,64 |

| 250x250x28 | 104,5 | 9,57 |

| 250x250x30 | 111,44 | 8,97 |

| 250x250x35 | 128,51 | 7,78 |

| Weight table for steel equal bent angle | ||

| Name and dimensions of the corner | Angle meter weight | Meters per ton |

| 36x3 | 1,57 | 636,9 |

| 40x2.5 | 1,48 | 675,7 |

| 40x3 | 1,76 | 568,2 |

| 50x3 | 2,23 | 448,4 |

| 50x4 | 2,90 | 344,8 |

| 55x3 | 2,43 | 411,5 |

| 60x3 | 2,70 | 370,4 |

| 60x4 | 3,53 | 283,3 |

| 60x3 | 2,67 | 374,5 |

| 70x4 | 4,16 | 240,4 |

| 70x4 | 4,10 | 243,9 |

| 80x3 | 3,64 | 274,7 |

| 80x4 | 4,79 | 208,8 |

| 80x5 | 5,92 | 168,9 |

| 80x6 | 7,01 | 142,7 |

| 80x7 | 8,11 | 123,3 |

| 80x4 | 4,74 | 211 |

| 80x5 | 5,87 | 170,4 |

| 100x4 | 6,05 | 165,3 |

| 100x5 | 7,49 | 133,5 |

| 100x6 | 8,89 | 112,5 |

| 100x7 | 10,31 | 97 |

| 100x4 | 6,00 | 166,7 |

| 100x5 | 7,44 | 134,4 |

| 100x6 | 8,79 | 113,8 |

| 120x5 | 9,06 | 110,4 |

| 120x6 | 10,78 | 92,8 |

| 120x5 | 11,10 | 90,1 |

| 160x4 | 9,76 | 102,5 |

Steel equal angle: GOST

The documentation regulating the production of products reflects the physical properties and manufacturing methods, indicates product parameters and permissible deviations from the established norm. This takes into account the dependence of permissible deviations on wall dimensions and accuracy indicators.

GOST

GOST No. 8509-93 applies exclusively to hot-rolled equal-flange steel angles. And GOST No. 19771-93 regulates the production of the same, but bent corners. Both documents establish categories of product accuracy, its physical characteristics, and permissible deviations from standards.

GOSTs contain information about materials that can be used in manufacturing. These materials, in turn, must also comply with GOST requirements.

The documents contain tables and figures with section values, mass, and weight of one linear meter of products. The tables were compiled taking into account the profile area, thickness and width of the flanges, radius of curvature, reference value of metal density, and nominal dimensions. But such calculations usually do not take into account deviations that are inevitable in the production of rolled metal.

Assortment

The assortment of rolled metal products is a detailed classification of metal products grouped by size, physical characteristics, quality, and other characteristics. The range of equal-angle angles corresponds to GOST 8509-93. It contains tables with corner dimensions, cross-sectional areas, and reference indicators.

The assortment is used for accurate calculation of materials, which allows you to use building materials correctly, avoid overuse, and carry out effective interaction with suppliers.

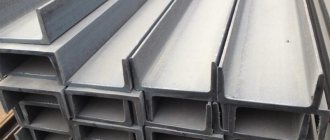

Technical information about the unequal corner.

Production Features

Angle bars are produced on automated production lines. The raw material for hot-rolled angles is steel ingots. The cube-shaped bloom is heated to the temperature of metal recrystallization and fed to rolling rolls. Under the influence of high pressure, soft metal is transformed into a product of the desired shape with specified parameters.

The advantages of this hot rolling technology include the following factors:

- production of rolled products without size restrictions;

- large thickness of processed workpieces;

- high speed of production of products.

Products made using this technology are distinguished by the accuracy of linear parameters and have high quality characteristics. Metal products have a smooth surface without visible or hidden defects and are characterized by increased bending strength. Steel that has undergone heat treatment has a uniform structure and has the necessary ductility. The area of use of hot-rolled angles depends on the type and size of the product.